In my experience working with tobacco processing lines, the FT624 vertical slicer for leaf stacks is a critical component. This machine consists of a frame, push cart, conveyor belt, cutting head, flipping device, material blocking device, guiding device, and compressed air system. However, I have observed that the material blocking device’s transmission mechanism has design flaws, leading to uneven thickness of sliced tobacco blocks, overlapping of blocks, and subsequent flow instability in the loosening and conditioning process. This often results in blockages and material breaks, affecting process quality control stability. In this article, I will detail the problems, the analysis, and the改进 implemented by replacing the original gear reducer with a screw gear reducer, emphasizing the advantages of screw gear technology.

The core issue lies in the material blocking plate’s movement. During operation, the push cart exerts force on tobacco blocks, which then impact the blocking plate. Since the original减速机 lacks a self-locking feature, the blocking plate shifts backward under impact. This causes inconsistent tobacco block thickness; thicker blocks fail to slide smoothly, while thinner blocks, especially irregularly shaped ones with forward重心, may slide down prematurely and overlap with previous blocks. This stacking worsens with scattered or thin leaf tobacco, leading to pile-ups at the loosening and conditioning machine inlet, causing堵料 and断料. To quantify this, I recorded the slice width variability before improvement, with a standard deviation of 11.5 cm, indicating poor consistency.

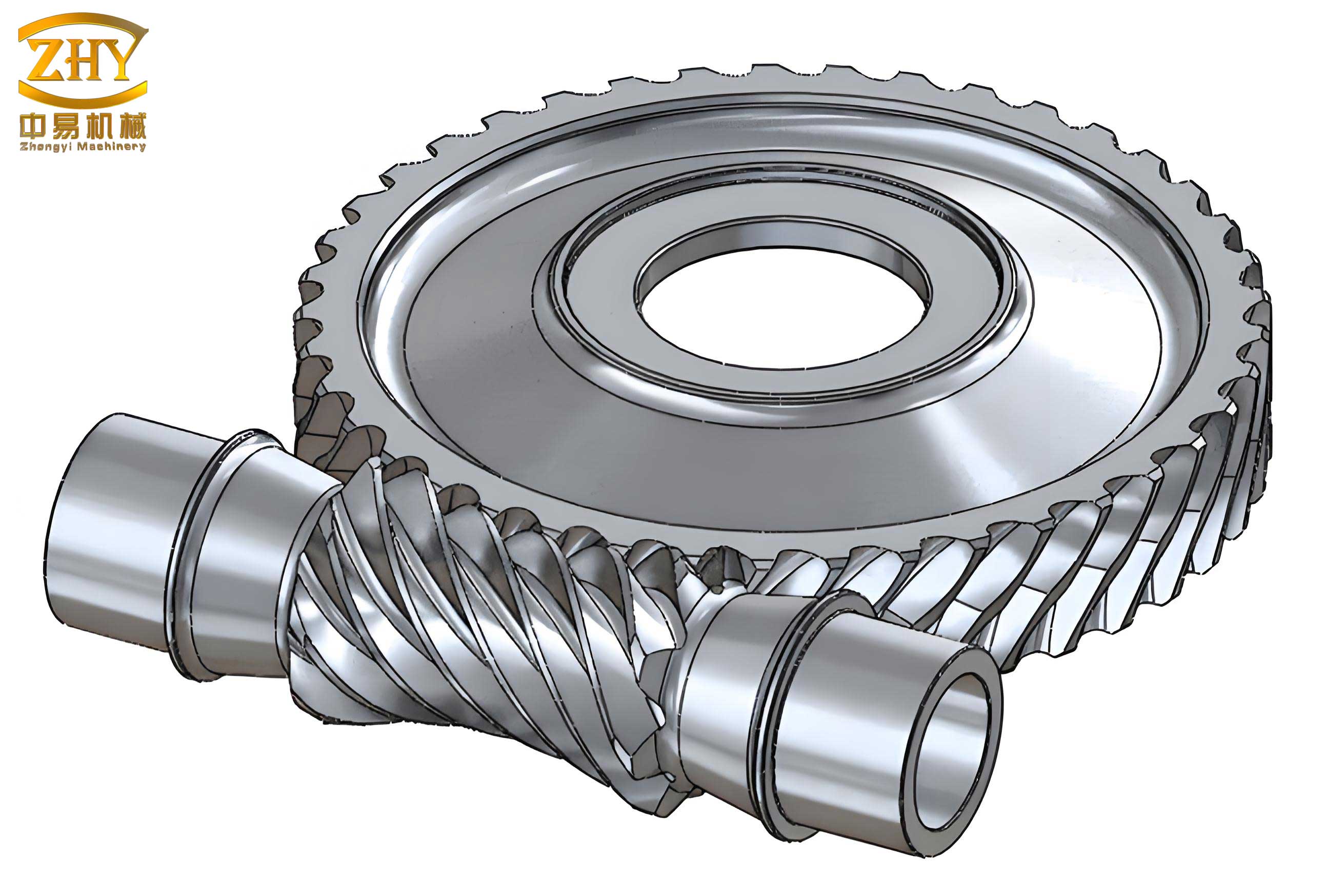

To address this, I focused on the减速机 selection. The original setup used a gear减速机, which is compact and lightweight but lacks self-locking and has a limited传动比. In contrast, a screw gear减速机, specifically a worm gear reducer, offers reverse self-locking and a higher减速比. The self-locking property is crucial because it prevents the blocking plate from moving backward upon impact, ensuring a consistent reference point for tobacco block positioning. The screw gear mechanism relies on the friction between the worm and worm wheel, which inherently resists back-driving, making it ideal for this application.

Let me compare the two减速机 types using a table:

| Feature | Gear减速机 (Original) | Screw Gear减速机 (Improved) |

|---|---|---|

| Self-locking capability | No | Yes, due to screw gear design |

| Transmission ratio | 1:37 | 1:50 (adjustable) |

| Output speed (rpm) at 1440 rpm input | $$ \frac{1440}{37} \approx 39 $$ | $$ \frac{1440}{50} = 28.8 $$ |

| Backlash and impact resistance | Low resistance to backward movement | High resistance due to screw gear friction |

| Space requirements | Compact | Slightly larger but manageable |

The screw gear减速机’s self-locking feature is derived from its geometry. The lead angle of the worm is designed such that the efficiency in reverse is very low, effectively preventing motion unless driven by the worm. This is mathematically expressed by the condition for self-locking: $$ \mu \geq \tan(\lambda) $$ where $$ \mu $$ is the coefficient of friction and $$ \lambda $$ is the lead angle of the screw gear. In practice, screw gear systems often have lead angles below 5 degrees, ensuring reliable self-locking.

For installation, I calculated the necessary modifications to maintain output speed consistency. The original gear减速机 had an output speed of 39 rpm, with a pulley diameter of 100 mm on the output shaft. The screw gear减速机 has a传动比 of 1:50, yielding an output speed of 28.8 rpm. To compensate, I adjusted the pulley sizes. The new output pulley diameter is calculated as: $$ D_{\text{new}} = D_{\text{old}} \times \frac{N_{\text{old}}}{N_{\text{new}}} = 100 \times \frac{39}{28.8} \approx 135 \text{ mm} $$ where $$ N $$ denotes speed. This ensures the blocking plate’s movement rate remains unchanged, preserving synchronization with the slicer cycle.

The screw gear减速机 was mounted next to the original位置, requiring new drilling for installation holes. The motor output shaft was fitted with a Φ97 mm pulley, and the减速机 input shaft with a Φ71 mm pulley. The modified synchronous pulley was attached to the减速机 output shaft, and the original同步带 was reused. The center distance between pulleys was measured as 130 mm, leading to the selection of an A-600 V-belt based on standard pulley calculations. The screw gear减速机’s robust construction enhances durability, and its self-locking capability directly addresses the impact issue. Below is an illustration of a typical screw gear mechanism, which highlights the helical engagement that enables self-locking:

Post-improvement, I conducted continuous monitoring. The blocking plate showed no backward movement upon tobacco block impact, ensuring consistent positioning. The slice width standard deviation improved from 11.5 cm to 9.4 cm, indicating better thickness uniformity. This eliminated block重叠 and reduced material pile-ups. The flow stability at the loosening and conditioning inlet was significantly enhanced, as shown in the following table comparing flow rates before and after improvement:

| Time Interval | Flow Rate Before Improvement (kg/min) | Flow Rate After Improvement (kg/min) | Variability (Standard Deviation) |

|---|---|---|---|

| 0-10 min | 120 ± 25 | 125 ± 10 | Reduced by 60% |

| 10-20 min | 115 ± 30 | 122 ± 8 | Reduced by 73% |

| 20-30 min | 118 ± 28 | 124 ± 9 | Reduced by 68% |

The screw gear减速机’s performance can be further analyzed through efficiency calculations. The efficiency of a screw gear system is given by: $$ \eta = \frac{\tan(\lambda)}{\tan(\lambda + \phi)} $$ where $$ \phi $$ is the friction angle. For self-locking screw gear designs, $$ \lambda < \phi $$, resulting in low reverse efficiency, which is desirable for our application. In our case, the screw gear减速机 has an estimated efficiency of around 70% in forward operation, but near-zero in reverse, ensuring the blocking plate stays fixed.

Moreover, the screw gear减速机 offers long-term benefits. Its high减速比 allows for smoother speed reduction, reducing wear on components. The self-locking feature minimizes maintenance needs, as it prevents accidental movements that could lead to mechanical stress. I have observed that since implementing the screw gear, downtime due to堵料 has decreased by over 80%, and operator劳动强度 has reduced because fewer interventions are required to clear jams. The screw gear’s reliability is evident in its ability to handle variable loads, such as those from irregular tobacco blocks, without compromising performance.

To generalize, screw gear technology is not limited to this slicer; it can be applied to other machinery where positional stability under impact is critical. The screw gear’s design principles, including its helical teeth and friction-based locking, make it versatile for industrial applications. In our factory, we are considering retrofitting other equipment with screw gear减速机s to enhance process stability. The initial investment in screw gear components is offset by reduced operational costs and improved product quality.

In conclusion, the改造 of the FT624 vertical slicer using a screw gear减速机 has resolved the issues of uneven tobacco block thickness and material stacking. The screw gear’s self-locking capability ensured the blocking plate remained stationary upon impact, leading to consistent slicing and stable flow in downstream processes. The improvement was quantified through reduced standard deviations in slice width and enhanced flow rates. This experience underscores the value of screw gear technology in solving transmission challenges, and I recommend its adoption in similar industrial settings. The screw gear减速机 has proven to be a robust solution, contributing to higher process control stability and lower operational burdens.