In the pursuit of higher precision, greater load capacity, and longer service life in linear motion systems, the planetary roller screw assembly has emerged as a superior alternative to traditional ball screw mechanisms. This paper presents a comprehensive parametric design methodology for a planetary roller screw assembly intended for demanding applications such as high-performance computer numerical control (CNC) machine tools. I will analyze its fundamental working principles and kinematic relationships, derive the critical structural parameter interdependencies and calculation formulas, and establish a complete design process from initial specifications to virtual validation. The core of this work lies in developing a calculable framework that links performance requirements—such as load, speed, stroke, and accuracy—to the precise geometrical dimensions of the screw, rollers, nut, and associated gear components.

The inherent advantage of a planetary roller screw assembly stems from its design, where multiple threaded rollers are arranged in a planetary configuration around a central screw. This distributes the load across numerous contact lines rather than relying on a recirculating stream of balls. Consequently, the lead is not constrained by the diameter of a rolling element, allowing for very fine leads below 0.5 mm while simultaneously offering significantly higher static and dynamic load ratings—often three and two-and-a-half times greater, respectively, than a comparable ball screw. For applications requiring high thrust in a compact envelope, exceptional durability, and precise positioning under heavy loads or in harsh environments, the planetary roller screw assembly is increasingly the mechanism of choice.

1. Working Principle and Kinematic Fundamentals

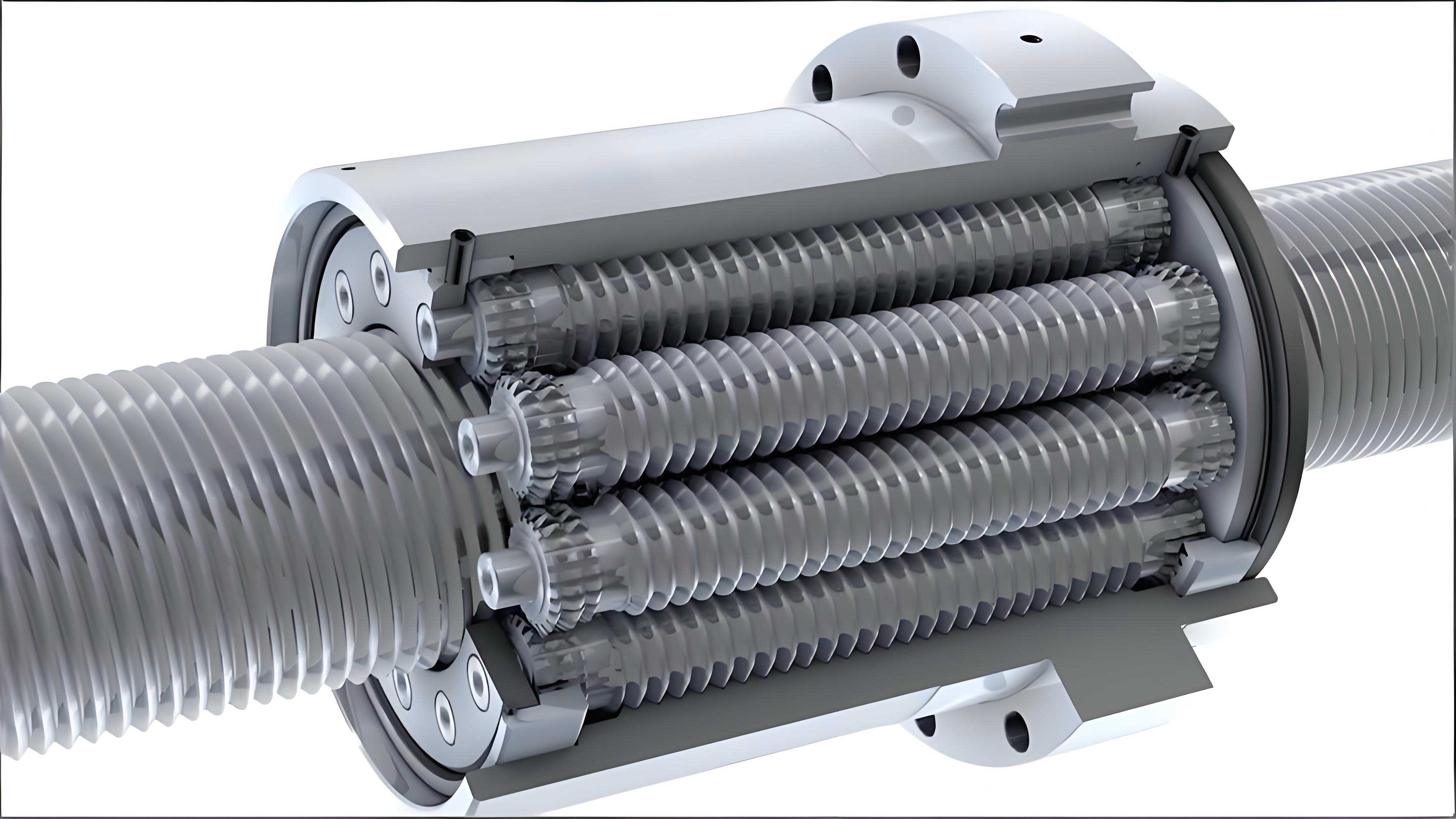

The operational principle of the planetary roller screw assembly can be understood through its core components: the central screw, the planetary rollers, the nut, the internal gear rings, and the planetary carrier, as illustrated in the schematic below. The screw and the nut possess multi-start threads, while each roller has a single-start thread along its central section and gear teeth on both ends.

When the screw rotates, its threads mesh with the threads on the central portion of the rollers. These roller threads, in turn, mesh with the internal threads of the nut. This interaction converts the screw’s rotary motion into an axial translation of the nut (or vice-versa if the nut is rotationally constrained). Simultaneously, the gear teeth on both ends of each roller engage with the teeth of the internal gear rings fixed inside the nut. This dual engagement is crucial: it synchronizes the motion of all rollers, preventing skewing and derailing, and ensures pure rolling contact, thereby minimizing friction and wear. The smooth journals at the ends of the rollers are supported by holes in the planetary carrier, which maintains their radial position. The motion is reversible; an axial force on the nut can cause the screw to rotate.

For constant transmission ratio and pure rolling, the screw, nut, and rollers must have the same helix angle and hand of thread. The fundamental geometric relationship governing the pitch diameters is:

$$ D_n = D_s + 2D_r $$

where $D_n$, $D_s$, and $D_r$ are the pitch diameters of the nut, screw, and roller, respectively.

The helix angle $\theta$ is defined by the lead. For the nut:

$$ \tan\theta_n = \frac{n_n P_n}{\pi D_n} $$

and for the roller:

$$ \tan\theta_r = \frac{n_r P_r}{\pi D_r} $$

where $n_n$ and $n_r$ are the number of starts, and $P_n$ and $P_r$ are the leads. Ensuring $\theta_s = \theta_n = \theta_r$ and that the nut and screw leads are equal ($P_s = P_n$) leads to a key relationship for the number of starts:

$$ n_n = n_s = \frac{D_n}{D_r} $$

This implies the number of starts on the screw and nut is determined by the ratio of their pitch diameters to the roller’s pitch diameter.

The kinematics of the system can be analyzed as a planetary gear train. Considering the screw (1), roller (2), and nut (3), the transmission ratio relative to the carrier (H) is:

$$ i^H_{13} = \frac{\omega_1 – \omega_H}{\omega_3 – \omega_H} = -\frac{D_n}{D_s} $$

Since the nut only translates axially ($\omega_3 = 0$), the angular velocity of the carrier is:

$$ \omega_H = \frac{D_s}{D_n + D_s} \omega_1 $$

Now, considering the gear train formed by the screw (1), a roller’s threaded section (2), its end gear teeth (4), and the internal gear ring (5), the ratio is:

$$ i^{H*}_{13} = \frac{\omega_1 – \omega_{H*}}{\omega_5 – \omega_{H*}} = -\frac{D_r}{D_s} \cdot \frac{Z_n}{Z_r} $$

The internal gear ring is fixed ($\omega_5 = 0$), yielding:

$$ \omega_{H*} = \frac{D_s Z_r}{D_s Z_r + D_r Z_n} \omega_1 $$

For consistent motion, the carrier velocity from both analyses must be equal ($\omega_H = \omega_{H*}$). This condition establishes the vital relationship between the gear teeth numbers and the pitch diameters:

$$ \frac{Z_n}{Z_r} = \frac{D_s}{D_r} + 2 $$

where $Z_n$ and $Z_r$ are the number of teeth on the internal gear ring and the roller end gear, respectively. These fundamental equations form the backbone of the parametric design for the planetary roller screw assembly.

2. Parametric Design Methodology

My design process for the planetary roller screw assembly begins with the application’s primary performance requirements: maximum axial load ($F_{max}$), travel speed or screw RPM ($n$), required stroke ($L$), and positional accuracy. From these, I determine critical load ratings and proceed to size the components through a sequence of calculations focused on strength, stability, and wear resistance.

2.1 Screw Core Sizing and Strength Verification

The screw is the primary load-bearing member. Its minor diameter ($D_{s1}$) is initially sized based on compressive/tensile stress and torsional stress from the drive torque. Using the von Mises criterion for the combined stress state at the critical section:

$$ \sigma_{eq} = \sqrt{ \left( \frac{4F}{\pi D_{s1}^2} \right)^2 + 3 \left( \frac{M_m}{0.2 D_{s1}^3} \right)^2 } \leq [\sigma] $$

where $F$ is the axial force, $M_m$ is the driving torque (including load lifting torque and friction), and $[\sigma]$ is the allowable stress of the screw material.

Next, the shear stress at the root of the screw thread must be checked:

$$ \tau_s = \frac{F}{\pi D_{s1} b C} \leq [\tau] $$

Here, $b$ is the thread root width (e.g., $b = 0.74P_s$ for a triangular thread), $C$ is the number of engaged threads, and $[\tau]$ is the allowable shear stress.

As a slender component under compression, the screw’s stability is paramount. The critical buckling load $F_{cr}$ is calculated based on end support conditions. For one end fixed and one free (a common configuration):

$$ F_{cr} = \frac{\pi^3 E D_{s1}^4}{64 (\beta L)^2} = k \frac{D_{s1}^4}{L^2} $$

where $E$ is the modulus of elasticity, $\beta$ is the end condition coefficient (e.g., $\beta=2$ for fixed-free), $L$ is the maximum unsupported length, and $k$ is a support constant. The design must satisfy $F_{cr} \gg F_{max}$ with a sufficient safety factor.

Finally, wear resistance often dictates the minimum pitch diameter. An empirical formula based on allowable contact pressure can be used:

$$ D_s \geq 0.65 \sqrt[1.5]{\frac{F_{max}}{n_s}} $$

where $n_s$ is the number of screw starts. After these sequential checks, the screw pitch diameter $D_s$ and minor diameter $D_{s1}$ are finalized.

2.2 Determination of Roller and Nut Parameters

With $D_s$ determined, the roller pitch diameter $D_r$ is selected. A common ratio is $D_s / D_r = 3$, but this can be optimized. The nut pitch diameter follows directly:

$$ D_n = D_s + 2D_r $$

The number of starts for the screw and nut is then:

$$ n_s = n_n = \frac{D_n}{D_r} $$

This value must be an integer. The lead $P_s$ is chosen based on the required linear speed ($v = n \cdot P_s$). The helix angle is verified using:

$$ \theta = \arctan\left(\frac{P_s}{\pi D_s}\right) = \arctan\left(\frac{n_r P_r}{\pi D_r}\right) $$

For standard triangular threads with a 90° included angle, the basic tooth height $H$ is half the pitch $P$.

The design of the roller end gears is critical for synchronization. First, the number of teeth on the roller end gear $Z_r$ is chosen (e.g., 20). The module $m$ is selected based on strength and size constraints: $m = D_{r2} / Z_r$, where $D_{r2}$ is the roller end gear pitch diameter, often made equal to $D_r$ for simplicity ($D_{r2} = D_r$). The number of teeth on the internal gear ring is then mandated by the kinematic condition:

$$ Z_n = Z_r \left( \frac{D_s}{D_r} + 2 \right) $$

This ensures the carrier kinematics are consistent, allowing all rollers to mesh properly with both the screw threads and the internal gear teeth simultaneously.

3. Application Case: Design for a CNC Machine Tool Axis

To demonstrate the parametric design, I consider replacing a ball screw in a CNC machine tool feed drive with a planetary roller screw assembly. The machine’s work cycle includes stages of extreme load, roughing, finishing, and rapid traverse.

3.1 Operational Load and Speed Analysis

The duty cycle is characterized by varying axial loads ($F_i$) and screw speeds ($n_i$) over different time percentages ($t_i$). The equivalent average speed $n_m$ and mean effective load $F_m$ are calculated to assess fatigue life. The mean speed is a simple weighted average:

$$ n_m = \sum \left( \frac{t_i}{100} \cdot n_i \right) $$

For the mean load, the cubed-root mean is used for life calculation (governed by the fatigue life formula $L_{10} = (C / F_m)^3$):

$$ F_{m} = \sqrt[3]{ \sum \left( \frac{t_i}{100} \cdot \frac{n_i}{n_m} \cdot F_i^3 \right) } $$

Where $C$ is the dynamic load rating of the planetary roller screw assembly. For the given CNC cycle, calculations yield $n_m \approx 115.15 \text{ rpm}$ and $F_m \approx 3.72 \text{ kN}$.

3.2 Strength Design and Parameter Calculation

Assuming a peak axial load $F_{max} = 9 \text{ kN}$, a lead $P_s = 10 \text{ mm}$, and a target screw pitch diameter $D_s = 30 \text{ mm}$ from preliminary sizing, I proceed with the detailed parameter calculation.

Screw Parameters: 5 starts, lead $P_s=10$ mm, pitch $p_s=2$ mm (since $p_s = P_s / n_s$). For a 90° triangular thread: Basic height $H_{1s}=1$ mm, crest-trough clearance $a_c=0.15$ mm, thread height $H_{2s}=1.15$ mm. Major diameter $D_{s3} = D_s + p_s/2 = 31$ mm. Minor diameter $D_{s1} = D_{s3} – 2H_{2s} = 28.7$ mm.

Roller Parameters: Selecting $D_s / D_r = 3$, thus $D_r = 10$ mm. Roller is single-start ($n_r=1$) with pitch $p_r = p_s = 2$ mm for matching helix angle. Roller major diameter $D_{r3} = D_r + p_r/2 = 11$ mm. Minor diameter $D_{r1} = 8.7$ mm. For the end gear: Choose $Z_r = 20$, module $m=0.5$ mm, pressure angle $\alpha=20°$. Pitch diameter $D_{r2} = m Z_r = 10$ mm (equal to $D_r$). Addendum diameter $D_{ar} = D_{r2} + 2m = 11$ mm. Dedendum diameter $D_{fr} = D_{r2} – 2.5m = 8.75$ mm.

Nut Parameters: Pitch diameter $D_n = D_s + 2D_r = 50$ mm. Number of starts $n_n = D_n / D_r = 5$. Major diameter $D_{n3} = D_n + p_s/2 = 51$ mm. Minor diameter $D_{n1} = D_{n3} – 2H_{2s} = 48.7$ mm.

Internal Gear Ring Parameters: Number of teeth $Z_n = Z_r (D_s/D_r + 2) = 20 \times (3 + 2) = 100$. Module $m=0.5$ mm (same as roller gear). Pitch diameter $D_{n2} = m Z_n = 50$ mm. Dedendum diameter $D_{fn} = D_{n2} – 2m = 49$ mm (for internal gear). Addendum diameter $D_{an} = D_{n2} + 2.5m = 51.25$ mm.

The key calculated parameters for this planetary roller screw assembly design are summarized in the table below.

| Component & Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Screw | |||

| Pitch Diameter | $D_s$ | 30.00 | mm |

| Major Diameter | $D_{s3}$ | 31.00 | mm |

| Minor Diameter | $D_{s1}$ | 28.70 | mm |

| Number of Starts | $n_s$ | 5 | – |

| Lead | $P_s$ | 10.00 | mm |

| Pitch | $p_s$ | 2.00 | mm |

| Planetary Roller | |||

| Pitch Diameter | $D_r$ | 10.00 | mm |

| Major Diameter | $D_{r3}$ | 11.00 | mm |

| Minor Diameter | $D_{r1}$ | 8.70 | mm |

| Number of Starts | $n_r$ | 1 | – |

| Gear Teeth Number | $Z_r$ | 20 | – |

| Gear Module | $m$ | 0.50 | mm |

| Nut | |||

| Pitch Diameter | $D_n$ | 50.00 | mm |

| Major Diameter | $D_{n3}$ | 51.00 | mm |

| Minor Diameter | $D_{n1}$ | 48.70 | mm |

| Number of Starts | $n_n$ | 5 | – |

| Internal Gear Ring | |||

| Gear Teeth Number | $Z_n$ | 100 | – |

| Pitch Diameter | $D_{n2}$ | 50.00 | mm |

3.3 Verification Calculations

Using the finalized dimensions, I verify the design against the initial requirements.

Screw Strength: With $F=9 \text{ kN}$ and estimated drive torque $M_m=28.65 \text{ N·m}$, the equivalent stress is:

$$ \sigma_{eq} = \sqrt{ \left( \frac{4 \times 9000}{\pi \times (0.0287)^2} \right)^2 + 3 \left( \frac{28.65}{0.2 \times (0.0287)^3} \right)^2 } \approx 17.0 \text{ MPa} $$

This is well below a typical allowable stress for high-strength steel (e.g., 167 MPa).

Thread Shear: For $C=30$ engaged threads and root width $b=0.74 \times 0.002 = 1.48\text{ mm}$:

$$ \tau_s = \frac{9000}{\pi \times 0.0287 \times 0.00148 \times 30} \approx 2.24 \text{ MPa} $$

This is also very safe.

Stability: For a fixed-free support and stroke $L=0.7 \text{ m}$, the critical load is:

$$ F_{cr} = k \frac{D_{s1}^4}{L^2} = (2.5 \times 10^4) \frac{(0.0287)^4}{(0.7)^2} \approx 25.2 \text{ kN} > 9 \text{ kN} $$

The design passes the stability check comfortably. All verifications confirm the suitability of the designed planetary roller screw assembly for the specified CNC machine tool application.

4. 3D Modeling and Virtual Assembly Validation

To validate the geometric correctness and assemblability of the parametrically derived dimensions, I create detailed 3D CAD models of each component. The screw and nut models are generated by performing a helical sweep of the 90° triangular tooth profile, with the sweep pitch equal to the lead per start ($p_s$). The multi-start feature is achieved by patterning the single helical thread around the axis. The roller modeling is more involved: a central helical thread (single-start, pitch $p_r$) is created, and then the end gears are modeled separately by extruding the gear tooth profile based on the calculated parameters ($Z_r$, $m$, $\alpha$). The internal gear ring is modeled similarly.

The virtual assembly process follows a logical sequence: First, the internal gear rings are fixed inside the nut housing. Second, the planetary carrier and retaining washers are placed. Third, the rollers are inserted, ensuring their end journals mate with the carrier holes and their end gears mesh with the internal gear ring teeth. All rollers are patterned circumferentially. Finally, the screw is engaged axially with the set of rollers. A critical check during this phase is verifying that the threaded section of the roller meshes correctly with both the screw and nut threads simultaneously when its end gear is engaged with the internal ring. This confirms the correctness of the relationship $Z_n / Z_r = D_s / D_r + 2$. Interference checks are run to ensure no unintended contact occurs, and the mechanism can be simulated to verify smooth relative motion. This digital prototyping step is invaluable for confirming the planetary roller screw assembly design before physical manufacture.

5. Material and Manufacturing Considerations

The performance of a planetary roller screw assembly is intimately tied to material selection and manufacturing precision. For high-load, high-precision applications like machine tools, the screw, rollers, and nut are typically manufactured from high-carbon chromium bearing steel (e.g., GCr15 or its equivalents like SAE 52100). This material offers excellent wear resistance, high and uniform hardness after heat treatment, high contact fatigue strength, good dimensional stability, and corrosion resistance—all essential for the heavily loaded, rolling-contact interfaces.

The internal gear rings and planetary carrier, which primarily provide synchronization and support rather than carrying the main axial load, can be made from high-strength alloy steels such as 42CrMo. This material provides high strength, good hardenability, and toughness, suitable for components experiencing complex stresses.

Manufacturing the roller is the most complex task. The central thread and the end gears must be produced with precise relative phasing. A common approach is to first machine or grind the central thread along the entire roller length. Then, using the thread itself as a datum, the end gears are cut (e.g., by precision gear shaping or skiving) in a single setup to ensure their angular position is synchronized with the thread’s start point on every roller. This guarantees that when the roller’s end gear is engaged with the fixed internal ring, its thread will automatically be in the correct phase to mesh simultaneously with both the screw and nut threads, a fundamental requirement for proper function of the planetary roller screw assembly.

6. Conclusion and Outlook

In this paper, I have presented a systematic parametric design framework for a high-performance planetary roller screw assembly. Starting from fundamental kinematic principles, I derived the essential mathematical relationships governing the pitch diameters, number of starts, lead, and gear teeth, culminating in the critical condition $Z_n / Z_r = D_s / D_r + 2$. A detailed design procedure was outlined, encompassing strength, stability, and wear calculations for the screw, and the subsequent determination of all companion component dimensions. This methodology was successfully applied to a case study for a CNC machine tool feed drive, demonstrating how application requirements are translated into a complete set of manufacturable parameters, which were then validated through 3D modeling and virtual assembly.

The parametric approach offers significant advantages: it streamlines the design process, ensures internal geometric consistency, and facilitates rapid adaptation to different performance specifications. The resulting planetary roller screw assembly design promises substantial benefits over traditional ball screws for this application, including higher load capacity in a potentially smaller envelope, suitability for higher speeds, and potentially longer operational life. Future work will involve the physical procurement of components based on these designs, followed by rigorous testing—including running-in under load, efficiency measurement, and precision life testing—to validate the theoretical performance predictions and further refine the design methodology for the broader industrial adoption of planetary roller screw assemblies.