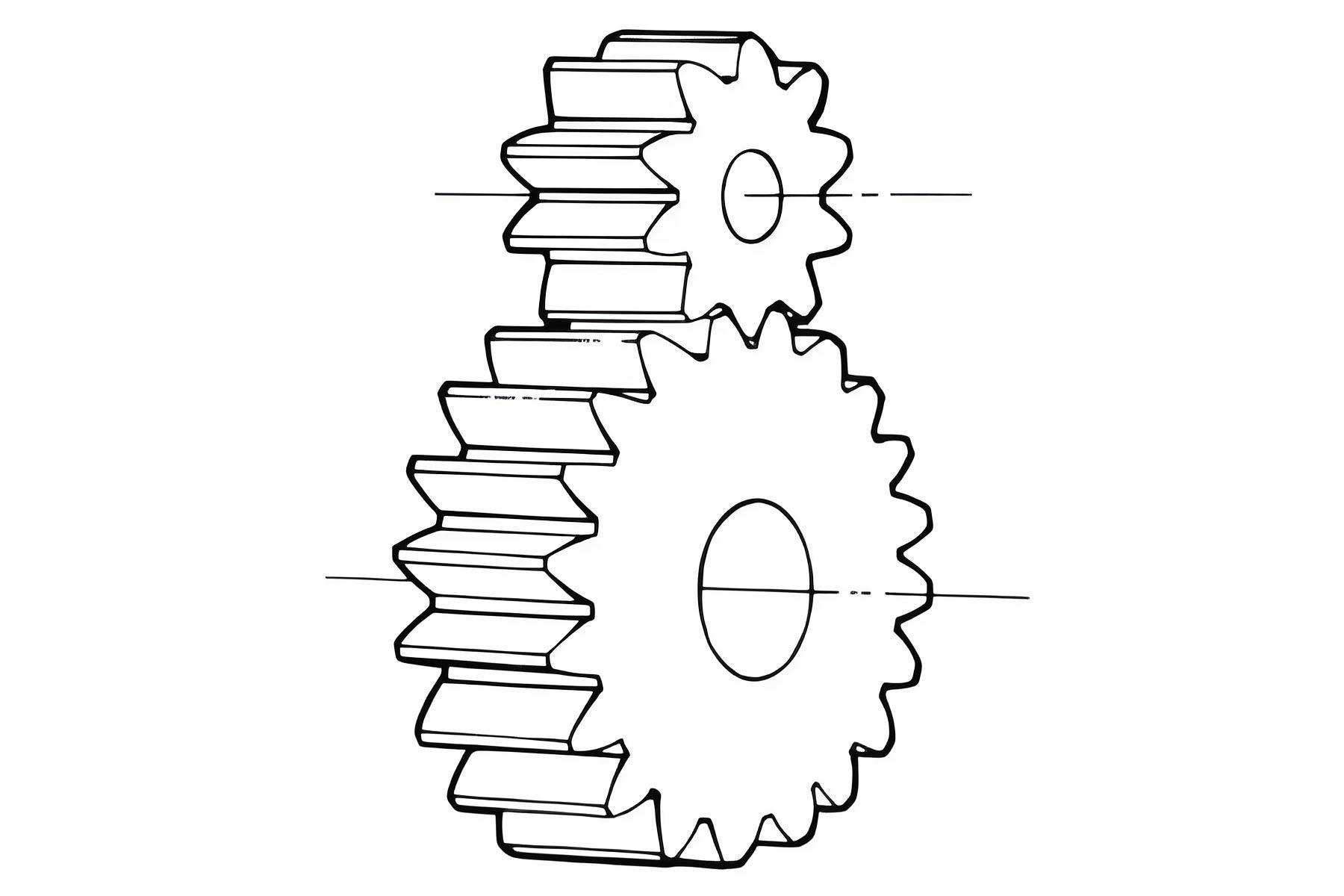

In the field of mechanical transmission, spur gears are fundamental components widely used in various industrial applications. Traditional machining methods for spur gears, such as hobbing or shaping, often suffer from low material utilization, low productivity, and high production costs. Moreover, during these processes, the fibers in the tooth profile are cut, leading to reduced strength and load-bearing capacity. To address these issues, cold forging has emerged as a promising alternative. Compared to hot forming, cold forging offers higher dimensional accuracy, eliminates the need for subsequent machining, provides excellent surface finish, and enhances strength due to work hardening. Additionally, it saves energy by omitting heating steps and significantly improves material efficiency. This article explores the cold forging process for spur gears, focusing on a coupled axial分流 and floating die technique, using finite element numerical simulation to analyze the forming behavior and optimize the process parameters.

The adoption of cold forging for spur gears not only enhances intrinsic and surface quality but also increases material utilization, reduces machining time, and lowers energy consumption. Furthermore, it allows for a favorable metal flow line distribution, which improves load-bearing capacity. In this study, I investigate the cold forging process for a specific spur gear design through finite element simulation, aiming to understand the metal flow, stress-strain distribution, and forming loads. The goal is to provide theoretical insights for practical production, ensuring high-quality spur gear manufacturing.

Spur gears are characterized by their straight teeth parallel to the axis, making them suitable for transmitting motion between parallel shafts. The geometric parameters of the spur gear studied here are as follows: module m = 2 mm, number of teeth Z = 18, tooth width h = 10 mm, normal pressure angle α = 20°, and profile shift coefficient x = 0.0. These parameters define the basic shape and function of the spur gear, influencing the forging process. The cold forging setup involves an upper die, a floating die, and a lower die, with a central分流 hole diameter of 10 mm to facilitate material flow and reduce forming loads. The initial billet is a cylindrical rod, and its dimensions are determined based on volume constancy conditions and necessary machining allowances. For this spur gear, the billet is designed as Φ30 mm × 15 mm.

To establish the finite element model, I used modeling software to create 3D geometries of the dies and billet. Considering the geometric symmetry of the spur gear, a quarter-model is adopted to reduce computational scale and save CPU time, improving efficiency. The geometric model is shown conceptually, with the billet positioned between the dies. The finite element simulation is performed using specialized software, where the dies are treated as rigid bodies, and the billet material is AISI-4140 (cold), modeled as a plastic body. The friction between the dies and billet is defined as shear friction with a coefficient of 0.12. The billet is meshed with tetrahedral elements to capture deformation details, and the upper die and floating die move at a speed of 1 mm/s during the simulation.

The key parameters for the spur gear cold forging simulation are summarized in the table below:

| Parameter | Value |

|---|---|

| Spur Gear Module (m) | 2 mm |

| Number of Teeth (Z) | 18 |

| Tooth Width (h) | 10 mm |

| Normal Pressure Angle (α) | 20° |

| Profile Shift Coefficient (x) | 0.0 |

| Billet Diameter | 30 mm |

| Billet Height | 15 mm |

| Central分流 Hole Diameter | 10 mm |

| Friction Coefficient | 0.12 |

| Die Speed | 1 mm/s |

| Material | AISI-4140 (cold) |

The volume constancy condition in cold forging is expressed as:

$$ V_{\text{initial}} = V_{\text{final}} + V_{\text{allowance}} $$

where \( V_{\text{initial}} \) is the initial billet volume, \( V_{\text{final}} \) is the final spur gear volume, and \( V_{\text{allowance}} \) accounts for machining allowances. For a cylindrical billet, the volume is calculated as:

$$ V_{\text{initial}} = \pi \left( \frac{D}{2} \right)^2 H $$

with \( D = 30 \) mm and \( H = 15 \) mm. The spur gear volume can be approximated based on its geometry, but in practice, iterative adjustments are made to ensure proper filling.

In the simulation, the equivalent strain field, equivalent stress field, velocity field, and load-displacement curves are extracted to analyze the spur gear forming process. The equivalent strain \( \bar{\epsilon} \) and equivalent stress \( \bar{\sigma} \) are defined using the von Mises criterion:

$$ \bar{\epsilon} = \sqrt{\frac{2}{3} \epsilon_{ij} \epsilon_{ij}} $$

$$ \bar{\sigma} = \sqrt{\frac{3}{2} s_{ij} s_{ij}} $$

where \( \epsilon_{ij} \) is the strain tensor and \( s_{ij} \) is the deviatoric stress tensor. These parameters reflect the deformation intensity and stress state during spur gear forging.

The simulation results reveal detailed insights into the cold forging of spur gears. At incremental step 60, the equivalent strain field shows higher strain in the tooth cavity regions compared to the central axis. This indicates that material flows preferentially into the tooth profiles due to lower resistance. The floating die assists in balancing axial forces, promoting filling of the lower tooth ends. As the upper die moves downward, the velocity field demonstrates that the upper part of the billet flows faster than the lower part, leading to asymmetric deformation initially. By incremental step 75, the tooth cavities are partially filled, and the equivalent stress increases in the tooth regions, reaching values that help heal internal defects. At incremental step 89, near the end of forming, the tooth cavities are almost fully filled, and the material experiences high triaxial compressive stresses in the corner regions, resulting in peak equivalent strain and stress.

The load-displacement curve for spur gear forging exhibits distinct phases. Initially, when the upper die contacts the billet, the load rises linearly. As deformation proceeds, similar to upsetting, the load increases slowly. When the material begins to flow into the tooth cavities, the load rises more steeply, and as filling progresses, the load increases gradually due to reduced free surfaces. In the final stage, with minimal displacement, the load surges dramatically as the material is compressed into the small corner spaces of the tooth cavities. This behavior is critical for predicting die life and optimizing process parameters for spur gear production.

To further analyze the spur gear forging process, I examine the velocity field distribution. In the early stages, material flows rapidly into the tooth cavities because the resistance is lower than that toward the central hole. This is facilitated by the floating die, which applies axial pressure to enhance filling. As forming advances, the flow velocity toward the central hole increases due to two-dimensional compressive stress, while the tooth regions experience three-dimensional stress, leading to higher equivalent stress. The interplay between these flows determines the final spur gear quality.

The table below summarizes the key observations from the simulation for spur gear cold forging:

| Incremental Step | Equivalent Strain | Equivalent Stress | Velocity Field Characteristic |

|---|---|---|---|

| 60 | High in tooth cavities | Moderate | Fast flow into teeth |

| 75 | Increasing overall | High in teeth | Balanced flow |

| 89 | Peak in corners | Maximum in teeth | Flow to central hole |

The effectiveness of the axial分流 and floating die coupling is evident from the simulation. The central分流 hole reduces forming loads by providing an escape path for excess material, while the floating die ensures uniform filling of the spur gear teeth. This combination addresses common issues in spur gear forging, such as incomplete filling and high die stress. The numerical simulation allows for virtual testing of different geometries and process conditions, saving time and resources in actual production.

In terms of material behavior, the AISI-4140 steel used for the spur gear billet exhibits work hardening during cold forging. The flow stress can be modeled using a power-law relationship:

$$ \sigma = K \epsilon^n $$

where \( K \) is the strength coefficient and \( n \) is the hardening exponent. For cold forging, this affects the forming loads and final spur gear strength. The simulation incorporates this material model to accurately predict deformation.

The advantages of cold forging for spur gears are manifold. Compared to traditional methods, it offers superior mechanical properties due to grain refinement and uninterrupted fiber lines. The table below compares cold forging with conventional machining for spur gears:

| Aspect | Cold Forging | Traditional Machining |

|---|---|---|

| Material Utilization | High (≥90%) | Low (≈50-60%) |

| Productivity | High | Low |

| Strength | Enhanced | Reduced |

| Surface Finish | Excellent | Good |

| Cost | Lower in mass production | Higher |

For spur gears, the load-bearing capacity is crucial, and cold forging improves it by aligning metal flow lines along the tooth profile. This reduces stress concentrations and enhances fatigue resistance. The simulation results confirm that the equivalent stress in the tooth regions is sufficiently high to consolidate the material, leading to a dense and strong spur gear structure.

The numerical simulation also highlights the importance of die design in spur gear forging. The floating die allows for adaptive movement, compensating for material flow variations and reducing die wear. The central分流 hole diameter of 10 mm is optimized based on preliminary trials to balance material savings and forming pressure. Further optimization can be achieved by varying parameters such as die speed, friction conditions, and billet dimensions.

In conclusion, the cold forging process for spur gears, utilizing axial分流 and floating die coupling, is highly effective for producing high-quality gears. The finite element simulation provides valuable insights into the deformation mechanics, including equivalent strain, stress, velocity fields, and load-displacement behavior. The results show that material initially flows into the tooth cavities, with increasing equivalent strain and stress, and in the final stage, the load spikes as the corners are filled. This understanding aids in controlling the process for optimal spur gear manufacturing.

The application of cold forging for spur gears offers significant benefits in terms of material efficiency, strength, and cost reduction. Future work could explore different spur gear geometries, such as helical or bevel gears, and investigate advanced die materials to extend tool life. Additionally, integrating artificial intelligence with simulation could enable real-time process optimization for spur gear production.

Overall, this study demonstrates the potential of numerical simulation in advancing cold forging technology for spur gears. By leveraging finite element analysis, manufacturers can reduce trial-and-error, improve product quality, and accelerate the development of efficient forging processes for spur gears and other precision components.