The transmission accuracy of a mechanical drive system is paramount for high-precision applications in fields such as aerospace, advanced machine tools, and precision instrumentation. Among precision linear actuators, the planetary roller screw assembly stands out for its superior load capacity, high stiffness, long operational life, and excellent dynamic performance. A critical metric defining its precision is the travel error—the deviation between the theoretical and actual axial displacement of the nut (or the measuring point on the screw). Accurately predicting and controlling this error requires a comprehensive understanding of its multifaceted sources. While existing research has explored various aspects, studies offering a holistic error model validated by extensive experimental data remain limited. This analysis aims to bridge that gap by systematically examining the influence of machining imperfections, assembly misalignments, and operational deformations on the travel error of a standard planetary roller screw assembly, culminating in a validated predictive model.

Fundamental Architecture and Error Sources

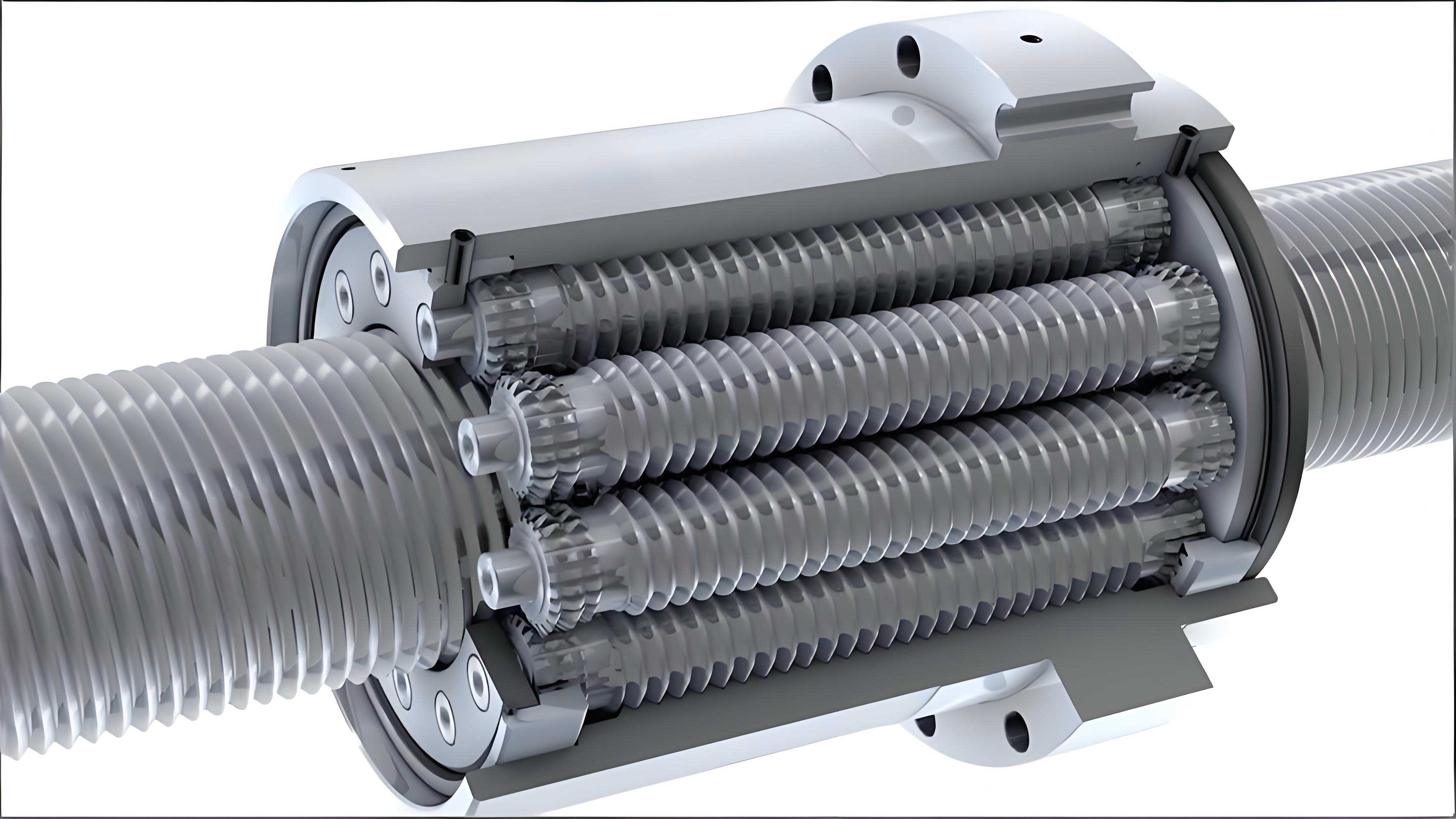

The standard planetary roller screw assembly converts rotary motion to linear motion through the meshing of threaded components. Its core structure consists of a central threaded screw, a nut with internal threads, and several threaded rollers distributed circumferentially around the screw. The rollers are housed in a planetary carrier and engage with both the screw and the nut threads, while an internal gear ring synchronizes their motion. This multi-contact design is the source of its high performance but also introduces complexity in error accumulation.

The travel error of a planetary roller screw assembly is not caused by a single factor but is the synthesized result of errors originating from manufacturing, assembly, and operation under load. These can be categorized into three primary groups:

- Machining Errors: Imperfections inherent to the manufacturing process of the screw, nut, and roller threads.

- Installation/Assembly Errors: Deviations from ideal alignment introduced during mounting on a test bench or within a machine.

- Deformation Errors: Elastic and thermal distortions of components under operational loads and friction.

Detailed Analysis of Error Components

1. Machining Errors

Machining errors are geometric deviations of the thread profiles from their theoretical design, primarily resulting from the precision of the grinding process and influences like grinding forces and heat.

a) Thread Profile Error: This encompasses lead error, pitch diameter error, and thread flank angle error. These errors cause a shift in the effective contact point between meshing threads, leading to an axial displacement error. Their contributions can be converted to equivalent axial components as follows:

Lead (Pitch) Error: $$ \Delta d_L = \Delta P_L $$

Pitch Diameter Error: $$ \Delta d_D = \Delta d_2 \cdot \tan\left(\frac{\alpha}{2}\right) $$

Flank Angle Error: $$ \Delta d_{\alpha} = \frac{H \cdot \sin\left(\frac{\Delta \alpha}{2}\right)}{\cos^2\left(\frac{\alpha}{2}\right)} $$

where \( \Delta P_L \) is the lead deviation, \( \Delta d_2 \) is the pitch diameter deviation, \( \alpha \) is the nominal thread angle, \( \Delta \alpha \) is the flank angle deviation, and \( H \) is the thread height.

b) Eccentricity Error: This refers to the offset between the thread axis and the journal axis (axis of rotation). When the screw rotates, this eccentricity causes the nut (or a measuring probe following the thread groove) to oscillate axially in a periodic, sinusoidal manner. This is a fundamental source of cyclical variation in the travel error. The error motion \( x_e \) and the resulting axial travel error \( \Delta d_e \) over one screw revolution can be modeled as:

$$ x_e = \frac{d_s}{2} \cdot \sin\left(z \cdot \frac{2\pi}{P_h}\right) + \frac{e_{sc} (d_s + \delta_{yr} + \Delta d_D)}{d_s + \Delta d_D} \cdot \sin\theta_s $$

$$ \Delta d_e = z|_{x_e=0} – P_h $$

where \( d_s \) is the screw pitch diameter, \( P_h \) is the lead, \( e_{sc} \) is the eccentricity, \( \delta_{yr} \) is radial thermal expansion, and \( \theta_s \) is the screw rotation angle.

2. Installation and Assembly Errors

These errors arise during the setup of the planetary roller screw assembly on a test rig or in its final application.

a) Tilt Installation Error: If the supporting centers (e.g., headstock and tailstock) are not perfectly aligned in height, the screw axis will be installed at a slight angle \( \Delta \gamma \) relative to the horizontal guide for the nut. This misalignment introduces an error in the measured axial travel. The error \( \delta_{in} \) can be derived from coordinate transformation of the screw’s helical path.

$$ \delta_{in} = Z’|_{X’=0} – P_h $$

where \( (Z’, X’) \) are coordinates in the tilted system, related to the original coordinates by a rotation of \( \Delta \gamma = \arctan(\Delta h / L) \), with \( \Delta h \) being the height difference and \( L \) the distance between supports.

b) Support Lift Error (Deflection Compensation Error): The screw and nut deflect under their own weight (gravity sag). Support units are often used to counteract this deflection. However, an imperfect lift amount \( \delta_s \) from these supports leaves a residual radial displacement. This radial displacement, like eccentricity, translates into a periodic axial travel error \( \delta_s \) (for screw measurement) or \( \delta_p \) (for nut measurement). The radial displacement due to gravity and imperfect support for the nut measurement case is:

$$ x_p = \frac{d_s}{2} \cdot \sin\left(z \cdot \frac{2\pi}{P_h}\right) + (\delta_{gs} + \delta_{gn} – \delta_s) \sin\left(z \cdot \frac{2\pi}{2L}\right) $$

$$ \delta_p = Z|_{x_p=0} – P_h $$

where \( \delta_{gs} \) and \( \delta_{gn} \) are the gravitational deflections of the screw and nut, respectively, calculated from beam theory.

3. Deformation Errors

During operation, components of the planetary roller screw assembly are not perfectly rigid and deform under load and temperature changes.

a) Thermal Deformation Error: Frictional heat generation during operation causes temperature rise \( \Delta T \), leading to thermal expansion. This results in both axial elongation and radial expansion, directly affecting travel accuracy.

$$ \delta_{yz} = \rho \cdot \Delta T \cdot L $$

$$ \delta_{yr} = \rho \cdot \Delta T \cdot d_s $$

where \( \rho \) is the coefficient of thermal expansion, \( \delta_{yz} \) is the axial thermal error, and \( \delta_{yr} \) is the radial thermal expansion (which influences eccentric error).

b) Elastic Deformation Error under Load: Under an axial load \( F \), the screw shaft experiences both tensile/compressive deformation \( \Delta L_F \) and torsional deformation \( \Delta L_T \). The combined elastic deformation error \( \Delta L_{FT} \) is:

$$ \Delta L_{FT} = \frac{4F z}{\pi d_s^2} \left( \frac{1}{E_s} + \frac{2 P_h^2}{\pi^2 d_s^2 G \eta} \right) $$

where \( z \) is the distance from the nut to the fixed end, \( E_s \) is Young’s modulus, \( G \) is the shear modulus, and \( \eta \) is transmission efficiency.

c) Load Distribution and Contact Deformation Error: This is a critical and complex component for a planetary roller screw assembly. Under axial load, the deformation is not just of the shaft but includes:

- Axial deformation of the screw, nut, and roller segments between threads (\( \Delta L_{Si}, \Delta L_{Ni}, \Delta L_{Ri} \)).

- Hertzian contact deformation at the screw-roller and roller-nut interfaces (\( \delta_{k} \)).

- Bending and shear deformation of the individual thread teeth (\( \epsilon_{k} \)).

The total axial deformation at the loaded end \( \Delta L_m \) is the sum of these deformations over all loaded teeth on all engaged rollers. It requires solving for the load distribution among the rollers and the engaged teeth, followed by calculating individual deformations using Hertzian contact theory and thread tooth compliance formulas. The governing equations for load distribution can be expressed as:

$$ \sum_{i=1}^{m} N_{ji} \cos\lambda \sin\beta = \frac{F}{n} $$

$$ N_{i-1}^{2/3} = N_{i}^{2/3} + \frac{n P_h (A_S + A_N)}{8K E_j A_S A_N} \cdot \cos^2\lambda \cdot \sin^2\beta \cdot \sum_{k=i}^{m} N_k $$

where \( N_{ji} \) is the normal force on the \( i \)-th tooth of component \( j \) (S, N, R), \( m \) is number of engaged teeth, \( n \) is number of rollers, \( \beta \) is contact angle, \( \lambda \) is lead angle, \( A \) is cross-sectional area, and \( K \) is a stiffness factor.

Synthesis: Travel Error Modeling

The total travel error \( E \) is a superposition of the various error components analyzed above. It typically consists of a periodic component (from eccentricity, tilt, etc.), a trend component (from thermal expansion, cumulative lead error), and random variations. For the planetary roller screw assembly, we develop two specific models: one for the screw’s inherent geometric error and one for the assembly’s error under load.

Model for Screw Travel Error (\(E_{PS}\))

This model predicts the error measured by a probe following the screw thread groove, primarily reflecting manufacturing and installation quality before the nut is engaged. It synthesizes the relevant axial components:

$$ E_{PS} = \Delta d_L + \Delta d_D + \Delta d_{\alpha} + \Delta d_e + \delta_{in} + \delta_{s} + \delta_{yz} $$

This equation sums the axial equivalents of lead, pitch diameter, and flank angle errors; the axial error from eccentricity; errors from tilt installation and imperfect support lift; and axial thermal expansion.

Model for Assembly Travel Error (\(E_{PM}\))

This model predicts the error in the actual nut position during operation, which is the most relevant for application performance. It incorporates all screw error sources plus the significant deformations that occur under load within the planetary roller screw assembly:

$$ E_{PM} = \Delta d_L + \Delta d_D + \Delta d_{\alpha} + \Delta d_e + \delta_{in} + \delta_{p} + \delta_{yz} + \Delta L_{FT} + \Delta L_{m} $$

Here, \( \delta_{p} \) is the support error relevant for the nut path, and \( \Delta L_{FT} \) and \( \Delta L_{m} \) are the shaft elastic and comprehensive load-contact deformation errors, respectively.

From the continuous travel error curve \( E(\theta) \), key evaluation indices are derived using a least-squares best-fit line:

- Travel Error over Measured Length (\(E_p\)): The maximum deviation of the actual error curve from the best-fit line.

- Travel Variation within one Revolution (\(V_{2\pi}\)): The peak-to-valley difference of the error within one screw turn (reflects periodic errors).

- Travel Variation within Effective Travel (\(V_u\)): The peak-to-valley difference of the error over the entire measured length.

The coefficients of the best-fit line \( E_p = a + b\theta \) are found by:

$$ a = \frac{\sum\theta_i^2 \sum E_i – \sum\theta_i \sum\theta_i E_i}{N\sum\theta_i^2 – \sum\theta_i \sum\theta_i} $$

$$ b = \frac{N\sum\theta_i E_i – \sum\theta_i \sum E_i}{N\sum\theta_i^2 – \sum\theta_i \sum\theta_i} $$

where \( \theta_i \) and \( E_i \) are the rotation angle and error at the \( i \)-th measurement point, and \( N \) is the total number of points.

Experimental Investigation and Error Measurement

1. Measurement of Machining Errors

The thread profile errors (lead, pitch diameter, flank angle) of the screw were measured using a dedicated thread profilometer. The screw is mounted between centers, and a laser displacement sensor, aligned at the thread lead angle, scans the thread flank. Software then calculates the actual profile parameters by comparing them to the nominal geometry. Four sample screws (designated 1-4) of the same nominal specification (27x10x5) but from different manufacturers were measured. Their machining errors are summarized below:

| Screw ID | Lead Error (μm) | Pitch Diameter Error (mm) | Flank Angle Error (°) |

|---|---|---|---|

| 1 | 0.18 | 0.001 | 0.12 |

| 2 | 0.12 | 0.001 | 0.15 |

| 3 | 0.35 | 0.003 | 0.23 |

| 4 | 0.31 | 0.003 | 0.19 |

2. Measurement of Installation Errors

Using dial indicators on the test bench, three installation errors were quantified for each planetary roller screw assembly sample:

- Eccentricity Error: Measured as half the total indicator reading (TIR) on the screw journal during rotation.

- Tilt Error: Derived from the height difference between headstock and tailstock centers.

- Support Lift Error: Measured as the residual deflection at the screw center after applying support units.

The measured values are presented in the following table:

| Measurement | Screw 1 (μm) | Screw 2 (μm) | Screw 3 (μm) | Screw 4 (μm) |

|---|---|---|---|---|

| Eccentricity Error | 10 | 8 | 11 | 72.61 |

| Tilt Error | 12 | 12 | 12 | 12 |

| Support Lift Error | 8 | 6 | 13 | 26 |

3. Travel Error Testing

A dedicated travel error test bench was employed. It consists of a drive motor, headstock and tailstock with precision centers, an air-bearing worktable (for nut connection), support units, a rotary encoder (measuring angular displacement \( \theta \)), and a laser interferometer (measuring linear displacement \( x \)). For screw error measurement, a spherical probe follows a screw thread groove. For assembly error measurement, the nut is fixed to the air-bearing table which moves axially with negligible friction.

The travel error is calculated as \( Y = x – (\theta / 2\pi) \cdot P_h \). All four screw samples were tested three times each under no-load conditions to obtain average screw travel error indices. Furthermore, one selected assembly was tested under six different axial loads (3, 6, 9, 12, 15, 18 kN) to evaluate the load-deformation effect. Tests were conducted in a controlled environment (20 ±1°C) after sufficient thermal stabilization.

Results, Analysis, and Model Validation

1. Screw Travel Error Results

The experimental results for the worst-case indices among all thread starts for each screw are compared with the values calculated from the \( E_{PS} \) model in the table below. The calculated values are derived by inputting the measured individual errors (Tables above) into the model equations.

| Screw ID | \(E_p\) (μm) | \(V_{2\pi}\) (μm) | \(V_u\) (μm) | |||

|---|---|---|---|---|---|---|

| Exp. | Model | Exp. | Model | Exp. | Model | |

| 1 | 22.44 | 21.91 | 3.75 | 3.66 | 9.45 | 9.16 |

| 2 | 18.67 | 17.15 | 2.68 | 2.47 | 6.45 | 6.01 |

| 3 | 35.24 | 33.15 | 3.77 | 3.49 | 9.37 | 8.63 |

| 4 | 31.69 | 29.95 | 25.75 | 23.88 | 41.06 | 38.05 |

Key Observations:

- The experimental values are consistently slightly higher than the model predictions, which is expected due to unmodeled system noise and environmental factors.

- Screws 1 and 2 show significantly better accuracy than screws 3 and 4, directly correlating with their smaller measured machining errors (Table 1). This underscores the dominant influence of manufacturing quality on the baseline accuracy of a planetary roller screw assembly.

- Screw 4 exhibits exceptionally high \(V_{2\pi}\) and \(V_u\) values. A breakdown of the \(V_{2\pi}\) contribution (see analysis below) reveals its large eccentricity error (72.61 μm) as the primary cause.

The relative errors between experimental and modeled values for all screws are within 1.62% to 4.37%, validating the accuracy of the screw error model \(E_{PS}\).

2. Influence Factor Analysis for \(V_{2\pi}\)

The travel variation per revolution \(V_{2\pi}\) is predominantly affected by periodic errors. The contribution of individual error sources to the modeled \(V_{2\pi}\) value is analyzed in the following table for the four screws:

| Screw | Total \(V_{2\pi}\) Model (μm) | Pitch Diameter Error | Eccentricity Error | Tilt Error | Support Lift Error | Thermal Radial Error* |

|---|---|---|---|---|---|---|

| 1 | 3.66 | 0.14 | 1.84 | 0.51 | 0.72 | 0.45 |

| 2 | 2.47 | 0.11 | 1.07 | 0.51 | 0.34 | 0.45 |

| 3 | 3.49 | 0.24 | 1.96 | 0.51 | 0.33 | 0.45 |

| 4 | 23.88 | 0.33 | 20.73 | 0.51 | 1.86 | 0.45 |

*Assumed small, constant thermal rise during stabilization.

This analysis clearly shows that eccentricity error is the most significant contributor to \(V_{2\pi}\), while pitch diameter error has a negligible effect. This highlights the critical importance of controlling rotational alignment and journal concentricity during both screw manufacturing and system assembly.

3. Assembly Travel Error Under Load

The results for the planetary roller screw assembly tested under varying axial loads are summarized below. A constant small thermal compensation was applied based on measured temperature rise (20.9°C to 24.3°C).

| Load (kN) | \(E_p\) (μm) | \(V_{2\pi}\) (μm) | \(V_u\) (μm) | |||

|---|---|---|---|---|---|---|

| Exp. | Model | Exp. | Model | Exp. | Model | |

| 0 | 27.73 | 25.92 | 8.15 | 7.89 | 15.10 | 14.46 |

| 3 | 36.58 | 35.13 | 7.92 | 7.70 | 14.34 | 13.89 |

| 6 | 42.65 | 41.07 | 8.14 | 7.93 | 14.33 | 13.74 |

| 9 | 48.72 | 47.02 | 8.06 | 7.76 | 14.65 | 14.13 |

| 12 | 54.83 | 53.29 | 7.98 | 7.72 | 14.44 | 13.98 |

| 15 | 61.02 | 59.54 | 8.13 | 7.79 | 14.52 | 14.09 |

| 18 | 67.44 | 66.22 | 8.09 | 7.86 | 14.29 | 13.75 |

Key Observations:

- Dominant Effect of Load Deformation: The travel error \(E_p\) increases monotonically and significantly with load, approximately tripling from 0 to 18 kN. This confirms that elastic deformations (\( \Delta L_{FT} + \Delta L_m \)) become the dominant error source under operational loads, far exceeding the influence of static geometric errors.

- Stability of Periodic Errors: The indices \(V_{2\pi}\) and \(V_u\) remain relatively stable regardless of the load magnitude. This is expected as they primarily reflect fixed geometric and installation periodic errors, which are not altered by uniform axial loading.

- Model Validation: The full assembly model \(E_{PM}\) shows excellent agreement with experimental data across all load levels. The relative error for \(E_p\) decreases from ~6.5% at no-load (where unmodeled system errors are more pronounced relative to the small total error) to within 1.8% – 4.0% under load, demonstrating the model’s high accuracy in predicting load-dependent behavior of the planetary roller screw assembly.

Conclusion

This comprehensive analysis has successfully deconstructed the travel error of a precision planetary roller screw assembly into its constituent sources: machining errors, installation errors, and deformation errors. A mathematical model was developed that synthesizes these components, converting radial, angular, and deformational deviations into their net effect on axial travel accuracy. Rigorous experimental measurement of individual errors (profile, eccentricity, tilt, etc.) provided the necessary inputs for the model.

The experimental validation on four different screws and under a range of loads leads to several critical conclusions:

- Manufacturing Quality is Foundational: The baseline accuracy (\(E_p\), \(V_{2\pi}\), \(V_u\)) of the screw is predominantly determined by machining process capability. Screws with smaller lead and eccentricity errors exhibited superior travel error indices.

- Installation Eccentricity is Critical for Smoothness: Eccentricity error was identified as the single largest contributor to the periodic travel variation \(V_{2\pi}\). Precision in mounting and alignment is therefore essential to minimize cyclical error.

- Load-Induced Deformation is the Dominant Operational Error: Under working loads, the elastic deformation of the screw shaft and, more importantly, the complex contact deformations within the threaded meshes become the primary source of travel error (\(E_p\)). This effect far outweighs static geometric errors during operation.

- Model Fidelity: The proposed travel error models for both the screw (\(E_{PS}\)) and the loaded assembly (\(E_{PM}\)) demonstrated high predictive accuracy, with relative errors consistently below 6.5% and often within 2-4% when compared to experimental measurements. This validates the model’s effectiveness as a tool for analyzing and predicting the transmission accuracy of a planetary roller screw assembly.

This work provides a validated framework for understanding and quantifying the factors that influence travel error in planetary roller screw assemblies. It offers valuable insights for manufacturers aiming to improve process control and for designers seeking to predict and compensate for positional errors in high-precision linear drive systems.