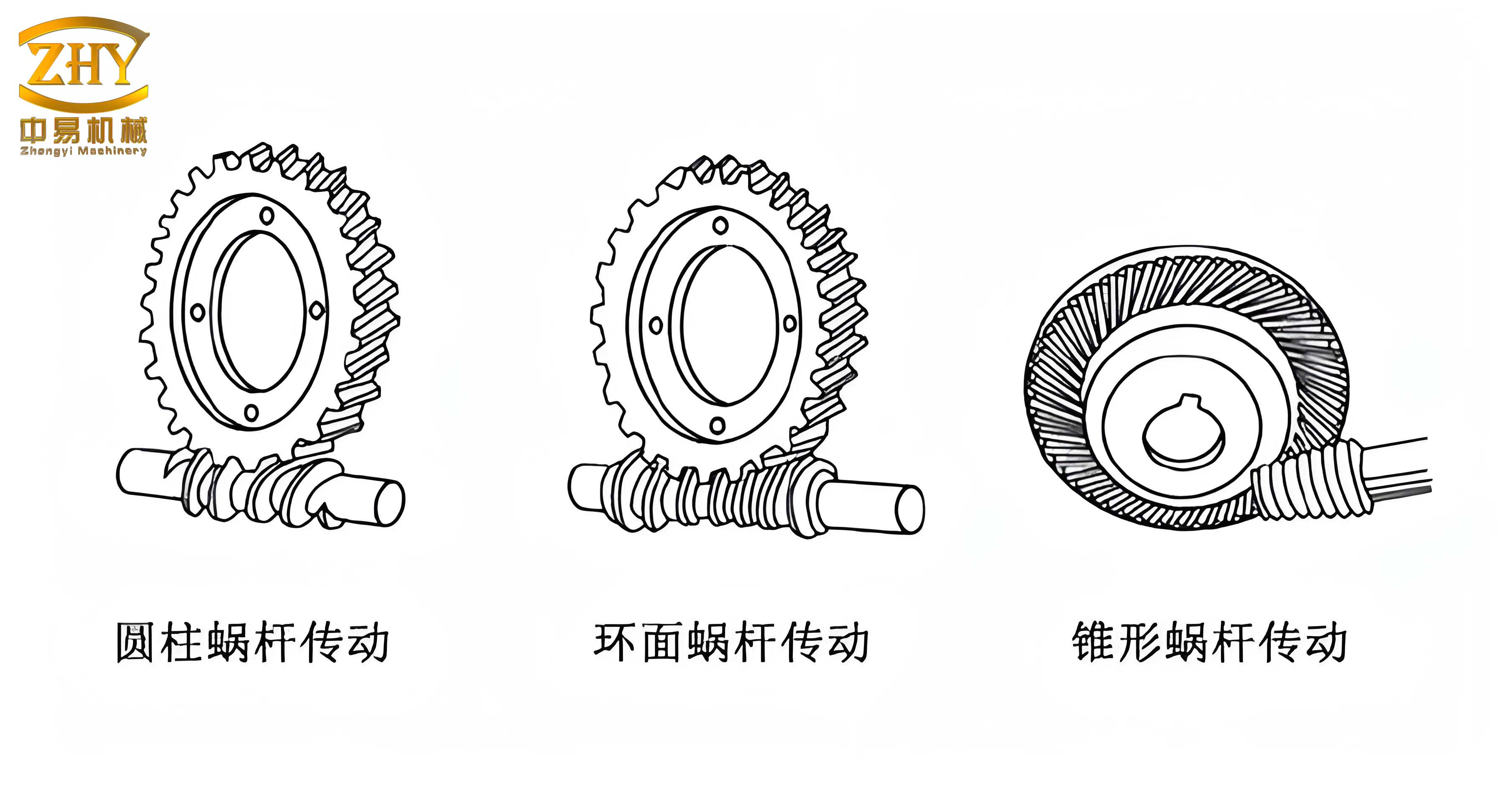

In the field of mechanical engineering, screw gear transmissions, commonly referred to as worm gear drives, play a pivotal role in transferring motion and power between non-intersecting shafts. These systems are renowned for their high single-stage reduction ratios, smooth operation, compact structure, and inherent self-locking capability, making them indispensable in applications ranging from automotive steering to industrial machinery. However, traditional manual design methods for screw gear sets are often time-consuming, error-prone, and lack the flexibility required in today’s fast-paced engineering environments. To address these challenges, we have developed a comprehensive parametric design system that leverages modern CAD software and programming tools. This system not only automates the design, validation, and modeling processes but also significantly enhances accuracy and efficiency. In this article, we present our methodology, detailed mathematical foundations, implementation strategies, and practical results, all from a first-person perspective as we engineered this solution.

The core of our parametric design system lies in its ability to transform user-defined operational requirements into precise geometric specifications for both the worm (screw) and the worm wheel (gear). The initial step involves determining essential input parameters, which are derived from specific application needs. These parameters uniquely define the final dimensions of the screw gear transmission. Key operational inputs include load conditions, transmission type, input power, screw rotational speed, desired transmission ratio, expected efficiency, and service life. For instance, in a typical reduction drive, the input power might be supplied by an electric motor, and the system must operate reliably under continuous duty cycles. Based on these inputs, appropriate materials for the screw and gear are selected. The screw, often the driving component, is typically manufactured from hardened steel alloys such as carburized steel, quenched steel, or nitrided steel to withstand high stresses and wear. Conversely, the gear, which is more susceptible to failure due to higher sliding friction, is commonly made from bronze alloys (e.g., tin bronze, aluminum bronze) or cast iron to provide good anti-friction and anti-seizure properties. This material pairing ensures durability and optimal performance of the screw gear assembly.

To systematically guide the design process, we established a clear design criterion rooted in failure mode analysis. For screw gear transmissions, primary failure modes include pitting, scuffing (adhesive wear), abrasive wear, and tooth breakage. Due to the high sliding velocities between meshing teeth, scuffing and wear are particularly prevalent, especially in the gear teeth. Therefore, our design methodology prioritizes surface contact fatigue strength for enclosed (closed) drives, with subsequent checks for bending fatigue strength and screw shaft deflection. For open drives, where exposure to contaminants accelerates wear, bending fatigue strength takes precedence. The parametric design flow, as illustrated in our system, follows a logical sequence: starting from operational parameters, we compute initial geometric values, perform iterative checks, and finalize dimensions before proceeding to 3D modeling. This flow ensures that every screw gear design meets both functional and safety standards.

Central to our system is the mathematical modeling of the screw gear components. For the screw, which is typically an Archimedean worm, the tooth profile is generated by sweeping a trapezoidal contour along an Archimedean spiral. The contour geometry is defined in a two-dimensional sketch, with key coordinates calculated based on fundamental parameters. Let the screw parameters include: module \( m \), pitch diameter \( d_1 \), tip diameter \( d_{a1} \), root diameter \( d_{f1} \), lead angle \( \gamma \), and axial pitch \( p_x \). The tooth profile, as shown in Figure 1, can be represented by a series of points. For a standard pressure angle \( \alpha = 20^\circ \), the coordinates of the trapezoid vertices are derived as follows:

$$ x_1 = \frac{p_x}{4} + \left( \frac{d_{a1} – d_1}{2} \right) \tan \alpha, \quad y_1 = \frac{d_{a1}}{2} $$

$$ x_2 = \frac{p_x}{4} + \left( \frac{d_{f1} – d_1}{2} \right) \tan \alpha, \quad y_2 = \frac{d_{f1}}{2} $$

$$ x_3 = -x_2, \quad y_3 = y_2 $$

$$ x_4 = -x_1, \quad y_4 = y_1 $$

These coordinates form the cutting profile used in the 3D modeling process. The helical path is defined by an Archimedean spiral with base circle diameter \( d_1 \) and lead equal to the screw’s lead \( L = p_x \cdot z_1 \), where \( z_1 \) is the number of starts. For multi-start screws, the cutting feature is patterned around the axis. This mathematical representation allows for precise parametric control over the screw geometry.

For the gear component, which features an involute tooth profile, the mathematical formulation is more complex. The involute curve is generated from a base circle, and its parametric equations in Cartesian coordinates are essential for accurate modeling. Let \( d_2 \) be the gear pitch diameter, \( d_{a2} \) the tip diameter, \( d_{f2} \) the root diameter, and \( d_b \) the base circle diameter. The involute profile for a single tooth space can be described by the following equations, where \( R_b = d_b / 2 \) is the base radius, \( \theta \) is the roll angle, and \( \phi \) is the half-angle of the tooth space on the base circle:

$$ x = R_b (\cos(\theta + \phi) + \theta \sin(\theta + \phi)) – R_b \sin \phi \cdot \cos(\theta + \phi) $$

$$ y = R_b (\sin(\theta + \phi) – \theta \cos(\theta + \phi)) + R_b \sin \phi \cdot \sin(\theta + \phi) $$

Here, \( \phi = \frac{S_b}{2R_b} \), with \( S_b \) being the tooth space width on the base circle. These equations enable the generation of discrete points along the involute, which are then connected via splines to form the gear tooth contour. This precise mathematical foundation ensures that the modeled screw gear pair maintains correct meshing characteristics and minimizes transmission errors.

To encapsulate the design parameters and their relationships, we have developed several reference tables. Table 1 summarizes the key input operational parameters required for initiating the screw gear design. Table 2 lists common material pairs for screw and gear along with their allowable stress limits. These tables serve as quick guides within our system, ensuring that users select appropriate values based on application constraints.

| Parameter | Symbol | Typical Range/Units | Description |

|---|---|---|---|

| Input Power | P | 1–100 kW | Power transmitted by the screw |

| Screw Speed | n₁ | 100–3000 rpm | Rotational speed of the screw |

| Transmission Ratio | i | 5–100 | Ratio of screw speed to gear speed |

| Service Life | L_h | 5000–20000 hours | Expected operational lifespan |

| Load Factor | K | 1.0–1.5 | Account for shock and vibrations |

| Efficiency Target | η | 0.7–0.95 | Desired transmission efficiency |

| Screw Material | Gear Material | Allowable Contact Stress [MPa] | Allowable Bending Stress [MPa] | Typical Applications |

|---|---|---|---|---|

| Carburized Steel | Tin Bronze | 200–300 | 50–80 | High-speed, heavy-duty drives |

| Quenched Steel | Aluminum Bronze | 180–250 | 40–70 | General industrial machinery |

| Nitrided Steel | Cast Iron | 150–220 | 30–60 | Low-cost, moderate duty |

The design calculations are rooted in standardized engineering formulas. For enclosed screw gear drives, the center distance \( a \) is initially estimated based on the surface contact fatigue strength criterion. The fundamental design equation is:

$$ a \geq \sqrt[3]{K T_2 \left( \frac{Z_E Z_\rho}{\sigma_{HP}} \right)^2 } $$

where \( T_2 \) is the torque on the gear, \( K \) is the load factor, \( Z_E \) is the elastic coefficient, \( Z_\rho \) is the contact ratio factor, and \( \sigma_{HP} \) is the allowable contact stress for the gear material. Once the center distance is tentatively selected, the screw pitch diameter \( d_1 \) and module \( m \) are determined using empirical relations, such as \( d_1 \approx (0.3–0.5)a \). The number of gear teeth \( z_2 = i \cdot z_1 \), with \( z_1 \) typically being 1, 2, or 4 for single- or multi-start screws. Subsequent checks include verifying the bending strength using the Lewis equation and assessing screw shaft deflection to ensure stiffness requirements are met. These calculations are automated in our system, with iterative loops adjusting parameters until all criteria are satisfied. This parametric approach ensures that every screw gear design is optimized for both performance and reliability.

Implementing this parametric design system required robust software tools. We chose SolidWorks as the CAD platform due to its widespread use in industry and powerful API (Application Programming Interface) that allows for extensive customization. Using Visual Basic (VB) as the programming language, we developed a standalone application that interfaces with SolidWorks. The VB program handles all design calculations, validations, and then drives SolidWorks to generate 3D models through API calls. Key API functions include creating sketches, extruding features, generating helical curves, and performing swept cuts. For example, to model the screw, the program first creates a cylinder based on the tip diameter and length, then defines the Archimedean spiral as a guide curve, and finally executes a swept cut with the trapezoidal profile. Similarly, for the gear, the involute points are computed and passed to SolidWorks to form a tooth space sketch, which is then swept along a helical path derived from the screw parameters. This seamless integration between VB and SolidWorks enables fully automated modeling of the screw gear pair.

Our system features a user-friendly interface, designed in VB, which guides users through the input process. The interface is divided into sections: operational parameters, material selection, design results, and 3D modeling controls. Users input values such as power, speed, and ratio, and the system immediately computes preliminary dimensions. A ‘Design & Validate’ button triggers the iterative calculation process, outputting final geometric parameters like module, pitch diameters, center distance, and tooth counts. These results are displayed in a structured format, as shown in Table 3, which summarizes a typical output set. Users can then manually tweak parameters if desired, before proceeding to 3D model generation.

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Center Distance | a | 150 | mm |

| Module | m | 5 | mm |

| Screw Pitch Diameter | d₁ | 50 | mm |

| Gear Pitch Diameter | d₂ | 250 | mm |

| Number of Screw Starts | z₁ | 2 | – |

| Number of Gear Teeth | z₂ | 50 | – |

| Lead Angle | γ | 11.31 | ° |

| Contact Stress | σ_H | 215 | MPa |

| Bending Stress | σ_F | 45 | MPa |

To demonstrate the system’s capabilities, we conducted a design example. Consider a ZA-type (Archimedean) screw gear drive for a reducer unit, powered by a three-phase induction motor. The input parameters are: power \( P = 9 \, \text{kW} \), screw speed \( n_1 = 1440 \, \text{rpm} \), transmission ratio \( i = 57 \), uniform loading, unidirectional operation, and a desired life of 12,000 hours with 8 hours daily usage. After inputting these into our system, the design calculations yielded a center distance of 150 mm, module of 5 mm, and a double-start screw. The contact stress was computed as 215 MPa, well below the allowable limit for the selected material pair (carburized steel screw and tin bronze gear). Bending stress and screw deflection were also within safe margins. The system then automatically generated the 3D models of both components. The resulting screw gear assembly is visualized in the following figure, which illustrates the precise meshing achieved through parametric design.

The modeling process for this screw gear pair involved precise steps. For the screw, a cylinder of diameter \( d_{a1} = 60 \, \text{mm} \) and length 100 mm was extruded. An Archimedean spiral with lead \( L = 2 \times p_x = 2 \times \pi m = 31.4 \, \text{mm} \) was created on the pitch cylinder. The trapezoidal cutting profile, with vertices calculated using the formulas above, was swept along this spiral to carve the tooth spaces. Since it’s a double-start screw, the cut was patterned around the axis. For the gear, a blank with outer diameter \( d_{a2} = 260 \, \text{mm} \) was created, and a throat contour was revolved to form the gear’s inner shape. The involute tooth profile was generated point-by-point using the parametric equations, with \( d_b = d_2 \cos \alpha = 250 \cos 20^\circ \approx 234.92 \, \text{mm} \). This profile was swept along a helix matching the screw’s lead to create a single tooth gap, which was then circularly arrayed to complete the gear teeth. Finally, features like shafts and keyways were added. The entire process, from input to final assembly, took under five minutes, showcasing the system’s efficiency.

Beyond basic modeling, our parametric design system incorporates advanced features for simulation and analysis. For instance, it can export model data for finite element analysis (FEA) to evaluate stress distributions and thermal performance. Additionally, the system supports customization for different screw gear types, such as ZI (involute) or ZN (convolute) worms, by adjusting the mathematical models accordingly. This flexibility makes it a versatile tool for various engineering scenarios. The integration with SolidWorks also allows for direct generation of engineering drawings, bill of materials, and even CNC machining codes, thereby bridging the gap between design and manufacturing. These capabilities underscore the practicality of our parametric approach for modern screw gear applications.

In terms of validation, we compared designs produced by our system with traditional handbook methods and physical prototypes. The results showed excellent agreement in dimensions and performance predictions. For example, the contact pattern observed in assembled prototypes matched the simulated meshing behavior, confirming the accuracy of our mathematical models. Moreover, the automated design process reduced human errors significantly, leading to more reliable screw gear sets. This reliability is crucial in critical applications where failure could result in costly downtime or safety hazards. Thus, our system not only speeds up design but also enhances product quality.

Looking ahead, we envision further enhancements to the parametric design system. Potential upgrades include integrating machine learning algorithms to optimize parameters for minimum weight or maximum efficiency, adding cloud-based collaboration features, and extending support to other gear types like helical or bevel gears. The core principles developed here for screw gear transmissions can be adapted to broader mechanical design domains. By continuing to refine this tool, we aim to contribute to the ongoing digital transformation in engineering design, where automation and precision are paramount.

In conclusion, we have successfully developed a parametric design system for screw gear transmissions that integrates design calculation, validation, and 3D modeling into a cohesive workflow. By leveraging SolidWorks API and Visual Basic programming, we have created a tool that drastically reduces design time, minimizes errors, and ensures optimal performance of screw gear pairs. The system’s foundation in accurate mathematical modeling, combined with user-friendly interfaces and comprehensive validation checks, makes it a valuable asset for engineers dealing with screw gear applications. As demonstrated through practical examples, this parametric approach not only streamlines the design process but also lays the groundwork for subsequent simulations and manufacturing, ultimately accelerating product development cycles and improving reliability in mechanical power transmission systems.