Throughout my extensive career in industrial plant maintenance and engineering, I have witnessed firsthand the critical role belt conveyors play in the backbone of material handling for sectors ranging from metallurgy and mining to power generation and chemicals. Their reliability is paramount. The drive unit, being the heart of the conveyor, is a frequent source of operational headaches. A sudden failure here doesn’t just stop a single machine; it can cascade into a full or partial system shutdown, leading to significant production losses. Therefore, the ideal drive solution must prioritize maximum reliability with minimal complexity and facilitate swift recovery when repairs are unavoidable. Based on my practical experience, one of the most effective strategies for achieving this balance, especially in retrofit scenarios with space constraints, is the adoption of a cycloidal drive system.

The Landscape of Conventional Drive Configurations: Strengths and Vulnerabilities

Before delving into the modernization solution, it is crucial to understand the existing options. The choice of drive configuration directly impacts maintenance philosophy, downtime duration, and lifecycle cost.

| Drive Configuration | Key Components & Layout | Primary Advantages | Primary Disadvantages & Maintenance Impact |

|---|---|---|---|

| Motorized Pulley (Integrated) | Motor and reduction gearing fully enclosed within the drive pulley. | Compact, space-saving design. Simplified initial installation and alignment. Clean appearance with no exposed moving parts. | Extremely difficult and time-consuming repair. Any internal fault (motor, bearing, gear) requires disassembling the conveyor belt to extract the entire heavy pulley unit. Specialized workshop repair is almost always necessary, leading to prolonged downtime. |

| External Reducer (Traditional) | Separate motor, stand-alone gear reducer (e.g., helical, bevel-helical), and drive pulley, connected via couplings. | High reliability and efficiency. Simple, modular design. Easy access for inspection and maintenance. Individual components can be replaced quickly without major belt disruption. | Larger footprint requiring a solid foundation. Higher initial investment in structure and components. Alignment of three separate units is critical. |

| External Motorized Pulley | Motor mounted externally on the pulley shaft, with reduction gearing still housed inside the pulley shell. | Reduces motor-related downtime compared to full motorized pulley; the external motor can be replaced separately. | Inherits the core disadvantage: any failure of the internal gearing still necessitates the arduous removal of the entire pulley assembly, resulting in major downtime. |

The analysis clearly shows a trade-off. The modular external reducer offers the best maintainability but demands space. The integrated solutions save space but catastrophically compromise repairability. This is precisely where the unique attributes of a cycloidal drive come into play, offering a compelling third path.

The Engineering Excellence of the Cycloidal Drive Principle

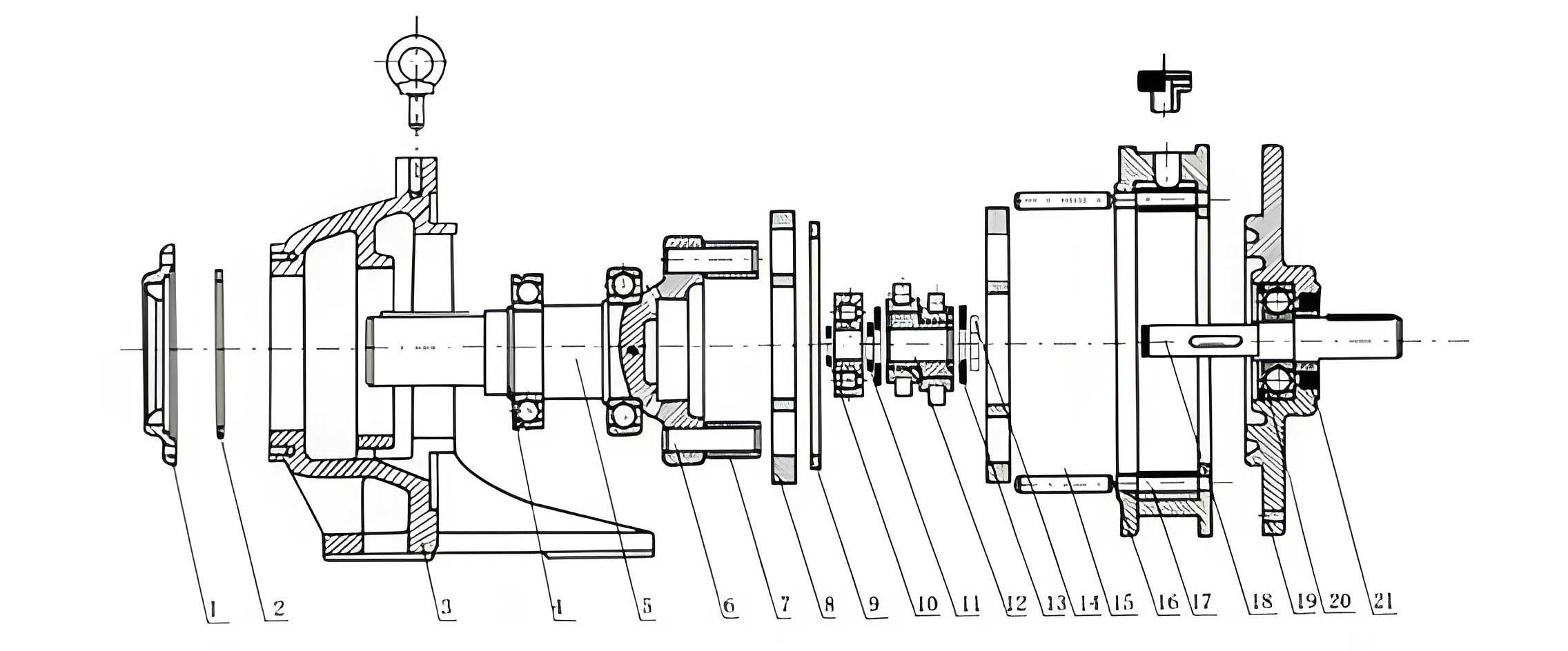

The cycloidal drive, or cycloidal speed reducer, operates on a profoundly different principle than conventional involute gear trains. Its advantages are not incidental but are rooted in its kinematics and design. Understanding these fundamentals is key to appreciating its suitability for drive modernization.

At its core, a cycloidal drive uses an eccentric input motion to generate cycloidal motion in a disc. This disc, with lobes (or teeth), meshes with stationary pin gears housed in the casing. The motion is then converted to a concentric, reduced-speed output through a series of pins and rollers. This mechanism yields extraordinary benefits:

- Exceptionally High Single-Stage Reduction Ratios: Unlike helical gears requiring multiple stages for high ratios, a cycloidal drive achieves this in a compact stage.

$$ i = \frac{N_p}{N_p – N_l} $$

Where $i$ is the reduction ratio, $N_p$ is the number of pins in the housing, and $N_l$ is the number of lobes on the cycloidal disc. By selecting these numbers, single-stage ratios from about 6:1 to over 100:1 are standard. Multi-stage units can achieve ratios exceeding 1,000,000:1, though for conveyors, the high single-stage ratio is most relevant. - Superior Load Distribution and High Efficiency: Power is transmitted through multiple lobes simultaneously. If a unit has $N_l$ lobes, theoretically half of them ($N_l / 2$) are in contact at any time. This distributes the load over a large surface area, reducing stress and allowing for an overhung load capacity that often surpasses that of helical units of comparable size. The rolling action of the lobes against the pins leads to high mechanical efficiency, typically 90-94% per stage, comparable to or better than many multi-stage helical reducers.

$$ P_{loss} = P_{in} (1 – \eta) $$

Where $P_{loss}$ is power lost as heat, $P_{in}$ is input power, and $\eta$ is the drive efficiency. - Compact, In-Line Design: The input and output shafts are co-axial. This, combined with the high ratio density, results in a reducer that is remarkably compact and lightweight—often 50% to 70% smaller and lighter than an equivalent helical reducer. This compactness is the linchpin for retrofit applications.

- Exceptional Durability and Shock Load Tolerance: The contacting components (disc and pins) are typically made of high-grade bearing steel (e.g., GCr15/52100) and hardened (58-62 HRC). The rolling contact creates minimal wear. Furthermore, the multi-lobe engagement provides high torsional stiffness and can absorb significant shock loads, making a cycloidal drive ideal for applications with frequent starts, stops, or uneven loading—common in conveyor systems.

Designing the Retrofit: A Practical Implementation Blueprint

The goal of the retrofit is to create a drive system that marries the maintenance-friendly, modular nature of an external reducer with the spatial economy of an integrated pulley. The compactness of the cycloidal drive makes this fusion possible.

The proposed configuration is elegantly simple. We utilize a hollow-shaft type cycloidal drive (often designated as BWY, X, or B series in various catalogs). The hollow shaft allows the drive pulley’s shaft to pass directly through it. The reducer is then mounted directly onto a fabricated baseplate or, due to its light weight, can even be welded directly to the existing conveyor head-frame structure. A flexible coupling, such as a chain, grid, or elastomeric spider coupling, connects the output flange of the cycloidal drive to the drive pulley. The standard foot-mounted motor is connected to the input side of the reducer via another flexible coupling.

The key design calculations involve verifying that the selected cycloidal drive meets the conveyor’s operational demands:

- Required Output Torque ($T_{req}$): This is derived from the conveyor’s total motion resistance.

$$ T_{req} = F_u \times \frac{D_{pulley}}{2} $$

Where $F_u$ is the effective tension at the drive pulley (in Newtons) and $D_{pulley}$ is the pulley diameter (in meters). The service factor ($SF$) for conveyors (typically 1.5-2.0) must be applied.

$$ T_{selected} \geq T_{req} \times SF $$ - Thermal Power Rating: The reducer must be able to dissipate the heat generated by power losses under continuous operation.

$$ P_{thermal} = P_{motor} \times \eta_{reducer} $$

The selected unit’s thermal rating must exceed the actual transmitted power. - Overhung Load and Thrust Load Capacity: The forces exerted by the coupling and belt tension on the output shaft must be checked against the reducer’s catalog ratings.

This configuration delivers the best of both worlds: the motor and cycloidal drive are external, stand-alone units. If a failure occurs—be it a motor burnout or a rare reducer issue—the repair is a straightforward swap of the faulty module. There is no need to touch the conveyor belt or the heavy drive pulley. The pulley itself becomes a simple mechanical component, with only its bearings requiring occasional maintenance.

Quantifiable Results and Operational Impact

The theoretical advantages of this cycloidal drive retrofit translate directly into measurable operational benefits. In one major plant modernization project, we faced a fleet of nearly 50 conveyors, a significant number of which were originally equipped with motorized pulleys. The historical failure rate for these integrated units exceeded 20 incidents annually, with each event consuming over two hours of critical production time for replacement and system restart.

We embarked on a phased retrofit program, prioritizing the most critical and failure-prone lines. For six key conveyors where spatial limitations ruled out traditional external reducers, the compact cycloidal drive solution was implemented. The results have been unequivocal:

| Performance Metric | Pre-Retrofit (Motorized Pulley) | Post-Retrofit (Cycloidal Drive System) | Improvement / Observation |

|---|---|---|---|

| Drive-Related Downtime | > 40 hours/year (est. for 6 lines) | 0 hours (to date, over several years) | Elimination of unplanned downtime from drive unit failures. |

| Mean Time To Repair (MTTR) | > 120 minutes (pulley extraction) | Estimated < 60 minutes (module swap) | Drastic reduction in recovery time for potential future failures. |

| Motor Load Current | Baseline (100%) | 94% – 97% of baseline | 3-6% reduction, indicating higher overall drive train efficiency and direct energy savings. |

| Maintenance Preparedness | Required specialized logistics for heavy pulley handling. | Standard motor and reducer can be stocked as spares. | Simplified spare parts management and reduced capital tied in spare pulleys. |

The energy saving, while a welcome bonus, stems from the high mechanical efficiency of the cycloidal drive and the reduction of parasitic losses often present in less efficient or worn motorized pulleys. The primary triumph is the transformational improvement in system availability and maintainability.

Advanced Considerations and Selection Guidelines

For engineers considering this approach, several nuanced factors deserve attention to ensure a successful and durable installation.

Lubrication and Sealing: Modern cycloidal drive units are typically filled with a high-quality synthetic or mineral gear oil for life, requiring no routine oil changes under normal conditions. However, the sealing system must be robust, especially in dusty or humid environments common to conveyor applications. Double-lip seals or labyrinth seals are preferred. The compatibility of seal materials with any potential environmental contaminants should be verified.

Mounting and Alignment: While the reducer is lightweight, its mounting must be rigid to prevent distortion under load, which can affect bearing life and gear mesh. Precise alignment between the motor, reducer, and the drive pulley shaft (via the coupling) remains non-negotiable. Misalignment forces are transferred to the reducer’s bearings and can lead to premature failure. The use of laser alignment tools is recommended during installation.

Backlash and Starting Characteristics: A cycloidal drive typically has marginally higher torsional backlash than a precision helical reducer. For most conveyor applications, this is inconsequential. However, for systems requiring extremely precise positioning or synchronization, it should be noted. Conversely, the high starting torque capability and shock load tolerance of the cycloidal drive are distinct advantages for heavily loaded or intermittently fed conveyors.

System Inertia and Control: When retrofitting, one must consider the total system inertia ($J_{total}$) as seen by the motor, especially if variable frequency drives (VFDs) are used for speed control.

$$ J_{total} = J_{motor} + \frac{J_{reducer\_in}}{i^2} + \frac{J_{pulley} + J_{load}}{i^2} $$

The high reduction ratio ($i$) of the cycloidal drive dramatically reduces the reflected inertia of the conveyor and load at the motor shaft. This can simplify motor control and reduce acceleration torque demands, potentially allowing for a smaller motor size in new designs or smoother starts in retrofits.

Conclusion: A Paradigm for Practical Modernization

The integration of a cycloidal drive into belt conveyor drive systems is far more than a simple component swap. It represents a strategic design philosophy that places operational resilience and lifecycle cost at the forefront. By leveraging its unique co-axial compactness, high ratio density, and robust construction, this solution effectively bridges the historical gap between the maintainability of external reducers and the spatial efficiency of integrated drives.

From my applied engineering perspective, the evidence is clear. The retrofit delivers tangible, multi-faceted value: it annihilates a major source of protracted downtime, simplifies maintenance logistics, reduces energy consumption, and enhances the overall robustness of the material handling system. It empowers plant engineers and maintenance teams with a rapid-response capability that was previously unavailable with space-constrained drive options.

For original equipment manufacturers (OEMs), this approach enriches the portfolio, offering clients a high-reliability, compact external drive option. For plant operators and retrofitting engineers, it provides a powerful and proven toolkit for upgrading existing infrastructure. In the relentless pursuit of industrial efficiency and uptime, the cycloidal drive stands out as a superior mechanical element, transforming a critical point of vulnerability into a bastion of reliability. Its adoption is a testament to pragmatic engineering—solving real-world problems with elegant, durable, and efficient technology.