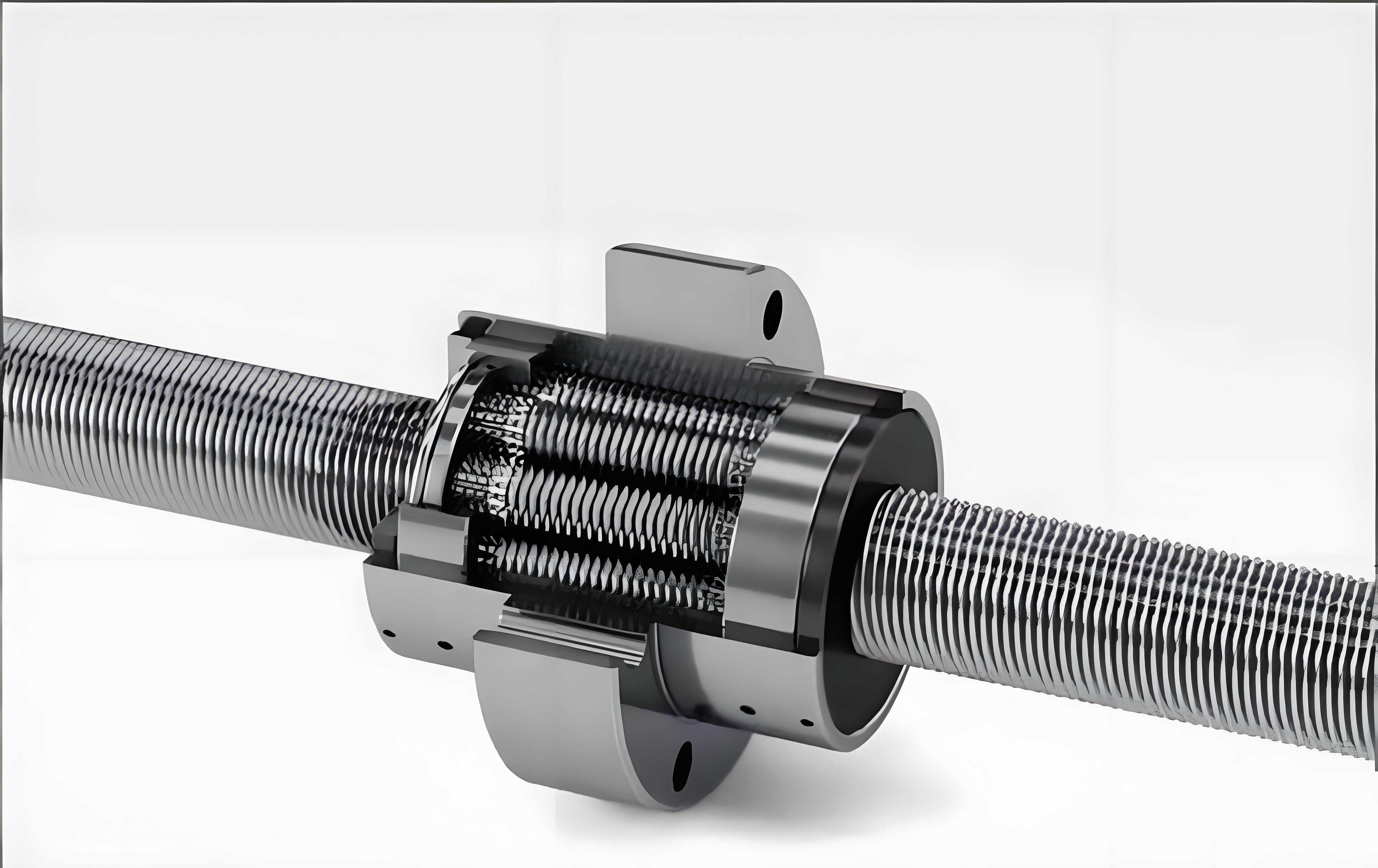

In the field of precision mechanical transmission, the planetary roller screw assembly stands out as a highly efficient mechanism for converting rotary motion into linear motion, and vice versa, due to its non-self-locking nature. As a researcher deeply involved in the analysis of such systems, I have focused on the critical aspect of pre-tightening force, which is essential for eliminating backlash, enhancing stiffness, and ensuring precise positioning. The planetary roller screw assembly consists primarily of a screw, multiple rollers, a nut, and a retainer, ingeniously combining planetary motion with helical motion. Its advantages include high load capacity, substantial rigidity, efficiency, minimal wear, and long service life, making it indispensable in aerospace, precision machine tools, industrial robots, and other high-speed, heavy-duty applications. However, without proper pre-load, the assembly suffers from significant transmission clearance, leading to poor accuracy and reduced stiffness. Conversely, excessive pre-tightening force accelerates wear and shortens lifespan. Therefore, a thorough investigation into the pre-tightening force of the planetary roller screw assembly is paramount for optimal design and performance.

My analysis begins with the contact deformation within the planetary roller screw assembly. The contacts between the rollers and the screw, and between the rollers and the nut, are typically point contacts. In engineering, Hertzian contact theory is employed to model these interactions. Under load, elliptical contact areas form at each interface. For the planetary roller screw assembly, the geometry involves the pitch diameters of the screw ($d_s$), rollers ($d_r$), and nut ($d_n$), along with the principal curvatures at the contact points. The first principal curvature radii for the roller, screw, and nut are denoted as $R_{r11}$, $R_{s21}$, and $R_{n21}$, respectively, with their reciprocals representing the principal curvatures. The contact ellipses between the roller and screw have semi-major and semi-minor axes $a$ and $b$, while those between the roller and nut have $a’$ and $b’$.

According to Hertzian theory, the sum of principal curvatures at a contact point, $\sum \rho$, is given by:

$$ \sum \rho = \rho_{11} + \rho_{12} + \rho_{21} + \rho_{22} $$

For the roller-screw contact, $\rho_{11}$ and $\rho_{12}$ are the first and second principal curvatures of the roller, while $\rho_{21}$ and $\rho_{22}$ are those of the screw. For the roller-nut contact, $\rho_{21}$ and $\rho_{22}$ pertain to the nut. The elastic deformation $\delta$ at the contact is expressed as:

$$ \delta = \frac{2K(e)}{\pi m_a} \left[ \frac{3}{2} \left( \frac{1-\mu_1^2}{E_1} + \frac{1-\mu_2^2}{E_2} \right) \right]^{2/3} \left( \frac{Q^2 \sum \rho}{8} \right)^{1/3} $$

Here, $\mu_1$ and $\mu_2$ are the Poisson’s ratios of the two contacting bodies, $E_1$ and $E_2$ are their Young’s moduli, $Q$ is the normal load at the contact point, $K(e)$ is the complete elliptic integral of the first kind, $e$ is the ellipticity of the contact ellipse, and $m_a$ is a factor related to ellipticity:

$$ m_a = \left[ \frac{2L(e)}{\pi (1-e^2)^{1/2}} \right]^{1/3} $$

where $L(e)$ is the complete elliptic integral of the second kind. The function $F(\rho)$ satisfies:

$$ F(\rho) = \frac{|(\rho_{11} – \rho_{12}) + (\rho_{21} – \rho_{22})|}{\sum \rho} = \frac{(2-e^2)L(e) – 2(1-e^2)K(e)}{(2-e^2)L(e)} $$

Using computational tools like MATLAB, the ellipticity $e$ can be solved iteratively, enabling the determination of the relationship between elastic deformation and load. For the planetary roller screw assembly, the curvatures are derived from the geometry. For the roller-screw contact:

$$ \rho_{r1} = \rho_{r2} = \frac{2 \sin \alpha}{d_r} $$

$$ \rho_{s1} = \frac{2 \sin \alpha}{d_s}, \quad \rho_{s2} = 0 $$

For the roller-nut contact:

$$ \rho_{r1} = \rho_{r2} = \frac{2 \sin \alpha}{d_r} $$

$$ \rho_{n1} = -\frac{2 \sin \alpha}{d_n}, \quad \rho_{n2} = 0 $$

where $\alpha$ is the contact angle. Substituting these into the deformation equation yields the elastic deformation as a function of normal load:

$$ \delta_s = C_s Q^{2/3} $$

$$ \delta_n = C_n Q^{2/3} $$

Here, $\delta_s$ and $\delta_n$ are the contact deformations for roller-screw and roller-nut interfaces, respectively, and $C_s$ and $C_n$ are the contact stiffness coefficients:

$$ C_s = \frac{2K(e)}{\pi m_a} \left[ \frac{3}{2} \left( \frac{1-\mu_r^2}{E_r} + \frac{1-\mu_s^2}{E_s} \right) \right]^{2/3} \left( \frac{\sum \rho_s}{8} \right)^{1/3} $$

$$ C_n = \frac{2K(e)}{\pi m_a} \left[ \frac{3}{2} \left( \frac{1-\mu_r^2}{E_r} + \frac{1-\mu_n^2}{E_n} \right) \right]^{2/3} \left( \frac{\sum \rho_n}{8} \right)^{1/3} $$

with the sums of curvatures:

$$ \sum \rho_s = 2 \left( \frac{2 \sin \alpha}{d_r} \right) + \frac{2 \sin \alpha}{d_s} $$

$$ \sum \rho_n = 2 \left( \frac{2 \sin \alpha}{d_r} \right) + \frac{2 \sin \alpha}{d_n} $$

where $\mu_r$, $\mu_s$, $\mu_n$ and $E_r$, $E_s$, $E_n$ are the Poisson’s ratios and Young’s moduli of the roller, screw, and nut, respectively.

Moving to pre-tightening force analysis, in a single-nut planetary roller screw assembly, pre-load is typically applied by adjusting roller diameter or thread clearance. However, a common method involves modifying the screw pitch diameter. Pre-tightening is achieved by increasing the screw pitch diameter by $\Delta S$ (preload amount) while decreasing the nut pitch diameter accordingly. This induces contact deformation at both interfaces. The total deformation due to pre-tightening is:

$$ \delta = \delta_s + \delta_n = \frac{\Delta S \cos \lambda \cos \alpha}{2} $$

where $\lambda$ is the helix angle of the roller. The forces at the roller-screw contact point are analyzed: the normal force $F_n$, radial force $F_r$, axial force $F_a$, and tangential force $F_t$ relate as:

$$ F_n = \frac{F_a}{\sin \alpha \cos \lambda} = \frac{F}{n \sin \alpha \cos \lambda} $$

Here, $F$ is the total pre-tightening force, and $n$ is the number of contact points between rollers and screw. A similar analysis applies to the roller-nut contact. Combining these equations, the relationship between pre-tightening force $F$ and preload amount $\Delta S$ for the planetary roller screw assembly is derived:

$$ \Delta S = \frac{2(C_s + C_n)}{\cos \lambda \cos \alpha} \left( \frac{F}{n \sin \alpha \cos \lambda} \right)^{2/3} $$

To illustrate, consider a planetary roller screw assembly with the geometric parameters listed in Table 1. Assume the number of contact points $n = 240$, and material properties: $\mu_r = \mu_s = \mu_n = 0.29$, $E_r = E_s = E_n = 207 \text{ GPa}$. Calculating the preload amount versus pre-tightening force yields the data summarized in Table 2 and plotted graphically.

| Parameter | Screw | Roller | Nut |

|---|---|---|---|

| Theoretical Pitch Diameter (mm) | 19.5 | 6.5 | 32.5 |

| Thread Half-Angle (°) | 45 | 45 | 45 |

| Roller Profile Radius (mm) | — | 4 | — |

| Helix Angle (°) | 14.691 | 8.815 | 8.815 |

| Pitch (mm) | 1 | 1 | 1 |

| Number of Starts | 5 | 1 | 5 |

| Lead (mm) | 5 | 1 | 5 |

| Pre-tightening Force, F (kN) | Preload Amount, ΔS (μm) |

|---|---|

| 0 | 0 |

| 2 | 5.2 |

| 4 | 8.3 |

| 6 | 10.7 |

| 8 | 12.8 |

| 10 | 14.6 |

| 12 | 16.2 |

The relationship shows that as pre-tightening force increases, the preload amount increases but with a diminishing rate, due to the nonlinear Hertzian contact behavior. This is crucial for designing preload mechanisms in a planetary roller screw assembly to avoid over-constraint.

Next, I analyze factors influencing the pre-tightening force in a planetary roller screw assembly. Variations in contact angle $\alpha$ and helix angle $\lambda$ alter contact stresses, thereby affecting the pre-tightening force. Using the parameters from Table 1 and fixing $\Delta S = 15 \mu m$, I examine the effects of these angles. First, with constant helix angle ($\lambda = 8.815^\circ$), the pre-tightening force as a function of contact angle is computed and presented in Table 3.

| Contact Angle, α (°) | Pre-tightening Force, F (kN) |

|---|---|

| 30 | 4.8 |

| 35 | 5.5 |

| 40 | 6.0 |

| 45 | 5.8 |

| 50 | 5.4 |

| 55 | 5.0 |

| 60 | 4.6 |

The data indicates that as the contact angle increases from $30^\circ$ to $60^\circ$, the pre-tightening force initially rises to a maximum around $40^\circ$ and then decreases. This non-monotonic behavior stems from the interplay between normal force components and contact stiffness in the planetary roller screw assembly.

Second, with constant contact angle ($\alpha = 45^\circ$), the pre-tightening force versus helix angle is analyzed, as shown in Table 4.

| Helix Angle, λ (°) | Pre-tightening Force, F (kN) |

|---|---|

| 2 | 6.2 |

| 4 | 6.1 |

| 6 | 6.0 |

| 8 | 5.8 |

| 10 | 5.5 |

| 12 | 5.2 |

Here, increasing the helix angle leads to a gradual decrease in pre-tightening force, with the rate of decrease accelerating at higher angles. This is because a larger helix angle reduces the axial force component for a given normal force, thereby lowering the effective pre-load. Comparing the two factors, the contact angle has a more pronounced influence on the pre-tightening force than the helix angle in a planetary roller screw assembly. This insight is vital for optimizing thread profiles and preload settings.

To delve deeper, the contact stiffness coefficients $C_s$ and $C_n$ depend on the sum of curvatures, which are functions of $\alpha$, $d_r$, $d_s$, and $d_n$. From the equations:

$$ \sum \rho_s = 2 \left( \frac{2 \sin \alpha}{d_r} \right) + \frac{2 \sin \alpha}{d_s} = 2 \sin \alpha \left( \frac{2}{d_r} + \frac{1}{d_s} \right) $$

$$ \sum \rho_n = 2 \left( \frac{2 \sin \alpha}{d_r} \right) + \frac{2 \sin \alpha}{d_n} = 2 \sin \alpha \left( \frac{2}{d_r} + \frac{1}{d_n} \right) $$

Substituting into the preload equation:

$$ \Delta S = \frac{2}{\cos \lambda \cos \alpha} \left( C_s + C_n \right) \left( \frac{F}{n \sin \alpha \cos \lambda} \right)^{2/3} $$

where $C_s$ and $C_n$ are proportional to $(\sum \rho)^{1/3}$. Thus, the pre-tightening force $F$ can be expressed implicitly. For design purposes, a simplified formula can be derived by assuming similar materials and small ellipticity, but the full Hertzian model is recommended for accuracy. The nonlinearity is evident from the exponent $2/3$, implying that doubling the pre-tightening force increases the preload amount by a factor of $2^{2/3} \approx 1.587$, not 2. This characteristic must be accounted for in tolerance allocation and assembly processes for the planetary roller screw assembly.

Moreover, the number of rollers and contact points $n$ significantly affects the pre-tightening force distribution. In a planetary roller screw assembly, multiple rollers share the load, but manufacturing errors can lead to uneven load sharing. The preload equation assumes ideal contact; however, in practice, statistical variations in roller diameters and thread pitches necessitate a safety factor. I propose a modified equation incorporating a load distribution factor $K_d$:

$$ \Delta S = \frac{2(C_s + C_n)}{\cos \lambda \cos \alpha} \left( \frac{F}{K_d n \sin \alpha \cos \lambda} \right)^{2/3} $$

where $K_d \geq 1$ accounts for uneven loading. Experimental calibration of $K_d$ is advised for critical applications.

Another aspect is the effect of temperature on pre-tightening force in a planetary roller screw assembly. Thermal expansion can alter pitch diameters and contact angles, thereby modifying the preload. The thermal strain $\epsilon$ due to temperature change $\Delta T$ is $\epsilon = \beta \Delta T$, where $\beta$ is the coefficient of thermal expansion. For a steel planetary roller screw assembly ($\beta \approx 11 \times 10^{-6} /^\circ \text{C}$), a $50^\circ \text{C}$ rise increases dimensions by 0.055%, which might seem small but can affect precision preload settings. The adjusted pitch diameters become:

$$ d_s’ = d_s (1 + \beta \Delta T), \quad d_r’ = d_r (1 + \beta \Delta T), \quad d_n’ = d_n (1 + \beta \Delta T) $$

Recalculating the curvatures and contact stiffness, the pre-tightening force at elevated temperature $F’$ relates to the preload amount $\Delta S$ by:

$$ \Delta S = \frac{2(C_s’ + C_n’)}{\cos \lambda \cos \alpha} \left( \frac{F’}{n \sin \alpha \cos \lambda} \right)^{2/3} $$

where $C_s’$ and $C_n’$ are updated stiffness coefficients. This thermal sensitivity underscores the need for material selection and thermal management in high-precision planetary roller screw assembly systems.

In terms of applications, the pre-tightening force analysis directly impacts the design of aerospace actuators, where the planetary roller screw assembly must maintain stiffness under varying loads and temperatures. Similarly, in industrial robots, precise preload ensures repeatability and minimizes positioning errors. My findings suggest that for a given preload amount, optimizing the contact angle around $40^\circ$ can maximize the pre-tightening force, enhancing load capacity. However, trade-offs exist: a higher contact angle may increase friction and wear, so a holistic design approach is essential.

To further illustrate, consider a case study where a planetary roller screw assembly with parameters from Table 1 is used in a CNC machine tool. The required axial stiffness is 500 N/μm, which translates to a specific pre-tightening force. Using the derived relationships, I can back-calculate the necessary preload amount $\Delta S$. The axial stiffness $K_{axial}$ of the assembly is approximately:

$$ K_{axial} \approx \frac{n \sin^2 \alpha \cos^2 \lambda}{2(C_s + C_n)^{3/2}} \left( \frac{3F}{2} \right)^{1/3} $$

This formula, though simplified, shows the cubic root dependence on pre-tightening force, emphasizing the nonlinear stiffness behavior. For $K_{axial} = 500 \text{ N/μm}$, solving iteratively yields $F \approx 8.5 \text{ kN}$ and $\Delta S \approx 13.5 \mu m$. Such calculations guide assembly technicians in setting preload via screw pitch diameter adjustment.

In conclusion, my analysis of the planetary roller screw assembly pre-tightening force, based on Hertzian contact theory, establishes a clear relationship between preload amount and pre-tightening force, characterized by a power law with exponent 2/3. The contact angle and helix angle significantly influence this relationship, with the contact angle exhibiting a peak effect around $40^\circ$. These insights provide a theoretical foundation for preload design in planetary roller screw assemblies, ensuring optimal performance in demanding applications. Future work could explore dynamic preload effects, lubrication impacts, and advanced materials to further enhance the capabilities of the planetary roller screw assembly.