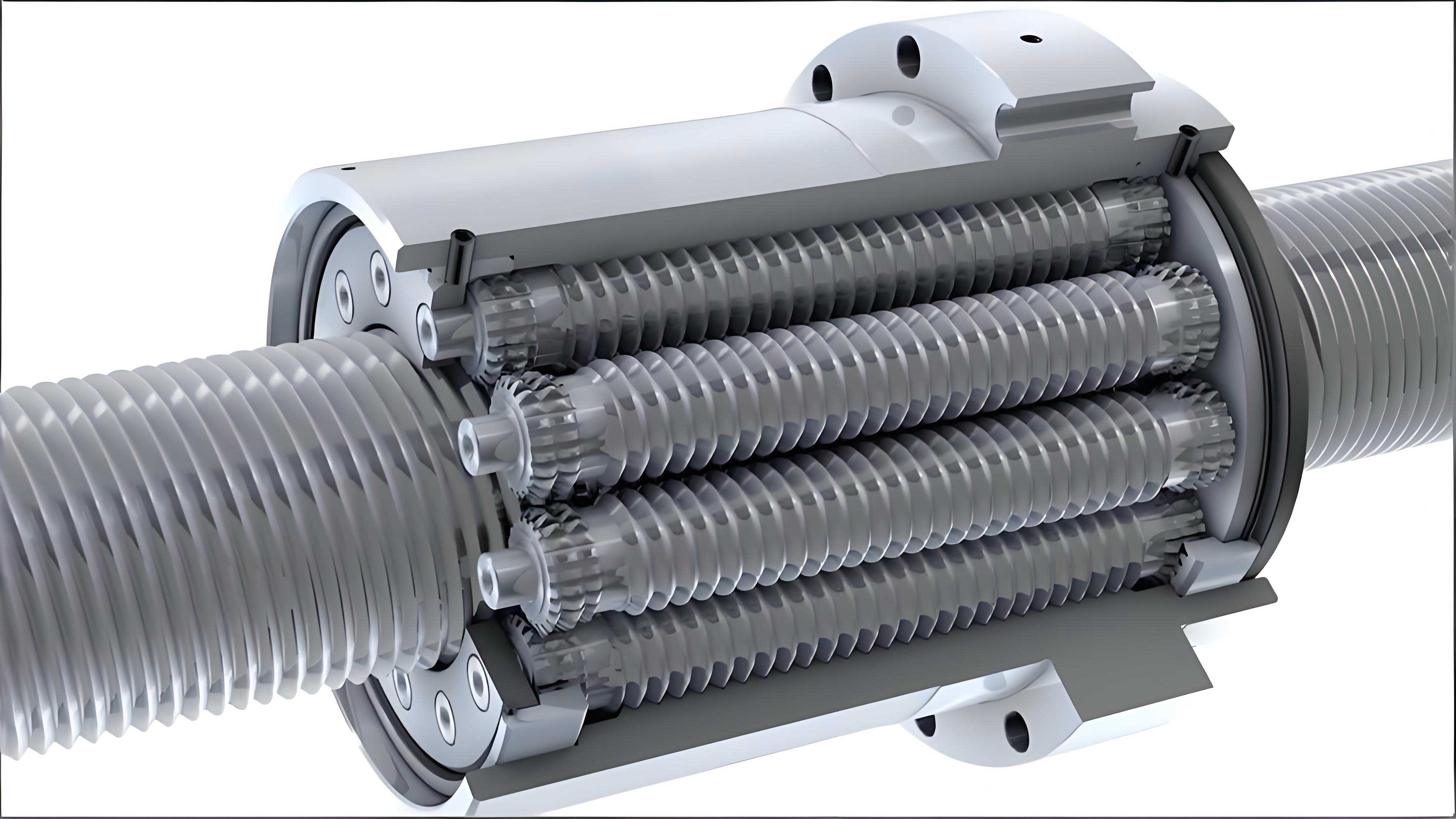

In my extensive experience with high-precision electromechanical actuation systems, the planetary roller screw assembly stands out as a critical component for converting rotary motion into linear force. Its design offers superior load capacity, longevity, and precision compared to alternatives like ball screws. However, these advantages are contingent upon proper operation and handling. Recently, our team encountered a significant failure: a planetary roller screw assembly fractured during the disassembly phase following a rigorous 1,000-hour load endurance test. This incident prompted a comprehensive investigation to determine the root cause, which I will detail in this analysis. The core objective is to understand the failure mechanism to prevent future occurrences and ensure the reliability of such systems in demanding applications like aerospace and marine steering.

The specific planetary roller screw assembly in question was integrated into a high-power electromechanical actuator (EMA) rated for 20 kW. This actuator was designed for ship rudder control, where reliability is paramount. The planetary roller screw assembly had a nominal diameter of 63 mm and an effective stroke of 800 mm. After successfully completing the scheduled load test, a routine disassembly was initiated to inspect for lubrication status and wear. During this process, an axial force was mistakenly applied to the actuator rod while the screw shaft was being separated from its support bearing housing. This created an unintended tilting moment. The fracture occurred abruptly at location A, near the thread run-out at the root of the screw shaft. The failure was sudden, with no audible warning or prior indication of distress, which immediately suggested a brittle fracture mode.

My initial step in the failure analysis of this planetary roller screw assembly was a macroscopic examination of the fracture surface. The broken pieces were carefully collected and examined. The fracture surface appeared relatively flat and exhibited a bright gray color. There was no significant plastic deformation or mechanical damage evident in the region adjacent to the break. Under low magnification, the fracture origin was clearly identifiable at the surface of the thread root. A zone approximately 2.3 mm deep from the outer surface appeared finer in texture, while the remaining area was rougher. Radiating patterns emanated from the origin, typical of a fast, brittle crack propagation. No gross material defects like large inclusions or cavities were visible to the naked eye. This preliminary observation strongly pointed towards a cleavage-type fracture initiated at a stress concentrator.

To delve deeper, we employed scanning electron microscopy (SEM) to analyze the fracture’s微观形貌. The entire surface was examined at high magnification. The finer zone near the origin, including the initiation site, exhibited a morphology of shallow dimples. In contrast, the rougher majority of the fracture surface displayed a quasi-cleavage pattern, characterized by river markings and brittle facets. Energy-dispersive X-ray spectroscopy (EDS) performed on the fracture surface detected primarily iron (Fe) and a smaller amount of chromium (Cr), consistent with a chromium alloy steel. The absence of corrosive elements or products ruled out environmental corrosion as a contributing factor. The combined macroscopic and SEM evidence confirmed that the planetary roller screw assembly failed via a brittle fracture mechanism, likely triggered by an overload condition.

The material integrity of the planetary roller screw assembly was scrutinized next. Chemical composition analysis was performed using standard spectroscopic methods. The results are summarized in Table 1, comparing the measured values with the standard specification for GCr15 bearing steel, a common material for such high-strength components.

| Chemical Element | Measured Value (%) | GCr15 Standard (YB9-68) (%) |

|---|---|---|

| Carbon (C) | 0.99 | 0.95 – 1.05 |

| Manganese (Mn) | 0.28 | 0.20 – 0.40 |

| Silicon (Si) | 0.24 | 0.15 – 0.35 |

| Chromium (Cr) | 1.42 | 1.30 – 1.65 |

| Sulfur (S) | 0.007 | ≤ 0.020 |

| Phosphorus (P) | 0.025 | ≤ 0.027 |

| Nickel (Ni) | 0.12 | – |

| Copper (Cu) | 0.16 | – |

The composition aligns perfectly with GCr15, confirming the material met the required specification. The key mechanical properties for GCr15 in its hardened state are listed in Table 2, which were used for subsequent stress analysis.

| Material Parameter | Value |

|---|---|

| Elastic Modulus, E | 2.19 × 1011 N/m² |

| Poisson’s Ratio, μ | 0.3 |

| Tensile Strength, σb | 861.3 MPa |

| Yield Strength, σs | 518.42 MPa |

| Density, ρ | 7.8 g/cm³ |

| Elongation | 27.95% |

| Quenched Hardness | 62 – 66 HRC |

Microhardness testing was conducted on a cross-section from the fractured planetary roller screw assembly, starting from the thread surface and moving inward. Vickers hardness (HV0.2) was measured at regular intervals and converted to Rockwell C scale (HRC). The data, presented in Table 3 and graphically conceptualized, shows a high surface hardness typical of a case-hardened or through-hardened component, which gradually decreases towards the core.

| Distance from Thread Top (mm) | HV0.2 | Approx. HRC |

|---|---|---|

| 0.00 | 750 | 62.3 |

| 0.25 | 737 | 61.8 |

| 0.50 | 696 | 60.1 |

| 0.75 | 658 | 58.3 |

| 1.00 | 702 | 60.3 |

| 1.25 | 690 | 59.8 |

| 1.50 | 658 | 58.3 |

| 1.75 | 663 | 58.5 |

| 2.00 | 653 | 58.0 |

| 2.25 | 540 | 51.7 |

| 2.50 | 449 | 45.1 |

| 2.75 | 384 | 39.3 |

| 3.00 | 307 | 30.7 |

| 3.25 | 253 | 22.8 |

| 3.50 | 219 | – |

| 3.75 | 207 | – |

| 4.00 | 215 | – |

| 4.25 | 210 | – |

The hardness profile indicates a hardened case depth of approximately 3.0 mm from the thread crest and about 2.3 mm from the thread root, which corresponds well with the finer zone observed on the fracture surface. This hardened layer consists of martensite, providing high strength but lower toughness. Metallographic examination confirmed the microstructure: a surface layer of martensite (the hardened case) transitioning to a core of ferrite and spheroidized pearlite. Non-metallic inclusion assessment according to GB/T 10561-2005 revealed a塑性夹杂物 (sulfide) rating of 1.5 and脆性夹杂物 (oxide) rating below 0.5, with a combined rating under 2.0. These levels are considered acceptable and normal for high-quality bearing steel. Therefore, we conclusively ruled out material defects or improper heat treatment as the primary cause of failure for this planetary roller screw assembly.

With material causes eliminated, the focus shifted to mechanical loading conditions. The fracture initiated at the thread root, a classic stress concentration site. In fracture mechanics, a pre-existing flaw or a geometric discontinuity like a thread can be treated as a crack. For the planetary roller screw assembly, the thread root acts as a surface crack. The stress intensity factor \( K_I \) at the tip of such a crack determines its propensity to propagate. For a semi-elliptical surface crack in a round bar under tension, the formula is:

$$ K_I = Y(\alpha, \beta, \gamma, K_t) \cdot \sigma \sqrt{\pi a} $$

Here, \( \sigma \) is the nominal stress remote from the crack, \( a \) is the crack depth, and \( Y(\alpha, \beta, \gamma, K_t) \) is a dimensionless correction factor that depends on crack geometry parameters \( \alpha = a/d \) (crack depth to diameter ratio), \( \beta = a/c \) (crack aspect ratio), \( \gamma = s_1/s \) (position along crack front), and the theoretical stress concentration factor \( K_t \) of the notch (the thread). For the thread root of this planetary roller screw assembly, \( K_t \) is approximately 2.79. The nominal stress under pure axial load can be calculated. The rated axial load for this planetary roller screw assembly was \( 4.1 \times 10^5 \, \text{N} \). To be conservative, we considered an overload scenario of 50%, i.e., \( 6 \times 10^5 \, \text{N} \). The root diameter at the fracture location was 60 mm.

$$ \sigma_{\text{axial}} = \frac{F}{A} = \frac{6 \times 10^5 \, \text{N}}{\pi \times (0.03 \, \text{m})^2} \approx 2.12 \times 10^8 \, \text{Pa} = 212 \, \text{MPa} $$

Using standard solutions for a surface crack in a tensioned rod, for the deepest point of the crack front (\( \gamma = 1 \)), the correction factor \( Y \) can be estimated. For typical values applicable to this geometry, we used \( Y \approx 1.6 \). Assuming a small inherent flaw or considering the thread as an initial crack, let’s assume a conservative crack depth \( a = 0.1 \, \text{mm} = 1 \times 10^{-4} \, \text{m} \). The calculated stress intensity factor becomes:

$$ K_I = 1.6 \times 212 \times 10^6 \, \text{Pa} \times \sqrt{\pi \times 1 \times 10^{-4} \, \text{m}} \approx 1.6 \times 212 \times 10^6 \times 0.0177 \approx 6.0 \times 10^6 \, \text{Pa} \sqrt{\text{m}} $$

This is approximately \( 60 \, \text{MPa} \sqrt{\text{m}} \). The fracture toughness \( K_{IC} \) for hardened GCr15 steel can vary but is typically in the range of 20-30 \( \text{MPa} \sqrt{\text{m}} \) for very high hardness materials. Even taking a lower bound value of \( K_{IC} = 23 \, \text{MPa} \sqrt{\text{m}} \), the calculated \( K_I \) under pure axial overload (50%) is significantly higher, suggesting fracture would occur. However, this calculation assumes pure axial loading. The critical insight came from reconstructing the disassembly event. The recorded axial force applied during the problematic disassembly step was 162,000 N (16.2 metric tons). Crucially, this force was not purely axial due to the tilting of the assembly. It induced a substantial bending moment at the screw root. The distance from the force application point to the fracture origin (location A) was about 0.15 m. Therefore, the bending moment \( M \) was:

$$ M = F \times L = 162,000 \, \text{N} \times 0.15 \, \text{m} = 24,300 \, \text{N} \cdot \text{m} $$

At the fracture cross-section (root diameter \( d = 60 \, \text{mm} \)), the bending stress must be considered. The section modulus \( W \) for a solid circular cross-section is:

$$ W = \frac{\pi d^3}{32} = \frac{\pi \times (0.06 \, \text{m})^3}{32} \approx 2.12 \times 10^{-5} \, \text{m}^3 $$

The maximum bending stress \( \sigma_{\text{bending}} \) is:

$$ \sigma_{\text{bending}} = \frac{M}{W} = \frac{24,300 \, \text{N} \cdot \text{m}}{2.12 \times 10^{-5} \, \text{m}^3} \approx 1.146 \times 10^9 \, \text{Pa} = 1146 \, \text{MPa} $$

This bending stress acts on one side of the shaft. The nominal axial stress from the 162,000 N force is:

$$ \sigma_{\text{axial}} = \frac{162,000 \, \text{N}}{\pi \times (0.03 \, \text{m})^2} \approx 57.3 \times 10^6 \, \text{Pa} = 57.3 \, \text{MPa} $$

Using the principle of superposition for combined loading, the total maximum tensile stress at the point of crack initiation (on the side under tension from bending) would be the sum:

$$ \sigma_{\text{total}} = \sigma_{\text{axial}} + \sigma_{\text{bending}} = 57.3 \, \text{MPa} + 1146 \, \text{MPa} \approx 1203 \, \text{MPa} $$

This value far exceeds the yield strength (518.4 MPa) and even approaches the ultimate tensile strength (861.3 MPa) of the material. In reality, for a brittle material with high hardness, fracture occurs with minimal plastic yielding. The presence of the sharp thread root (stress concentration factor \( K_t \approx 2.79 \)) further amplifies the local stress. The local peak stress \( \sigma_{\text{local}} \) can be estimated as:

$$ \sigma_{\text{local}} = K_t \cdot \sigma_{\text{total}} \approx 2.79 \times 1203 \, \text{MPa} \approx 3356 \, \text{MPa} $$

Such an enormous local stress easily exceeds the cohesive strength of the material, leading to immediate brittle fracture. This explains why the fracture occurred suddenly during disassembly. The primary loading condition was not pure axial overload but a severe bending moment induced by the misaligned force application. This bending moment, resulting in radial-type loading on the planetary roller screw assembly, was the root cause.

To validate this theoretical assessment, we performed a finite element analysis (FEA) of the planetary roller screw assembly under the recorded loading conditions. A three-dimensional model of the screw shaft was created, focusing on the region near the thread run-out. The material properties from Table 2 were assigned. The boundary conditions simulated the actual scenario: the section where the screw interfaces with the support bearing was fixed (all degrees of freedom constrained). The load was applied as a combination of the axial force (162,000 N) and the associated bending moment (24,300 N·m) at the relevant location. The mesh was refined around the thread root to capture stress gradients accurately.

The FEA results vividly illustrated the stress concentration. The maximum von Mises stress was located precisely at the thread root near the run-out region. The computed stress values exceeded 1000 MPa in this localized area, with peak values reaching around 900-1100 MPa depending on the exact modeling assumptions. This range aligns with our simplified theoretical calculation for combined stress. The stress contour plot clearly showed a high-stress band emanating from the thread root, correlating perfectly with the observed fracture origin and path. The FEA confirmed that the imposed bending moment, not the axial force alone, created a stress state sufficient to cause instantaneous brittle fracture in the hardened material of the planetary roller screw assembly. The analysis also highlighted that under pure axial load (even at 50% overload), the stresses, while high, were more uniformly distributed and might not have caused immediate failure if not for the stress concentrator. However, the superimposition of bending was catastrophic.

In conclusion, the failure of this planetary roller screw assembly was a direct consequence of an abnormal operational event during disassembly. The comprehensive analysis—encompassing fractography, material characterization, and mechanical stress evaluation—converges on a single cause: the application of a large radial load component (manifesting as a bending moment) to the screw shaft. The material of the planetary roller screw assembly, GCr15 steel, was within specification and exhibited the expected high hardness and strength but low fracture toughness. The thread root, an inherent stress concentrator, became the initiation site when the combined tensile stress from axial force and, dominantly, bending stress surpassed the material’s fracture strength. The failure mode was low-cycle fatigue/cleavage fracture under a single, severe overload event.

This incident underscores critical handling and design considerations for planetary roller screw assemblies. Firstly, it is paramount to remember that while planetary roller screw assemblies excel under axial loads, they are highly sensitive to radial loads and bending moments. Installation, operation, and maintenance procedures must ensure that such parasitic loads are minimized or eliminated. Alignment between the actuator’s output force and the load path is crucial. Secondly, during disassembly or any non-operational handling, proper support and tooling must be used to prevent unintended moments. The design of interfaces and support structures should aim to mitigate stress concentrations, perhaps by optimizing thread run-out geometry or using fillets. Finally, for critical applications, a damage tolerance analysis considering the thread as a potential crack initiation site could be incorporated into the design validation process. By understanding and respecting the load limits and failure modes of the planetary roller screw assembly, engineers can harness its full potential while ensuring system reliability and safety.