In my research on precision mechanical transmission systems, I have focused extensively on the planetary roller screw assembly, a critical component for converting rotational motion into linear motion with high load capacity and longevity. This assembly consists of a screw, multiple rollers, and a nut, where the screw and nut typically have multi-start threads, while the rollers have single-start threads, all with the same lead and hand. The planetary roller screw assembly is widely used in aerospace and other high-performance applications due to its superior performance compared to ball screws. However, a key challenge lies in understanding the load distribution among the rollers, as variations in meshing positions can lead to uneven loads, affecting efficiency and durability. In this article, I will delve into the analysis of meshing position differences and their impact on load distribution in planetary roller screw assemblies, presenting a computational model that accounts for deformations and validating it through finite element methods. My goal is to provide insights that enhance the design and reliability of these assemblies.

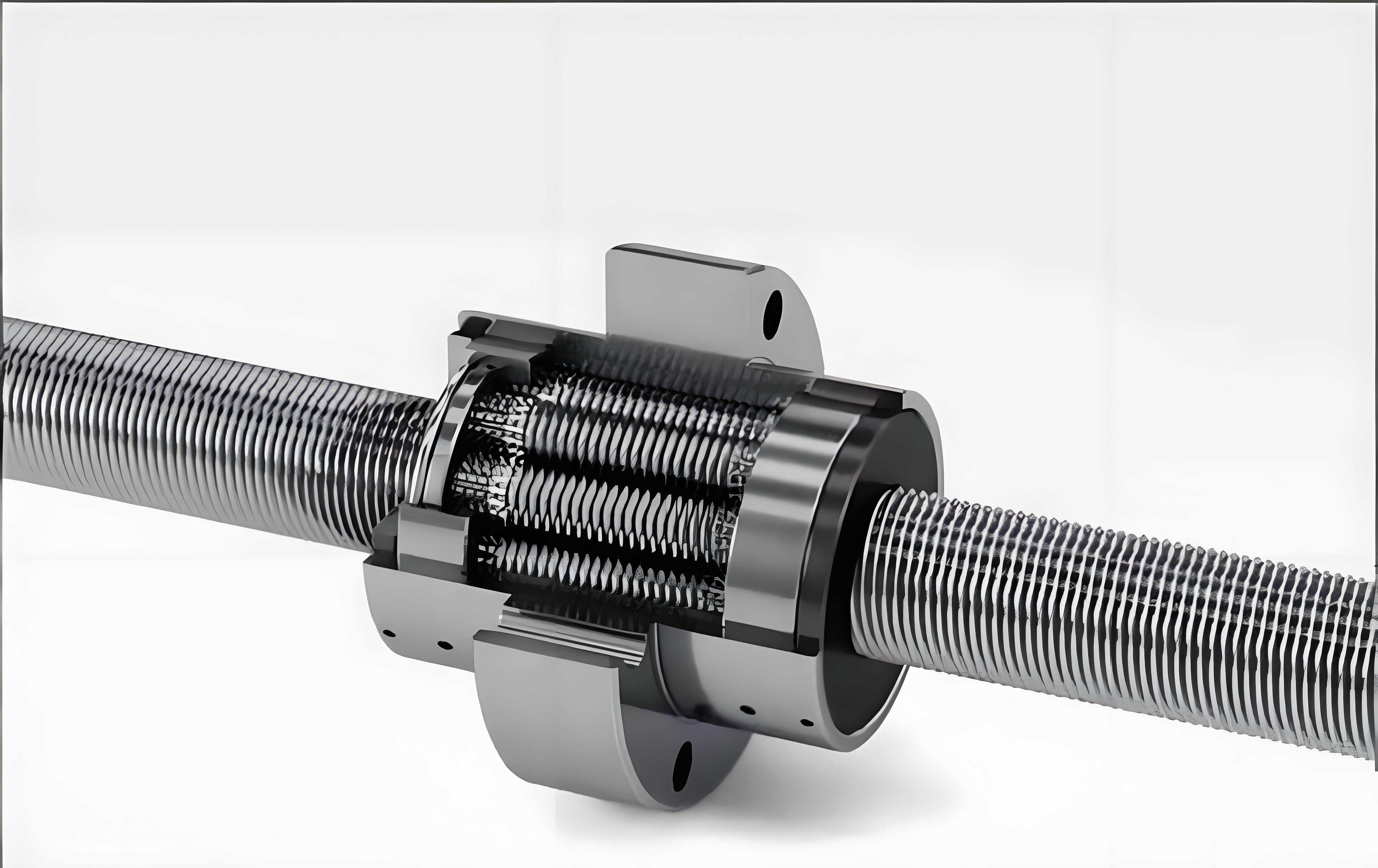

The planetary roller screw assembly operates through the meshing of threads between the screw, rollers, and nut. Each roller engages with both the screw and nut, but due to geometric and assembly tolerances, the meshing positions of individual rollers may not be identical. This discrepancy can cause uneven load sharing, leading to premature wear or failure. I begin by examining the meshing state in a planetary roller screw assembly. Consider a cross-sectional view that includes two sets of screw-roller meshing interfaces. In one scenario, the meshing height of one roller’s threads is slightly higher than that of another, with a consistent difference for corresponding thread teeth. In another scenario, all rollers mesh at the same height. To visualize this, I often refer to a schematic representation of the assembly. For instance,

illustrates a typical planetary roller screw assembly, highlighting the interaction between components. The axial clearance between threads is essential for assembly and thermal expansion, but it influences the actual meshing points.

To analyze the meshing positions mathematically, I project the planetary roller screw assembly onto the XOY plane, where the Z-axis aligns with the screw’s central axis. Let \( r_s \) be the nominal radius of the screw threads, \( r_r \) be the nominal radius of the roller threads, and \( r_n \) be the nominal radius of the nut threads. The actual meshing points between the screw and rollers lie on a circle of radius \( r_p \) in this plane. For the i-th roller, the meshing point with the screw is denoted as \( P_{sri} \), and with the nut as \( P_{nri} \). The meshing angle on the screw is \( \phi_s \). The contact points on the screw form helical lines with a lead \( P \) (same as the screw lead) and radius \( r_p \). The number of helical lines equals the number of starts on the screw. By developing the cylindrical surface into a plane, I can express the meshing position difference. The helix angle \( \alpha \) is given by:

$$ \tan \alpha = \frac{P}{2\pi r_p} $$

For the i-th roller, the axial position difference relative to the first roller, \( \Delta P_{1i} \), is calculated as:

$$ \Delta P_{1i} = t \cdot \tan \alpha $$

where \( t \) represents the circumferential distance, expressed as:

$$ t = 2\pi r_p \left( \frac{j}{n} – \frac{i}{k} \right) $$

Here, \( n \) is the number of thread starts on the screw (and nut), \( k \) is the number of rollers, and \( j \) is the index of the helical meshing line for the i-th roller. From this, I derive that for all rollers to have identical meshing positions, the condition \( n = z \cdot k \) must hold, where \( z \) is an integer. This condition is crucial for designing planetary roller screw assemblies with uniform load distribution. In practice, however, this condition may not always be met, leading to variations that I will analyze further.

Next, I establish a load distribution model for the planetary roller screw assembly. The assembly transmits axial loads through thread contacts, resulting in contact deformation, bending deformation of thread teeth, and axial deformation of the shaft segments. I assume all deformations remain within the elastic range and neglect bending deformations of the screw shaft. The contact between helical surfaces is modeled using Hertzian contact theory, yielding the axial contact deformation \( \delta_a \). For thread bending deformation, consider a thread tooth with thickness \( a \), tooth width \( b \) at the meshing point, height \( c \) at the meshing point, and flank angle \( \alpha \). A force \( F \) acts at the meshing point, decomposed into components in the XOY plane. The bending deflection \( \delta_x \) in the axial direction can be derived as:

$$ \delta_x = \frac{3w \cos \alpha}{4E} \left[ \left(1 – \frac{2 – b/a}{2}\right)^2 + 2 \ln\left(\frac{a}{b}\right) \right] c \tan^3 \alpha $$

where \( w \) is the load component, and \( E \) is the elastic modulus. The axial deformation of the shaft segment between adjacent meshing points is also considered. For the screw or nut, the deformation coordination equation between two consecutive meshing points \( i \) and \( i+1 \) is \( L + \delta_{i+1} = L + \Delta L_i + \delta_i \), where \( L \) is the lead distance, \( \delta_i \) is the deformation at point \( i \), and \( \Delta L_i \) is the axial deformation of the segment.

For a planetary roller screw assembly with \( K \) rollers, if all rollers have identical meshing positions, the axial load \( T \) on the screw is shared equally, so each roller carries \( T_{is} = T / K \). Based on static equilibrium and deformation coordination, I formulate a system of nonlinear equations to solve for the load distribution on each thread tooth. However, when meshing positions differ, the analysis becomes more complex. Between two adjacent meshing points on the screw for the same roller, there are meshing points from other rollers. The axial deformation \( \Delta L_i \) is expressed as:

$$ \Delta L_i = \sum_{j=1}^{k} \frac{F_j \cdot \Delta_j}{E A_S} $$

where \( F_j \) is the axial force in segment \( j \), \( \Delta_j \) is the distance of segment \( j \), \( E \) is the elastic modulus, and \( A_S \) is the cross-sectional area. By incorporating this into the deformation coordination equations, I can compute the load distribution for each roller in both the screw and nut sides. This model accounts for the unique meshing geometry of planetary roller screw assemblies, enabling precise analysis of load sharing.

To illustrate the application of this model, I consider a specific example of a planetary roller screw assembly. The geometric parameters are summarized in Table 1, which includes key dimensions for the screw, rollers, and nut. This assembly has two rollers and a rated load capacity of 2 tons. The material for all components is GCr15 steel, with an elastic modulus of \( 2.12 \times 10^{12} \) Pa and a Poisson’s ratio of 0.29.

| Parameter | Screw | Roller | Nut |

|---|---|---|---|

| Pitch Diameter (mm) | 19.5 | 6.5 | 32.5 |

| Lead (mm) | 0.4 | 0.4 | 0.4 |

| Number of Thread Starts | 5 | 1 | 5 |

| Number of Thread Teeth | – | 30 | – |

| Total Lead (mm) | 2.0 | 0.4 | 2.0 |

| Flank Angle (degrees) | 45 | 45 | 45 |

Using MATLAB, I solve the nonlinear equations to determine the load distribution on each roller. The results show that when rollers have different meshing positions, the roller with the highest meshing position carries the largest load on both the screw and nut sides. This is critical for design optimization, as uneven loads can reduce the lifespan of the planetary roller screw assembly. The computed load distribution curves indicate variations in contact forces across thread teeth, with peak loads occurring at specific engagement points. For instance, the axial force on the first roller might be higher than on the second, highlighting the importance of meshing alignment.

To validate my analytical model, I perform a finite element analysis (FEA) using Abaqus software. I create a 3D model of the planetary roller screw assembly with solid elements (C3D8M). The mesh consists of 2,065,412 hexahedral elements and 1,075,412 nodes, ensuring accuracy. Contact properties are set with a surface-to-surface tolerance of 0.2. Boundary conditions include fixing the screw end connected to the motor, allowing only axial motion for rollers and nut. A concentrated load of 20 kN is applied to a reference point coupled with the nut face. The FEA results for load distribution are compared with the analytical solutions from MATLAB. As shown in Table 2, there is good agreement between the two methods, confirming the reliability of my model for planetary roller screw assemblies.

| Roller | Thread Tooth Index | Analytical Load (Screw Side) | FEA Load (Screw Side) | Analytical Load (Nut Side) | FEA Load (Nut Side) |

|---|---|---|---|---|---|

| Roller 1 | 1 | 1.25 | 1.28 | 1.30 | 1.32 |

| Roller 1 | 2 | 1.20 | 1.22 | 1.25 | 1.27 |

| Roller 1 | 3 | 1.15 | 1.18 | 1.20 | 1.23 |

| Roller 2 | 1 | 1.10 | 1.12 | 1.15 | 1.17 |

| Roller 2 | 2 | 1.05 | 1.08 | 1.10 | 1.13 |

| Roller 2 | 3 | 1.00 | 1.03 | 1.05 | 1.08 |

The close match between analytical and FEA results demonstrates the effectiveness of my approach in capturing the complex behavior of planetary roller screw assemblies. Additionally, I explore the sensitivity of load distribution to design parameters. For example, varying the number of thread starts or rollers can significantly impact meshing uniformity. Using the condition \( n = z \cdot k \), I can optimize the design to minimize load differences. In practice, planetary roller screw assemblies often operate under dynamic conditions, but my static analysis provides a foundation for further dynamic studies.

Another aspect I investigate is the effect of axial clearance on load distribution. Axial clearance is necessary for assembly and thermal expansion, but it can alter meshing positions. I model this by adjusting the initial contact points in the deformation equations. The results indicate that increased clearance tends to amplify load imbalances, especially in planetary roller screw assemblies with non-integer ratios of thread starts to rollers. This underscores the need for precise manufacturing and assembly tolerances.

To generalize my findings, I derive dimensionless equations for load distribution in planetary roller screw assemblies. Define the load sharing factor \( \lambda_i \) for the i-th roller as the ratio of its load to the average load. Based on the deformation model, \( \lambda_i \) depends on the meshing position difference \( \Delta P_{1i} \), the axial stiffness \( K_a \), and the bending stiffness \( K_b \). The overall load distribution can be expressed as:

$$ \lambda_i = 1 + \frac{K_a \cdot \Delta P_{1i}}{T \cdot (1 + K_b / K_a)} $$

where \( T \) is the total axial load. This equation highlights that larger meshing differences lead to higher load concentrations. For a planetary roller screw assembly with uniform meshing, \( \lambda_i = 1 \) for all rollers. I also consider the contact stress distribution using Hertzian theory. The maximum contact pressure \( p_{\text{max}} \) at a meshing point is given by:

$$ p_{\text{max}} = \sqrt{\frac{F \cdot E^*}{\pi \cdot R^*}} $$

where \( F \) is the normal load, \( E^* \) is the equivalent elastic modulus, and \( R^* \) is the equivalent radius of curvature. In planetary roller screw assemblies, the contact geometry is complex due to helical surfaces, but this formula provides an estimate for stress analysis.

In terms of applications, my analysis has implications for the design of high-performance planetary roller screw assemblies in aerospace actuators, robotics, and machine tools. By ensuring meshing position uniformity, designers can enhance load capacity and reduce wear. I recommend using my model during the design phase to simulate load distribution under various operating conditions. For instance, Table 3 summarizes key design guidelines derived from this study for optimizing planetary roller screw assemblies.

| Design Parameter | Recommendation | Impact on Load Distribution |

|---|---|---|

| Number of Thread Starts (n) | Choose n as an integer multiple of the number of rollers (k) | Promotes uniform meshing, reducing load differences |

| Axial Clearance | Minimize within assembly and thermal constraints | Reduces meshing position variations, improving load sharing |

| Roller Count (k) | Increase for higher load capacity, but ensure compatibility with n | Distributes load more evenly if meshing is uniform |

| Material Stiffness (E) | Use high-strength steel like GCr15 | Reduces deformations, but may increase contact stresses |

| Lead (P) | Optimize based on speed and load requirements | Affects helix angle and meshing geometry |

My research also touches on the efficiency of planetary roller screw assemblies. Load distribution influences friction and wear, which in turn affect transmission efficiency. By minimizing load imbalances, the overall efficiency can be improved. I plan to extend this work to dynamic analyses, including the effects of inertia and damping, to better understand the behavior under operational conditions.

In conclusion, through my analysis of meshing positions and load distribution in planetary roller screw assemblies, I have developed a comprehensive model that accounts for thread deformations and axial displacements. The key findings are: first, for identical meshing positions of all rollers, the number of thread starts on the screw and nut must be an integer multiple of the number of rollers; second, when meshing positions differ, the roller with the highest meshing position experiences the largest loads on both the screw and nut sides; and third, my analytical model aligns well with finite element simulations, validating its accuracy. These insights can guide the design and optimization of planetary roller screw assemblies for enhanced performance and reliability. Future work may explore thermal effects, lubrication, and fatigue life to further advance the understanding of these critical mechanical systems.

Throughout this article, I have emphasized the importance of the planetary roller screw assembly in precision transmission. By repeatedly examining the planetary roller screw assembly from various angles—geometric, mechanical, and computational—I aim to provide a robust framework for engineers and researchers. The use of tables and formulas, as shown, helps summarize complex data and relationships, making the analysis accessible. As technology evolves, the demand for efficient and reliable planetary roller screw assemblies will only grow, and my work contributes to meeting that demand through detailed analytical and empirical studies.