In the field of mechanical transmission design, involute spur gears are widely utilized due to their excellent meshing performance, high load-bearing capacity, and smooth operation. However, the traditional design and analysis process for these spur gears often involves lengthy cycles, particularly in strength verification, which requires extensive and tedious calculations. Conventionally, engineers create gear models in third-party CAD software and then import them into finite element analysis (FEA) tools for stress evaluation. Due to incompatibilities in software interfaces, this approach frequently leads to model information loss or reduced accuracy, necessitating significant repair work to ensure reliable results. To address these challenges, I have developed a programmatic method using ANSYS Parametric Design Language (APDL) that enables precise parametric modeling and automated contact analysis of involute spur gears. This approach transforms cumbersome modeling tasks into automated, repeatable procedures, enhancing efficiency in engineering applications.

The core of this method lies in the parametric modeling of spur gear geometry. Instead of relying on external software, the entire process—from defining the gear profile to performing finite element analysis—is embedded within ANSYS through APDL scripting. This not only ensures model integrity but also allows for rapid iteration across different gear designs. In this article, I will detail the principles behind parametric modeling of spur gears, outline the APDL-based workflow, present a comprehensive case study, and discuss the advantages of this automated system. The focus will remain on spur gears, as they serve as fundamental components in many transmission systems, and their accurate analysis is critical for performance and durability.

Principles of Parametric Modeling for Spur Gears

To create an accurate finite element model of a spur gear, one must first define its geometric profile parametrically. The geometry of a standard involute spur gear is determined by a set of basic parameters. These parameters are essential inputs for any modeling routine and are typically standardized in gear design. Table 1 summarizes the key parameters required for defining a spur gear.

| Parameter | Symbol | Description |

|---|---|---|

| Number of Teeth | \(z\) | Total teeth on the gear. |

| Module | \(m\) | Ratio of pitch diameter to number of teeth, defining tooth size. |

| Pressure Angle | \(\alpha\) | Angle between the line of action and the tangent to the pitch circle. |

| Profile Shift Coefficient | \(x\) | Modifies tooth thickness and root strength; positive for addendum modification. |

| Addendum Coefficient | \(h_a^*\) | Factor for addendum height, typically 1 for standard gears. |

| Dedendum Coefficient | \(c^*\) | Factor for dedendum depth, ensuring clearance; often 0.25. |

| Center Distance | \(a\) | Distance between the centers of two mating gears. |

| Face Width | \(B\) | Axial length of the gear tooth. |

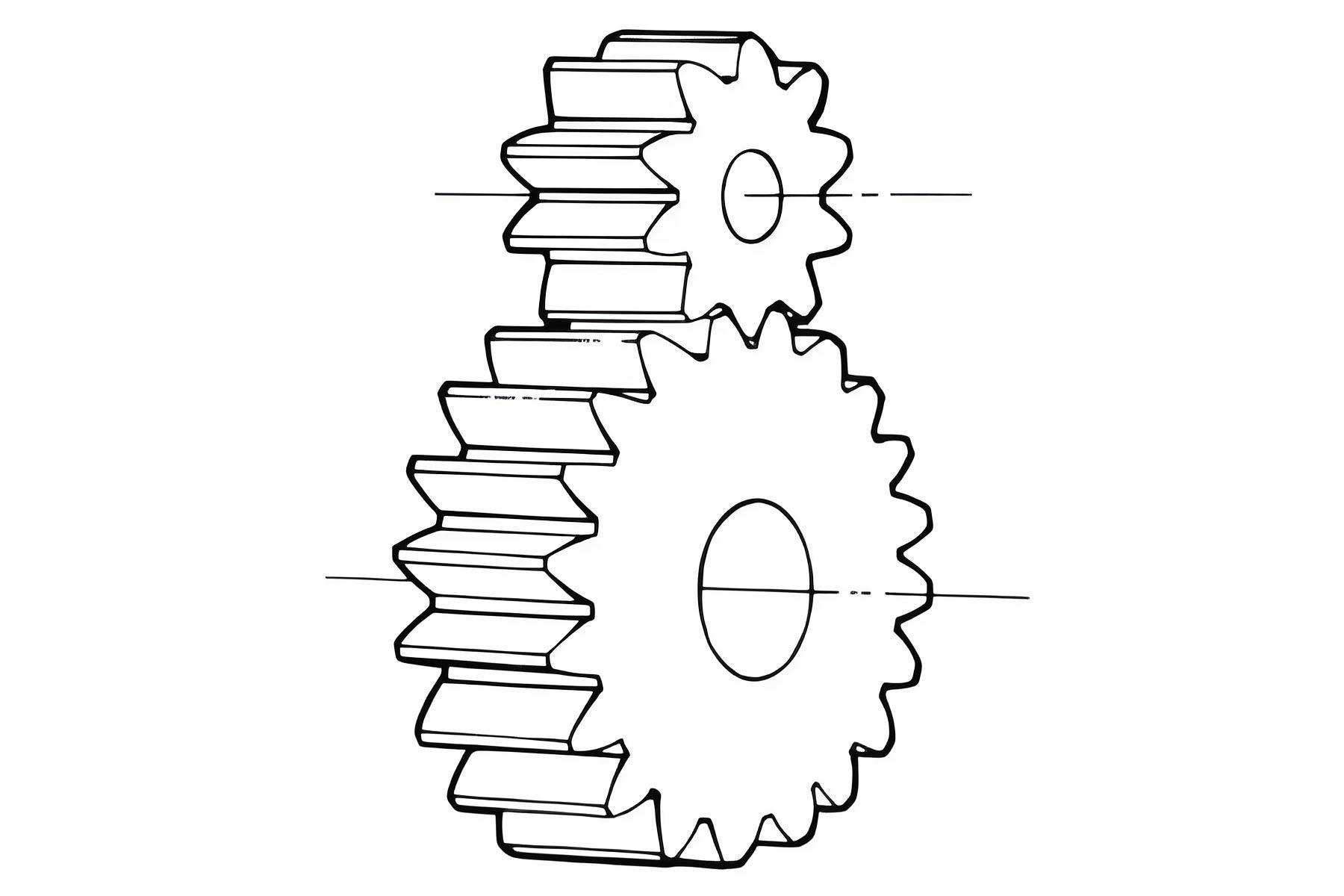

Given the periodic symmetry of a spur gear, the modeling process can be simplified by generating the profile for a single tooth and then replicating it around the gear’s circumference. The tooth profile consists of two main segments: the involute flank and the fillet curve at the root. The involute curve forms the active meshing surface, while the fillet connects the flank to the root circle, influencing stress concentration. Figure 1 illustrates the geometry of a single tooth on the transverse plane.

The involute curve is derived from a base circle with radius \(r_b\). For any point \(K\) on the involute, defined by its pressure angle \(\alpha_K\) and radius \(r_K\), the polar coordinates can be expressed using the fundamental involute equation. The polar angle \(\theta_K\) and radius \(r_K\) are given by:

$$ \theta_K = \tan(\alpha_K) – \alpha_K $$

$$ r_K = \frac{r_b}{\cos(\alpha_K)} $$

Here, \(\alpha_K\) is the pressure angle at point \(K\), and \(r_b\) is the base radius calculated as \(r_b = \frac{m z \cos(\alpha)}{2}\). To generate a discrete set of points along the involute flank for APDL, the angle \(\alpha_K\) is varied from the base circle to the tip circle. The parametric form in terms of the roll angle \(\phi\) (where \(\phi = \tan(\alpha_K)\)) is often used in scripts.

The fillet region, which transitions from the involute to the root circle, is typically approximated by a trochoid or a circular arc. According to ISO standards, the fillet radius \(\rho_f\) for a spur gear can be estimated as:

$$ \rho_f = 0.38m $$

However, for higher accuracy in finite element analysis, especially for contact stress evaluation, a more precise representation may be required. In my APDL routine, I divide the fillet segment into \(n\) equal intervals to generate a smooth curve. For the \(i\)-th point on the fillet, with radius \(r_i\) ranging from the base radius \(r_b\) to the root radius \(r_f\), the polar coordinate \(\theta_i\) is computed based on geometric relations. If using a radial line method, the coordinates can be derived as:

$$ r_i = r_b + (i-1) \frac{r_f – r_b}{n} $$

$$ \theta_i = \tan\left(\arccos\left(\frac{r_b}{r_i}\right)\right) – \arccos\left(\frac{r_b}{r_i}\right) $$

where \(r_f\) is the root radius, calculated as \(r_f = \frac{m z}{2} – m (h_a^* + c^* – x)\) for a standard spur gear. By combining points from the involute and fillet curves, a complete tooth profile is constructed. This profile is then mirrored to form both sides of the tooth, extruded along the axial direction to create a 3D solid, and patterned around the gear axis to generate the full spur gear model.

APDL-Based Workflow for Spur Gear Modeling and Contact Analysis

The automation of spur gear analysis via APDL follows a structured flowchart, ensuring that each step—from parameter input to result extraction—is executed seamlessly. The entire process is encapsulated within APDL macro files, allowing for easy modification and reuse. The workflow, as implemented in my system, consists of the following key stages:

- Parameter Input: The user interacts with a custom-developed GUI within ANSYS to input all necessary spur gear parameters, such as those listed in Table 1, along with material properties and operational conditions (e.g., speed, torque). This eliminates manual editing of APDL code and reduces errors.

- Single Tooth Profile Generation: Based on the input parameters, the APDL script calculates the geometric dimensions (e.g., pitch diameter \(d = m z\), base diameter \(d_b = d \cos(\alpha)\)) and constructs the 2D tooth profile using the involute and fillet equations described earlier. This profile is created on a coordinate plane in ANSYS.

- 3D Gear Modeling: The 2D profile is revolved and patterned to form a complete spur gear. Specifically, the single tooth area is extruded along the face width \(B\) to create a solid tooth. This tooth is then copied and rotated around the gear axis at angular increments of \(\frac{360^\circ}{z}\) to generate all teeth. The gear body (e.g., a cylindrical hub) is also created and boolean-united with the teeth to form a single continuous solid model for each spur gear in the pair.

- Automatic Meshing of Gear Pair: Once both driver and driven spur gears are modeled, they are positioned at the specified center distance \(a\). The APDL script then adjusts their angular orientation to achieve a no-backlash meshing condition at the pitch point, ensuring initial contact is properly aligned for analysis.

- Finite Element Mesh Generation: A critical step for accurate contact analysis is mesh refinement. The script automatically partitions the gear geometry to enable swept meshing. In the contact region—typically encompassing 3 to 5 teeth around the meshing point—the element size is set to approximately \(\frac{1}{20}\) of the tooth height for high resolution. In non-critical regions, a coarser mesh with element size about \(\frac{1}{4}\) of the tooth height is used to reduce computational cost. The mesh is generated using SOLID185 or similar hexahedral elements, which are well-suited for contact simulations.

- Contact Pair Definition and Boundary Conditions: Surface-to-surface contact pairs are created between the mating teeth of the spur gears. The contact elements (CONTA174) and target elements (TARGE170) are assigned with appropriate material properties and contact algorithms (e.g., augmented Lagrangian). Boundary conditions are applied: the inner bore of the driver spur gear is constrained in radial and axial directions, and a rotational velocity is applied. The driven spur gear’s inner bore is similarly constrained, and a resisting torque is applied to simulate loading.

- Solution and Result Extraction: The model is solved using static structural analysis with large deflection effects considered. Post-processing commands are embedded to extract key results such as von Mises stress, contact pressure, deformation, and root bending stress. These results are automatically plotted and saved for review.

This workflow is entirely driven by APDL macros, making it highly efficient for analyzing multiple spur gear designs with minimal user intervention. The automation significantly reduces the time spent on model preparation, which is often the bottleneck in traditional FEA of spur gears.

Detailed Case Study: Analysis of a Transmission Spur Gear Pair

To demonstrate the practical application of this APDL-based system, I present a detailed case study involving a pair of spur gears from a transmission unit. The gears are manufactured from 20CrNi2MoA alloy steel, case-hardened to a surface hardness of 62-65 HRC. The material properties are: Young’s modulus \(E = 205.8 \, \text{GPa}\), Poisson’s ratio \(\mu = 0.28\). The operational conditions and geometric parameters are summarized in Table 2.

| Parameter | Driver Gear (Pinion) | Driven Gear (Gear) |

|---|---|---|

| Number of Teeth, \(z\) | 18 | 26 |

| Module, \(m\) (mm) | 7 | |

| Pressure Angle, \(\alpha\) (degrees) | 20 | |

| Profile Shift Coefficient, \(x\) | 0.1826 | 0.0524 |

| Addendum Coefficient, \(h_a^*\) | 1 | |

| Dedendum Coefficient, \(c^*\) | 0.25 | |

| Face Width, \(B\) (mm) | 115 | |

| Center Distance, \(a\) (mm) | 156 | |

| Rotational Speed (rpm) | 2.23 | — |

| Input Power (kW) | 1.52 | — |

| Calculated Torque (Nm) | ~6500 (derived from power and speed) | Resisting torque applied |

Using the APDL interface, these parameters were entered into the system. The script then automatically generated the 3D models of both spur gears, performed no-backlash assembly, meshed the models, and set up the contact analysis. The total number of elements generated was approximately 150,000, with refined mesh in the contact zone. The solution was obtained using a static structural solver with nonlinear contact options enabled.

The results of the analysis provide insights into the stress distribution and deformation of the spur gears under load. Key outputs include:

- Deformation and Strain: The maximum elastic deformation occurred at the tooth tips, with values on the order of \(7.4 \times 10^{-3}\) mm. The strain contour showed concentration at the contact region and root fillet, as expected for spur gears in mesh.

- Von Mises Stress: The equivalent stress distribution indicated high stress zones at the root fillet (bending stress) and on the tooth flank (contact stress). The peak von Mises stress was found to be approximately 919 MPa, located near the contact area on the driven spur gear.

- Contact Pressure and Stresses: The contact pressure distribution along the tooth flank exhibited a semi-elliptical pattern, with maximum Hertzian-like pressure reaching around 1.02 GPa. The radial and tangential stress components were also extracted; radial stresses showed compression on the contact face, while tangential stresses indicated tensile regions at the root.

To validate the FEA results, I compared the maximum contact stress from the simulation with theoretical Hertz contact stress calculations. The theoretical contact stress \(\sigma_H\) for spur gears can be estimated using the formula:

$$ \sigma_H = Z_E \sqrt{ \frac{F_t}{b d_1} \cdot \frac{u+1}{u} \cdot \frac{2}{\cos^2(\alpha) \tan(\alpha)} } $$

where \(Z_E\) is the elasticity factor, \(F_t\) is the tangential load, \(b\) is the face width, \(d_1\) is the pinion pitch diameter, and \(u\) is the gear ratio \(z_2/z_1\). For this spur gear pair, substituting the values yields \(\sigma_H \approx 998 \, \text{MPa}\). The simulated value of 919 MPa is within a reasonable agreement (about 8% difference), considering simplifications in theoretical formulas and mesh discretization effects. This confirms that the APDL-based parametric modeling approach yields accurate results for spur gear contact analysis.

Advantages and Engineering Implications

The implementation of a fully parameterized APDL system for spur gear analysis offers several significant advantages over conventional methods. Firstly, it eliminates the need for multiple software tools, thereby avoiding data translation errors and saving time. Engineers can quickly modify design parameters (e.g., module, tooth count, pressure angle) and rerun analyses without manual remodeling, which is particularly beneficial for optimization studies. Secondly, the automated mesh refinement ensures consistent and appropriate element sizing, balancing accuracy and computational efficiency. This is crucial for contact problems where stress gradients are high, as in spur gear teeth.

From an engineering perspective, this approach accelerates the design validation cycle. For transmission manufacturers who must evaluate numerous spur gear configurations, the ability to automate finite element analysis reduces labor costs and shortens time-to-market. Moreover, the parametric nature allows for easy integration with design-of-experiments (DOE) or Six Sigma methodologies, enabling systematic exploration of the design space for spur gears. The consistent output format also facilitates comparison and reporting.

Potential enhancements to the system could include extending it to helical gears or incorporating dynamic analysis for noise and vibration assessment. However, even in its current form focused on spur gears, the APDL-based module has proven to be a valuable tool in practical engineering projects.

Conclusion

In this article, I have presented a comprehensive method for parametric modeling and contact analysis of involute spur gears using ANSYS APDL. The method leverages the mathematical definitions of involute geometry to generate precise 3D models directly within the FEA environment, bypassing external CAD software. The automated workflow encompasses parameter input, model generation, meshing, contact definition, and result extraction, all controlled through APDL scripts. A detailed case study demonstrated the system’s capability to produce reliable stress results that align with theoretical predictions. By streamlining the analysis process, this approach enhances productivity, reduces repetitive tasks, and supports informed decision-making in the design of spur gear transmissions. As engineering demands for efficiency and accuracy grow, such programmatic solutions will become increasingly integral to advanced mechanical design.