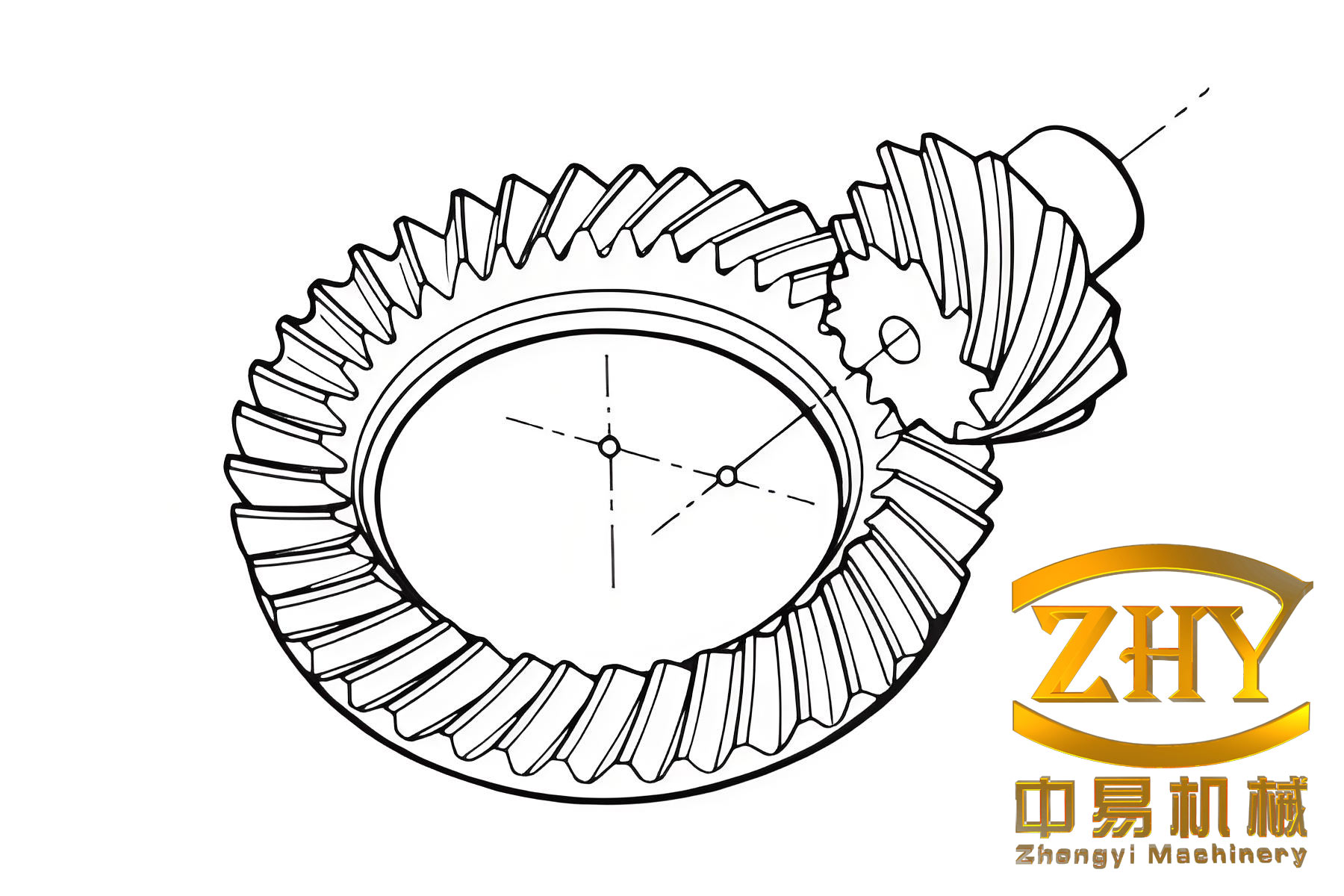

In the field of automotive, aerospace, marine, engineering machinery, and machine tools, hypoid bevel gears serve as core components due to their exceptional performance. Compared to conventional gears, hypoid bevel gears offer advantages such as larger overlap ratio, superior meshing characteristics, higher load-bearing capacity, increased transmission efficiency, smooth operation, low noise, and compact structure. The quality of hypoid bevel gears directly impacts the overall performance of machinery. Precision forging, as an advanced manufacturing technique, provides significant benefits over traditional cutting methods, including higher material utilization, improved production efficiency, reduced costs, and enhanced fatigue resistance due to continuous fiber flow lines in the forged parts. While precision forging of straight bevel gears and cylindrical spur gears has matured, the forging of spiral bevel gears, especially hypoid bevel gears with offset axes, remains challenging. The asymmetric tooth profile, complex geometry, and difficulty in demolding make precision forging of hypoid bevel gear driving pins particularly demanding. This study focuses on the numerical simulation of precision forging for a hypoid bevel gear driving pin using closed-die forging, aiming to elucidate metal flow patterns and deformation mechanics to guide process optimization.

The hypoid bevel gear under investigation is derived from an automotive drive axle application. The primary objective is to form the tooth profile through precision forging, while the shaft portion remains non-deformed. To reduce computational load in finite element analysis, only the tooth body is considered for simulation. The basic parameters of the hypoid bevel gear are summarized in Table 1.

| Parameter | Value |

|---|---|

| Number of Teeth | 6 |

| Module | 12.032 mm |

| Outer End Addendum | 15.413 mm |

| Outer End Whole Depth | 19.816 mm |

| Mean Pressure Angle | 22.5° |

| Spiral Angle | 45.998° |

| Spiral Direction | Left-hand |

| Offset Distance | 44.45 mm |

| Cutter Diameter | 304.8 mm |

| Tooth Side Clearance | 0.3–0.4 mm |

The three-dimensional model of the forging and die assembly was created using CAD software, with the hypoid bevel gear geometry accurately represented. The forging process involves closed-die forging, where the dies first close to form a sealed cavity, followed by punch compression to force metal flow into the tooth profile. The billet design is critical to ensure complete filling without defects. Based on volume constancy in plastic deformation, the billet is shaped as a truncated cone with diameters slightly smaller than the root circles at both ends of the tooth body, facilitating axial flow toward the radial direction into the cavity. The billet volume $V_b$ is calculated from the forging volume $V_f$ considering a forging factor $k$ (typically 1.03–1.05 for precision forging):

$$ V_b = k V_f $$

The height of the billet $h_b$ is then derived from its geometry. For a truncated cone with top diameter $d_t$, bottom diameter $d_b$, and height $h_b$, the volume is:

$$ V_b = \frac{\pi h_b}{12} (d_t^2 + d_t d_b + d_b^2) $$

Solving for $h_b$ ensures proper metal distribution. The finite element model was constructed by importing STL files of the billet and dies into DEFORM-3D, a commercial FEM software for metal forming simulations. The model includes the entire tooth portion to account for circumferential forces during forging.

The simulation employs a coupled thermomechanical rigid-viscoplastic finite element method, as temperature variations significantly affect material behavior, heat transfer, and friction. The billet material is 20CrMnTi, a low-alloy steel commonly used for hypoid bevel gears in automotive applications. Its constitutive behavior is described by flow stress models dependent on temperature, strain, and strain rate. Experimental data from compression tests on a Gleeble-1500 thermomechanical simulator provided stress-strain curves, which were incorporated into the material library. The flow stress $\sigma$ can be expressed using a Hensel-Spittel type equation:

$$ \sigma = A e^{m_1 T} \epsilon^{m_2} \dot{\epsilon}^{m_3} e^{m_4 / \epsilon} (1 + \epsilon)^{m_5 T} e^{m_6 \epsilon} T^{m_7} \dot{\epsilon}^{m_8} $$

where $A$, $m_1$ to $m_8$ are material constants, $T$ is temperature, $\epsilon$ is strain, and $\dot{\epsilon}$ is strain rate. For simplification in simulation, tabular data from experiments were used. Key material properties are listed in Table 2.

| Property | Value |

|---|---|

| Young’s Modulus | 2.07 × 10⁵ MPa |

| Poisson’s Ratio | 0.25 |

| Density | 7.85 g/cm³ |

| Thermal Conductivity | 40 W/(m·K) |

| Specific Heat | 460 J/(kg·K) |

| Coefficient of Thermal Expansion | 1.2 × 10⁻⁵ /K |

The dies are modeled as rigid bodies with mesh for heat transfer analysis, using material AISI-H13 (4Cr5MoSiV1). Simulation parameters were set to replicate industrial conditions, as detailed in Table 3.

| Parameter | Value |

|---|---|

| Billet Temperature | 1100°C |

| Die Temperature | 350°C |

| Environment Temperature | 20°C |

| Shear Friction Coefficient | 0.3 |

| Heat Transfer Coefficient (Billet-Die) | 11 W/(m²·K) |

| Heat Transfer Coefficient (Billet-Environment) | 0.02 W/(m²·K) |

| Plastic Work to Heat Conversion Factor | 0.9 |

| Punch Speed | 200 mm/s |

| Mesh Elements (Billet) | 80,000 tetrahedral |

| Mesh Elements (Dies) | 80,000 tetrahedral each |

| Step Size Control | Based on 1/3 of smallest element edge |

The numerical simulation provides insights into the deformation process of the hypoid bevel gear. The equivalent stress distribution, equivalent strain distribution, velocity field, and load-stroke curves were analyzed to understand metal flow and forming mechanics. The equivalent stress $\sigma_e$ is computed using the von Mises criterion:

$$ \sigma_e = \sqrt{\frac{3}{2} s_{ij} s_{ij}} $$

where $s_{ij}$ is the deviatoric stress tensor. Similarly, the equivalent strain $\epsilon_e$ is defined as:

$$ \epsilon_e = \sqrt{\frac{2}{3} \epsilon_{ij} \epsilon_{ij}} $$

where $\epsilon_{ij}$ is the strain tensor. The simulation reveals that deformation initiates at the small end of the hypoid bevel gear tooth profile, with stress concentration initially appearing near the root area. As the punch advances, metal flows radially from the small end toward the large end, filling the spiral cavity progressively. The stress distribution dynamically shifts from the small-end root to the small-end tip, then spirally toward the large-end tip, reflecting the asymmetric geometry of the hypoid bevel gear. The maximum equivalent stress reaches 377 MPa at the corner regions upon complete filling, indicating areas prone to wear or cracking in the dies.

The equivalent strain distribution shows that the small end experiences more severe deformation, with maximum values up to 5.06 at the small-end root, due to earlier contact and constrained flow. Strain decreases toward the large end, consistent with the filling sequence. The velocity field illustrates orderly metal flow without backflow or turbulence, suggesting minimal internal defects like folds. The velocity vectors align with the spiral direction, emphasizing the importance of die design for guiding flow in hypoid bevel gear forging.

The load-stroke curve, plotted in Figure 1 (simulated), delineates three stages: initial, filling, and completion. In the initial stage, up to approximately 10% of the stroke, the load increases linearly as the billet undergoes upsetting before contacting the die cavity. The filling stage, covering most of the stroke, shows a steady rise in load with increasing curvature, indicating growing resistance as the hypoid bevel gear tooth cavity fills. The completion stage, near the end of the stroke, exhibits a sharp load increase to 1980 kN as metal compresses into final corners, highlighting the need for high press capacity. The load $F$ can be related to the flow stress and contact area $A_c$ by:

$$ F = \sigma_e A_c $$

where $A_c$ evolves with deformation. Table 4 summarizes key simulation results.

| Metric | Value | Description |

|---|---|---|

| Maximum Equivalent Stress | 377 MPa | Occurs at tooth corner regions |

| Maximum Equivalent Strain | 5.06 | At small-end root area |

| Final Forging Load | 1980 kN | At end of stroke |

| Total Simulation Steps | 244 | For complete filling |

| Metal Flow Pattern | Radial from small to large end | Spiral progression |

| Temperature Rise in Billet | ~50°C | Due to plastic work |

To validate the numerical simulation, experimental forging was conducted on a J53-300 double-disk friction press with a nominal force of 3000 kN and energy of 20 kJ. The die assembly, designed based on simulation insights, successfully produced a hypoid bevel gear driving pin with complete tooth filling, sharp contours, and no defects like folds or cracks. The experimental load measured approximately 2100 kN, close to the simulated value, confirming the accuracy of the FEM model. The forged hypoid bevel gear exhibited good surface finish and dimensional accuracy, demonstrating the feasibility of precision forging for such complex components.

The discussion extends to the implications of these findings for hypoid bevel gear manufacturing. The stress and strain distributions inform die life optimization, as high-stress areas may require hardened coatings or cooling channels. The velocity field analysis suggests that preform design can further reduce flow resistance and improve filling uniformity. For instance, a billet with tailored geometry matching the hypoid bevel gear spiral could minimize strain inhomogeneity. Additionally, the load prediction aids in press selection, ensuring sufficient capacity without overdesign. The coupled thermomechanical model also allows for predicting microstructure evolution, such as grain refinement and phase transformations, which influence the mechanical properties of the forged hypoid bevel gear. The Hall-Petch equation relates grain size $d$ to yield strength $\sigma_y$:

$$ \sigma_y = \sigma_0 + \frac{k_y}{\sqrt{d}} $$

where $\sigma_0$ and $k_y$ are material constants. Fine grains from dynamic recrystallization during forging enhance strength, beneficial for hypoid bevel gear performance.

Further analysis considers the effect of friction on hypoid bevel gear forging. Using a constant shear friction model, the friction stress $\tau_f$ is given by:

$$ \tau_f = m \frac{\sigma_e}{\sqrt{3}} $$

where $m$ is the friction factor. Sensitivity studies show that reducing friction improves metal flow and lowers forming load, suggesting lubricant optimization for hypoid bevel gear production. Similarly, temperature variations impact flow stress; a higher billet temperature decreases stress but may cause overheating or scaling. The optimal temperature range for 20CrMnTi in hypoid bevel gear forging is 1050–1150°C, balancing formability and microstructure control.

The numerical simulation also enables evaluation of defect formation. For hypoid bevel gears, common defects include underfilling, laps, and cracks. The strain rate distribution $\dot{\epsilon}_e$ is critical, as high rates may induce adiabatic heating and localized softening, while low rates increase flow stress. The strain rate sensitivity coefficient $m$ in the flow stress relation $\sigma = K \dot{\epsilon}^m$ affects uniformity. Simulation results indicate that the strain rate in the hypoid bevel gear tooth region ranges from 1 to 100 s⁻¹, within acceptable limits for hot forging.

In terms of process optimization, the closed-die forging approach for hypoid bevel gears offers advantages over open-die or multi-stage forging, including better dimensional control and higher productivity. However, die design must account for the spiral tooth geometry to ensure demolding. Simulation-based design of experiments can identify key parameters, such as billet dimensions, die angles, and press speed, to minimize trials. For example, the fill ratio $R_f$, defined as the volume of metal in the cavity divided by the total cavity volume, should approach 1 for complete filling. For the hypoid bevel gear, $R_f$ reached 0.99 in simulation, validated by experiment.

The broader context of hypoid bevel gear precision forging involves economic and environmental benefits. Material savings of up to 30% compared to machining reduce costs and waste, aligning with sustainable manufacturing. The near-net-shape forming of hypoid bevel gears also decreases subsequent machining steps, lowering energy consumption. Life cycle assessment studies could quantify these benefits further.

Future work on hypoid bevel gear forging may explore advanced materials like powder metals or composites, and integrate artificial intelligence for real-time process control. Multi-scale modeling coupling macroscopic deformation with microscopic phenomena could predict properties more accurately. Additionally, additive manufacturing of dies with conformal cooling could enhance efficiency for hypoid bevel gear production.

In conclusion, this numerical simulation study provides a comprehensive analysis of precision forging for hypoid bevel gear driving pins. Through finite element modeling, we elucidated the metal flow, stress-strain distributions, and load requirements, validating results with experimental forging. The insights gained support die design optimization, press selection, and process parameter tuning for high-quality hypoid bevel gear manufacturing. The successful application of closed-die forging to such complex geometries underscores the potential of precision forging for advancing hypoid bevel gear technology in various industries.

The mathematical models and simulation frameworks developed here can be extended to other gear types, contributing to the broader field of metal forming. As demand for efficient and reliable hypoid bevel gears grows, continued research in numerical simulation and experimental validation will drive innovations in manufacturing processes, ensuring superior performance and sustainability.