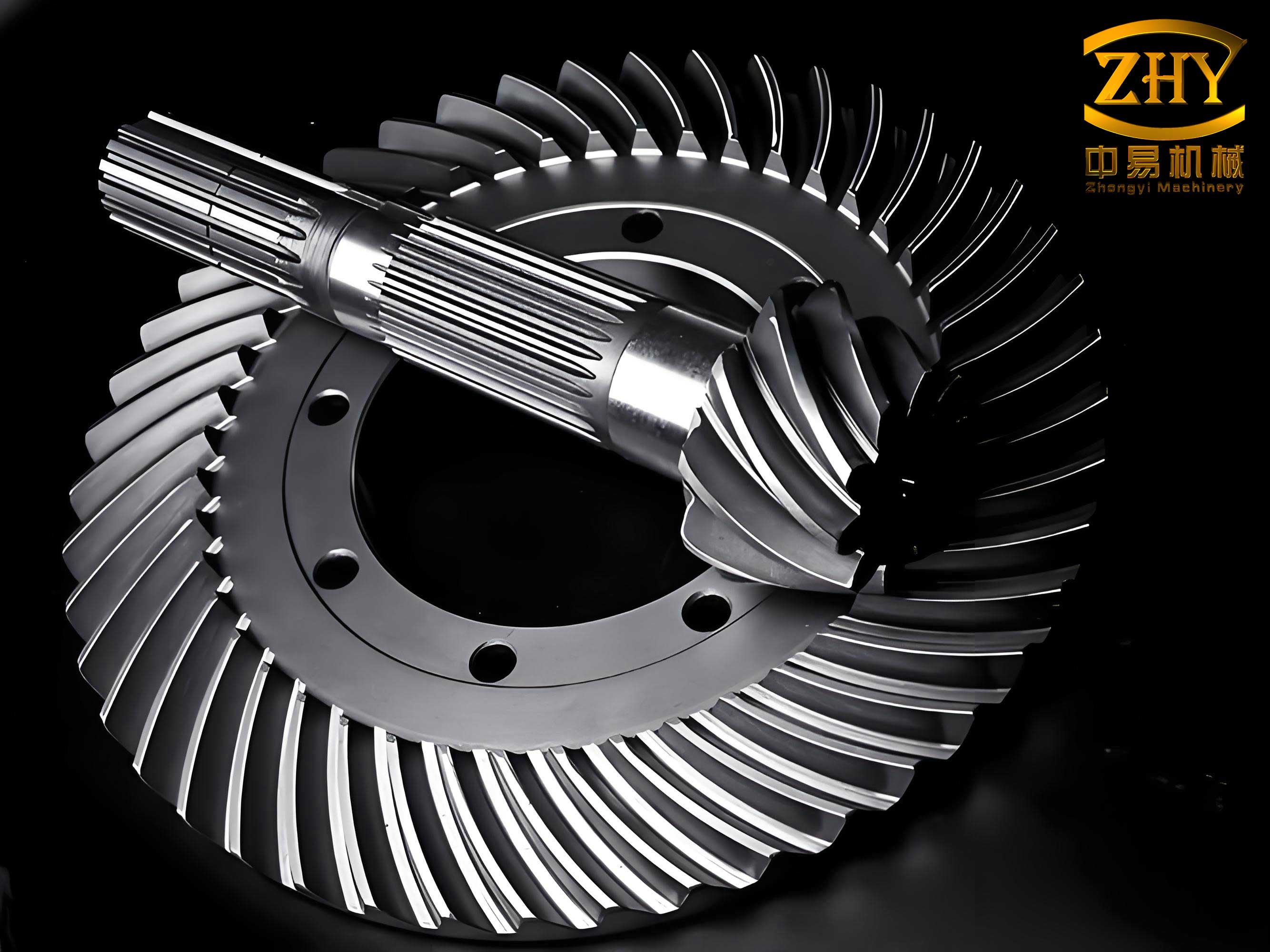

Spiral bevel gears are quintessential components in power transmission systems, renowned for their ability to transmit high torque between intersecting or offset axes smoothly and efficiently. Their curved teeth facilitate gradual engagement, which contributes to lower noise and vibration levels compared to straight bevel gears. Consequently, they are indispensable in critical applications ranging from agricultural and construction machinery to aerospace drive systems and automotive differentials. The pursuit of optimal performance in spiral bevel gears has driven extensive research into advanced design methodologies that enhance load capacity, reduce transmission error, and improve longevity. Among these, the concept of non-zero displacement and the use of the Local Synthesis method for manufacturing parameter design represent significant advancements beyond conventional design practices. This article delves into these integrated techniques, providing a comprehensive exploration of their principles, mathematical foundations, implementation for tooth contact analysis, and the pivotal role of computer-aided simulation for three-dimensional modeling and pre-manufacturing validation.

Fundamentals and Limitations of Conventional Spiral Bevel Gear Design

Traditional design of spiral bevel gears is largely based on standardized systems like the Gleason method. This approach establishes a direct relationship between the pitch cone and the root/face cones. The gear pair is designed to operate with a fixed, theoretically constant velocity ratio. The manufacturing parameters for cutting the pinion and gear are derived from a set of basic gear blank dimensions, often with limited flexibility to deviate from established norms. While this methodology is robust and well-understood, it presents several inherent limitations:

- Limited Control over Contact Pattern: The final contact pattern (the elliptical area of contact between mating teeth under load) is largely a consequence of the chosen standard parameters and the machine settings. It is difficult to pre-set or optimize the contact pattern’s location, size, and orientation for specific operational conditions prior to physical cutting and testing.

- Fixed Geometric Constraints: The range for selecting displacement coefficients (akin to addendum modification in cylindrical gears) is narrow. This restricts the designer’s ability to avoid undercutting on low-pinion-tooth-count designs, prevent pointed teeth, or balance bending stresses between the pinion and gear effectively.

- Trial-and-Error Prototyping: Due to the unpredictable nature of the contact pattern, the development cycle often requires multiple physical prototypes. Gears are cut, tested in a rolling tester, their contact patterns are examined, and machine settings are empirically adjusted in an iterative process. This is time-consuming and costly.

The mathematical foundation for a conventional spiral bevel gear tooth surface is generated by simulating the cutting process. The surface $$ \mathbf{r}^{(2)}(u, \theta) $$ of the gear (member 2) generated by a crown cutter (or a face-mill cutter) can be described by a series of coordinate transformations from the cutter coordinate system $$ S_c $$ to the gear coordinate system $$ S_2 $$:

$$

\mathbf{r}^{(2)}(u, \theta) = \mathbf{M}_{2c}(\phi_2) \cdot \mathbf{r}^{(c)}(u)

$$

Here, $$ \mathbf{r}^{(c)}(u) $$ is the cutter surface equation, $$ \theta $$ is the machine root angle or a related motion parameter, $$ \phi_2 $$ is the gear rotation angle linked to the cutter rotation via the machine’s generating roll ratio, and $$ \mathbf{M}_{2c} $$ is the homogeneous coordinate transformation matrix. The pinion surface $$ \mathbf{r}^{(1)} $$ is derived similarly but with its own unique set of machine settings ($$ \mathbf{M}_{1c} $$). The meshing of these two independently generated surfaces is not guaranteed to be optimal without careful, pre-meditated design of these transformation parameters.

The Principle of Non-Zero Displacement Design

The non-zero displacement design, also referred to as “separate cone design,” introduces a pivotal conceptual shift. It deliberately decouples the pitch cone from the standard reference cones (the root and face cones, now more appropriately termed the “design cones” or “reference cones”).

In conventional design, the pitch cone and the reference cone are coincident. In non-zero displacement design, they are separated by an offset. The key invariant is the pitch cone. The pitch cone angles ($$ \delta_1, \delta_2 $$), the pitch diameters, and consequently the nominal velocity ratio ($$ i_{12} = z_2 / z_1 $$) remain unchanged. This ensures the kinematic function of the gear pair is preserved. What changes are the angles of the reference cones ($$ \delta_{a1}, \delta_{a2} $$) from which the blank dimensions (addendum, dedendum, face angle, root angle) are calculated.

This separation is quantified by a parameter often denoted as the “displacement factor” or “ratio of modification,” $$ K_a $$. It relates the pitch circle radius ($$ R_p $$) to the reference circle radius ($$ R $$) on the back cone development:

$$

K_a = \frac{R_p}{R}

$$

For a standard gear pair, $$ K_a = 1 $$. For a non-zero displacement design:

– If $$ K_a > 1 $$, it is termed a positive displacement (or positive shift). The reference cone is “withdrawn” from the pitch cone, leading to a pinion with a thicker tooth root and a gear with a thinner tooth root compared to the standard design. This is analogous to a positive transmission in cylindrical gears.

– If $$ K_a < 1 $$, it is termed a negative displacement (or negative shift). The reference cone “advances” toward the pitch cone, resulting in a pinion with a thinner root and a gear with a thicker root.

The primary advantage of this approach is the dramatic expansion of the feasible range for the radial displacement coefficients ($$ x_1, x_2 $$). Designers can now select coefficients from a much broader “enclosed chart” (similar to the blocking contour diagram for cylindrical gears) to achieve specific goals:

- Avoiding undercutting on pinions with low tooth numbers.

- Preventing excessive tooth tip thinning.

- Achieving balanced bending strength between the pinion and gear.

- Optimizing the contact ratio.

The basic geometric calculations for non-zero displacement spiral bevel gears are outlined below. The pitch cone angles remain as standard:

$$

\delta_1 = \arctan\left(\frac{\sin \Sigma}{z_2/z_1 + \cos \Sigma}\right), \quad \delta_2 = \Sigma – \delta_1

$$

where $$ \Sigma $$ is the shaft angle. The reference cone angles are then modified:

$$

\delta_{a1} = \arctan\left( \frac{K_a \tan \delta_1}{1 – (1-K_a)(\tan \delta_1 / \tan \alpha_t)} \right), \quad \delta_{a2} = \Sigma – \delta_{a1}

$$

where $$ \alpha_t $$ is the transverse pressure angle at the reference point. The addendum and dedendum are calculated based on these new reference cone angles and the chosen displacement coefficients. The following table illustrates a comparative example of blank parameters for a gear pair designed with positive and negative non-zero displacement, highlighting the significant differences in tooth proportions.

| Parameter | Positive Displacement Design | Negative Displacement Design | ||

|---|---|---|---|---|

| Pinion | Gear | Pinion | Gear | |

| Number of Teeth (z) | 25 | 32 | 25 | 32 |

| Operating Pressure Angle, $$ \alpha_{op} $$ (°) | 25.865 | 25.865 | 22.337 | 22.337 |

| Displacement Factor, $$ K_a $$ | 1.016 | 1.016 | 0.988 | 0.988 |

| Radial Displacement Coefficient, $$ x $$ | +0.673 | +0.004 | -0.175 | -0.312 |

| Tangential Displacement Coefficient, $$ x_t $$ | +0.014 | +0.014 | +0.0081 | +0.0081 |

| Addendum at Reference Cone (mm) | 8.240 | 4.561 | 3.625 | 2.872 |

| Addendum at Pitch Cone (mm) | 6.881 | 2.333 | 4.674 | 4.589 |

| Dedendum at Reference Cone (mm) | 2.008 | 5.687 | 6.672 | 7.425 |

| Dedendum at Pitch Cone (mm) | 3.367 | 7.915 | 5.623 | 5.708 |

Local Synthesis Method for Pre-Controlled Meshing Performance

While non-zero displacement optimizes the macro-geometry of the gear blanks, the Local Synthesis method is employed to precisely design the micro-geometry of the tooth surfaces—the curvatures—to achieve a pre-defined, high-quality meshing condition. This method is grounded in the “local conjugate” principle, which acknowledges that perfect line contact (full conjugate action) is neither practical nor desirable for spiral bevel gears due to sensitivity to misalignment. Instead, a controlled point contact with a specific transmission error function is targeted.

The core idea of Local Synthesis is to start with a fully defined gear tooth surface (typically cut using a conventional duplex spread-blade method). At a chosen reference point $$ M $$ on this surface, the principal curvatures and directions are known or can be calculated. The designer then pre-specifies three key meshing conditions at this point for the desired pinion-gear pair:

- Tangent Direction of the Contact Path on the Gear ($$ \lambda_2 $$): This is the angle between the contact path and the gear root line at point $$ M $$. It influences the orientation of the contact ellipse across the tooth face.

- Second Derivative of the Transmission Error Function ($$ m_{21}’ $$): Transmission Error (TE) is defined as the deviation of the gear’s actual angular position from its theoretical position when the pinion rotates uniformly. Local Synthesis aims for a parabolic TE function: $$ \Delta \phi_2(\Delta \phi_1) = \frac{1}{2} m_{21}’ (\Delta \phi_1)^2 $$. A negative $$ m_{21}’ $$ produces a convex parabolic curve, which is known to be more forgiving to assembly misalignments (as it can absorb linear TE components) and helps reduce noise.

- Length of the Semi-Major Axis of the Contact Ellipse ($$ a $$): This controls the size of the instantaneous contact area under a specified load, influencing contact pressure.

Given these three conditions ($$ \lambda_2, m_{21}’, a $$) and the known gear surface curvatures at $$ M $$, the theory of differential geometry and gear meshing is used to uniquely solve for the required principal curvatures and directions of the pinion tooth surface at the conjugate point $$ M’ $$. Once the pinion’s surface curvatures at the reference point are known, the machine-tool settings (cutter geometry, radial, angular, and tilt settings, machine root angle, etc.) for generating that specific pinion surface can be calculated inversely.

The mathematical derivation involves the equations of meshing and the analysis of relative curvature. The relationship between the principal curvatures of the gear ($$ \kappa_f^{(2)}, \kappa_s^{(2)} $$) and the pinion ($$ \kappa_f^{(1)}, \kappa_s^{(1)} $$) at the contact point is governed by the normal curvature relationship in the direction of relative motion. The pre-set contact ellipse length $$ a $$ is related to the relative principal curvatures $$ \kappa_r $$ and the applied load $$ w $$ via the Hertzian contact theory approximation:

$$

a \propto \sqrt[3]{\frac{w}{\kappa_r}}

$$

The condition for the tangent direction $$ \lambda_2 $$ provides an equation linking the principal directions of the two surfaces. Finally, the condition for $$ m_{21}’ $$ is derived from the second-order expansion of the equation of meshing. Solving this system of equations yields the target pinion surface parameters. The following table exemplifies the resulting machine settings for the convex side of the pinion from the previous example, designed using Local Synthesis with identical target conditions.

| Parameter | Positive Displacement Design | Negative Displacement Design | ||

|---|---|---|---|---|

| Pinion (Convex Side) | Gear | Pinion (Convex Side) | Gear | |

| Cutter Diameter (mm) | 191.88 | 190.50 | 235.75 | 228.60 |

| Cutter Point Width / Bladel.ength (mm) | 2.54 | 2.50 | 2.54 | 2.50 |

| Machine Root Angle (°) | 36.298 | 48.009 | 35.081 | 49.040 |

| Radial Setting (mm) | 87.462 | 88.396 | 100.139 | 97.625 |

| Angular Setting/Cradle Angle (°) | 66.792 | -61.966 | 76.519 | -73.550 |

| Ratio of Roll / Generating Gear Ratio | 1.609772 | 1.265917 | 1.634278 | 1.267302 |

Tooth Contact Analysis (TCA) and 3D Simulation

After determining the machine settings through Local Synthesis, Tooth Contact Analysis (TCA) is performed to simulate the meshing of the theoretical pinion and gear surfaces across the entire cycle of engagement. TCA solves the system of equations stating that the position vectors and surface normals of both teeth must coincide at every instant of contact (considering the assembly position):

$$

\mathbf{r}_f^{(1)}(u_1, \theta_1, \phi_1) = \mathbf{r}_f^{(2)}(u_2, \theta_2, \phi_2)

$$

$$

\mathbf{n}_f^{(1)}(u_1, \theta_1, \phi_1) = \mathbf{n}_f^{(2)}(u_2, \theta_2, \phi_2)

$$

Here, $$ \phi_1 $$ and $$ \phi_2 $$ are the rotation angles of the pinion and gear, related by $$ \phi_2 = (z_1/z_2) \phi_1 + \Delta \phi_2(\phi_1) $$. Solving these equations numerically provides:

– The transmission error curve $$ \Delta \phi_2(\phi_1) $$ across the mesh cycle.

– The path of the contact point across both tooth surfaces.

– The orientation and dimensions of the contact ellipse at any position.

The results from the TCA for our example gear pair, designed with the same Local Synthesis targets ($$ \lambda_2=40^\circ, m_{21}’=-0.013, a=4.42 \text{ mm} $$), confirm the successful pre-control. Both designs exhibit symmetric, parabolic transmission error curves with modest amplitude. The contact paths are correctly oriented across the tooth faces, demonstrating that the methodology works effectively for both positive and negative non-zero displacement spiral bevel gears.

The final, crucial step is three-dimensional computer simulation for manufacturing validation. Using the calculated machine settings, the exact mathematical model of the cutting process is executed in software to generate the coordinates of points on the tooth flanks, fillets, and edges. These point clouds are then used to construct precise 3D solid models of the pinion and gear.

This simulation offers unparalleled insights before a single piece of metal is cut:

- Visualization of Tooth Form: It allows direct comparison of tooth shapes resulting from different displacement strategies. For instance, a positive displacement pinion will show noticeably thicker tooth roots and a more pronounced tooth tip taper compared to a negative displacement pinion.

- Detection of Geometric Issues: Potential problems like undercutting, excessive tooth tip thinning (pointing), or abnormal tooth profile shapes can be identified and corrected in the digital phase.

- Assembly and Interference Checking: The full assembly of the spiral bevel gear pair can be simulated to check for proper clearance and the absence of unintentional contact outside the active flank areas.

The 3D models generated from this process provide definitive geometric data, such as precise tooth thicknesses at various points, which are critical for manufacturing and quality control. The table below shows key tooth thickness data from the simulation, highlighting the tangible geometric differences between the two design approaches.

| Parameter | Positive Displacement Design | Negative Displacement Design | ||

|---|---|---|---|---|

| Pinion | Gear | Pinion | Gear | |

| Tip Thickness at Outer End (mm) | 2.475 | 4.207 | 3.573 | 3.973 |

| Chordal Thickness at Root, Outer End (mm) | 11.533 | 11.530 | 11.417 | 12.007 |

Conclusion and Engineering Significance

The integration of non-zero displacement design with the Local Synthesis method represents a sophisticated and powerful paradigm for the advanced engineering of spiral bevel gears. Non-zero displacement liberates the designer from traditional geometric constraints, enabling the optimal selection of displacement coefficients to improve strength, prevent defects, and tailor the macro-geometry for specific needs. The Local Synthesis method builds upon this by providing a deterministic, mathematical approach to design the tooth surface micro-geometry. It allows for the pre-control of critical meshing characteristics—the contact pattern location and orientation, the transmission error function, and the contact ellipse size—directly from the design stage.

The subsequent application of TCA validates these designs digitally, while 3D simulation and solid modeling translate theoretical parameters into a visual and geometrically precise representation of the final product. This integrated digital thread—from blank design (non-zero displacement) to surface design (Local Synthesis) to performance simulation (TCA) and physical validation (3D modeling)—dramatically reduces the reliance on costly and time-consuming physical trial-and-error. It shortens development cycles, lowers prototyping costs, and ensures that the manufactured spiral bevel gears will exhibit the desired high-performance characteristics from the first article. This methodology is particularly valuable for custom, high-performance applications of spiral bevel gears where reliability, efficiency, and noise control are paramount.