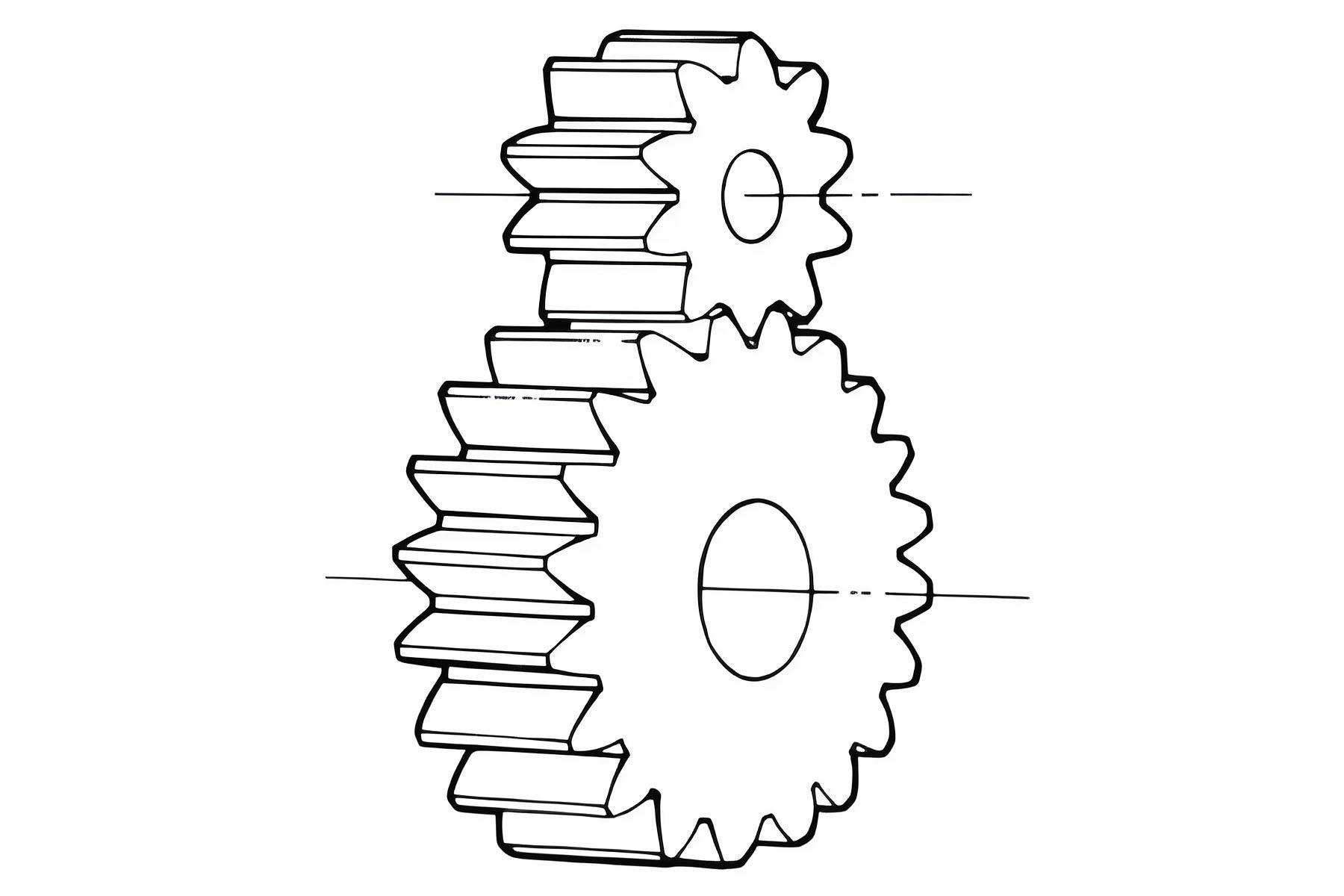

In mechanical transmissions, especially in heavy-duty applications, spur gears are widely used due to their simplicity and efficiency. However, spur gears often face challenges such as tooth root bending stress leading to fatigue fracture and excessive vibration and noise under high-speed operations. Reducing these issues is crucial for enhancing the durability and performance of spur gear systems. This study focuses on a novel approach: incorporating holes within the gear body, termed “holey spur gears,” to mitigate stress concentrations and dynamic excitations. We explore the optimization of hole parameters for strength improvement and analyze the dynamic behavior of such spur gear systems, demonstrating significant benefits in stress reduction and vibration damping.

Spur gears are fundamental components in many mechanical systems, and their design often prioritizes minimizing weight while maintaining strength. The concept of holey spur gears involves drilling holes in the gear web to alter stress distributions and inertial properties. Previous research has indicated that holey gears can reduce root bending stress and improve vibrational characteristics. For instance, studies on holey double-circular-arc gears showed noise reduction effects, while others highlighted stress distribution improvements. It is estimated that an 8% reduction in bending stress can increase the fatigue life of spur gears by up to 270% for typical tempered steels. Thus, optimizing hole parameters in spur gears presents a promising avenue for enhancing performance.

We begin by establishing a finite element model for spur gears based on the generating principle of an involute rack cutter. The tooth profile of spur gears consists of involute curves, root fillets, and web contours. For computational efficiency, we model a segment with five teeth, as loading effects are localized within about three teeth. The mesh is refined appropriately to account for holes while balancing accuracy and computational cost. The model uses 8-node elements, with node and element counts varying based on hole dimensions. For example, a standard five-tooth spur gear model has 36,225 nodes and 30,720 elements. Holes are introduced along the tooth centerline by adjusting nodal coordinates, resulting in a holey spur gear model. This approach allows for detailed stress analysis and parameter optimization.

The primary goal is to minimize tooth root bending stress in spur gears through hole optimization. We consider two key parameters: hole diameter and hole position (i.e., the distance from the gear center to the hole center along the tooth centerline). Due to manufacturing constraints, hole diameters are limited to specific sizes, and positions are varied to assess their impact. An orthogonal experimental design is employed to systematically evaluate these factors. The spur gear parameters used in this study are summarized in Table 1.

| Gear Parameter | Pinion | Gear |

|---|---|---|

| Number of Teeth, z | 24 | 61 |

| Module, m (mm) | 8 | |

| Pressure Angle, α (°) | 20 | |

| Face Width, B (mm) | 240 | 200 |

| Input Torque, T (N·m) | 722.58 | |

For the orthogonal design, four levels are chosen for both hole diameter and position, as shown in Table 2. The hole position is defined relative to the gear center, with different values for the pinion and gear of the spur gear pair.

| Level | Hole Diameter (mm) | Hole Position – Pinion (mm) | Hole Position – Gear (mm) |

|---|---|---|---|

| 1 | 3.0 | 88.32 | 235.46 |

| 2 | 4.0 | 91.20 | 238.39 |

| 3 | 5.0 | 94.08 | 241.32 |

| 4 | 6.0 | 96.96 | 244.24 |

Stress analysis is performed using a simplified three-tooth model, as spur gears have a low contact ratio. The load is applied as three concentrated normal forces at the pitch circle, distributed along the face width to simulate realistic loading conditions. For a standard spur gear without holes, the root bending stresses are calculated as 55.723 MPa for the pinion and 47.217 MPa for the gear. The orthogonal experiments for the pinion yield the root stress values under different conditions, presented in Table 3.

| Hole Diameter / Position | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|

| Level 1 | 58.98 | 62.90 | 67.57 | 73.86 |

| Level 2 | 56.00 | 57.52 | 59.15 | 61.16 |

| Level 3 | 53.86 | 52.14 | 49.82 | 47.50 |

| Level 4 | 55.34 | 54.93 | 53.93 | 52.56 |

Statistical analysis of the data reveals that hole position has a highly significant effect on root stress, with a probability value of 0.00307, while hole diameter is less influential (probability value 0.80843). The optimal hole position for the pinion is found to be 94.08 mm, minimizing stress. For practicality, we set the hole position to 94.0 mm and diameter to 5.0 mm. Similarly, for the gear, the optimal hole position is 242.0 mm with a 5.0 mm diameter. The resulting root bending stresses are 49.930 MPa for the pinion and 43.055 MPa for the gear. Compared to standard spur gears, these represent reductions of approximately 10% for the pinion and 8.8% for the gear, which can significantly enhance the fatigue life of spur gear systems.

To further validate the benefits, we develop a dynamic model for the spur gear system. The equation of motion for a single spur gear pair can be expressed as:

$$m x” + C x’ + K(t) x = P + \sum_{i=1}^{n} K_i e_i$$

where \(m\) is the equivalent mass of the spur gear pair, \(C\) is the damping coefficient, \(K(t)\) is the time-varying mesh stiffness, \(x\) is the relative displacement along the line of action, \(P\) is the static load due to torque, \(K_i\) is the stiffness of the i-th tooth pair, and \(e_i\) is the composite error. The equivalent mass is calculated from the moments of inertia and base circle radii of the spur gears:

$$m = \frac{m_1 m_2}{m_1 + m_2}, \quad m_j = \frac{I_j}{r_{b_j}^2} \quad (j=1,2)$$

Here, \(I_j\) is the moment of inertia and \(r_{b_j}\) is the base circle radius for each spur gear. The excitation function includes stiffness variations, errors, and impact forces. For dynamic analysis, we consider the steady-state response to periodic excitations. The acceleration response can be derived as:

$$x”(t) = \sum_{i=1}^{n} \frac{a_i i^2 \omega^2 \cos(i\omega t – \psi_i) + b_i i^2 \omega^2 \sin(i\omega t – \psi_i)}{K \sqrt{(1 – \lambda_i^2)^2 + (2\zeta \lambda_i)^2}}$$

where \(\omega\) is the mesh frequency, \(\lambda_i = i\omega / \omega_n\) with \(\omega_n\) as the natural frequency, and \(\zeta\) is the damping ratio. The root-mean-square (RMS) value of acceleration is used as a metric for vibration and noise:

$$a_{\text{rms}} = \sqrt{\frac{\sum_{i=1}^{n} x”_i^2}{n}}$$

We also create a contact finite element model for both standard and holey spur gears to obtain transmission error, which serves as an input for dynamic simulations. The transmission error curves, derived from nodal displacements, are plotted and show that holey spur gears exhibit reduced fluctuations compared to standard spur gears. Key parameters for dynamic analysis include equivalent mass, moment of inertia, damping, and excitation forces. The moments of inertia for standard and holey spur gears are compared in Table 4.

| Gear Type | Pinion Moment of Inertia (kg·m²) | Gear Moment of Inertia (kg·m²) | Equivalent Mass (kg) |

|---|---|---|---|

| Standard Spur Gear | 0.33 | 8.09 | 32.08 |

| Holey Spur Gear | 0.32 | 7.99 | 30.79 |

The damping coefficient is set to 0.1, typical for gear meshing. Impact forces due to tooth engagement are calculated using:

$$F_s = v_s \sqrt{\frac{b J_1 J_2}{(J_1 r’_{b2}^2 + J_2 r_{b1}^2) q_s}}$$

where \(v_s\) is the engagement velocity, \(b\) is the face width, \(J_1\) and \(J_2\) are moments of inertia, \(r_{b1}\) and \(r_{b2}\) are base circle radii, and \(q_s\) is a geometric factor. These forces are fitted over the mesh cycle to model excitation.

Dynamic simulations are conducted by varying the rotational speed from 0 to 6000 rpm. The natural frequencies of the standard and holey spur gear systems are calculated as 1758.5 Hz and 1641.2 Hz, respectively, leading to primary resonance speeds of 4396.25 rpm and 4103.00 rpm. The RMS acceleration values across speeds are plotted, showing that holey spur gears consistently exhibit lower vibration levels. The average RMS acceleration for the standard spur gear system is 116.39 m/s², while for the holey spur gear system, it is 105.02 m/s²—a reduction of approximately 9.77%. This demonstrates that holey spur gears effectively mitigate vibration and noise, contributing to smoother operation and longer service life.

In conclusion, this study comprehensively analyzes holey spur gears through finite element modeling, orthogonal optimization, and dynamic simulation. The optimization of hole parameters, particularly position, significantly reduces tooth root bending stress in spur gears, with up to 10% stress reduction for the pinion and 8.8% for the gear. Additionally, the dynamic analysis reveals that holey spur gear systems exhibit lower vibration and noise, with an average reduction of 9.77% in acceleration RMS values. These findings highlight the potential of holey spur gears for enhancing the performance and durability of mechanical transmissions. Future work could explore different hole patterns, material effects, and experimental validation to further optimize spur gear designs for various applications.