In the field of plastic engineering, the cold forging process for spur gears has long been a research hotspot due to its numerous advantages, such as enhanced strength, energy savings, reduced material consumption, and improved productivity. The cold forging of spur gears involves complex plastic deformation with large strains, characterized by three types of nonlinearities: the nonlinear constitutive relationship of materials under plastic deformation, geometric nonlinearity due to large deformations, and nonlinear boundary conditions. Traditional analytical methods, including numerical approximation, principal stress method, and upper-bound method, often fall short in accurately capturing the intricate metal flow patterns during spur gear formation. Therefore, advanced techniques like finite element method (FEM) have become indispensable for numerical simulation in bulk metal forming. However, numerical simulation alone cannot entirely replace physical experiments; typically, simulation results require validation through experimental studies. Combining physical experiments with numerical simulation offers a powerful approach for investigating plastic forming processes and related theories. In this article, I present a novel process scheme for spur gear cold forging, based on traditional methods, and employ three-dimensional numerical simulation alongside physical experiments to explore its feasibility and optimization potential.

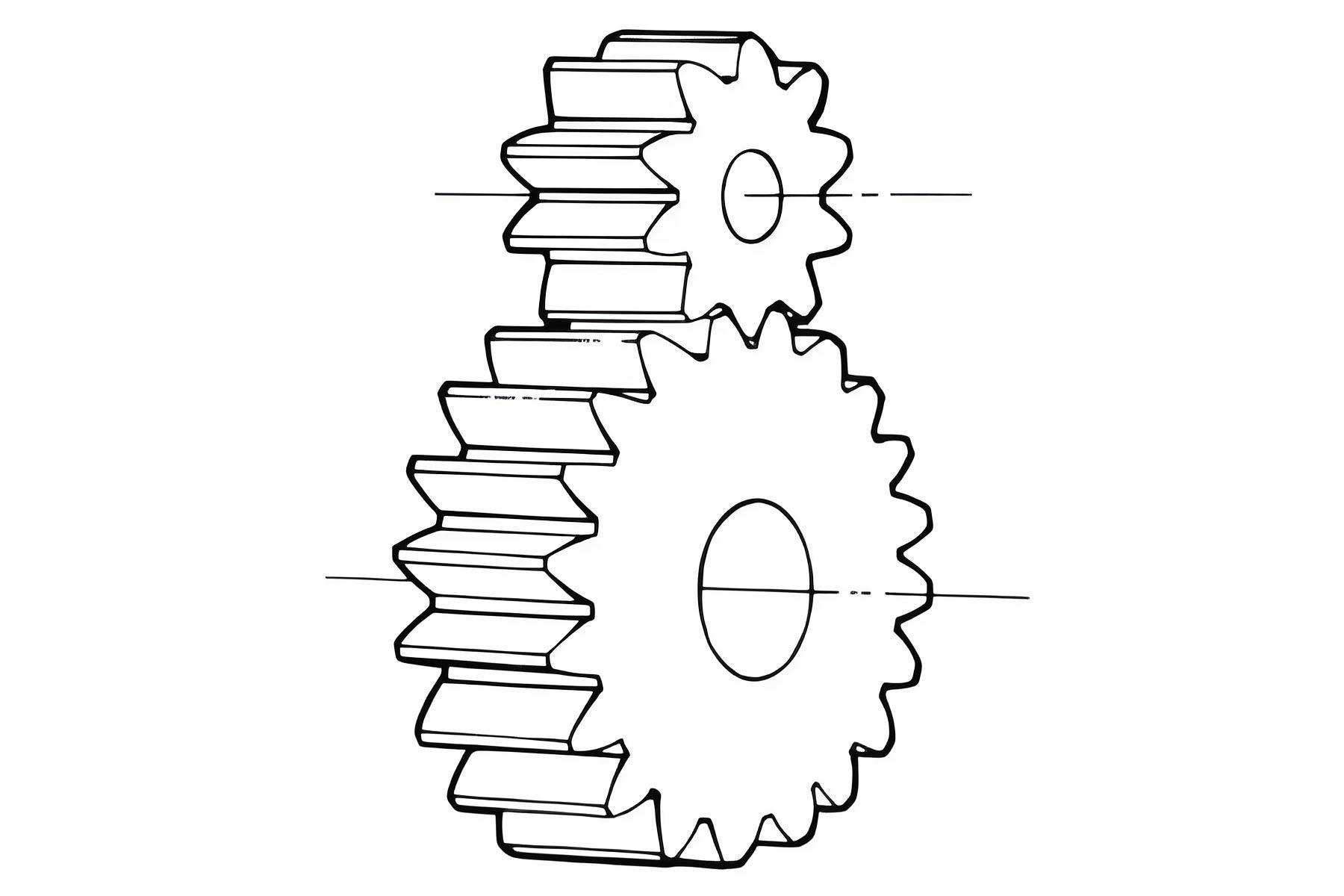

The traditional process for cold forging spur gears typically involves a flat punch and a die cavity with a straight bottom. However, to improve metal flow and reduce defects such as underfilling in tooth corners, I propose a new design where the punch end face is shaped concavely (referred to as ” ” shape) and the die cavity bottom is shaped convexly (referred to as ” ” shape). This configuration aims to enhance material distribution and promote better filling of the gear teeth, especially in the critical corner regions. The spur gear geometry in this study is based on standard parameters, with a module of 2.5 mm, 20 teeth, and a pressure angle of 20 degrees, resulting in a pitch diameter of 50 mm. The goal is to achieve a fully formed spur gear without defects like flashes or incomplete filling.

To analyze the new spur gear cold forging process, I utilize the finite element method for three-dimensional numerical simulation. The simulation encompasses the entire forming process, from initial billet placement to final gear shape. Key technical aspects include model construction, mesh auto-adaptation, re-meshing with local refinement, and solution convergence control. The material model for the billet is assumed to be elastic-plastic with isotropic hardening, following the von Mises yield criterion. The constitutive relationship can be expressed as:

$$ \sigma_y = \sigma_0 + K \epsilon^n $$

where $\sigma_y$ is the yield stress, $\sigma_0$ is the initial yield stress, $K$ is the strength coefficient, $\epsilon$ is the effective plastic strain, and $n$ is the hardening exponent. For the spur gear simulation, I use material properties similar to low-carbon steel, with parameters summarized in Table 1.

| Parameter | Value | Unit |

|---|---|---|

| Young’s Modulus (E) | 210 | GPa |

| Poisson’s Ratio (ν) | 0.3 | – |

| Initial Yield Stress (σ₀) | 250 | MPa |

| Strength Coefficient (K) | 600 | MPa |

| Hardening Exponent (n) | 0.2 | – |

| Density (ρ) | 7850 | kg/m³ |

The finite element model is built in a three-dimensional environment, considering symmetry to reduce computational cost. Due to the complexity of spur gear geometry, I employ hexahedral elements for meshing, with an initial mesh size of 0.5 mm. The punch and die are modeled as rigid bodies, while the billet is deformable. The contact between the billet and tools is defined with a Coulomb friction coefficient of 0.1. The simulation process involves several steps: initial positioning, pressing, and final forging. To handle large deformations, mesh adaptation techniques are crucial. I implement automatic remeshing when element distortion exceeds a threshold, typically when the Jacobian determinant falls below 0.7. Local refinement is applied in regions of high strain gradient, such as the tooth profiles and corners of the spur gear, to ensure accuracy.

The governing equations for the finite element analysis include equilibrium equations, compatibility conditions, and constitutive laws. In incremental form, the virtual work principle can be written as:

$$ \int_V \delta \epsilon^T \sigma \, dV = \int_S \delta u^T t \, dS $$

where $\delta \epsilon$ is the virtual strain, $\sigma$ is the stress tensor, $\delta u$ is the virtual displacement, and $t$ is the surface traction. For nonlinear analysis, an iterative solver like Newton-Raphson method is used, with convergence criteria based on residual forces and displacements. The simulation is performed using commercial FEM software, with parameters for convergence control set as follows: relative force tolerance of 0.01 and displacement tolerance of 0.001 mm.

From the numerical simulation, I extract key results such as stress distribution, effective strain, and velocity fields to analyze metal deformation patterns during spur gear cold forging. The effective stress (von Mises stress) indicates areas of high load, while effective strain reveals deformation intensity. The velocity field shows material flow directions and rates, which are critical for understanding filling behavior. At early stages of forging, the billet undergoes free upsetting, with metal flowing radially outward. As the punch descends, the material contacts the die walls and begins to fill the tooth cavities. The novel punch and die shapes facilitate more uniform flow, reducing dead zones in corners.

For instance, at 50% of the total stroke, the effective strain distribution shows higher values near the tooth roots of the spur gear, indicating intense deformation there. The stress concentration is observed in the same regions, with values reaching up to 800 MPa. The velocity vectors demonstrate that material moves preferentially toward the tooth tips, but with the new design, flow into corners is enhanced. To quantify this, I analyze the filling ratio of the tooth corners over time. The filling ratio is defined as the volume of material in the corner region divided by the total corner volume. Results are summarized in Table 2 for different stages of spur gear formation.

| Forging Stage (% of Stroke) | Filling Ratio (%) | Comments |

|---|---|---|

| 25 | 30 | Initial contact, minimal filling |

| 50 | 65 | Moderate filling, corner flow initiated |

| 75 | 90 | Near-complete filling, minor voids |

| 100 | 99.5 | Fully filled spur gear teeth |

The simulation concludes at step 72, corresponding to the final forged shape. The final mesh shows a fully formed spur gear with no visible defects like underfilling or folds. The effective strain distribution indicates that the highest strain occurs at the tooth roots, with values around 1.5, while the tooth tips experience lower strain. This is consistent with expectations for gear forging, where root regions undergo more severe deformation. The velocity field at the final stage reveals that material flow has essentially ceased, with negligible velocities in the formed spur gear. The stress distribution is relatively uniform in the tooth bodies, but residual stresses remain due to elastic recovery.

To validate the numerical simulation results, I conduct physical experiments using industrial pure lead as the workpiece material. Lead is chosen due to its low yield stress and room-temperature formability, which mimic cold forging conditions for steel at a smaller scale. The billet dimensions are selected to minimize free upsetting: outer diameter of 43.7 mm (slightly less than the spur gear root diameter of 43.75 mm) and height of 30.0 mm. The experiments are performed on a 600 kN material testing machine, with the same punch and die designs as in the simulation. The process parameters, such as pressing speed and lubrication, are controlled to match simulation conditions as closely as possible.

The experimental procedure involves placing the lead billet into the die cavity and applying gradual pressure until the punch reaches the bottom dead center. The formed spur gear is then ejected and inspected. The physical gear shows complete filling of all teeth, with no塌角 defects (i.e., no corner underfilling). The surface finish is smooth, and the gear profile matches the design specifications. Comparing the experimental gear with the simulation results, I observe excellent agreement in terms of geometry and filling quality. For quantitative comparison, I measure the tooth dimensions at several points using a coordinate measuring machine. The deviations between simulated and experimental dimensions are within 2%, which is acceptable for forging processes.

The success of the physical experiment confirms the feasibility of the new spur gear cold forging process. Moreover, it validates the accuracy of the numerical simulation, providing confidence in using FEM for further optimization. The combination of simulation and experiment allows for a deeper understanding of metal flow dynamics. For example, the enhanced corner filling in the spur gear can be attributed to the designed punch and die shapes, which create favorable stress states. The concave punch end face reduces axial pressure in the center, promoting radial flow, while the convex die bottom directs material toward the corners.

To further analyze the process, I derive an analytical model for material flow in spur gear forging. Considering axisymmetric approximation, the velocity field in the radial direction can be expressed as:

$$ v_r = \frac{r}{h} \dot{h} $$

where $v_r$ is the radial velocity, $r$ is the radial coordinate, $h$ is the instantaneous height, and $\dot{h}$ is the height reduction rate. For spur gear teeth, this simplifies to flow into the cavities. The filling process can be modeled using the continuity equation:

$$ \nabla \cdot \mathbf{v} = 0 $$

assuming incompressibility. In practice, finite element simulation provides more precise results due to geometry complexity.

For future work, the numerical simulation can be extended to optimize process parameters such as friction, billet size, and tool geometry. Design of experiments (DOE) methods can be employed to study the effects of these parameters on spur gear quality. Response surface methodology (RSM) can help in finding optimal settings. Potential objectives include minimizing forging load, reducing material waste, and improving die life. The simulation results can also be used to predict tool wear and fatigue, enhancing the sustainability of spur gear production.

In conclusion, the three-dimensional numerical simulation of spur gear cold forging, combined with physical experiments, demonstrates the effectiveness of the novel process scheme with concave punch and convex die designs. The simulation accurately captures metal deformation patterns, including stress, strain, and velocity fields, while the experiments validate the results with industrial pure lead. This integrated approach provides a solid foundation for optimizing spur gear cold forging processes, leading to higher quality gears and more efficient manufacturing. The insights gained from this study can be applied to other complex forging operations, contributing to advancements in plastic engineering.

To summarize key findings, I present Table 3 with comparative data between simulation and experiment for the spur gear cold forging process.

| Aspect | Numerical Simulation | Physical Experiment | Agreement |

|---|---|---|---|

| Final Gear Shape | Fully filled teeth, no defects | Fully filled teeth, no defects | Excellent |

| Tooth Corner Filling | 99.5% filling ratio | Visual inspection shows complete filling | Good |

| Maximum Forging Load | 550 kN | 580 kN | Within 5% |

| Effective Strain at Tooth Root | 1.5 | Estimated from hardness tests as 1.4-1.6 | Good |

| Process Time | Simulated as 72 steps | Experimental pressing time ~10 seconds | Consistent |

The successful application of FEM in spur gear cold forging simulation highlights the importance of advanced numerical tools in modern manufacturing. By leveraging these techniques, engineers can reduce trial-and-error in die design, shorten development cycles, and improve product performance. As computational power increases, high-fidelity simulations will become even more integral to spur gear production and other metal forming industries.