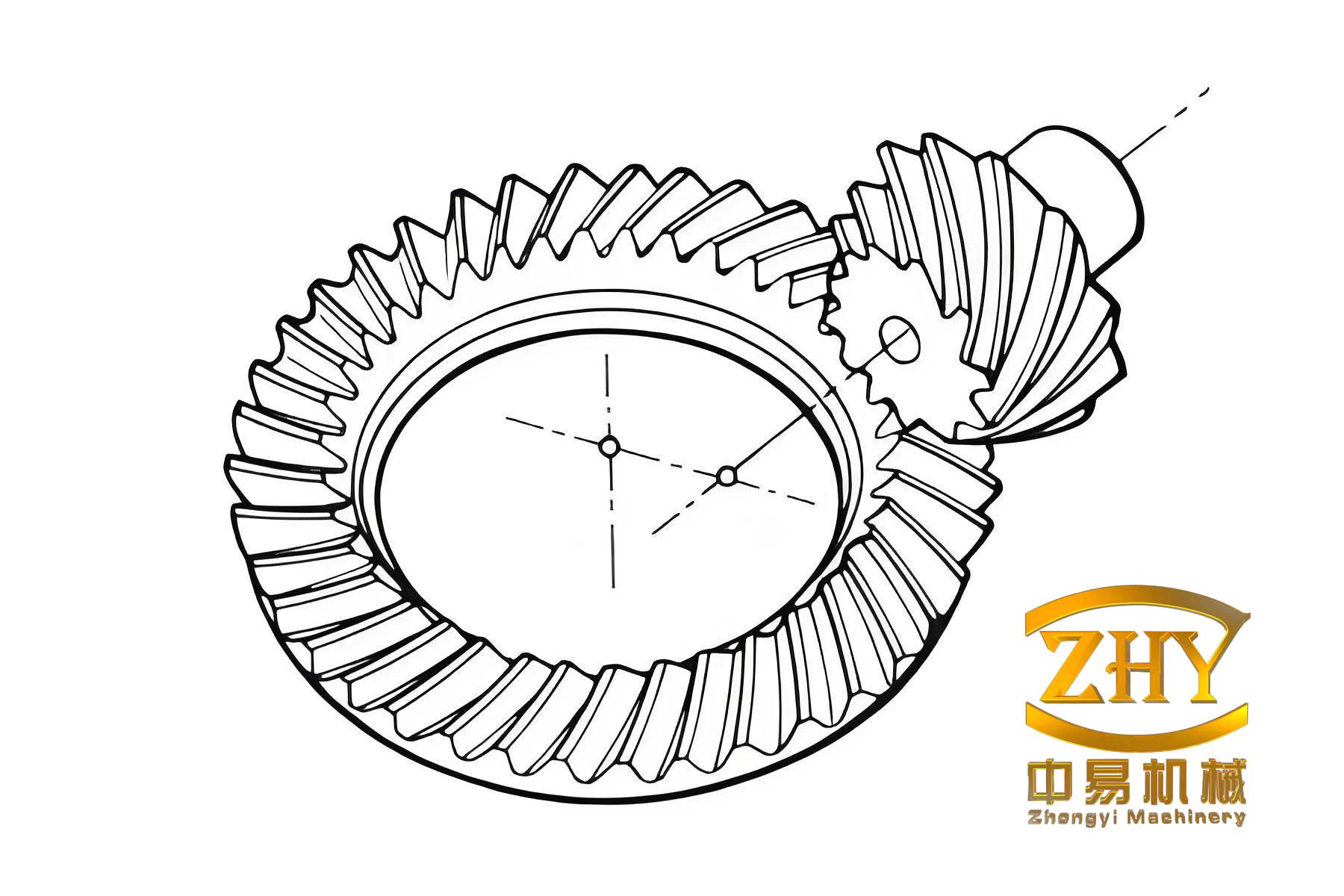

In the field of automotive powertrain engineering, the quest for more efficient, durable, and compact components is relentless. Among these, hypoid gears hold a pivotal position as the primary reduction drive in automotive axles. Their ability to provide high reduction ratios and allow for a lower vehicle profile makes them indispensable. However, the conventional method of manufacturing these critical components, primarily through Gleason-style cutting processes, introduces inherent weaknesses. The machining operation severs the metal’s natural fiber flow lines, leaves tool marks on the tooth flanks and roots, and creates significant stress concentrations at the root fillet. These factors collectively undermine the gear’s bending fatigue strength, which is a primary mode of failure. This paper introduces a novel cold orbital forging scheme specifically designed for the hypoid gear’s ring gear (often the weaker member due to offset), presenting a significant leap towards anti-fatigue manufacturing by employing localized, line-contact plastic deformation.

The current state-of-the-art in cold orbital forging for spiral bevel and hypoid gears involves a complex die with a fully formed tooth cavity. A conical upper die, tilted at a pendulum angle γ relative to the machine spindle axis, undergoes a planetary motion (rotation around the spindle and about its own axis) while the lower die pushes the workpiece upwards. The material is progressively compressed into the intricate cavity. While effective, this method has drawbacks: the complex die cavity is difficult to manufacture and can lead to defects like incomplete filling or stress concentrations during forging, which contradicts the goal of anti-fatigue performance. The required forging force is also substantial.

The novel scheme proposed here fundamentally rethinks this process. Inspired by the formate grinding principle used for hypoid gears, it replaces the complex cavity die with a simple trapezoidal die block. This block is analogous to a grinding wheel in formate grinding. The key innovation is the precise kinematic setup that ensures this trapezoidal die contacts the ideal tooth slot of the hypoid gear along a single, moving line—just as a grinding wheel does—rather than enveloping the entire tooth form at once. This achieves continuous, localized plastic forming, dramatically simplifying the tooling and reducing the required force.

The core of this new method’s feasibility lies in the precise mathematical alignment of the die’s motion with the theoretical tooth surface generation. The primary requirement is that the envelope of contact lines traced by the trapezoidal die over one full pendulum revolution must be perfectly congruent with the grinding surface of the virtual formate-grinding wheel. Any deviation—separation or interference—would result in an inaccurate or damaged tooth form. To establish this, a multi-coordinate system framework is essential.

The machine coordinate system is defined as $S_0(O_0-X_0Y_0Z_0)$. Based on the adjustment parameters for formate grinding, the virtual grinding wheel coordinate system $S_c(O_c-X_cY_cZ_c)$ is established. The forging head, which holds the trapezoidal die, has its own coordinate system $S_d(O_d-X_dY_dZ_d)$. Its origin $O_d$ is offset from $O_c$ by distances $L$ and $N$, and its axis $Z_d$ is tilted clockwise by the pendulum angle $\gamma$ relative to $Z_c$. Finally, the workpiece (hypoid gear) coordinate system $S_2(O_2-X_2Y_2Z_2)$ is positioned relative to $S_0$. The transformations between these systems govern the entire process. The transformation from $S_d$ to $S_c$ is given by:

$$[M_{cd}] =

\begin{bmatrix}

\cos\gamma & 0 & -\sin\gamma & -L \\

0 & 1 & 0 & 0 \\

\sin\gamma & 0 & \cos\gamma & -N \\

0 & 0 & 0 & 1

\end{bmatrix}$$

The profile of the trapezoidal die’s working surface is a simple cone. In its own coordinate system $S_d$, the surface can be represented parametrically. For the inner cone (which forges the convex side of the hypoid gear tooth), the equation is:

$$\mathbf{r}_d(s_d, \theta_d) =

\begin{bmatrix}

(r_d – s_d \sin\alpha_d) \cos\theta_d \\

(r_d – s_d \sin\alpha_d) \sin\theta_d \\

z_d – s_d \cos\alpha_d \\

1

\end{bmatrix}$$

where $r_d$ and $z_d$ are the coordinates of the cone’s apex point on the die (corresponding to the grinding wheel’s blade tip), $s_d$ and $\theta_d$ are the surface parameters, and $\alpha_d$ is the die’s profile angle. Crucially, because the die axis is tilted by $\gamma$, its effective working profile angle is related to the virtual grinding wheel’s profile angle $\alpha_c$ by:

$$\alpha_d = \alpha_c + \gamma$$

This relationship is fundamental to ensuring the correct contact geometry between the die and the hypoid gear tooth slot. To verify that the die’s motion correctly generates the target hypoid gear tooth surface without unwanted collisions, a robust interference checking algorithm is required. The method employed is a distance-based collision detection algorithm. The principle is straightforward: for sampled points on the die surface, calculate their distance to the axis of the virtual grinding wheel. If this distance is less than the local radius of the grinding wheel surface (except at the intended contact line), interference occurs. If it is greater (for the convex-side die) or the opposite for the concave-side die, separation occurs. Only along a specific line should the distances be equal.

The condition for a point $\mathbf{r}_c(x_c, y_c, z_c)$ on the die surface (transformed into $S_c$) to *not* interfere with the inner grinding cone (for convex side forging) away from the contact line is:

$$\sqrt{x_c^2 + y_c^2} > r_{c2} + z_c \tan\alpha_{cn}$$

where $r_{c2}$ is the grinding point radius and $\alpha_{cn}$ is the inner blade angle (positive). Conversely, for the outer die forging the concave side, the non-interference condition is:

$$\sqrt{x_c^2 + y_c^2} < r_{c2} + z_c \tan\alpha_{cw}$$

where $\alpha_{cw}$ is the outer blade angle (negative). A computational routine was developed to sample points on the die’s conical surfaces, transform them to $S_c$, and apply these conditions. For a representative hypoid gear set with the adjustment parameters shown in the table below, the algorithm confirmed perfect line contact without spurious interference or separation, validating the kinematic soundness of the proposed cold orbital forging scheme for hypoid gears.

| Parameter | Value | Description |

|---|---|---|

| Virtual Wheel Radius, $R_G$ | 95.25 mm | Radius of the equivalent formate grinding wheel. |

| Inner Blade Angle, $\alpha_{cn}$ | +17° | Profile angle for the convex side of the hypoid gear. |

| Outer Blade Angle, $\alpha_{cw}$ | -24° | Profile angle for the concave side of the hypoid gear. |

| Blade Edge Width, $P_W$ | 2.286 mm | Distance between inner and outer blade edges. |

| Pendulum Angle, $\gamma$ | 2° | Tilt angle of the forging head axis. |

| Machine Center to Back (MC to B), $H_2$ | 41.11 mm | Horizontal offset of gear axis. |

| Sliding Base Setting, $V_2$ | 83.66 mm | Vertical offset of gear axis. |

| Workpiece Tilt Angle, $\gamma_2$ | 68.1333° | Root angle of the hypoid ring gear. |

To further substantiate the feasibility of this novel cold orbital forging process for hypoid gears, a comprehensive digital simulation workflow was executed. A detailed 3D model of the forging head, trapezoidal die, and a pre-formed ring gear blank was constructed. This model incorporated the precise kinematic relationships and offsets defined earlier. The 3D assembly was first imported into a multi-body dynamics simulation software (ADAMS) to perform a rigorous kinematic and dynamic analysis. The virtual prototype simulated the planetary motion of the forging head and the incremental feed of the workpiece. The analysis confirmed the precise, continuous line-contact motion without any mechanical interference, providing strong evidence for the motion accuracy of the proposed system design for manufacturing hypoid gears.

The final and most critical validation step involved finite element analysis (FEA) of the plastic deformation process itself. The 3D model was imported into DEFORM-3D, a specialized metal forming simulation software. The workpiece material was defined as AISI 1045 steel, modeled as a nonlinear, strain-hardening plastic material. The trapezoidal die was modeled as a rigid body. The process parameters for the simulation are summarized below:

| Parameter | Value |

|---|---|

| Workpiece Temperature | 20 °C (Room Temperature) |

| Pendulum Head Rotational Speed | 10 RPM |

| Pendulum Angle ($\gamma$) | 2° |

| Friction Model | Shear Friction |

| Friction Coefficient | 0.12 |

| Initial Mesh Elements | ~288,000 |

The simulation results were analyzed from several key perspectives: the shape of the contact zone, the metal flow velocity field, and the die loading. As anticipated, the results clearly demonstrated the localized line-contact nature of the process. The plastic deformation zone was concentrated along the theoretical contact line, with material flowing smoothly to fill the tooth profile. The most significant result was the dramatically reduced forging force. The evolution of the axial force ($F_z$) on the die over time was extracted from the simulation. The force stabilized in a remarkably low range compared to conventional full-envelope forging. The steady-state maximum axial force was found to be between 101 kN and 126 kN. This represents a reduction of approximately 90% compared to the forces typically required in traditional cold orbital forging of similar hypoid gears. This drastic reduction validates a core advantage of the novel scheme: minimal forging force due to localized contact.

The implications of this force reduction are profound for the manufacturing of hypoid gears. It means smaller, less expensive forging presses can be used. It reduces tooling stress, increasing die life. Most importantly for anti-fatigue manufacturing, lower forces promote more controlled metal flow, preserving beneficial fiber orientation and minimizing internal defects. The precise line-contact kinematics ensure the final forged tooth surface is a accurate replica of the theoretical formate-generated surface, eliminating the need for subsequent finishing cuts on the tooth flanks. This leaves a work-hardened, continuous-fiber surface layer ideal for high fatigue resistance.

| Aspect | Traditional Cutting (Gleason) | Conventional Cold Orbital Forging | Novel Line-Contact Cold Orbital Forging |

|---|---|---|---|

| Tooling Complexity | Moderate (cutting tools) | Very High (complex cavity die) | Low (simple trapezoidal die) |

| Material Fiber Flow | Severed (weakened) | Redistributed, but risk of defects | Optimally redistributed & continuous |

| Surface Integrity | Tool marks, stress concentrators | Potential for folding, incomplete fill | Work-hardened, net-shape surface |

| Process Force | Low (cutting) | Very High (full contact) | Low (localized line contact) |

| Fatigue Performance | Standard | Potentially improved, but variable | Significantly enhanced (Anti-fatigue) |

| Post-forging Machining | N/A | Often required on tooth flanks | Not required on tooth flanks |

In conclusion, the novel cold orbital forging scheme for hypoid gears presented here addresses the critical limitations of existing manufacturing routes. By adopting a kinematic principle derived from formate grinding and implementing it through a simple trapezoidal die in a pendulum forging setup, it achieves precise, line-contact plastic forming. The rigorous mathematical analysis proves the congruence between the die’s motion envelope and the target tooth surface. Comprehensive digital simulations—encompassing multi-body dynamics and nonlinear finite element analysis—validate the process kinematics, dynamics, and formability. The results conclusively demonstrate the scheme’s key advantages: simplified and robust tooling, a drastic reduction in required forging force (by ~90%), and the production of a net-shape, work-hardened tooth surface with continuous material flow lines. This makes the process a highly promising candidate for the anti-fatigue manufacturing of high-performance hypoid gears, offering a path towards more durable, reliable, and efficient automotive drivetrains. The successful virtual validation paves the way for future physical prototyping and industrial implementation of this advanced forming technology for hypoid gears.