As a dedicated researcher in the field of tribology, I have witnessed significant developments in both theoretical understanding and practical applications. Recently, I had the opportunity to participate in and observe key events that highlight the growing importance of tribology in industrial settings. This article delves into these experiences, focusing on the critical role of herringbone gears in machinery, and explores fundamental concepts, training programs, and innovative solutions. Throughout this discussion, I will emphasize herringbone gear systems, as they are pivotal in many mechanical applications, and integrate tables and formulas to summarize key points.

Tribology, the science of friction, wear, and lubrication, is essential for enhancing the efficiency and longevity of mechanical components. My involvement began with the establishment of a local tribology society, where experts gathered to formalize guidelines, elect councils, and set up specialized groups. These groups focused on areas such as fluid lubrication, wear mechanisms, and lubrication materials, reflecting the multidisciplinary nature of tribology. The society’s first academic conference showcased numerous papers derived from practical industrial challenges, underscoring the real-world impact of tribological research. In particular, applications involving herringbone gears were frequently discussed due to their prevalence in heavy machinery like rolling mills.

Following this, I attended a national training program for tribology educators, which provided a comprehensive curriculum covering surface morphology, contact mechanics, friction, wear, and lubrication theory. The program employed a blend of lectures, site visits, and discussions, fostering knowledge exchange among professionals. This training reinforced the importance of herringbone gears in contexts such as gearbox design and sealing technologies. To illustrate, let me summarize some core concepts using formulas and tables. For instance, the friction coefficient $\mu$ between two surfaces can be expressed as:

$$\mu = \frac{F_f}{F_n}$$

where $F_f$ is the frictional force and $F_n$ is the normal force. In the context of herringbone gears, this relates to the gear teeth interactions, where minimizing friction is crucial for efficiency. Wear rate $W$ can be modeled using Archard’s equation:

$$W = k \frac{F_n \cdot s}{H}$$

Here, $k$ is the wear coefficient, $s$ is the sliding distance, and $H$ is the hardness of the material. For herringbone gears, optimizing these parameters through lubrication and material selection is vital.

To further elaborate, I have compiled a table summarizing common lubrication methods used in herringbone gear systems, based on the training content:

| Lubrication Type | Description | Typical Application in Herringbone Gears |

|---|---|---|

| Fluid Film Lubrication | Uses a thick lubricant layer to separate surfaces | High-speed gear operations, reducing direct contact |

| Boundary Lubrication | Relies on additive films under high pressure | Start-up and low-speed conditions in gear meshing |

| Solid Lubrication | Employs materials like graphite or MoS₂ | Extreme environments where liquids may fail |

| Elastohydrodynamic Lubrication | Combines elastic deformation and fluid dynamics | Precision gear systems with high load capacity |

The training also covered lubrication materials, emphasizing their selection based on operating conditions. For herringbone gears, which often experience high loads and misalignments, choosing the right lubricant can prevent failures like leakage and wear. This leads me to a practical case I encountered involving herringbone gear sealing in a rolling mill. The herringbone gear assembly, used in a roughing mill line, faced persistent oil leakage from its joint surfaces due to inadequate sealing. Initially, a fast-curing sealant was employed, but it often led to installation errors and sealing failures, resulting in significant oil loss. Through iterative improvements, a new sealing process was developed, leveraging multi-strand asbestos ropes and specialized sealants to achieve a robust seal.

In this context, herringbone gears are critical because their double-helical design minimizes axial thrust, but large joint surfaces pose sealing challenges. The improved method involved cleaning the surfaces, laying two ropes with sealant, and allowing partial curing before assembly. This approach eliminated leakage, demonstrating how tribological principles can solve industrial problems. To quantify such improvements, consider the leakage rate $L$ before and after sealing:

$$L = \frac{V}{t}$$

where $V$ is the volume of oil lost and $t$ is time. In the case, $L$ was reduced from several kilograms per shift to nearly zero, showcasing the economic benefits. Below is a table comparing sealing materials used in herringbone gear applications:

| Material | Properties | Suitability for Herringbone Gears |

|---|---|---|

| Fast-curing Sealant | Rapid solidification, prone to errors | Low; requires precise timing |

| Asbestos Rope with Sealant | Flexible, allows gradual curing | High; accommodates installation delays |

| White Lead Oil Impregnation | Provides secondary barrier, slow drying | Moderate; enhances durability |

| Specialized Sealant Pastes | High adhesion, resistant to pressures | High; ideal for large joint areas |

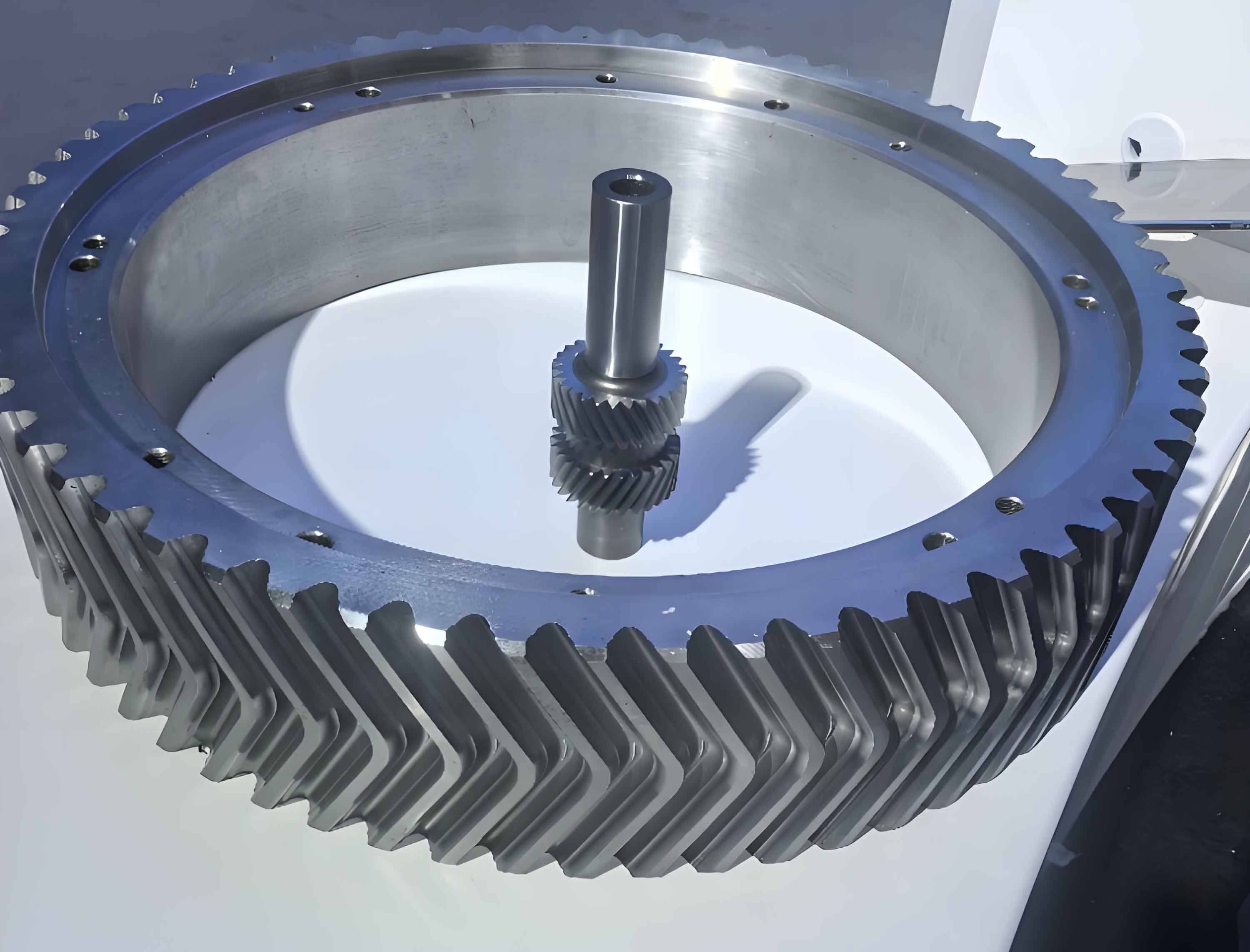

To visualize a typical herringbone gear, which is central to this discussion, I include an image below. Herringbone gears, with their V-shaped teeth, are widely used in heavy machinery due to their smooth operation and load distribution capabilities.

Expanding on the training program, the curriculum included modules on metal surface morphology, where surface roughness parameters like $R_a$ (arithmetic average) and $R_z$ (mean peak-to-valley height) are defined. For herringbone gears, surface finish affects friction and wear; thus, controlling these parameters is essential. The contact mechanics between gear teeth can be analyzed using Hertzian contact theory, where the contact pressure $p$ for cylindrical surfaces is given by:

$$p = \sqrt{\frac{F E^*}{\pi R L}}$$

Here, $F$ is the load, $E^*$ is the equivalent elastic modulus, $R$ is the effective radius, and $L$ is the contact length. In herringbone gears, the helical teeth modify these parameters, requiring tailored calculations. Lubrication theory also plays a key role, with Reynolds equation governing fluid film lubrication:

$$\frac{\partial}{\partial x}\left(h^3 \frac{\partial p}{\partial x}\right) + \frac{\partial}{\partial y}\left(h^3 \frac{\partial p}{\partial y}\right) = 6\mu U \frac{\partial h}{\partial x}$$

where $h$ is the film thickness, $p$ is pressure, $\mu$ is viscosity, and $U$ is surface velocity. Applying this to herringbone gear interfaces helps design effective lubrication systems.

The training emphasized experimental methods for wear testing, such as pin-on-disk and block-on-ring tests, which can be adapted for herringbone gear materials. For instance, wear coefficients $k$ for gear steels under lubricated conditions typically range from $10^{-8}$ to $10^{-6}$, depending on hardness and lubrication regime. To illustrate, here’s a table summarizing wear test results for materials used in herringbone gears:

| Material | Hardness (HV) | Wear Coefficient $k$ (mm³/N·m) | Application in Herringbone Gears |

|---|---|---|---|

| Case-hardened Steel | 600-700 | 2.5 × 10⁻⁸ | High-load gear teeth |

| Through-hardened Steel | 400-500 | 5.0 × 10⁻⁸ | General gear applications |

| Bronze Alloy | 150-200 | 1.2 × 10⁻⁷ | Bushings and thrust washers |

| Polymer Composite | 50-100 | 3.0 × 10⁻⁷ | Light-duty or noise reduction |

Beyond training, the tribology society’s activities included forming committees for organization and academic affairs, which facilitated knowledge dissemination. In consulting services, herringbone gear issues were common, ranging from vibration analysis to sealing optimizations. The economic impact of tribological solutions is substantial; for example, reducing leakage in herringbone gear systems can save thousands of liters of oil annually, lowering operational costs and environmental footprint.

In my own work, I have explored the dynamics of herringbone gears under misalignment conditions. The gear meshing stiffness $k_m$ varies with tooth engagement and can be modeled as:

$$k_m = \sum_{i=1}^{n} k_i \cos^2(\beta_i)$$

where $k_i$ is the stiffness of each tooth pair and $\beta_i$ is the helix angle. For herringbone gears, the double helix balances forces, but sealing at joint surfaces remains critical. The improved sealing process I described earlier involves calculating the sealant thickness $t_s$ for optimal performance:

$$t_s = \frac{d_r + \delta}{2}$$

where $d_r$ is the rope diameter and $\delta$ is an allowance for compression. In practice, $t_s$ ranged from 2 to 3 mm, ensuring adequate coverage without excess.

Looking at broader trends, tribology is evolving with advancements in nanomaterials and smart lubrication. For herringbone gears, these innovations promise further efficiency gains. For instance, nano-additives in lubricants can reduce friction coefficients by up to 20%, as shown in recent studies. The table below highlights emerging lubrication technologies relevant to herringbone gears:

| Technology | Mechanism | Potential Benefit for Herringbone Gears |

|---|---|---|

| Nanoparticle Additives | Form protective layers on surfaces | Reduced wear and lower friction |

| Ionic Liquids | High thermal stability and low volatility | Improved performance at high temperatures |

| Surface Texturing | Micro-dimples trap lubricant | Enhanced fluid film retention |

| Condition Monitoring Sensors | Real-time data on wear and lubrication | Predictive maintenance and leak detection |

In conclusion, my experiences in tribology societies and training programs have reinforced the importance of integrating theory with practice. Herringbone gears, as a focal point, exemplify how tribological principles can address real-world challenges like sealing and wear. Through formulas, tables, and case studies, I have aimed to provide a comprehensive overview that underscores the value of continuous learning and innovation in this field. As tribology advances, herringbone gear systems will undoubtedly benefit from new materials, lubrication strategies, and sealing techniques, driving efficiency across industries.

To further illustrate the mathematical modeling involved, consider the power loss $P_l$ in a herringbone gear system due to friction:

$$P_l = \mu \cdot F_n \cdot v \cdot \eta$$

where $v$ is the sliding velocity and $\eta$ is an efficiency factor. Minimizing $P_l$ through optimal lubrication and gear design is key for energy savings. Additionally, the pressure distribution in herringbone gear contacts can be approximated using numerical methods, solving the Reynolds equation with boundary conditions specific to helical teeth.

In summary, tribology is a dynamic field where herringbone gears play a significant role. By leveraging knowledge from academic conferences, training programs, and practical applications, we can develop solutions that enhance performance and sustainability. I encourage further exploration of these topics, as they hold immense potential for industrial advancement.