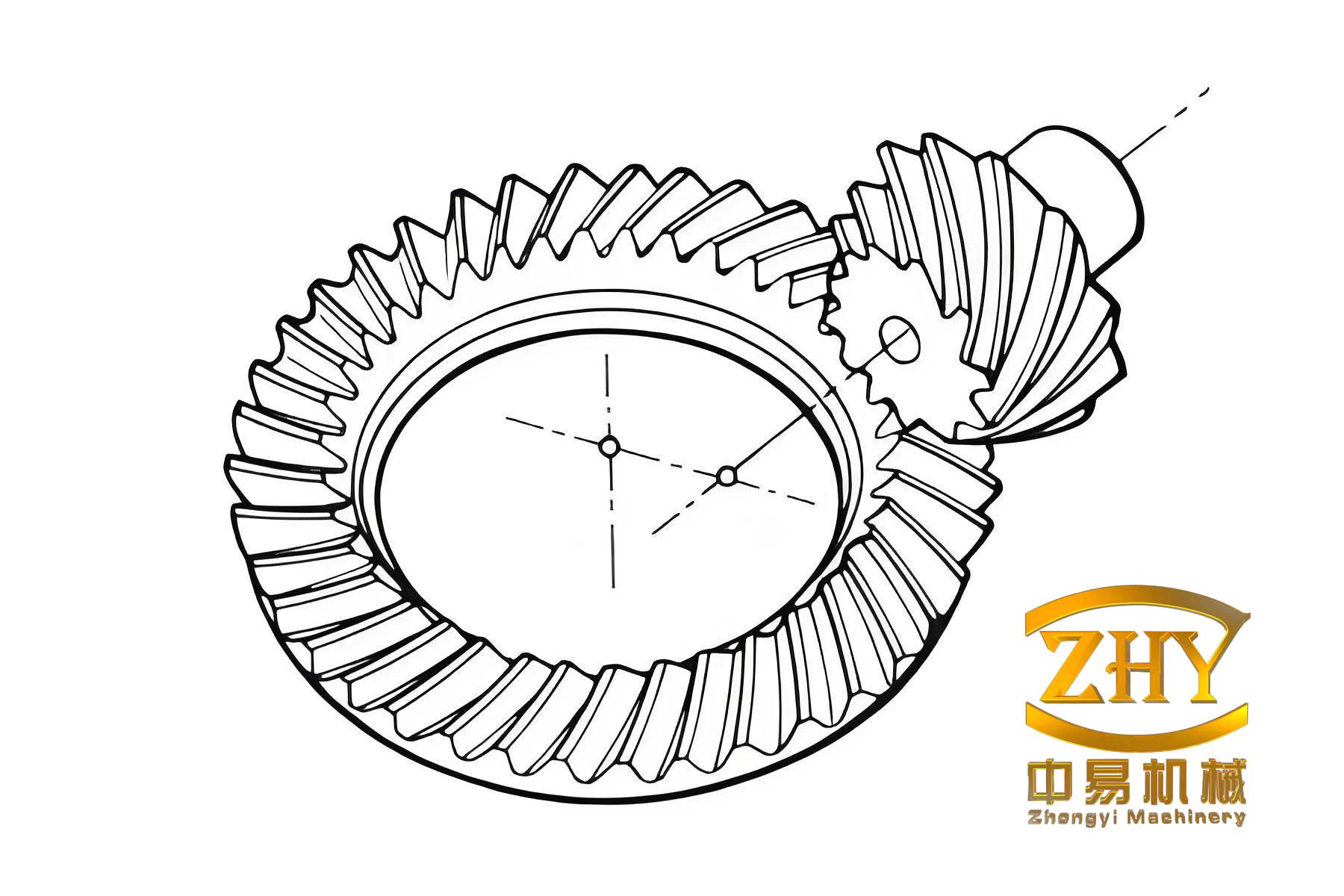

In my extensive experience designing and manufacturing hypoid gears, I have encountered numerous challenges, particularly when working with machines that lack spindle tilting capabilities. The method of generating hypoid gears using the face-hobbling or face-milling process on a standard spiral bevel gear cutting machine, such as the Gleason series, requires precise adjustments and calculations. This article delves into the fundamental principles, detailed computational methodology, and practical setup procedures for producing high-quality hypoid gear sets using a simple duplex method on a non-tilting spindle machine. The focus is on ensuring accurate tooth contact patterns, proper gear meshing, and optimal performance for automotive differentials and other power transmission systems. Throughout this discussion, the term ‘hypoid gear’ will be frequently emphasized, as it is central to our topic.

The core principle behind machining hypoid gears on a machine without spindle tilt revolves around the concept of a generating crown gear, often referred to as the generating gear or imaginary gear. In this setup, both the pinion (small gear) and the gear (large gear) are generated based on the principle of a crown gear with a flat top. The generating plane of this crown gear is perpendicular to the machine cradle axis and coincides with the common tangent plane at the midpoint of the tooth flank. The critical condition is that the relative velocity vector at the pitch point between the generating gear and the workpiece must align with the tangent direction of the tooth spiral line at that point. For a hypoid gear pair, this introduces an offset between the axes, which significantly affects the spiral angles and generation parameters.

Let us define the essential geometric and kinematic relationships. Consider a hypoid gear pair where the pinion and gear have axes that are offset by a distance $E$. At the mean point $P$ on the tooth flank, the pitch cones are tangent. The generating gear’s axis is aligned with the cradle axis. The spiral angles for the pinion, gear, and generating gear at point $P$ are denoted as $\beta_p$, $\beta_g$, and $\beta_0$, respectively. The distances from the respective axes to point $P$ are $R_p$, $R_g$, and $R_0$. The angular velocities are $\omega_p$, $\omega_g$, and $\omega_0$. The fundamental kinematic equation governing the generation is derived from the velocity vector alignment:

$$ \frac{R_p \sin \beta_p}{\omega_p} = \frac{R_g \sin \beta_g}{\omega_g} = \frac{R_0 \sin \beta_0}{\omega_0} $$

If $z_p$ and $z_g$ are the tooth numbers of the pinion and gear, and $z_{0p}$, $z_{0g}$ are the imaginary tooth numbers of the generating gear when cutting the pinion and gear respectively, the roll ratios (or generating ratios) can be expressed as:

$$ \frac{\omega_0}{\omega_p} = \frac{z_p}{z_{0p}} = \frac{R_p \sin \beta_p}{R_0 \sin \beta_0} $$

$$ \frac{\omega_0}{\omega_g} = \frac{z_g}{z_{0g}} = \frac{R_g \sin \beta_g}{R_0 \sin \beta_0} $$

These ratios are crucial for setting up the machine’s differential and generating change gears. The offset $E$ directly influences the spiral angles and the machine settings, such as the sliding base (machine center to back) and the vertical offset of the workpiece. In the simple duplex method, the gear is cut using a double-sided cutter head in a single indexing setup, and the pinion is subsequently cut with separate settings for its convex and concave flanks, often using a modified roll method to localize the bearing contact.

To translate these principles into actionable machine settings, a comprehensive set of calculations is required. Below, I present a detailed parameter table and the associated formulas used to determine all necessary adjustments for machining a hypoid gear set. This example is based on a typical automotive drive axle hypoid gear pair. The calculations follow a step-by-step sequence, ensuring that each parameter is derived from basic gear geometry and the constraints of the non-tilting spindle machine.

| Parameter Symbol | Description | Example Value | Calculation Formula |

|---|---|---|---|

| $z_g$ | Number of teeth on the gear (large wheel) | 41 | Given |

| $z_p$ | Number of teeth on the pinion (small wheel) | 10 | Given |

| $d_g$ | Gear pitch diameter | – | Given |

| $\beta_g$ | Gear mean spiral angle | 50° | Given |

| $\beta_p$ | Pinion mean spiral angle | – | Calculated |

| $E$ | Offset distance (hypoid offset) | – | Given |

| $\alpha_n$ | Normal pressure angle at mean point | 20° | Given |

| $h_{ag}$ | Gear addendum | – | Given |

| $h_g$ | Gear whole depth | – | Given |

| $\delta_fg$ | Gear root angle | – | Given |

| $\delta_fp$ | Pinion root angle | – | Given |

| $\delta_g$ | Gear pitch angle | – | Calculated |

| $\delta_a g$ | Gear face angle | – | Calculated |

| $\delta_a p$ | Pinion face angle | – | Calculated |

The initial data for a hypoid gear design typically includes tooth numbers, pitch diameter, spiral angle, offset, pressure angle, and gear tooth proportions. From these, we compute the fundamental cone angles and distances. The mean cone distance for the gear, $R_g$, is a critical starting point:

$$ R_g = \frac{d_g}{2 \sin \delta_g} $$

The pinion pitch angle $\delta_p$ is related to the gear pitch angle and the offset. For hypoid gears, the relationship is not straightforward due to the offset. An approximate formula often used is based on the shaft angle $\Sigma$ (usually 90°):

$$ \tan \delta_p = \frac{\sin \Sigma}{\frac{z_g}{z_p \cos \beta_p / \cos \beta_g} + \cos \Sigma} $$

However, for exact calculations, iterative methods or derived geometric equations from the hypoid coordinate system are employed. The offset $E$ introduces a component in the calculations. The mean radius of the gear, $r_g$, and pinion, $r_p$, at the midpoint are:

$$ r_g = R_g \cos \delta_g, \quad r_p = R_p \cos \delta_p $$

where $R_p$ is the mean cone distance of the pinion. The hypoid offset affects the lateral location of the pitch cones. The spiral angles $\beta_g$ and $\beta_p$ are not independent; they are linked by the offset and the pitch radii. A key relationship is:

$$ E = r_g \sin \beta_g + r_p \sin \beta_p $$

This equation is fundamental for checking consistency. In practice, the gear spiral angle $\beta_g$ is often chosen based on design criteria, and the pinion spiral angle $\beta_p$ is derived. The normal module at the mean point, $m_n$, is calculated from the gear data:

$$ m_n = \frac{d_g \cos \beta_g}{z_g} $$

With these basics, we proceed to the detailed machine setting calculations. The following table outlines the sequence of computations for determining the cutter head settings, machine positions, and change gear ratios. These are essential for setting up a machine like the Gleason No. 116 or similar for cutting hypoid gears using the duplex method.

| Step | Parameter | Symbol | Calculation Formula | Example Value (Illustrative) |

|---|---|---|---|---|

| 1 | Gear mean cone distance | $R_g$ | $R_g = \frac{d_g}{2 \sin \delta_g}$ | 150.00 mm |

| 2 | Pinion mean cone distance | $R_p$ | Derived from geometry and offset | 45.00 mm |

| 3 | Mean point normal module | $m_n$ | $m_n = \frac{2 r_g \cos \beta_g}{z_g}$ | 5.50 mm |

| 4 | Offset angle in pinion plane | $\eta_p$ | $\eta_p = \arcsin\left(\frac{E}{R_p}\right)$ | 10.5° |

| 5 | Offset angle in gear plane | $\eta_g$ | $\eta_g = \arcsin\left(\frac{E}{R_g}\right)$ | 3.5° |

| 6 | Distance from gear mean point to pinion axis | $X_{gp}$ | $X_{gp} = R_g \sin \eta_g$ | 9.16 mm |

| 7 | Distance from pinion mean point to gear axis | $X_{pg}$ | $X_{pg} = R_p \sin \eta_p$ | 8.20 mm |

| 8 | Gear addendum at mean point | $h_{agm}$ | $h_{agm} = h_{ag} \frac{R_g – 0.5 b \sin \delta_g}{R_g}$ where $b$ is face width | 3.00 mm |

| 9 | Gear dedendum at mean point | $h_{fgm}$ | $h_{fgm} = h_g – h_{agm}$ | 3.80 mm |

| 10 | Pinion addendum at mean point | $h_{apm}$ | $h_{apm} = h_g – h_{fgm} – c$ where $c$ is clearance | 3.20 mm |

| 11 | Cutter blade pressure angle (convex side) | $\alpha_{cx}$ | Selected based on gear design, often 20°-22° | 20° |

| 12 | Cutter blade pressure angle (concave side) | $\alpha_{cn}$ | Selected, may differ from convex for contact correction | 18° |

| 13 | Nominal cutter radius | $r_{c0}$ | $r_{c0} \approx \frac{R_g}{\sin \beta_g}$ (initial estimate) | 195.00 mm |

| 14 | Blade point radius (tip radius) | $r_t$ | From cutter design, e.g., $r_t = r_{c0} – \text{blade height}$ | 190.00 mm |

The cutter head specifications are pivotal. For the gear cutting, a duplex head with two different pressure angles on the inside and outside blades is used. The actual generating radius of the cutter head, $r_c$, differs from the nominal radius due to the hypoid generation geometry. It is calculated considering the spiral angle and the offset. For the gear (large wheel) cutting, the generating radius on the convex side $r_{c,g,cx}$ and concave side $r_{c,g,cn}$ are:

$$ r_{c,g,cx} = \frac{R_g}{\sin \beta_{g,cx}} + \Delta_{cx}, \quad r_{c,g,cn} = \frac{R_g}{\sin \beta_{g,cn}} + \Delta_{cn} $$

where $\beta_{g,cx}$ and $\beta_{g,cn}$ are the gear spiral angles for the convex and concave flanks, which may slightly differ due to the duplex cutting action. The increments $\Delta$ account for the cutter geometry and machine constants. Similarly, for the pinion, the generating radii are computed based on the pinion spiral angles $\beta_{p,cx}$ and $\beta_{p,cn}$.

The machine setup involves several positional adjustments: the vertical wheel offset (sliding base), the axial wheel offset (workhead setting), the cutter tilt (which is zero for non-tilting spindle), the cutter radial distance (tool position), and the cradle angle. Each of these is calculated from the geometric parameters. Let’s denote the machine settings for cutting the gear:

- Vertical wheel offset: $V_g$

- Axial wheel offset: $H_g$

- Machine center to back (bed distance): $X_{Bg}$

- Cutter radial setting: $S_g$

- Cradle angle: $q_g$

The formulas for these settings are derived from the hypoid geometry relative to the machine coordinate system. For a non-tilting spindle, the cutter axis remains perpendicular to the cradle axis. The vertical offset $V_g$ is directly related to the hypoid offset $E$ and the gear pitch angle:

$$ V_g = E \cos \delta_g + K_v $$

where $K_v$ is a machine constant. The axial offset $H_g$ involves the gear mean cone distance and the cutter radius:

$$ H_g = R_g \sin \delta_g – \sqrt{r_c^2 – (R_g \cos \delta_g)^2} + K_h $$

with $K_h$ as another machine constant. The bed setting $X_{Bg}$ ensures the correct depth of cut:

$$ X_{Bg} = h_{fgm} + \text{clearance} + \text{stock allowance} $$

For the pinion cutting, the settings are more complex because the pinion is usually cut with a single-blade setup for each flank, or with a duplex head but with modified roll. The spiral angles for the pinion flanks are determined from the gear flanks and the desired contact pattern. The relationship involves the so-called “spiral angle difference” $\Delta \beta$ which controls the bias of the bearing contact. If $\beta_{g,cx}$ and $\beta_{g,cn}$ are known from the gear cutting, the corresponding pinion spiral angles are:

$$ \beta_{p,cx} = \beta_{g,cn} + \Delta \beta_{cx}, \quad \beta_{p,cn} = \beta_{g,cx} + \Delta \beta_{cn} $$

where $\Delta \beta_{cx}$ and $\Delta \beta_{cn}$ are small angles chosen to achieve a localized contact pattern. Typically, these are in the range of 0.5° to 2°. The generating radii for the pinion cutter heads are then:

$$ r_{c,p,cx} = \frac{R_p}{\sin \beta_{p,cx}}, \quad r_{c,p,cn} = \frac{R_p}{\sin \beta_{p,cn}} $$

The machine settings for pinion cutting include similar offsets but adjusted for the pinion geometry. Additionally, the roll ratio (generating ratio) must be set precisely. The roll ratio $R_{roll}$ is the ratio of the cradle rotation to the workpiece rotation. For the gear, it is often constant and given by:

$$ R_{roll,g} = \frac{z_{0g}}{z_g} $$

where $z_{0g}$ is the imaginary generating gear tooth number for the gear. For the pinion, the roll ratio may be modified during the cut to produce a lengthwise crowning or to adjust the contact pattern. This is known as modified roll and requires a supplemental mechanism on the machine. The basic roll ratio for the pinion is:

$$ R_{roll,p} = \frac{z_{0p}}{z_p} $$

The imaginary tooth numbers are calculated from the spiral angles and distances:

$$ z_{0g} = \frac{z_g R_0 \sin \beta_0}{R_g \sin \beta_g}, \quad z_{0p} = \frac{z_p R_0 \sin \beta_0}{R_p \sin \beta_p} $$

Here, $R_0$ is the distance from the cradle axis to the pitch point, often taken as the cutter radius or a derived value.

To consolidate, I present a comprehensive table summarizing the key machine adjustment calculations for both gear and pinion, based on the example hypoid gear pair. This table includes the essential formulas and illustrative values. It is crucial for any machinist or engineer setting up a hypoid gear cutting operation.

| Component | Setting | Symbol | Formula | Example Value |

|---|---|---|---|---|

| Gear (Large Wheel) | Vertical Wheel Offset | $V_g$ | $V_g = E \cos \delta_g + K_v$ | 15.2 mm |

| Axial Wheel Offset | $H_g$ | $H_g = R_g \sin \delta_g – \sqrt{r_c^2 – (R_g \cos \delta_g)^2} + K_h$ | -5.8 mm | |

| Bed Distance | $X_{Bg}$ | $X_{Bg} = h_{fgm} + 0.2 + \text{stock}$ | 4.5 mm | |

| Cutter Radial Setting | $S_g$ | $S_g = r_c + \Delta S$ (adjustment for contact) | 195.5 mm | |

| Cradle Angle Start | $q_{g0}$ | Based on tooth spacing, e.g., $q_{g0} = 0$ for reference | 0° | |

| Pinion (Small Wheel) | Vertical Offset (Convex) | $V_{p,cx}$ | $V_{p,cx} = E \cos \delta_p + \Delta V_{cx}$ | 14.8 mm |

| Vertical Offset (Concave) | $V_{p,cn}$ | $V_{p,cn} = E \cos \delta_p + \Delta V_{cn}$ | 15.0 mm | |

| Axial Offset (Convex) | $H_{p,cx}$ | $H_{p,cx} = R_p \sin \delta_p – \sqrt{r_{c,p,cx}^2 – (R_p \cos \delta_p)^2}$ | -3.2 mm | |

| Axial Offset (Concave) | $H_{p,cn}$ | $H_{p,cn} = R_p \sin \delta_p – \sqrt{r_{c,p,cn}^2 – (R_p \cos \delta_p)^2}$ | -3.5 mm | |

| Bed Distance (Convex) | $X_{Bp,cx}$ | $X_{Bp,cx} = h_{fpm} + \text{adjustment}$ | 4.0 mm | |

| Bed Distance (Concave) | $X_{Bp,cn}$ | $X_{Bp,cn} = h_{fpm} + \text{adjustment}$ | 4.2 mm | |

| Roll Ratio (Gear) | $R_{roll,g}$ | $R_{roll,g} = \frac{z_{0g}}{z_g}$ | 1.2345 | |

| Roll Ratio (Pinion Convex) | $R_{roll,p,cx}$ | $R_{roll,p,cx} = \frac{z_{0p,cx}}{z_p}$ | 2.5678 | |

| Roll Ratio (Pinion Concave) | $R_{roll,p,cn}$ | $R_{roll,p,cn} = \frac{z_{0p,cn}}{z_p}$ | 2.5890 |

The change gears for the index and differential mechanisms are calculated from these roll ratios. For instance, on a Gleason machine, the index ratio is $N_{index} = \frac{\text{driver teeth}}{\text{driven teeth}} = \frac{z_w}{z_g}$ for the gear, where $z_w$ is the number of teeth on the work gear. The differential ratio accounts for the generating motion. The exact formulas depend on the specific machine model and its kinematic chain.

Another critical aspect is the calculation of the cutter blade pressure angles. Due to the hypoid geometry, the nominal pressure angle must be corrected to account for the curvature and the generating process. The limit pressure angle correction $\Delta \alpha_{lim}$ is given by:

$$ \Delta \alpha_{lim} = \arctan\left( \frac{\sin \beta_g \cos \beta_p – \cos \beta_g \sin \beta_p \cos \Sigma}{\sin \Sigma} \right) – \alpha_n $$

For a 90° shaft angle, this simplifies. Additionally, due to the flat-top generating gear principle, a further correction $\Delta \alpha_{gen}$ is applied:

$$ \Delta \alpha_{gen} = \arcsin\left( \frac{\sin \beta_g \sin \beta_p}{\sin \Sigma} \right) $$

The actual blade pressure angles for cutting the gear are then:

$$ \alpha_{blade,g,cx} = \alpha_n + \Delta \alpha_{lim} + \Delta \alpha_{gen}, \quad \alpha_{blade,g,cn} = \alpha_n – \Delta \alpha_{lim} + \Delta \alpha_{gen} $$

In practice, standard cutter blades with available pressure angles (e.g., 20°, 18°, 22°) are selected close to these calculated values, and final contact correction is achieved through machine setting adjustments.

The tooth thickness and space width calculations ensure proper backlash and tooth strength. The gear mean point normal circular space width $W_{gn}$ is:

$$ W_{gn} = m_n \left( \frac{\pi}{2} + 2 x_g \tan \alpha_n \right) $$

where $x_g$ is the gear profile shift coefficient. For hypoid gears, the profile shift is often negative to avoid undercut and to balance strength. The pinion tooth thickness is then the complement considering backlash $j_n$:

$$ s_{pn} = p_n – W_{gn} – j_n $$

with $p_n = \pi m_n$. These values are used to set the cutter blade settings (blade point width) and to compute the measurement dimensions over pins or balls for quality control.

After computing all settings, the actual machining involves careful setup and trial cuts. The hypoid gear cutting process is iterative; initial cuts are inspected for tooth contact pattern, and adjustments are made to the machine settings (e.g., slight changes in vertical offset, bed distance, or roll ratio) to optimize the contact towards the center of the tooth flank with a slight bias for stability under load. The non-tilting spindle machine requires that all corrections be made through these linear and rotational adjustments rather than cutter head tilt.

In conclusion, manufacturing hypoid gears on a machine without spindle tilt is a meticulous process that relies on precise geometric calculations and empirical adjustments. The simple duplex method, combined with the generating principle, enables the production of hypoid gear sets with satisfactory performance. Key to success is a deep understanding of the relationships between offset, spiral angles, cutter geometry, and machine kinematics. Regular use of tables and formulas, as demonstrated, helps streamline the setup and ensure consistency. The hypoid gear, with its offset axes, offers advantages in torque transmission and design flexibility, making its manufacturing knowledge invaluable in the automotive and heavy machinery industries. Continuous practice and refinement of these calculations lead to improved efficiency and gear quality.

To further illustrate the complexity, consider the following extended formulas used in deriving some of the intermediate parameters. The gear pitch angle $\delta_g$ for a hypoid gear pair with 90° shaft angle can be approximated by:

$$ \delta_g = \arctan\left( \frac{\sin \Sigma}{\frac{z_g}{z_p} \frac{\cos \beta_p}{\cos \beta_g} + \cos \Sigma} \right) $$

For exact computation, especially with large offsets, numerical methods solve the set of equations derived from the hypoid coordinate transformation. The pinion pitch angle is then $\delta_p = \Sigma – \delta_g$. The mean radii $r_g$ and $r_p$ are also given by:

$$ r_g = \frac{d_g}{2} – h_{agm} \sin \delta_g, \quad r_p = \frac{d_p}{2} – h_{apm} \sin \delta_p $$

where $d_p$ is the pinion pitch diameter, related to the gear pitch diameter by the ratio and offset. The hypoid gear geometry ensures smooth engagement and high load capacity, but demands precision in manufacturing.

Finally, I emphasize that while the calculations are systematic, the art of hypoid gear cutting lies in interpreting the contact pattern and making fine adjustments. Experience shows that even with perfect calculations, trial and error are needed to account for machine deflections, cutter wear, and material properties. Therefore, documenting settings and results for each hypoid gear job builds a valuable knowledge base for future production runs.