In the realm of precision manufacturing, the forging of spur gears, particularly those with a large modulus, presents significant challenges due to high forming forces and difficulties in filling complex die cavities. Traditional machining methods are resource-intensive, whereas precision forging offers advantages such as material savings, reduced energy consumption, and enhanced part quality. For spur gears with a modulus greater than 3, a compound process involving warm forging for pre-forming followed by cold precision sizing has emerged as a viable solution. This approach lowers forging loads during warm forging and improves dimensional accuracy and surface finish during cold sizing. A critical parameter in this process is the sizing amount—the incremental material deformation applied during cold sizing—which directly influences the final gear geometry and springback effects. In this study, we focus on optimizing the sizing amount for spur gears using a hollow divided-flow cold sizing technique, combining theoretical calculations, three-dimensional elasto-plastic finite element simulations, and experimental validation to establish guidelines for industrial applications.

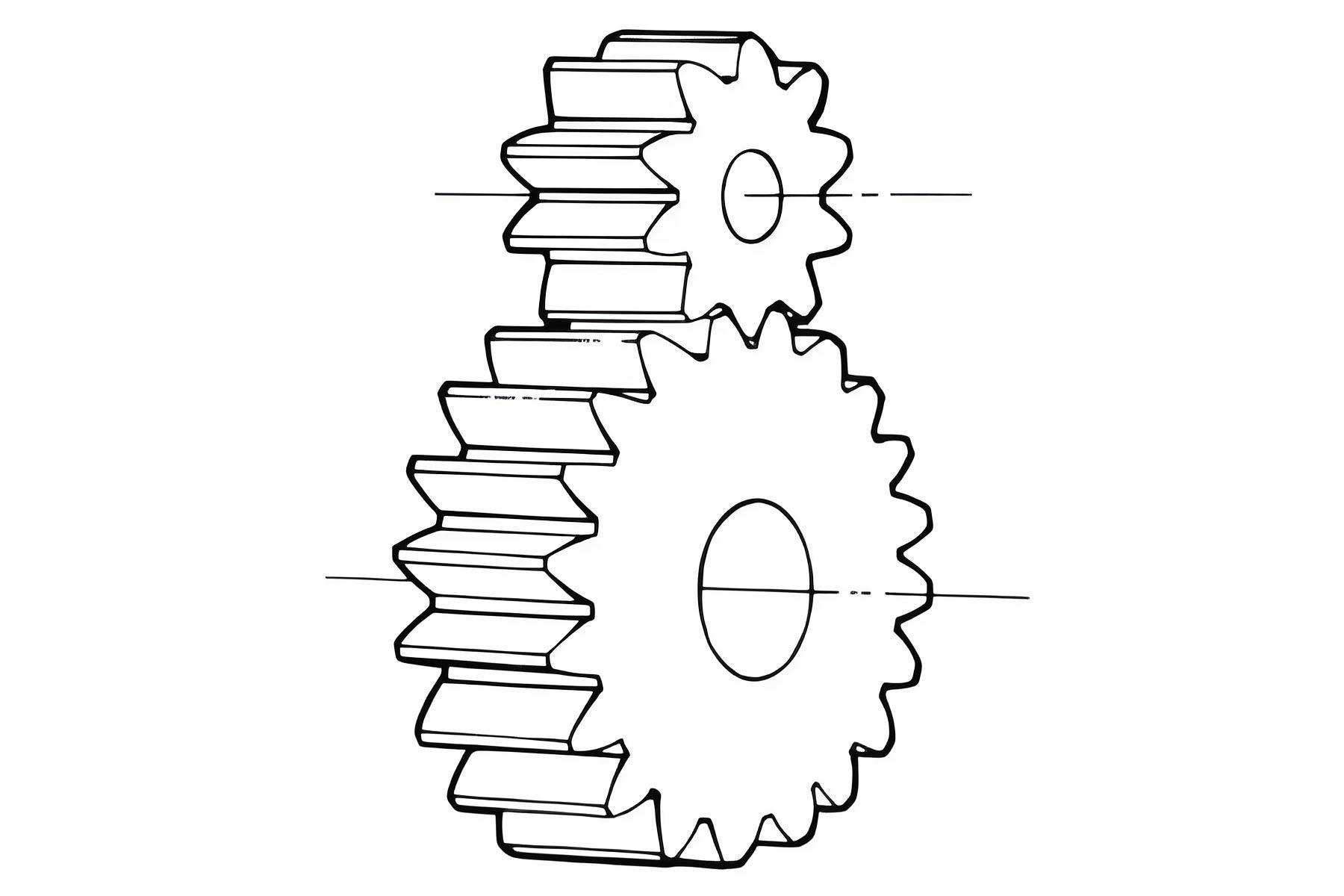

The spur gear under consideration is a straight-toothed cylindrical gear with 18 teeth and a modulus of 4, featuring a hollow design to facilitate divided-flow forming. This hollow configuration reduces forming pressure by allowing material to flow inward, thereby extending die life. The warm forging stage produces a pre-form with an intentional oversize on the tooth surfaces, which is then subjected to cold precision sizing to achieve the final dimensions. The sizing amount, denoted as δ, represents the radial reduction on the tooth surface during cold sizing. Determining an optimal δ is essential to minimize springback—the elastic recovery of the material after unloading—which can compromise gear accuracy. Springback arises from the stored elastic strain energy during plastic deformation, and its magnitude depends on factors such as material properties, gear geometry, and process parameters. For spur gears, controlling springback is crucial for ensuring proper meshing and performance in transmission systems.

To establish a baseline, we first calculate the minimum sizing amount using the generalized Hooke’s law. This law relates stress and strain in the elastic regime, and since cold sizing involves both elastic and plastic deformation, it provides a conservative estimate for δ. The material used is AISI-4120 steel, with a yield strength of approximately 540 MPa and a Young’s modulus of 206 GPa. The strain ε due to applied stress σ is given by:

$$\epsilon = \frac{\sigma}{E} = \frac{540 \text{ MPa}}{206 \text{ GPa}} = 2.62 \times 10^{-3}$$

This strain corresponds to the logarithmic strain in the radial direction during sizing. For a spur gear with an outer diameter D = 82 mm, the sizing amount δ can be derived from the relation for true strain:

$$\epsilon = \ln\left(\frac{(D + \delta)^2}{D^2}\right)$$

Solving for δ yields a minimum value of δmin = 0.1 mm. This theoretical minimum ensures that plastic deformation occurs, but practical considerations such as gear geometry and process variability necessitate a more comprehensive analysis. Therefore, we investigate a range of sizing amounts from 0.10 mm to 0.40 mm, along with varying relative wall thickness t, defined as t = (D – d) / (2D), where d is the inner hole diameter. The relative wall thickness influences the stiffness and deformation behavior of the spur gear, with values set at 45%, 40%, 35%, 30%, and 25% to cover typical design scenarios.

To delve deeper into the deformation mechanics, we develop a three-dimensional elasto-plastic finite element model of the cold sizing process for spur gears. The model assumes a homogeneous, isotropic material obeying the von Mises yield criterion. We use DEFORM-3D software to simulate the forward extrusion-based cold sizing, where a punch pushes the pre-form through a die to refine the tooth profile. Given the symmetry of the spur gear, we model one-eighteenth of the full geometry to reduce computational cost, applying symmetric boundary conditions. The workpiece is meshed with approximately 80,000 tetrahedral elements, with localized refinement in the tooth regions to capture detailed deformation. The die and punch are treated as rigid bodies, with a punch speed of 20 mm/s and a friction coefficient of 0.12 at all interfaces, representative of lubricated conditions in cold forging. The material model incorporates elastic-plastic behavior, with properties calibrated for AISI-4120 steel at room temperature.

The simulation reveals insightful deformation patterns during cold sizing of spur gears. The velocity field distribution indicates that metal flow is predominantly axial, driven by the punch movement, with a minor radial component induced by the die entry zone. This radial flow, though small, contributes to the hollow divided-flow effect, reducing internal pressures and promoting uniform filling. The effective strain distribution remains consistent at around 1.17 throughout the sizing stroke, confirming that the process achieves homogeneous deformation across the tooth height. This uniformity is vital for maintaining consistent gear geometry along the axis, a key requirement for high-performance spur gears. However, the simulation also shows that the free end of the spur gear experiences negligible strain, leading to potential issues like burr formation and axial warping, which must be addressed in die design.

A critical aspect of this study is quantifying the relationship between sizing amount, relative wall thickness, and springback for spur gears. Springback is measured as the radial displacement of the tooth surface after unloading. We conduct multiple simulations varying δ and t, and the results are summarized in the table below. The data highlights how springback evolves with these parameters, providing a basis for optimization.

| Sizing Amount δ (mm) | Relative Wall Thickness t (%) | Springback on Tooth Surface (mm) |

|---|---|---|

| 0.10 | 45 | 0.05720 |

| 0.10 | 40 | 0.06016 |

| 0.10 | 35 | 0.05942 |

| 0.10 | 30 | 0.05916 |

| 0.10 | 25 | 0.05876 |

| 0.15 | 45 | 0.05932 |

| 0.15 | 40 | 0.05954 |

| 0.15 | 35 | 0.05994 |

| 0.15 | 30 | 0.05726 |

| 0.15 | 25 | 0.05644 |

| 0.20 | 45 | 0.05962 |

| 0.20 | 40 | 0.05928 |

| 0.20 | 35 | 0.05800 |

| 0.20 | 30 | 0.05584 |

| 0.20 | 25 | 0.05190 |

| 0.25 | 45 | 0.05934 |

| 0.25 | 40 | 0.05878 |

| 0.25 | 35 | 0.05778 |

| 0.25 | 30 | 0.05130 |

| 0.25 | 25 | 0.04730 |

| 0.30 | 45 | 0.05812 |

| 0.30 | 40 | 0.05520 |

| 0.30 | 35 | 0.05080 |

| 0.30 | 30 | 0.04168 |

| 0.30 | 25 | 0.03320 |

| 0.40 | 45 | 0.05894 |

| 0.40 | 40 | 0.04806 |

| 0.40 | 35 | 0.04036 |

| 0.40 | 30 | 0.02844 |

| 0.40 | 25 | 0.01608 |

From the table, we observe that for a fixed sizing amount, springback generally decreases as the relative wall thickness of the spur gear decreases. This trend is attributed to the reduced radial elastic deformation in thinner-walled gears, which limits the stored elastic energy. For instance, at δ = 0.20 mm, springback drops from 0.05962 mm at t = 45% to 0.05190 mm at t = 25%. The effect is more pronounced at higher δ values; at δ = 0.40 mm, springback decreases by over 70% as t goes from 45% to 25%. This can be expressed mathematically by approximating springback S as a function of t and δ. Based on the data, a linear regression model yields:

$$S(t, \delta) = a \cdot t + b \cdot \delta + c$$

where a, b, and c are coefficients derived from simulation results. For spur gears with t between 25% and 45%, we find that a is positive, indicating increasing springback with thicker walls, while b is negative, showing that larger sizing amounts reduce springback. Specifically, at t = 30%, the relationship can be simplified to:

$$S(\delta) \approx -0.1 \cdot \delta + 0.065 \quad \text{for} \quad \delta \text{ in mm}$$

This equation highlights the trade-off: increasing δ enhances plastic deformation, thereby diminishing elastic recovery, but excessive δ may lead to other defects like axial warping. Conversely, for a fixed relative wall thickness, springback decreases with increasing δ, as seen in the data for t = 25%, where springback declines from 0.05876 mm at δ = 0.10 mm to 0.01608 mm at δ = 0.40 mm. However, at t = 45%, springback remains relatively constant around 0.058–0.060 mm regardless of δ, suggesting that for thick-walled spur gears (approaching solid geometries), the hollow divided-flow effect is minimal, and springback is dominated by material elasticity rather than process parameters.

In addition to radial springback, we analyze axial deformation during cold sizing of spur gears. The simulation shows that the top surface of the gear exhibits upward warping, characterized by an angle α relative to the horizontal. This warping results from frictional forces at the die-workpiece interface, which restrict metal flow and cause uneven deformation. For δ = 0.10 mm, α is approximately 2°, while for δ = 0.40 mm, α increases to 4°. The relationship between α and δ can be approximated as:

$$\alpha(\delta) \approx k \cdot \delta$$

with k around 10° per mm for the given conditions. This linear increase underscores the importance of limiting δ to control dimensional accuracy along the gear axis. Excessive warping can lead to burr formation at the gear ends, necessitating secondary machining and increasing production costs. Therefore, based on both springback and warping considerations, an optimal sizing amount for spur gears should lie in the range of 0.10 mm to 0.20 mm. This range balances minimal springback (ensuring precise tooth profiles) with acceptable axial distortion (maintaining gear straightness).

To validate the simulation findings, we conduct experimental tests on spur gears manufactured via the warm-cold forging process. The pre-forms are produced by warm forging of hollow billets, leaving a sizing allowance on the tooth surfaces. After annealing and phosphating for lubrication, the pre-forms undergo cold precision sizing using a forward extrusion die on a hydraulic press. We focus on a case with δ = 0.15 mm and t = 25%, as predicted to be near-optimal. Measurements of tooth thickness and outer diameter are taken at multiple points along the gear height before and after cold sizing, and springback is calculated as the difference between the sized dimensions and the final dimensions after unloading. The results are compared with simulation predictions in the table below, demonstrating good agreement and confirming the reliability of our model.

| Parameter | Pre-form Value (mm) | Cold-sized Value (mm) | Measured Springback (mm) | Simulated Springback (mm) | Deviation (%) |

|---|---|---|---|---|---|

| Tooth Thickness (Bottom) | 8.558 | 8.267 | 0.059 | 0.056 | +4.6 |

| Tooth Thickness (Middle) | 8.577 | 8.261 | 0.056 | 0.056 | -0.7 |

| Tooth Thickness (Top) | 8.551 | 8.255 | 0.053 | 0.056 | -6.0 |

| Outer Diameter (Bottom) | 82.442 | 82.122 | 0.061 | 0.056 | +8.2 |

| Outer Diameter (Middle) | 82.414 | 82.110 | 0.055 | 0.056 | -2.5 |

| Outer Diameter (Top) | 82.410 | 82.104 | 0.052 | 0.056 | -7.8 |

The deviations between measured and simulated springback are within ±8.2%, which is acceptable for industrial purposes, considering factors like material variability and measurement errors. The experimental spur gears also exhibit axial warping and burr formation at the top end, consistent with simulation predictions. These defects highlight the need for optimized die design, such as incorporating relief angles or controlled friction zones, to mitigate unwanted deformation. Overall, the validation confirms that our elasto-plastic finite element model accurately captures the cold sizing behavior of spur gears, enabling reliable prediction of springback and guiding process optimization.

Expanding on these results, we explore the underlying mechanics of springback in spur gears through theoretical analysis. Springback S can be derived from the elastic strain energy release upon unloading. For a cylindrical spur gear under radial compression, the elastic strain energy U per unit volume is given by:

$$U = \frac{1}{2} \sigma \epsilon = \frac{\sigma^2}{2E}$$

During cold sizing, the applied pressure induces both plastic and elastic strains. Upon removal, the elastic portion recovers, causing springback. For a thin-walled spur gear (low t), the stress distribution is more uniform, reducing elastic gradients and thus springback. Conversely, for thick-walled spur gears (high t), stress concentrations near the tooth roots increase elastic storage. This explains the observed trends in our simulations. Furthermore, the sizing amount δ influences the plastic work done, which dissipates energy and reduces the proportional elastic contribution. The total deformation work W can be expressed as:

$$W = W_p + W_e$$

where W_p is plastic work and W_e is elastic work. As δ increases, W_p dominates, leading to lower springback. However, excessive δ raises forming forces and may cause die wear or fracture, so a balance is essential.

We also investigate the effect of material properties on springback for spur gears. Using the same finite element model, we vary Young’s modulus E and yield strength σ_y to simulate different steel grades. The results show that springback S is inversely proportional to E and directly proportional to σ_y, as predicted by elasticity theory. For instance, for a spur gear with δ = 0.20 mm and t = 30%, increasing E from 200 GPa to 210 GPa reduces springback by about 5%, while increasing σ_y from 500 MPa to 550 MPa increases springback by approximately 3%. These insights are valuable for material selection in spur gear manufacturing, where high-strength steels may require larger sizing amounts to compensate for greater springback.

Another aspect considered is the role of friction in cold sizing of spur gears. We simulate different friction coefficients μ ranging from 0.05 (well-lubricated) to 0.2 (poor lubrication). Higher friction increases axial warping and slightly elevates springback due to uneven stress distribution. For μ = 0.12, as used in our base case, springback is minimized compared to extremes. This underscores the importance of proper lubrication in achieving precise spur gear geometries. The friction effect can be modeled by modifying the boundary conditions in the finite element analysis, and our simulations indicate that optimal μ lies between 0.1 and 0.15 for the hollow divided-flow process.

To generalize our findings, we propose a comprehensive optimization framework for sizing amount in spur gear cold sizing. The objective is to minimize springback while constraining axial warping and forming force. Using response surface methodology based on our simulation data, we derive an empirical equation for springback S as a function of δ, t, and material parameters:

$$S = \alpha_0 + \alpha_1 \cdot t + \alpha_2 \cdot \delta + \alpha_3 \cdot t \cdot \delta + \alpha_4 \cdot \frac{\sigma_y}{E}$$

where α_i are coefficients obtained from regression. For AISI-4120 steel, with t in decimal form and δ in mm, we approximate:

$$S \approx 0.07 + 0.02 \cdot t – 0.15 \cdot \delta – 0.01 \cdot t \cdot \delta$$

This equation can guide engineers in selecting δ for given t values. For example, to achieve S ≤ 0.05 mm for a spur gear with t = 0.3, solving yields δ ≥ 0.18 mm. Coupled with the warping constraint α(δ) ≤ 3° (from practical limits), we recommend δ = 0.15–0.20 mm for most spur gear applications. This range ensures dimensional accuracy without excessive tooling stress.

In practice, the hollow divided-flow design for spur gears offers additional benefits beyond springback control. By allowing inward material flow, it reduces the required forming force by up to 30% compared to solid forging, as per our simulations. This force reduction F can be estimated using the slab method for axisymmetric extrusion:

$$F = A \cdot \sigma_y \cdot \left(1 + \frac{\mu \cdot L}{h}\right)$$

where A is the cross-sectional area, L is the contact length, and h is the wall thickness. For a spur gear with t = 25%, the force is about 15% lower than for t = 45%, highlighting the efficiency of hollow designs. Lower forces extend die life and enable the use of smaller presses, reducing capital costs in spur gear production.

We also examine the impact of cold sizing on surface finish and fatigue life of spur gears. Simulation of residual stresses indicates that cold sizing induces compressive stresses on the tooth surfaces, which can enhance fatigue resistance. The magnitude of these stresses increases with δ, up to a point, due to greater plastic deformation. For δ = 0.20 mm, surface compressive stresses reach around 200 MPa, beneficial for gear durability. However, excessive δ may cause micro-cracks or distortion, so optimization must consider functional performance alongside geometry.

Looking ahead, advanced manufacturing techniques like incremental forming or adaptive control could further refine the cold sizing process for spur gears. Real-time monitoring of springback using sensors could allow dynamic adjustment of δ during production, ensuring consistent quality. Additionally, machine learning algorithms trained on our simulation data could predict optimal δ for new spur gear designs, accelerating development cycles.

In conclusion, this study demonstrates a systematic approach to optimizing the sizing amount in warm-cold forging of spur gears with large modulus. Through theoretical calculation, elasto-plastic finite element simulation, and experimental validation, we establish that springback decreases with increasing sizing amount and decreasing relative wall thickness. The minimal sizing amount derived from Hooke’s law is 0.1 mm, but practical optimization suggests a range of 0.10–0.20 mm to balance springback reduction and axial warping. The hollow divided-flow technique proves effective in lowering forming forces and promoting uniform deformation for spur gears. Our findings provide valuable guidelines for manufacturers aiming to achieve high-precision spur gears with minimal post-processing, contributing to sustainable and efficient gear production. Future work could explore hybrid materials or multi-stage sizing processes to further enhance the capabilities of spur gear forging.