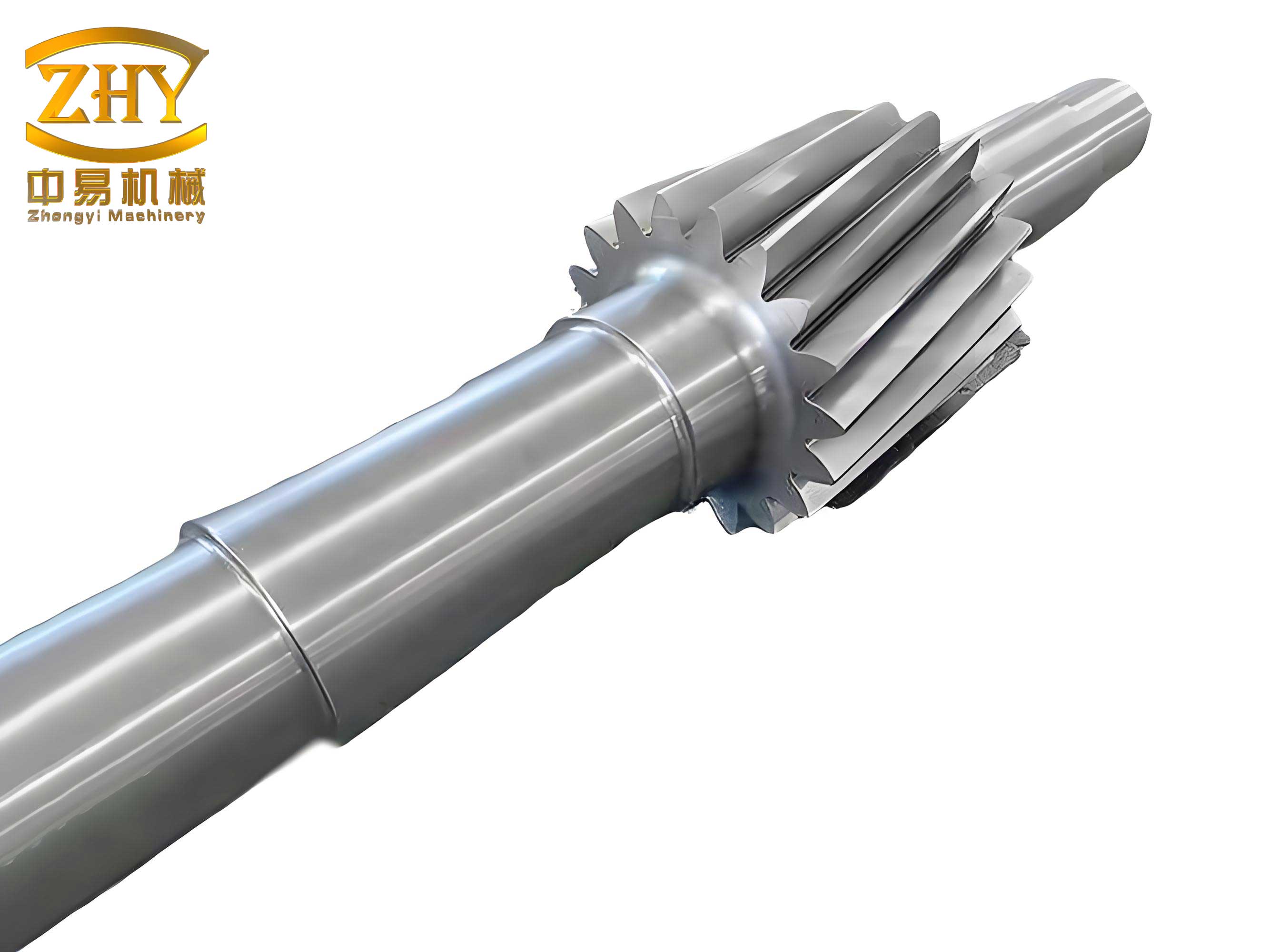

In my extensive experience designing precision injection molds for export, particularly for complex transmission components, the helical gear shaft presents a unique and fascinating challenge. This component is integral to countless mechanisms, offering superior performance over spur gears due to its gradual engagement, which results in smoother operation, higher load capacity, and reduced noise. When manufactured from engineering plastics like POM (Polyoxymethylene), the gear shaft gains additional benefits such as inherent lubrication, corrosion resistance, and weight reduction. However, its very geometry—a helical tooth form combined often with other features like external threads—demands a sophisticated mold design where conventional ejection is impossible. The core challenge lies in demolding the helical segment without damaging the delicate teeth. This article details a proven mold design for a helical gear shaft, focusing on the pivotal two-stage ejection mechanism that elegantly solves the demolding problem.

The specific gear shaft in question, as illustrated, is a compact component with a helical gear on one end and a shaft featuring an external thread on the other. Key specifications and material considerations are summarized below:

| Feature | Specification | Note |

|---|---|---|

| Gear Type | Helical (Right Hand) | 24 teeth, 32 diametral pitch |

| Helix Angle | 12° | Dictates rotation required for demolding |

| Major Dimensions | ~33.9 mm length, Ø20.65 mm max dia. | Compact part |

| Wall Thickness | ~1.5 mm (average) | Uniform for dimensional stability |

| Material | POM (Acetal) | |

| Shrinkage | 2.0% | Critical for gear tooth accuracy |

| Key Features | Helical gear, external thread, 8 internal torque-transfer slots | Multiple undercuts necessitate complex actions. |

POM was selected for its exceptional properties, which are ideal for a functional gear shaft:

$$ \text{High Stiffness} \approx E \sim 3.1 \, \text{GPa}, \quad \text{Low Friction} \implies \mu \sim 0.1-0.3, \quad \text{Excellent Fatigue Endurance} $$

Its low moisture absorption ensures dimensional stability of the gear teeth, and its high mechanical strength approaches that of metals, making it suitable for transmitting torque.

Core Mold Design Strategy

The design philosophy centered on separating the challenges: placing the threaded shaft section in the fixed (stationary) half and the helical gear section in the moving (ejection) half of the mold. This strategic decision simplifies the subsequent mechanisms.

Cavity Layout and Feeding

For high-volume production, a 1×12 cavity layout was implemented. The external thread requires a “split” or “side” core action, mandating that cavities be aligned linearly to accommodate the sliding mechanisms. Therefore, a double “Y” runner system feeding two rows of six cavities was designed to approximate runner balance and ensure consistent filling. The gate is a submarine-type located at the shoulder of the gear shaft, which shears off automatically during ejection.

Side Core Action for the External Thread

The external thread on the gear shaft is an undercut feature that cannot be released by a simple mold opening. A side-action using a “split core” or “haff block” mechanism is required. To optimize automation and prevent the part from sticking in the moving half, the mechanism was placed in the fixed half. Upon mold opening, springs drive the slanted split-core blocks outward, freeing the threaded section before any ejection occurs. Wear plates and interchangeable insert details ensure longevity and maintainability.

The Heart of the Design: Two-Stage Ejection Mechanism

The demolding of the helical gear shaft is the most critical aspect. A direct linear push would shear the plastic teeth. The solution is to force the gear shaft to rotate out of its helical cavity. This is achieved through a precisely timed two-stage ejection system.

The ejection system consists of two independent plates:

1. Upper Ejection Plate Assembly: Holds the helical gear cavity inserts.

2. Lower Ejection Plate Assembly: Holds the ejector pins (for the shaft bore) and the runner ejectors.

These plates are initially coupled by heavy-duty return springs and a system of limit bolts.

The sequence of operation is as follows:

| Stage | Action | Kinematic Result |

|---|---|---|

| Mold Opening | Fixed and moving halves separate. Side cores retract, freeing the threaded section. | Gear shaft remains in moving half, locked in helical cavity. |

| Ejection Stage 1 | Machine ejector rod pushes the lower ejection plate. Springs transfer force to the upper ejection plate. Both plates advance together. | The entire gear shaft is pushed linearly out of the main core pin. The helical gear is still engaged in its rotating insert. |

| Transition | After a precise travel distance \( S_1 \) (e.g., 6.35 mm), the upper plate is stopped by a positive mechanical stop (e.g., support pillars). | The helical gear cavity insert stops moving. |

| Ejection Stage 2 | The lower ejection plate continues its advance alone, pushing the gear shaft via the central ejector pin. | The gear shaft is forced to rotate as it is linearly pushed out of the now-stationary helical cavity insert. The motion is governed by the helix angle \(\beta\): $$ S_2 = r \cdot \theta \cdot \tan(\beta) $$ where \(S_2\) is the second-stage linear travel, \(r\) is the pitch radius, and \(\theta\) is the rotation angle. |

| Full Ejection | Stage 2 completes its travel. | The gear shaft is completely free, rotated and clear of the mold. The runner system is also ejected. |

| Mold Closing | A standard mechanical pre-return system (e.g., DME ER-101) ensures the lower plate retracts first, pulling the upper plate back via limit bolts. | All ejection components are safely reset before the mold halves close. |

The genius of this system is its simplicity and reliability. The rotating force is generated inherently by the interaction between the helical teeth and the stationary insert, eliminating the need for external motors, gears, or racks. The kinematics ensure a smooth, damage-free release of the plastic gear shaft.

Supporting Systems for Robust Production

Cooling System Design

Cycle time and part warpage are critical for a precision gear shaft. An efficient cooling circuit is essential. The design incorporated cooling channels in the fixed and moving halves, as well as within the side core blocks. A particularly effective feature was the use of baffled cooling (“bubblers” or “water spears”) inside the deep core pins forming the shaft’s bore. The cooling time \(t_c\) can be estimated using the classic formula for amorphous/crystalline materials:

$$ t_c \propto \frac{h^2}{\alpha \pi^2} \ln\left[\frac{\pi}{4}\frac{T_m – T_w}{T_e – T_w}\right] $$

where \(h\) is the wall thickness, \(\alpha\) is the thermal diffusivity, \(T_m\) is melt temperature, \(T_w\) is coolant temperature, and \(T_e\) is the ejection temperature. Efficient cooling minimizes \(t_c\), directly boosting productivity.

Venting

Inadequate venting can cause burns, short shots, and high cavity pressure. Venting was strategically placed at the end of fill paths along the parting line and at the end of the runner system. Proper vent depth for POM (typically 0.015-0.02 mm) prevents flash while allowing air to escape.

Conclusion

The successful design of an injection mold for a helical gear shaft hinges on a deep understanding of the part’s geometry and a creative approach to demolding. The two-stage ejection system described here provides an elegant and mechanically robust solution. By cleverly separating the linear and rotational motions during ejection, it allows the helical gear shaft to unscrew itself from the mold without complex external actuators. This design, validated through high-volume production, ensures excellent part quality, high durability, and optimal cycle times. The principles outlined—strategic parting line selection, integrated side actions, and sequenced kinematic ejection—are broadly applicable and serve as a valuable reference for engineers tackling the design of molds for complex rotational parts like the indispensable helical gear shaft.