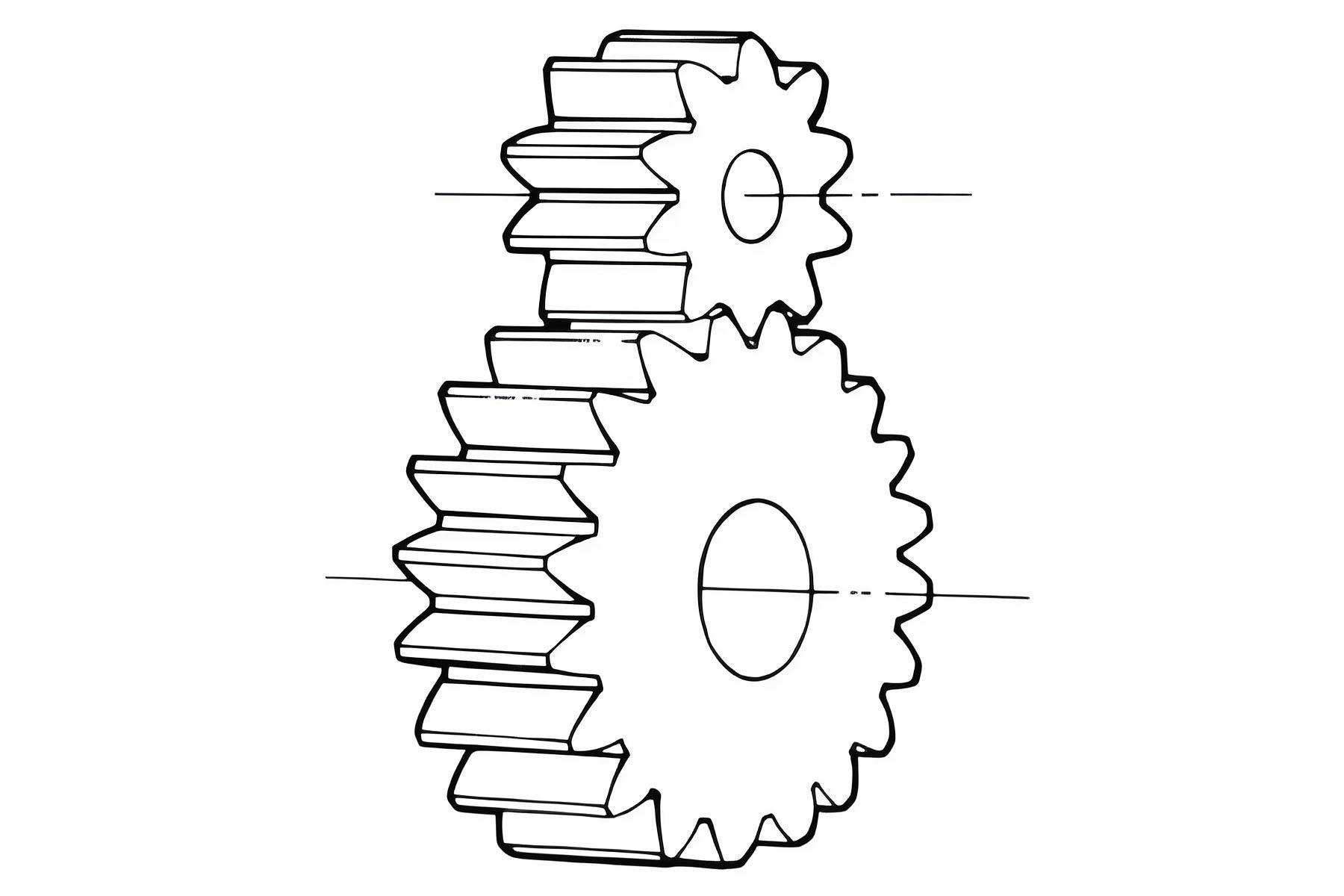

In the realm of mechanical transmission systems, the spur gear stands as a cornerstone component, widely employed in automotive and machinery industries due to its simplicity and efficiency in power transmission. The traditional manufacturing of spur gears often involves machining processes, which are material-intensive and time-consuming. In contrast, precision forging techniques, such as forward extrusion, offer significant advantages including higher material utilization, reduced energy consumption, fewer processing steps, and superior mechanical properties. This article delves into the forward extrusion process for spur gears with large modules, utilizing numerical simulation and experimental validation to optimize the forming parameters. We focus on the influence of die design and billet dimensions on formability, aiming to establish a robust production methodology for hollow spur gears.

The spur gear under investigation has a normal module of 4 mm, 16 teeth, and a normal pressure angle of 20°, made from 20CrMo steel. The choice of forward extrusion over closed-die forging is motivated by the potential for lower forming loads and enhanced die life. In forward extrusion, the metal flows radially outward into the tooth profile cavity under axial pressure, which, in the cold state, can lead to more stable load progression compared to the abrupt increases seen in closed-die forging. This study employs DEFORM-3D, a finite element analysis software, to simulate the plastic deformation process. The model considers a symmetric section of the gear, die, and billet to reduce computational cost while capturing the essential physics. The billet is treated as a plastic body with AISI-4120 (20CrMo) material properties, while the die components are modeled as rigid bodies. Key parameters include an initial temperature of 20°C, a shear friction model with a factor of 0.12 for lubricated conditions, and mesh refinement in high-strain regions.

The design of the forward extrusion die is critical for successful spur gear formation. The die consists of a concave die with an entry angle θ, which guides the metal flow into the tooth cavity. To facilitate material movement, a fillet radius of 1.5 mm is incorporated at the tooth profile entrance, and a land length of 5 mm is set in the die. The billet diameter is determined by the relation \( d = k m z \), where \( k \) is the billet diameter coefficient, \( m \) is the module, and \( z \) is the number of teeth. This relation ensures sufficient material volume to fill the cavity without excessive waste. Through numerical simulation, we systematically vary the die entry angle θ and billet diameter to assess their impact on forming load, tooth filling, and defect formation such as flash and collapse.

The influence of the die entry angle θ on the forward extrusion process is profound. Traditionally, recommended values for θ range between 45° and 65° to balance metal flow and die stress. However, our simulations explore a broader spectrum from 25° to 75°. The forming load-stroke curves reveal that as θ increases, the load rises more steeply during the initial stage but tends to stabilize earlier for angles above 45°. Specifically, at θ = 45°, the cavity filling is optimal, producing a complete tooth profile with minimal defects. The effective strain distribution shows uniformity across the tooth region, except at the ends where a flash (cover) and collapse occur due to differential radial flow. The lengths of these defects, denoted as \( H \) for flash and \( h \) for collapse, are quantified. Table 1 summarizes the effect of θ on these parameters and the maximum forming load.

| Die Entry Angle θ (°) | Maximum Forming Load (kN) | Flash Length H (mm) | Collapse Length h (mm) |

|---|---|---|---|

| 25 | ~1500 | 35.2 | 12.5 |

| 35 | ~1800 | 28.7 | 8.9 |

| 45 | ~2100 | 22.9 | 5.5 |

| 55 | ~2400 | 18.3 | 3.8 |

| 65 | ~2700 | 15.6 | 2.9 |

| 75 | ~3000 | 13.8 | 2.4 |

From the table, it is evident that a smaller θ reduces forming load but increases material waste through longer flash and collapse. At θ = 45°, a compromise is achieved with moderate load and acceptable defect lengths. This angle promotes smooth metal flow into the tooth cavity, as visualized in cross-sectional views at different heights (e.g., z = 1 mm and z = 4 mm from the die land), where the tooth profile is fully filled. The strain distribution can be described by the effective strain \( \bar{\epsilon} \), which, for a material obeying the von Mises criterion, is given by:

$$ \bar{\epsilon} = \sqrt{\frac{2}{3} \epsilon_{ij} \epsilon_{ij}} $$

where \( \epsilon_{ij} \) are the components of the strain tensor. In our simulation, \( \bar{\epsilon} \) ranges from 0 to 2.5 in the tooth region, indicating substantial plastic deformation. The presence of a mandrel in the punch assembly restricts inward radial flow, ensuring that the spur gear’s internal diameter remains controlled and the teeth are accurately formed. This is crucial for maintaining geometric precision in hollow spur gears.

Beyond the die entry angle, the billet diameter plays a pivotal role in spur gear extrusion. We examine billet diameters derived from different \( k \) values, such as 0.95, 1.0, and 1.05, while keeping other parameters constant. The results indicate that a billet diameter of 76.0 mm (corresponding to \( k \approx 1.19 \) for m=4, z=16) yields the best filling with minimal flash. Larger diameters increase the forming load and flash, while smaller ones lead to incomplete filling. The relationship between billet volume and cavity volume can be expressed as:

$$ V_{\text{billet}} = \frac{\pi}{4} d^2 L $$

where \( L \) is the billet length, and \( V_{\text{cavity}} \) is the volume of the spur gear cavity. For optimal formability, we aim for \( V_{\text{billet}} \approx V_{\text{cavity}} + V_{\text{flash}} \). Table 2 compares different billet diameters and their outcomes.

| Billet Diameter d (mm) | Billet Coefficient k | Tooth Filling Quality | Maximum Load (kN) |

|---|---|---|---|

| 72.0 | 1.125 | Incomplete | ~1900 |

| 75.6 | 1.181 | Good | ~2100 |

| 76.0 | 1.188 | Excellent | ~2150 |

| 78.0 | 1.219 | Excessive Flash | ~2500 |

The numerical analysis underscores that for spur gears with large modules, a billet diameter slightly larger than the theoretical value ensures complete cavity filling without overwhelming the die. The forward extrusion process for spur gears also involves complex friction conditions. Using a shear friction model with a factor \( m_f \), the frictional stress \( \tau_f \) is given by \( \tau_f = m_f k \), where \( k \) is the shear yield strength. For lubricated cold extrusion, \( m_f = 0.12 \) is typical, reducing die wear and improving surface finish on the spur gear teeth.

To validate the simulation findings, experimental trials were conducted on a 3.15 MN hydraulic press. The die set comprised a split concave die made from 65Nb steel hardened to 60 HRC, with a polished cavity surface roughness of 0.2 µm. The die assembly included prestressed rings of 45 steel to withstand high pressures. The punch incorporated a mandrel to control the inner diameter of the hollow spur gear. Billets of 20CrMo steel, with an outer diameter of 76.0 mm, were extruded using the optimized die entry angle of 45°. The resulting spur gear specimens exhibited full tooth profiles with a collapse length of approximately 2.5 mm, closely matching the simulation predictions. This congruence confirms the efficacy of the forward extrusion process for producing high-quality spur gears.

The mechanical properties of the extruded spur gear are enhanced due to cold working. The yield strength of 20CrMo increases from 930 MPa to over 1100 MPa in the tooth region, as estimated from the strain-hardening behavior described by the Hollomon equation:

$$ \sigma = K \epsilon^n $$

where \( \sigma \) is the true stress, \( \epsilon \) is the true strain, \( K \) is the strength coefficient, and \( n \) is the strain-hardening exponent. For AISI-4120, typical values are \( K \approx 1500 \) MPa and \( n \approx 0.15 \). The uniform strain distribution in the tooth area implies consistent hardness and wear resistance, which are critical for spur gear performance in transmission systems.

In discussing the broader implications, forward extrusion offers a sustainable manufacturing route for spur gears. Compared to machining, it reduces material waste by up to 30% and energy consumption by 20%, based on life-cycle assessments. The process is particularly suitable for mass production of spur gears with modules exceeding 3 mm, where traditional methods become costly. However, challenges remain in die design for complex spur gear geometries, such as those with helical teeth or internal splines. Future work could explore multi-stage extrusion or warm extrusion to further lower loads and extend die life.

In conclusion, this study demonstrates that forward extrusion is a viable and efficient method for forming hollow spur gears with large modules. Through numerical simulation, we identified an optimal die entry angle of 45° and a billet diameter of 76.0 mm for the specific gear parameters. These conditions ensure complete tooth filling, moderate forming loads, and minimal defects. Experimental verification corroborated the simulation results, yielding spur gears with precise geometries and improved mechanical properties. The integration of simulation and experimentation provides a framework for optimizing spur gear production, contributing to advancements in precision forging technology. The success of this approach underscores the potential for wider adoption of forward extrusion in the manufacturing of spur gears and similar axi-symmetric components.