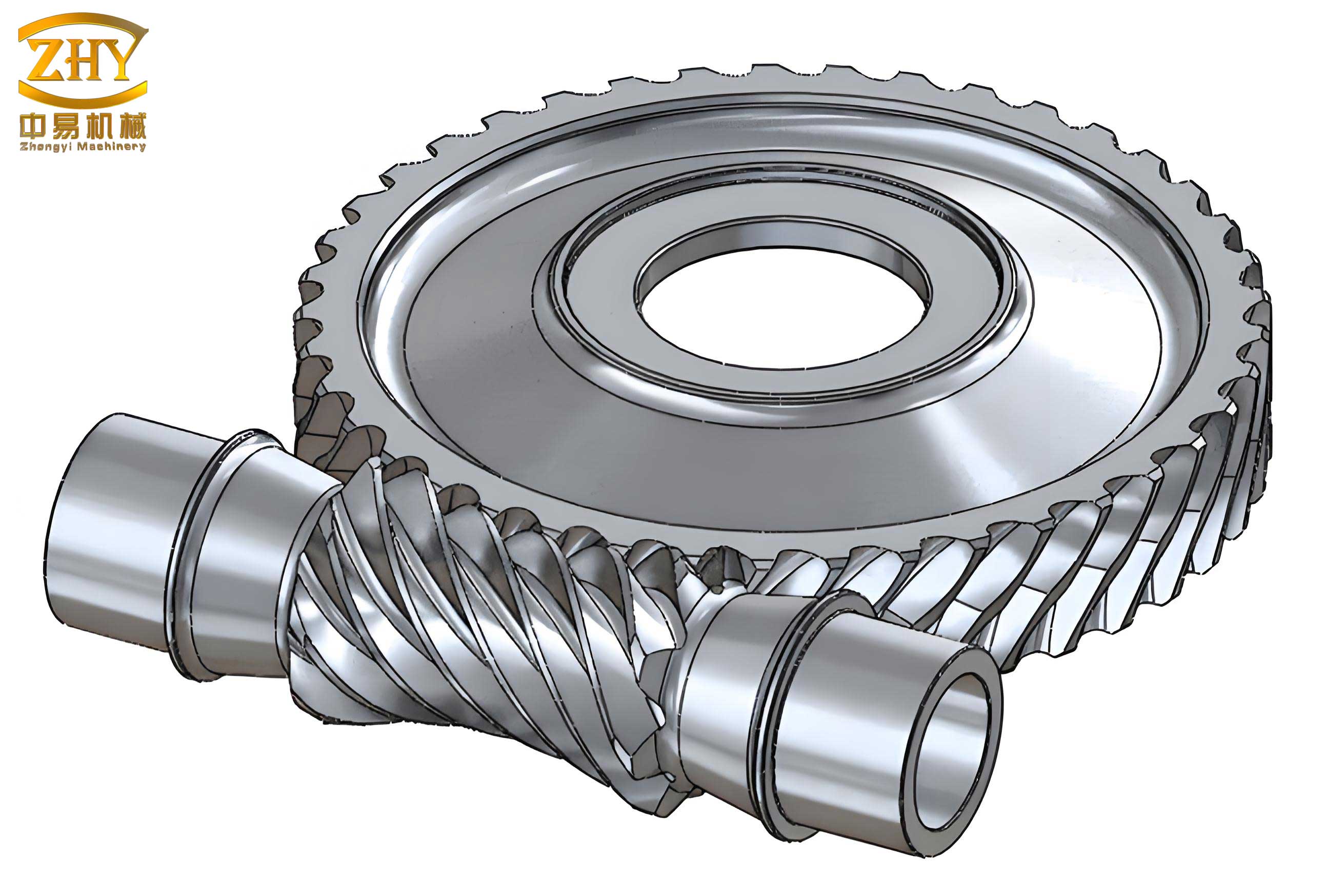

In my work on automotive Electric Power Steering (EPS) systems, the central reduction mechanism is almost always a screw gear drive, commonly referred to as a worm and gear set. This component is critical as it connects directly to the electric motor, providing the necessary speed reduction and torque multiplication for steering assistance. The performance of this screw gear pair profoundly impacts the overall efficiency, responsiveness, and durability of the EPS system. Traditionally, many designs have utilized a double-threaded screw gear with standard tooth profiles. However, through my analysis and iterative design process, I identified opportunities for significant improvement in both mechanical efficiency and structural reliability by reconsidering two fundamental parameters: the number of threads on the screw gear and the tooth thickness of the driven gear.

The primary objectives of my redesign were clear: first, to increase the transmission efficiency of the screw gear drive to reduce power loss and improve energy economy; and second, to enhance the bending strength at the root of the gear teeth, particularly given the common material mismatch where the screw gear is made of high-strength steel and the driven gear is often a polymer like PA46 for noise reduction. The inherent strength disparity can lead to premature failure in the polymer gear if not properly addressed. My approach involved a structured methodology combining theoretical analysis, specialized gear design software (Kisssoft), finite element simulation (Ansys Workbench), and culminating in physical prototype testing.

Theoretical Foundation for Screw Gear Optimization

The initial phase of my work was dedicated to a thorough theoretical examination. I needed to mathematically model how changes in the number of threads and the gear tooth thickness would affect the two target performance metrics: efficiency and root bending stress.

Influence of Thread Count on Mechanical Efficiency

The meshing efficiency of a screw gear drive is a key performance indicator. For a ZI-type (ZI stands for “Zylinderschnecke mit eingeteiltem Schneckenrad,” or cylindrical worm with a hobbed gear) screw gear, the meshing efficiency \(\eta\) can be derived from the lead angle \(\gamma\) and the equivalent friction angle \(\phi_v\). The relationship is given by:

$$

\eta = \frac{\tan\gamma}{\tan(\gamma + \phi_v)}

$$

The lead angle \(\gamma\) is itself a function of the screw gear’s geometric parameters:

$$

\tan\gamma = \frac{m z_1}{d_1}

$$

where \(m\) is the normal module, \(z_1\) is the number of threads on the screw gear, and \(d_1\) is its reference diameter. From this equation, it is evident that for a fixed module \(m\) and reference diameter \(d_1\)—which are often constrained by packaging and manufacturing considerations in an automotive EPS—the lead angle \(\gamma\) increases directly with the number of threads \(z_1\). Analyzing the efficiency function, one can find that as \(\tan\gamma\) increases, the overall meshing efficiency \(\eta\) also increases. Therefore, my first hypothesis was that moving from a conventional double-threaded (\(z_1=2\)) to a triple-threaded (\(z_1=3\)) screw gear should yield a measurable improvement in the efficiency of the power transmission.

Influence of Tooth Thickness on Bending Strength

The second critical aspect is the bending fatigue strength at the root of the gear teeth. For the driven gear in a screw gear pair, the bending stress \(\sigma_F\) can be calculated using a standardized formula. For a standard tooth profile, the nominal bending stress is:

$$

\sigma_F = \frac{1.53 K T_2}{d_1 d_2 m} Y_F Y_{\beta} \leq [\sigma]_F

$$

Here, \(K\) is the load factor, \(T_2\) is the torque on the gear, \(d_2\) is the gear’s reference diameter, \(Y_F\) is the form factor, \(Y_{\beta}\) is the helix angle factor, and \([\sigma]_F\) is the allowable bending stress of the gear material. The nominal tooth thickness \(S_a\) at the reference circle is typically:

$$

S_a = \pi m / 2

$$

Given the significant difference in yield strength between a steel screw gear (e.g., 40Cr, ~780 MPa) and a polymer gear (e.g., PA46, ~84 MPa), the polymer gear becomes the weak link. My strategy was to asymmetrically modify the tooth thickness. By introducing a tooth thickness modification coefficient \(x^*_s\) (where \(0 \leq x^*_s \leq 1\)), I effectively increased the gear’s tooth thickness while correspondingly reducing the screw gear’s tooth thickness to maintain proper meshing clearance. This modification increases the virtual operating module for the gear to \(m_1 = m (1 + x^*_s)\). Consequently, the formula for the bending stress in the modified, thicker gear tooth becomes:

$$

\sigma_F = \frac{1.53 K T_2}{d_1 d_2 m (1 + x^*_s)} Y_F Y_{\beta} \leq [\sigma]_F

$$

From this derived equation, it is clear that with all other factors remaining constant, increasing the tooth thickness coefficient \(x^*_s\) directly reduces the calculated bending stress \(\sigma_F\). This leads to a higher safety factor against tooth breakage, thereby addressing the material strength disparity and potentially increasing the service life of the entire screw gear assembly.

My theoretical analysis thus yielded two actionable design principles for optimizing the automotive EPS screw gear drive: (1) Increase the number of threads on the screw gear to improve meshing efficiency. (2) Implement an asymmetric tooth thickness modification, increasing the gear’s tooth thickness to reduce its root bending stress and improve its safety factor.

Software-Aided Design and Verification Using Kisssoft

With the theoretical framework established, I proceeded to the detailed design phase. I employed Kisssoft, a specialized software for machine element design, to model, calculate, and verify the performance of the proposed triple-threaded screw gear with modified tooth thickness. The starting point was to define the core design requirements based on the existing EPS system’s packaging constraints and performance targets.

| Parameter | Gear (Wheel) | Screw Gear (Worm) |

|---|---|---|

| Number of Teeth / Threads | 44 | 3 |

| Normal Module [mm] | 2 | |

| Center Distance [mm] | 55 | |

| Normal Pressure Angle [°] | 14.5 | |

| Lead Angle (Target) [°] | – | 20 |

Within Kisssoft, I configured several critical settings to match the real-world operating conditions of an automotive EPS screw gear drive:

- Tooth Thickness Modification: In the tolerance settings, I specified a negative tooth thickness coefficient (\(-x^*_s\)) for the screw gear, which automatically applies a positive coefficient (\(+x^*_s\)) to the gear.

- Tooth Profile: I selected a short tooth profile (1.00 / 0.20 / 0.80) to maximize the root thickness and further improve bending strength.

- Material & Lubrication: The materials were defined as PA46 for the gear and 40Cr steel for the screw gear. The lubrication was set to grease lubrication, simulating a sealed-for-life EPS system.

- Operational Parameters: The input power was set to 0.3 kW at 1000 RPM. To simulate the demanding stop-start nature of steering, the number of starts per hour was set to 100.

- Bearing Support: The distance from the screw gear mesh to the supporting bearings was defined to accurately calculate shaft deflections and their effect on load distribution.

Through iterative adjustment in Kisssoft, I converged on an optimal tooth thickness coefficient of \(x^*_s = 0.2232\). The software then calculated the complete set of geometric parameters and, most importantly, the predicted performance factors.

| Parameter | Gear (Wheel) | Screw Gear (Worm) |

|---|---|---|

| Profile Shift Coefficient | -0.2797 | 0 |

| Tooth Thickness Coefficient \(x^*_s\) | +0.2232 | -0.2232 |

| Axial Tooth Thickness [mm] | 3.791 | 2.242 |

| Tip Diameter [mm] | 95.863 | 20.948 |

| Reference Diameter [mm] | 92.457 | 17.543 |

| Performance Metric | Value |

|---|---|

| Gear Root Safety Factor | 1.715 |

| Gear Flank (Surface) Safety Factor | 2.327 |

| Thermal Safety Factor | 1.71 |

| Diameter Factor (Screw Gear) | 8.242 |

| Meshing Efficiency \(\eta\) | 84.74% |

| Total Assembly Efficiency (estimated) | 74.82% |

The Kisssoft results were highly promising. The calculated meshing efficiency of 84.74% for the triple-threaded design represented a significant theoretical gain. Furthermore, the root safety factor for the PA46 gear was calculated to be well above 1.0, specifically 1.715, indicating a robust design against bending fatigue. Using the software’s export function, I generated accurate 3D CAD models of both the triple-threaded screw gear and the thickened gear for the next stage of analysis.

Finite Element Analysis for Strength Validation Using Workbench

While Kisssoft provides reliable safety factors based on standardized calculations, I wanted to perform a more detailed stress analysis of the gear tooth root under a static overload condition, simulating a worst-case steering effort. For this, I imported the 3D models of both the standard and the thickened gear designs (each paired with its corresponding screw gear) into Ansys Workbench for Finite Element Analysis (FEA).

The simulation setup was designed to replicate a standard strength validation test for an EPS screw gear drive:

- Material Properties: I assigned linear elastic material properties: PA46 (E=6.1 GPa, ν=0.4) to the gear and 40Cr steel (E=206 GPa, ν=0.3) to the screw gear.

- Contacts: The mating tooth flanks were defined as bonded contacts to simulate a locked, load-sharing position under maximum torque.

- Meshing: A global automatic mesh was applied, with a refined contact sizing of 0.5 mm specifically in the啮合 region to ensure accuracy in the stress concentration areas.

- Boundary Conditions & Loading: To simulate the test bench setup where the screw gear input is fixed and torque is applied to the output, I applied:

- A Fixed Support on one end face of the screw gear shaft.

- A Remote Displacement on the gear’s hub, constraining all translational degrees of freedom and allowing rotation only about its axis.

- A moment of 50 N·m directly applied to the gear body, representing the maximum output torque demand.

The FEA solved for the stress distribution. The results provided a clear visual and quantitative comparison:

- Standard Tooth Gear: The maximum equivalent (von Mises) stress was found to be 61.37 MPa, located at the root fillet of the most heavily loaded tooth.

- Thickened Tooth Gear (with \(x^*_s = 0.2232\)): The maximum equivalent stress was significantly reduced to 50.87 MPa.

Given the yield strength of PA46 is approximately 84 MPa, the calculated safety factor for the thickened gear design under this 50 N·m load is \(84 / 50.87 \approx 1.65\). This FEA-derived safety factor closely aligned with the 1.715 predicted by Kisssoft, providing strong mutual validation for the effectiveness of the tooth thickening strategy. The stress reduction of nearly 10.5 MPa unequivocally demonstrated the benefit of the asymmetric tooth thickness modification for enhancing the structural integrity of the polymer gear in the screw gear drive.

Experimental Validation on Physical Prototypes

The final and most crucial step was to validate the software-based predictions through physical testing of manufactured prototypes. I oversaw the production of the optimized triple-threaded screw gear and the thickened gear based on the finalized Kisssoft parameters.

Root Bending Strength Test

The test replicated the FEA boundary condition: the screw gear input shaft was locked, and a steadily increasing torque was applied to the gear’s output until signs of failure. The requirement was to withstand a minimum of 50 N·m. The prototype screw gear assembly successfully endured torque levels exceeding 230 N·m before any visible plastic deformation (minor indentation) occurred in the gear tooth roots. This result far exceeded the design requirement and confirmed the substantial gain in bending strength achieved through the tooth thickness optimization.

Mechanical Efficiency Test

To measure the efficiency improvement, I conducted back-driving efficiency tests on complete EPS assist mechanisms incorporating both the old (double-threaded) and new (triple-threaded) screw gear drives. A controlled input torque of 1 N·m was applied to the screw gear shaft at a slow rotational speed (10 rad/min), and the output torque at the gear was measured throughout a full rotation cycle. The mechanical efficiency was calculated from the ratio of output to input work.

| Performance Metric | Baseline (Double-Threaded) | Optimized Design (Triple-Threaded, Thickened Gear) | Improvement |

|---|---|---|---|

| Measured Mechanical Efficiency | ~70% | ~77% | +7 percentage points |

| Gear Root Bending Safety Factor (@ 50 N·m load) |

~1.37 (Estimated from FEA on standard tooth) | ≥1.65 (FEA & Test Validated) | ≥20% increase |

| Lead Angle \(\gamma\) | ~13.5° | ~20° | Increased |

| Tooth Thickness Modification \(x^*_s\) | 0 (Standard) | 0.2232 | Asymmetric thickening applied |

The results were conclusive. The efficiency test showed that the mechanism employing the new triple-threaded screw gear drive achieved an average mechanical efficiency of approximately 77%. This represented a clear 7-percentage-point gain over the baseline double-threaded design, which operated at around 70% efficiency. This experimental value aligned well with the total efficiency (74.82%) estimated by Kisssoft when accounting for bearing losses. The hysteresis (difference between forward and reverse drive efficiency) was also observed to be reduced, contributing to more consistent steering feel.

Conclusion

Through this comprehensive project—spanning theoretical analysis, software-aided design, computational simulation, and physical testing—I successfully developed and validated an optimized screw gear drive for an automotive EPS system. The core of the optimization was a dual-strategy approach: increasing the screw gear thread count from two to three, and implementing an asymmetric tooth thickness modification to strengthen the polymer gear.

The theoretical models correctly predicted the directions of improvement. The specialized gear design software Kisssoft proved invaluable for rapidly iterating and calculating precise geometric parameters and safety factors. The FEA in Workbench provided a detailed visualization and verification of the stress reduction in the gear tooth root. Finally, experimental tests on physical prototypes provided irrefutable evidence of the success of the optimization.

The final design delivers a screw gear drive that is approximately 10% more efficient in terms of mechanical power transmission and features a gear tooth root safety factor increased by over 20%. These improvements directly translate to a more energy-efficient steering system with enhanced long-term durability and reliability, contributing positively to vehicle fuel economy and driver safety. This work underscores the effectiveness of integrating modern digital engineering tools with traditional mechanical design principles to solve complex automotive component challenges.