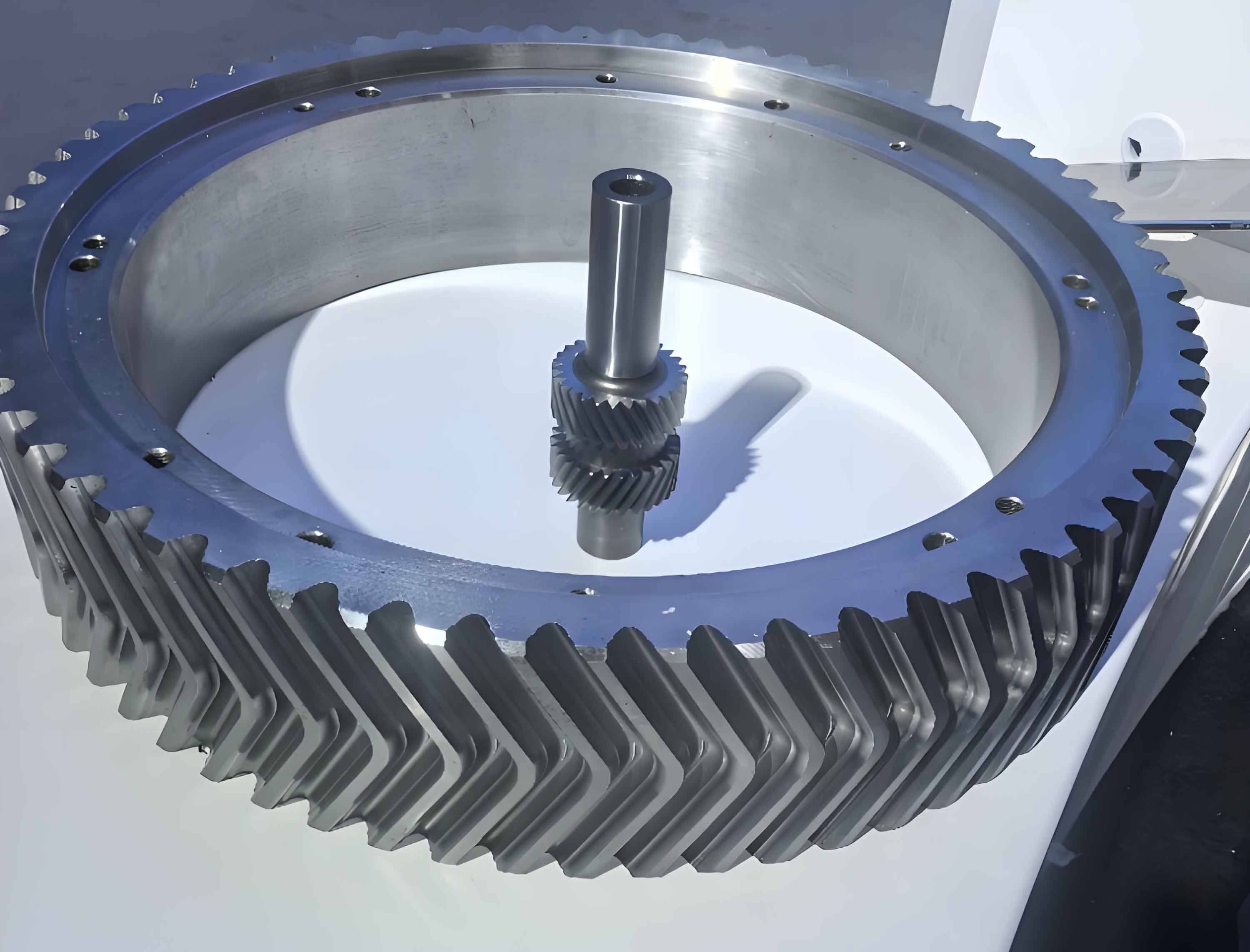

In the steel rolling industry, the durability of herringbone gears used in main drives of plate mills has long been a critical concern. These herringbone gears, essential for transmitting high torque under severe conditions, often suffer from premature failure, leading to frequent downtime and economic losses. This article details a comprehensive practice aimed at significantly extending the lifespan of herringbone gears in a plate mill drive, based on systematic analysis, targeted improvements, and rigorous industrial validation. Throughout this work, the focus remained on optimizing the design, material, and manufacturing of herringbone gears to overcome inherent weaknesses.

The herringbone gears in question were part of an older plate mill drive originally designed for an annual output of 300,000 tons, but operational demands had pushed production to over 600,000 tons, doubling the load on the gear system. This overloading exacerbated issues such as tooth surface damage, breakage, and shaft failures, with up to five gear shafts being scrapped in a single year due to pitting, plastic deformation, and fractures. The herringbone gears, with their unique double-helical structure, were particularly vulnerable due to a combination of factors. To address this, a research project was initiated to explore enhancement pathways, with the herringbone gears serving as a case study for broader applications in rolling mill gear units.

In analyzing the problems with the original herringbone gears, several key issues were identified. First, the forging quality of the gear blank was poor, with defects like inclusions and porosity, especially in the flange areas, leading to stress concentrations and fractures. The herringbone gears were initially cast with low surface hardness, and subsequent modifications, such as flame hardening, introduced micro-cracks and uneven hardness. Second, manufacturing precision was low; the gears were machined with finger-type milling cutters, resulting in inaccuracies that reduced contact ratios and increased stress. Third, the tooth profile parameters were suboptimal: a large module, small number of teeth, low pressure angle, and small helix angle minimized the total contact ratio, compromising both bending and contact strength. Fourth, structural aspects like the flange and fork head dimensions were not proportionally adjusted when the flange diameter was increased, worsening forging difficulties without benefits. Fifth, operational overloading was evident, with measured rolling torques exceeding design limits by significant margins. Lastly, lubrication was inadequate, with low-viscosity oil failing to protect the herringbone gears under high-impact conditions.

| Issue Category | Specific Problems | Impact on Herringbone Gears |

|---|---|---|

| Material Quality | Poor forging, inclusions, low toughness | Fractures in flanges and teeth |

| Manufacturing Precision | Low accuracy from finger milling, unground teeth | Reduced contact ratio, high localized stress |

| Tooth Profile Design | Large module, few teeth, low pressure angle | Low bending and contact strength |

| Structural Design | Unbalanced flange and fork head dimensions | Increased failure risk in shaft ends |

| Operational Loads | Overloading beyond design torque | Accelerated wear and fatigue |

| Lubrication | Low-viscosity oil, poor film formation | Increased pitting and scuffing |

To address these challenges, a multi-faceted improvement strategy was implemented, focusing on the herringbone gears’ entire lifecycle. First, the material quality was enhanced by using electroslag remelted steel for blanks, with a forging ratio above 3 to refine grain structure and reduce inclusions. This improved mechanical properties, notably impact toughness, which is crucial for herringbone gears under shock loads. The blanks were subjected to double tempering: after rough machining, a second tempering ensured a hardened layer remained post-finishing, achieving a surface hardness of $$280-320 \text{ HB}$$. This approach balanced strength and toughness, vital for the herringbone gears’ performance.

Second, manufacturing precision was elevated by adopting gear shaping instead of milling. The herringbone gears, which lacked relief grooves along the tooth width, were precision-cut on gear shapers, improving accuracy from Grade 8 to Grade 6 per relevant standards. This enhanced the meshing smoothness and load distribution across the herringbone gears. Third, the tooth profile parameters were optimized through computational analysis. After evaluating ten schemes, the selected design featured a reduced module, increased tooth count, and a higher pressure angle. For instance, the module was decreased, teeth number increased, and pressure angle raised to $$25^\circ$$. This increased the total contact ratio from approximately 1.5 to over 2.0, boosting both bending and contact strength. The contact strength capacity was calculated to improve by a factor, while bending strength saw a similar gain. The formulas used for these calculations are based on standard gear design principles:

For contact strength, the Hertzian stress formula applies: $$\sigma_H = Z_E \sqrt{\frac{F_t}{b d_1} \cdot \frac{u+1}{u} \cdot Z_H Z_\epsilon}$$ where $$Z_E$$ is the elasticity factor, $$F_t$$ is the tangential force, $$b$$ is face width, $$d_1$$ is pitch diameter, $$u$$ is gear ratio, $$Z_H$$ is zone factor, and $$Z_\epsilon$$ is contact ratio factor. For herringbone gears, the double-helical design increases effective face width and contact ratio, reducing $$\sigma_H$$.

For bending strength, the Lewis formula is adapted: $$\sigma_F = \frac{F_t}{b m_n} Y_F Y_S Y_\beta Y_K$$ where $$m_n$$ is normal module, $$Y_F$$ is form factor, $$Y_S$$ is stress correction factor, $$Y_\beta$$ is helix angle factor, and $$Y_K$$ is load distribution factor. With optimized parameters, the form factor $$Y_F$$ decreases, enhancing safety against tooth breakage in herringbone gears.

Fourth, structural modifications were made to the shaft ends: flange thickness was increased, and fork head dimensions adjusted to better distribute loads. Fifth, tooth length correction was applied; after machining, the herringbone gears showed end thickening, so a taper of 0.02-0.03 mm was ground along the tooth ends over 150-200 mm to improve contact patterns. Sixth, rigorous inspection was implemented using custom-built instruments for pitch, base tangent length, and radial runout measurements, ensuring the herringbone gears met design specs. Seventh, lubrication was upgraded to a higher-viscosity extreme pressure gear oil (e.g., 680 grade), with automated flow control and regular filtration to maintain cleanliness. Finally, field measurements confirmed rolling torques, providing data for design validation.

| Parameter | Original Herringbone Gears | Improved Herringbone Gears | Impact |

|---|---|---|---|

| Module (mm) | Large value (e.g., 30) | Reduced (e.g., 24) | Lower bending stress |

| Number of Teeth | Few (e.g., 20) | Increased (e.g., 30) | Higher contact ratio |

| Pressure Angle | 20° | 25° | Increased root thickness, reduced sliding |

| Helix Angle | Small (e.g., 15°) | Optimized (e.g., 25°) | Better load sharing |

| Surface Hardness (HB) | 180-220 | 280-320 | Enhanced wear resistance |

| Manufacturing Accuracy | Grade 8 | Grade 6 | Improved meshing |

| Total Contact Ratio | ~1.5 | >2.0 | Lower contact stress |

The industrial trial of the improved herringbone gears commenced and spanned over two years, with periodic inspections to monitor performance. Initially, after a few days of operation, early pitting was observed on tooth surfaces, concentrated at the ends and apex of the herringbone gears, along with local interference at the tooth roots. This was attributed to bearing wear, installation errors, and lack of run-in under load. However, over time, the damage progression slowed and began to converge. By the sixth inspection, severe damage was noted, including pitting, scuffing, and plastic deformation, but after bearing repairs and continued operation, subsequent checks showed the damage diminishing: pitting pits shallowed, edges smoothed, and surface hardness increased due to work-hardening to around $$300 \text{ HB}$$. Minor issues like edge chipping were addressed by adding tip relief of 0.5-1.0 mm. The table below summarizes the performance comparison between the old and new herringbone gears, highlighting the lifespan extension and reduced wear.

| Aspect | Old Herringbone Gears (Prior Use) | New Herringbone Gears (Trial Period) |

|---|---|---|

| Service Duration | Typically 6-12 months before failure | Over 24 months and still operational |

| Steel Rolled (tons) | ~300,000 per gear set | ~600,000 and continuing |

| Tooth Surface Damage | Severe pitting, scuffing, plastic deformation zones ~20 mm wide | Initial pitting and scuffing, but damage converged; plastic zones ~15 mm wide |

| Non-Working Flank Condition | Scratched and pitted | No contact, undamaged |

| Wear Amount (mm) | Upper/lower gears: ~1.0-1.5 on working flanks | Upper/lower gears: ~0.3-0.5 on working flanks |

| Increase in Backlash (mm) | ~2.0 | ~0.8 |

| Failure Modes | Frequent tooth breakage, flange fractures | Minimal; only minor surface issues |

The success of this practice with herringbone gears underscores several key conclusions. First, optimizing tooth profile parameters—such as reducing module, increasing tooth count, and adopting a higher pressure angle like $$25^\circ$$—significantly boosts the load capacity of herringbone gears. The total contact ratio, a critical factor for herringbone gears, can be enhanced through careful design, as shown by the formula for contact ratio: $$\epsilon_\gamma = \epsilon_\alpha + \epsilon_\beta$$ where $$\epsilon_\alpha$$ is transverse contact ratio and $$\epsilon_\beta$$ is overlap ratio. For herringbone gears, $$\epsilon_\beta$$ is high due to the double helix, contributing to smoother operation. Second, structural improvements in shaft ends, like balanced flange and fork head dimensions, enhance overall durability. Third, using high-quality materials with medium-hard tooth surfaces proves effective for retrofitting old gear drives; the herringbone gears benefited from refined steel with superior toughness and hardenability. Fourth, precision manufacturing via gear shaping is viable for herringbone gears without relief grooves, ensuring accuracy. Fifth, proper lubrication with high-viscosity extreme pressure oil is essential for herringbone gears under heavy loads and shock, reducing surface damage.

From an economic perspective, this upgrade of herringbone gears yielded substantial benefits: direct annual savings were estimated, and mill profitability increased due to reduced downtime. Over three years, the cumulative economic impact was significant, demonstrating the value of such retrofits. The herringbone gears, as critical components, now serve as a model for other rolling mill applications, where similar approaches can be applied to extend service life and improve reliability.

In summary, this practice highlights a holistic method for enhancing herringbone gears in demanding industrial environments. By integrating material science, precision engineering, and operational adjustments, the lifespan of herringbone gears can be dramatically extended. Future work may explore advanced coatings or real-time monitoring for herringbone gears, but the core principles established here—optimized design, quality manufacturing, and tailored maintenance—remain foundational. The herringbone gears in this plate mill drive now operate with greater resilience, underscoring the importance of continuous improvement in gear technology.