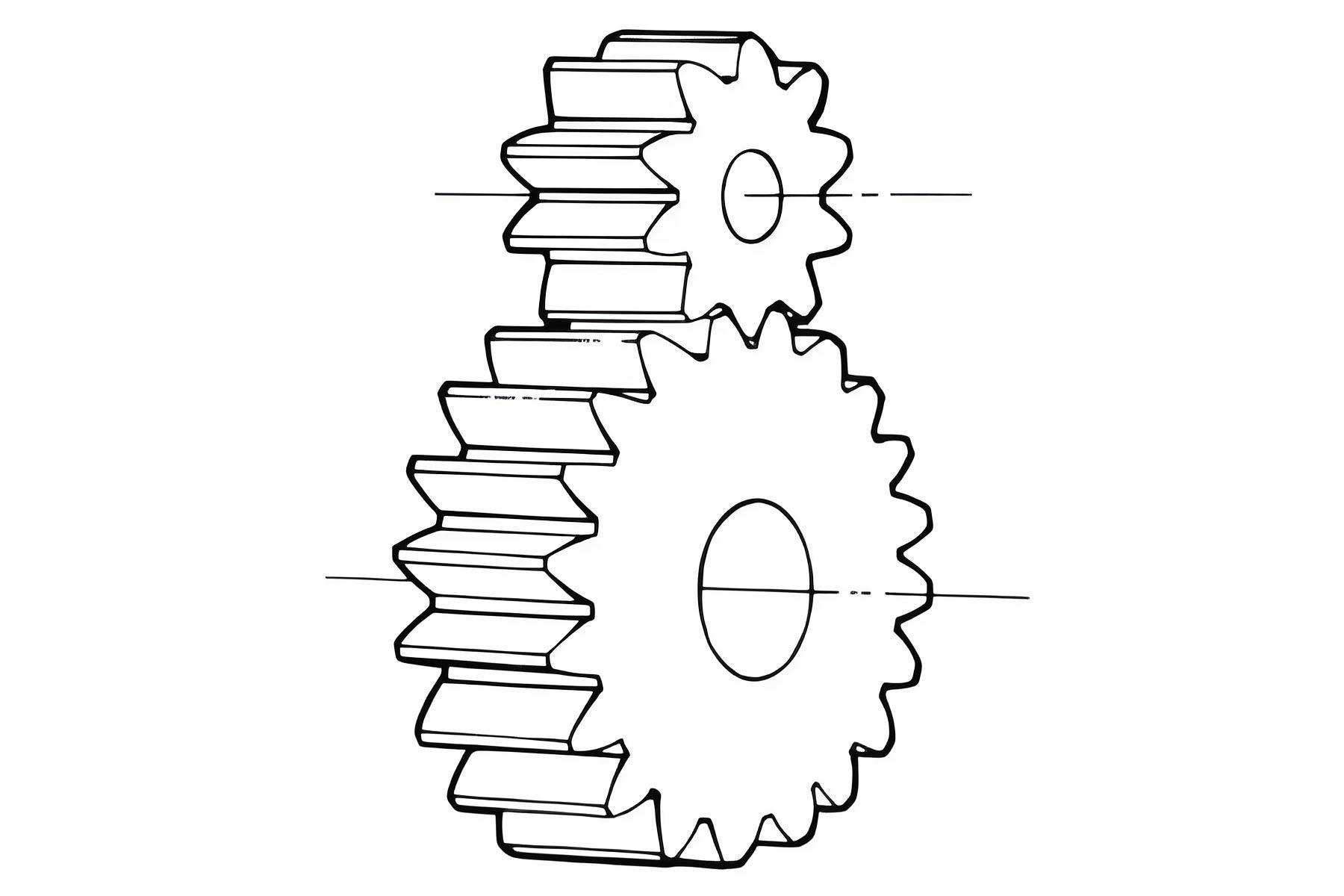

As a fundamental component in mechanical systems for transmitting motion and power, spur gears are widely utilized across various industries. Traditional manufacturing methods, such as cutting or hot forging combined with machining, often suffer from inefficiencies, high energy consumption, and limitations in strength, wear resistance, and impact tolerance. To address these issues, closed-die forging at room temperature presents a promising alternative. This process leverages the metal’s inherent flow properties to fill the tooth cavities, resulting in spur gears that require minimal or no subsequent machining. This approach not only enhances mechanical performance by preserving the fiber flow lines in the tooth region but also significantly boosts productivity. In this article, I employ three-dimensional finite element analysis software to simulate the forming process of spur gears under cold forging conditions. By examining equivalent stress, equivalent strain, and load-stroke curves, I aim to elucidate the metal flow behavior and provide theoretical insights for optimizing the production of spur gears.

The core of this analysis is based on the rigid-plastic finite element theory, which is well-suited for large plastic deformation processes like forging. In this framework, the tooling (dies and punches) is treated as rigid bodies, while the workpiece (the billet) is modeled as a plastic material. This simplification neglects elastic deformations in the tools, focusing solely on the plastic flow of the material. The fundamental principle governing plastic deformation is the volume constancy, expressed as:

$$ \nabla \cdot \mathbf{v} = 0 $$

where $\mathbf{v}$ is the velocity vector. The material behavior is described by the constitutive law relating stress and strain rate. For the rigid-plastic material, the flow stress $\bar{\sigma}$ is a function of the equivalent strain $\bar{\epsilon}$, strain rate $\dot{\bar{\epsilon}}$, and temperature $T$:

$$ \bar{\sigma} = f(\bar{\epsilon}, \dot{\bar{\epsilon}}, T) $$

However, in this cold forging simulation, thermal effects are neglected, assuming isothermal conditions at room temperature. The equivalent strain $\bar{\epsilon}$ and equivalent stress $\bar{\sigma}$ are calculated using the following formulas, which are crucial for analyzing deformation intensity:

$$ \bar{\epsilon} = \sqrt{\frac{2}{3} \epsilon_{ij} \epsilon_{ij}} $$

$$ \bar{\sigma} = \sqrt{\frac{3}{2} s_{ij} s_{ij}} $$

where $\epsilon_{ij}$ is the strain tensor and $s_{ij}$ is the deviatoric stress tensor. These metrics help in assessing the uniformity and severity of deformation during the forging of spur gears.

To simulate the closed-die forging of a spur gear, a three-dimensional model is constructed. The gear parameters are selected as follows: module $m = 2 \text{ mm}$, number of teeth $z = 20$, and pressure angle $\alpha = 20^\circ$. The billet is designed with an outer diameter slightly smaller than the root circle diameter of the spur gear to facilitate initial material flow. The height of the billet is determined based on the volume constancy principle to ensure complete filling of the die cavity. The material chosen for the spur gear billet is AISI 1045 steel, a common medium-carbon steel with good forgeability. Its flow stress behavior can be approximated by a power law model:

$$ \bar{\sigma} = K \bar{\epsilon}^n $$

where $K$ is the strength coefficient and $n$ is the strain-hardening exponent. For AISI 1045 at room temperature, typical values are $K = 600 \text{ MPa}$ and $n = 0.2$. Friction at the die-workpiece interface is modeled using the shear friction model, with a friction coefficient $\mu = 0.12$. The friction stress $\tau_f$ is given by:

$$ \tau_f = \mu \cdot \bar{\sigma} $$

This model accounts for the resistance to material flow, which is critical in closed-die forging. The forging process employs a floating die technique, where both the upper punch and the floating die move downward at a constant speed of $1 \text{ mm/s}$. To improve computational efficiency without loss of accuracy, due to symmetry, only one tooth sector (1/20 of the full spur gear) is analyzed. The finite element mesh consists of approximately 50,000 tetrahedral elements, with refinement near the tooth cavity corners to capture high gradient regions. The simulation parameters are summarized in Table 1.

| Parameter | Value | Description |

|---|---|---|

| Gear Module ($m$) | 2 mm | Defines tooth size |

| Number of Teeth ($z$) | 20 | Total teeth in spur gear |

| Pressure Angle ($\alpha$) | 20° | Tooth profile angle |

| Billet Diameter | 95% of root diameter | Initial billet outer diameter |

| Billet Height | Calculated from volume | Based on spur gear volume |

| Material | AISI 1045 Steel | Workpiece material |

| Friction Coefficient ($\mu$) | 0.12 | Shear friction model |

| Forging Speed | 1 mm/s | Punch and die velocity |

| Temperature | 20°C (isothermal) | Room temperature forging |

The simulation of spur gear forging is conducted in incremental steps, tracking the deformation history. The results are analyzed in terms of equivalent strain, equivalent stress, and forging load versus stroke. These outputs reveal the metal flow patterns and identify critical regions in the spur gear formation.

First, the equivalent strain distribution at three key stages of forging is examined. At an early stage (stroke = 2.5 mm), material begins to flow into the tooth cavity of the spur gear die. The strain values are relatively low, but slight increases are observed at the corner regions of the cavity due to geometric constraints. As the stroke progresses to 5 mm, more material is forced into the spur gear tooth space, leading to intensified deformation. The equivalent strain peaks at the cavity corners, reaching approximately 0.8. At the final forging stage (stroke = 7.5 mm), the spur gear tooth is fully formed, and the strain in the corner regions escalates to around 1.5, indicating severe plastic deformation. This pattern highlights that the tooth cavity corners are the most challenging areas to fill, requiring careful design to ensure complete spur gear formation. The strain distribution can be quantified using the equivalent strain formula, and the values at different stages are summarized in Table 2.

| Forging Stage | Stroke (mm) | Max Equivalent Strain ($\bar{\epsilon}$) | Location of Max Strain |

|---|---|---|---|

| Initial Flow | 2.5 | 0.3 | Tooth cavity entrance |

| Intermediate | 5.0 | 0.8 | Tooth cavity corners |

| Final Forming | 7.5 | 1.5 | Tooth cavity corners and root |

Similarly, the equivalent stress distribution follows trends analogous to strain. Initially, stresses are moderate, but as the spur gear tooth fills, the stress concentrations become pronounced at the cavity corners. At the final stage, the maximum equivalent stress reaches about 450 MPa, which is close to the material’s flow stress limit. This high stress is attributed to the triaxial compressive state in the closed-die environment, essential for spur gear precision. The von Mises stress criterion, given by $\bar{\sigma} = \sqrt{\frac{1}{2}[(\sigma_1 – \sigma_2)^2 + (\sigma_2 – \sigma_3)^2 + (\sigma_3 – \sigma_1)^2]}$, confirms that the material undergoes significant work-hardening. The stress evolution is detailed in Table 3, emphasizing the mechanical demands during spur gear forging.

| Forging Stage | Stroke (mm) | Max Equivalent Stress ($\bar{\sigma}$, MPa) | Dominant Stress State |

|---|---|---|---|

| Initial Flow | 2.5 | 200 | Uniaxial compression |

| Intermediate | 5.0 | 350 | Triaxial compression |

| Final Forming | 7.5 | 450 | High triaxial compression |

The load-stroke curve, a critical output in forging analysis, exhibits three distinct phases for spur gear formation. In Phase I (stroke 0–3 mm), the load increases linearly, resembling a upsetting process. This is because the billet has a slight clearance with the die, and deformation is primarily through bulk compression without extensive flow into the spur gear teeth. The load $F$ in this phase can be approximated by:

$$ F = A_0 \cdot \bar{\sigma} $$

where $A_0$ is the initial contact area. In Phase II (stroke 3–6 mm), the load rise becomes more gradual as material starts to flow into the spur gear tooth cavities. The free surface area decreases, leading to a steady increase in resistance. This phase is characterized by complex metal flow, and the load can be modeled using empirical relations that account for geometry and friction. Finally, in Phase III (stroke 6–7.5 mm), the load surges dramatically over a short stroke, reaching a peak value. This is the final filling stage, where the remaining material must overcome high triaxial stresses to completely form the spur gear teeth. The peak load $F_{\text{max}}$ is crucial for die design and can be estimated by:

$$ F_{\text{max}} = C \cdot \bar{\sigma}_{\text{avg}} \cdot A_{\text{projected}} $$

where $C$ is a factor accounting for shape complexity (higher for spur gears due to teeth), $\bar{\sigma}_{\text{avg}}$ is the average flow stress, and $A_{\text{projected}}$ is the projected area of the forged spur gear. For this simulation, the peak load is around 1.2 MN, indicating the high forces involved in spur gear forging. The load-stroke data is summarized in Table 4, illustrating the forging dynamics.

| Phase | Stroke Range (mm) | Load Behavior | Approximate Load at End (MN) | Dominant Mechanism |

|---|---|---|---|---|

| I: Upsetting | 0–3 | Linear increase | 0.4 | Bulk compression |

| II: Tooth Filling | 3–6 | Gradual increase | 0.8 | Material flow into cavities |

| III: Final Forming | 6–7.5 | Sharp exponential rise | 1.2 | High triaxial compression |

Metal flow patterns during spur gear forging are influenced by die geometry and process parameters. The analysis shows that material initially flows radially outward, but as the tooth cavities engage, flow is redirected into the spur gear tooth spaces. The corners act as dead zones, requiring sufficient pressure to fill. To optimize flow, die design considerations such as corner radii and lubrication are vital. The velocity field $\mathbf{v}$ can be derived from the simulation, and the flow lines indicate that the spur gear teeth are formed from the outer billet regions inward, ensuring fiber continuity. This alignment enhances the gear’s load-bearing capacity, a key advantage of forged spur gears over machined ones.

Furthermore, the impact of friction on spur gear forging cannot be overstated. Higher friction coefficients increase the forging load and may lead to incomplete filling or defects like laps. Using the shear friction model, the frictional work $W_f$ is computed as:

$$ W_f = \int \tau_f \cdot v_r \, dA $$

where $v_r$ is the relative velocity at the interface. For spur gear forging, minimizing friction through lubricants is essential to reduce loads and improve die life. Additionally, the choice of billet size affects the forging outcome. A billet too large may cause excessive flash or die wear, while one too small may not fill the spur gear teeth. The optimal billet volume $V_b$ is given by:

$$ V_b = V_g + V_{\text{flash}} $$

where $V_g$ is the volume of the spur gear and $V_{\text{flash}}$ is the flash volume (minimized in closed-die forging). In this simulation, the billet is sized to eliminate flash, focusing on precision forging of spur gears.

The finite element analysis also allows for predicting potential defects in spur gear forging. Based on the strain and stress results, areas with high tensile stresses might lead to cracking, though in closed-die forging, compressive stresses dominate. However, if the material flow is restricted, shear bands could form, compromising the spur gear integrity. Monitoring the strain rate $\dot{\bar{\epsilon}}$ is important, as very high rates might induce adiabatic heating, even in cold forging. For spur gears, maintaining a uniform strain rate across the tooth profile ensures consistent properties. The strain rate sensitivity parameter $m$ in the constitutive law $\bar{\sigma} = K \bar{\epsilon}^n \dot{\bar{\epsilon}}^m$ plays a role, but for AISI 1045 at room temperature, $m$ is small (~0.01), so rate effects are negligible.

In terms of die design for spur gear forging, the high stresses at corners necessitate the use of hardened tool steels and possibly stress-relief features. The die life can be estimated using fatigue models based on the cyclic loading during forging operations. For mass production of spur gears, optimizing the forging process through simulation reduces trial-and-error, saving time and cost. The use of floating dies, as in this analysis, helps in ejecting the forged spur gear and reduces axial loads.

To generalize the findings, the relationships between key variables in spur gear forging can be expressed through dimensionless analysis. For example, the forging force $F$ can be correlated with the spur gear geometry via a form factor $K_f$:

$$ F = K_f \cdot \bar{\sigma} \cdot A $$

where $A$ is the area. For spur gears, $K_f$ increases with tooth aspect ratio (height/tooth width). Empirical data from simulations can be used to derive $K_f$ values for different spur gear designs. Additionally, the fill efficiency $\eta$ of the tooth cavity is defined as:

$$ \eta = \frac{V_{\text{filled}}}{V_{\text{cavity}}} \times 100\% $$

In this simulation, $\eta$ reaches 99.5% at the final stroke, indicating successful spur gear formation. However, achieving 100% fill often requires overloading, which may not be practical. Therefore, process windows must be established to balance fill quality and die stress.

In conclusion, the finite element analysis of closed-die forging for spur gears provides deep insights into the deformation mechanics. The simulation highlights that the tooth cavity corners are critical regions, experiencing the highest strain and stress. The load-stroke curve reveals three phases, with a sharp load increase in the final stage, demanding robust die design. By leveraging such analysis, manufacturers can optimize billet dimensions, friction conditions, and die geometry to produce high-quality spur gears efficiently. Future work could explore warm forging to reduce forces or multi-stage processes for complex spur gear profiles. Overall, the integration of finite element simulation into spur gear production offers a theoretical foundation for enhancing performance and sustainability in gear manufacturing.

The adoption of closed-die forging for spur gears aligns with industry trends toward net-shape manufacturing, reducing material waste and energy consumption. As demonstrated, the finite element method is a powerful tool for predicting outcomes and troubleshooting potential issues. For spur gears, which are ubiquitous in automotive and machinery applications, forging not only improves mechanical properties but also enables high-volume production. I recommend further studies on microstructural evolution during forging to link process parameters with final spur gear performance metrics like fatigue strength. Ultimately, the synergy between simulation and experimentation will drive advancements in spur gear technology, meeting the growing demands for reliability and efficiency in mechanical systems.