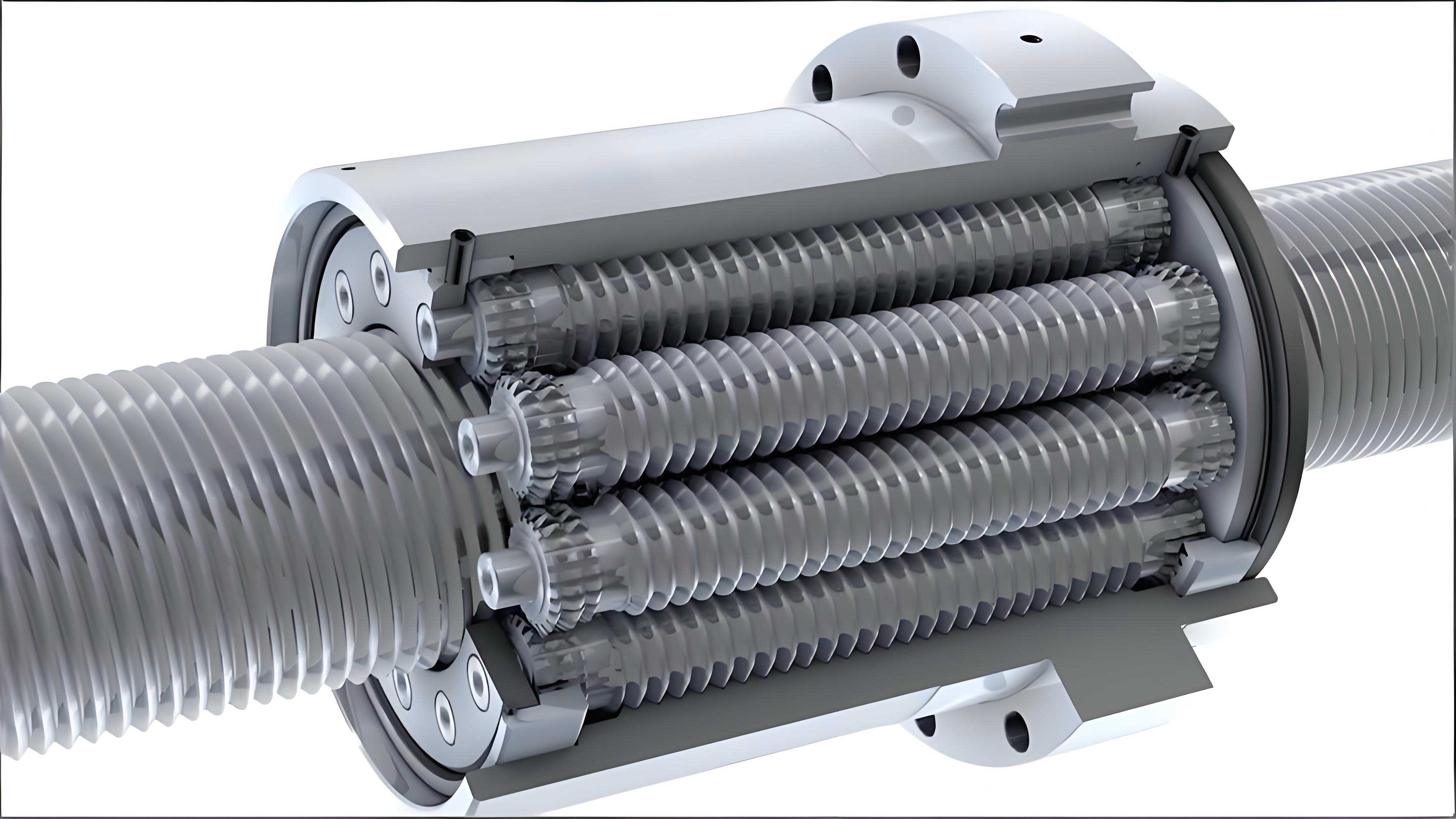

In modern precision engineering, the planetary roller screw assembly stands out as a critical component for converting rotary motion into linear motion with high efficiency and reliability. This assembly is renowned for its high transmission accuracy, substantial load capacity, minimal vibration, low noise, and extended durability, making it indispensable in advanced industries such as aerospace, defense, and renewable energy systems. However, a persistent challenge in manufacturing the planetary roller screw assembly lies in the precision of its core rolling element—the roller. During processing and heat treatment, rollers are prone to bending, which severely compromises the transmission precision and overall performance of the planetary roller screw assembly. To address this issue, we have developed and investigated a secondary radial rolling straightening method aimed at correcting bent rollers through a controlled plastic deformation process. This study focuses on establishing a theoretical model, conducting finite element simulations, and performing experimental validations to enhance the straightness and geometric accuracy of rollers in the planetary roller screw assembly.

The roller straightening process for the planetary roller screw assembly involves a radial pressure-based method where two grooved rolling tools symmetrically apply force to a bent roller. This technique, essentially a two-roller rotational straightening approach, leverages the principles of reverse bending to eliminate curvature. In our setup, the rolling tools rotate synchronously at controlled speeds while moving radially inward to engage the roller. The roller, initially with a predefined bend, is subjected to alternating tensile and compressive stresses as it rotates, inducing plastic deformation that gradually reduces its curvature. The key to success in straightening rollers for the planetary roller screw assembly lies in achieving sufficient plastic penetration depth, particularly in the smaller-diameter sections, without compromising the thread profile integrity. We designed the rolling tools with modified tooth profiles to mitigate defects like “rabbit ears” at the tooth tips, which are common in initial rolling processes. The straightening model considers geometric relationships, material properties, and process parameters to optimize the outcome for the planetary roller screw assembly.

To understand the underlying mechanics, we derived a theoretical framework based on elastoplastic theory. When a bent roller from a planetary roller screw assembly undergoes straightening, it experiences bending moments that lead to stress and strain distributions across its cross-section. The strain at any height \( Z \) from the neutral axis is given by:

$$ \epsilon_Z = \frac{\epsilon_h}{R} \times Z $$

where \( \epsilon_h \) is the maximum strain at the outer fiber, and \( R \) is the radius of curvature. The corresponding stress, accounting for material hardening, is expressed as:

$$ \sigma_Z = \sigma_t + \lambda \left( \frac{Z}{R} \epsilon_h E – \sigma_t \right) $$

Here, \( \sigma_t \) is the yield strength, \( E \) is the Young’s modulus, and \( \lambda \) is the hardening coefficient defined as \( \lambda = E’ / E \), with \( E’ \) being the average hardening modulus calculated from material tensile data. The depth of plastic deformation is characterized by the coefficient \( \zeta = R_t / R \), where \( R_t \) is the radius at the elastic limit. The internal bending moment \( M \) can be integrated across the cross-section:

$$ M = 2 \int_0^{R_t} y \sigma_z \, dz + 2 \int_{R_t}^R y \sigma_t z \, dz + 2 \int_{R_t}^R \lambda y \sigma_t \left( \frac{z}{R_t} – 1 \right) z \, dz $$

This leads to the normalized moment ratio:

$$ \bar{M} = \frac{4}{\pi} \left[ \left( \frac{1 – \lambda}{3} \right) \left( \frac{5}{2} – \zeta^2 \right) (1 – \zeta^2)^{1/2} + \frac{1 – \lambda}{2\zeta} \arcsin \zeta + \frac{\pi \lambda}{4\zeta} \right] $$

where \( \bar{M} = M / M_t \), with \( M_t \) as the elastic limit moment. For straightening, the curvature evolution is critical. The initial curvature \( A_0 \), reverse bending curvature \( A_w \), and springback curvature \( A_f \) relate through the residual curvature \( A_c \). The straightening condition requires that the residual curvature vanishes, leading to:

$$ A_w – A_f = 0 $$

Using the elastic limit curvature \( A_t = 2 \epsilon_t / H \), where \( H \) is the roller height, we define dimensionless curvature ratios:

$$ C_0 = \frac{A_0}{A_t}, \quad C_w = \frac{A_w}{A_t}, \quad C_f = \frac{A_f}{A_t}, \quad C_c = \frac{A_c}{A_t} $$

The straightening equation becomes:

$$ C_w – C_c – C_f = 0 $$

$$ C_0 + C_f – C_{\sum} = 0 $$

These equations guide the determination of required reverse bending curvature for effective straightening of rollers in the planetary roller screw assembly.

We implemented finite element simulations to model the straightening process for the planetary roller screw assembly. The setup included the roller as a deformable body and the rolling tools, axial plates, and radial plates as rigid bodies. The roller material was 16MnCr5, a common steel alloy in the planetary roller screw assembly, with properties detailed in Table 1. The mesh comprised approximately 400,000 hexahedral elements to ensure accuracy. Process parameters, such as rotational speed and radial feed rate, were based on empirical data to replicate real-world conditions in the planetary roller screw assembly manufacturing.

| Property | Value |

|---|---|

| Young’s Modulus (GPa) | 211 |

| Poisson’s Ratio | 0.28 |

| Density (kg/m³) | 7.85 × 10³ |

| Tensile Strength (MPa) | 1373 |

| Yield Strength (MPa) | 1187 |

The simulation parameters for different roller cases are summarized in Table 2. We varied initial curvature and压下量 (feed amount) to study their effects on straightening outcomes for the planetary roller screw assembly. The rolling tools rotated at 15 rpm with a radial feed rate of 0.01 mm/s. Friction between the roller and tools was modeled using Coulomb’s law with a coefficient of 0.3, while friction with plates was neglected to simplify contacts.

| Roller ID | Initial Curvature (mm⁻¹) | Feed Amount (mm) | Rotational Speed (rpm) | Feed Rate (mm/s) |

|---|---|---|---|---|

| 1 | 0.1 | -0.05 | 15 | 0.01 |

| 2 | 0.1 | -0.10 | ||

| 3 | 0.3 | -0.05 | ||

| 4 | 0.3 | -0.10 |

The simulations revealed that the secondary rolling process effectively reduces bending in rollers for the planetary roller screw assembly. The stress distribution showed a spiral pattern of residual stresses, with compressive stresses in the core and tensile stresses on the surface, aligning with theoretical predictions. The plastic deformation depth increased with higher feed amounts, leading to better straightening. However, excessive feed could cause over-deformation, emphasizing the need for parameter optimization in the planetary roller screw assembly production.

To validate our model, we conducted experiments using a precision rolling machine capable of adjusting phase angles and applying forces up to 150 kN. We processed 100 rollers with initial run-out errors exceeding 0.03 mm, typical in defective planetary roller screw assembly components. The rollers had a stepped design with small-diameter ends of 5.58 mm and a large-diameter middle section of 6.78 mm, over a length of 36.00 mm. We employed three types of rolling tool profiles: standard, partially polished, and concave-convex modified, to assess their impact on straightening quality for the planetary roller screw assembly. After straightening, we measured run-out errors and diameter variations at multiple points along the roller, as illustrated in Figure 10 of the original study (referenced conceptually without direct citation). The results, based on a sample of 20 rollers, are presented in Table 3 and Table 4.

| Section | Average Run-out Before (mm) | Average Run-out After (mm) | Reduction (%) |

|---|---|---|---|

| Small-diameter End (a) | 0.045 | 0.016 | > 60 |

| Middle Section (b) | 0.022 | 0.012 | 45 |

| Small-diameter End (c) | 0.046 | 0.014 | > 60 |

The data demonstrates significant improvements, with run-out errors reduced by over 60% at the ends and 45% in the middle, meeting the precision requirements for the planetary roller screw assembly. Additionally, the tooth profile accuracy and surface finish were enhanced, eliminating the rabbit-ear defects observed after initial rolling. This confirms the effectiveness of secondary rolling in refining the planetary roller screw assembly components.

| Measurement Point | Diameter Deviation Before (mm) | Diameter Deviation After (mm) | Improvement |

|---|---|---|---|

| C (Near End) | 0.020 | 0.010 | Reduced fluctuation |

| D | 0.016 | 0.008 | More consistent |

| E | 0.014 | 0.008 | Enhanced stability |

| F (Middle) | 0.011 | 0.005 | Precision achieved |

The diameter variations became more uniform post-straightening, with deviations within 0.015 mm, aligning with the tight tolerances needed for the planetary roller screw assembly. Compared to traditional grinding methods, this rolling process doubled efficiency and saved 40% in processing time, offering a cost-effective solution for high-volume production of the planetary roller screw assembly.

In conclusion, our study establishes a robust framework for straightening bent rollers in the planetary roller screw assembly through secondary radial rolling. The theoretical model, based on elastoplastic principles, accurately predicts curvature changes and residual stresses. Finite element simulations and experimental validations confirm that the process significantly reduces run-out errors and improves geometric accuracy, including tooth profile integrity and surface finish. By optimizing parameters such as feed amount and tool design, we can achieve rollers with run-out errors below 0.02 mm and diameter deviations within strict limits, essential for the high performance of the planetary roller screw assembly. This work provides key technical support for advancing rolling-based straightening processes, contributing to the reliability and precision of the planetary roller screw assembly in critical applications. Future research could explore adaptive control systems to further enhance straightening consistency for the planetary roller screw assembly across varying batch conditions.