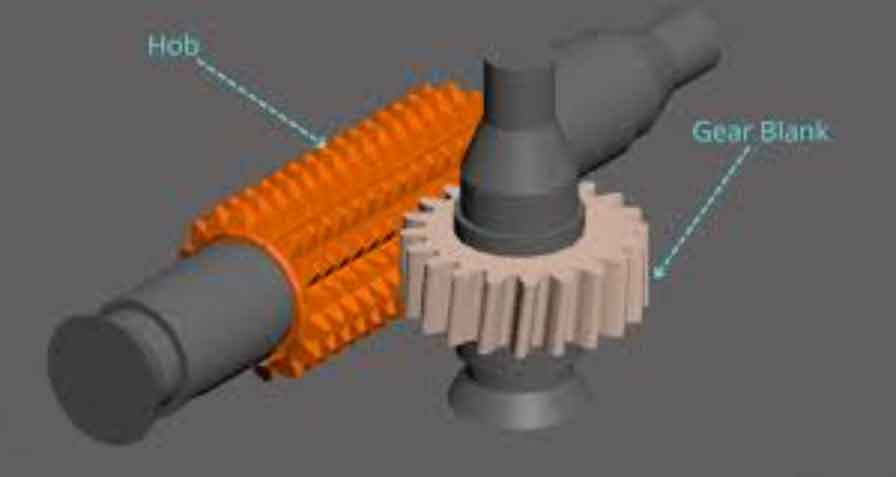

In the field of precision gear manufacturing for robotics and automation, RV reducers play a critical role due to their high torque capacity and compact design. As a key component, the planetary gear within an RV reducer must exhibit exceptional accuracy, particularly in the positional relationship between its internal and external teeth. This positional accuracy, encompassing both angular phase and concentricity, directly influences the reducer’s transmission error, load distribution, wear, noise, and overall service life. Therefore, controlling these parameters is paramount. Throughout my research and practical experience in gear manufacturing, I have focused extensively on the gear hobbing process for producing these planetary gears. Gear hobbing, a continuous generating machining method, offers a compelling balance of efficiency and precision compared to alternative processes like gear grinding or wire cutting. This article delves into the key challenges encountered during the trial production of planetary gears via gear hobbing and presents detailed, validated solutions. I will elaborate on the root causes of significant angular phase fluctuation and severe eccentricity between the internal and external teeth, and systematically outline the corrective measures that have proven effective. The discussion will be supported by theoretical analysis, practical validations, and summarized data to provide a comprehensive guide for optimizing the gear hobbing process for such complex components.

The manufacturing journey for an RV reducer planetary gear is lengthy and involves multiple intricate processes. While gear grinding can achieve high precision and facilitate tooth profile modifications, its relatively low processing efficiency makes it less ideal for mass production. On the other hand, gear hobbing stands out for its higher productivity. The continuous improvement in machine tool technology and cutter design has elevated gear hobbing accuracy to levels that can rival grinding in many applications. For planetary gears where the external tooth precision requirement, while still high, does not necessitate the ultimate finish of grinding, gear hobbing presents an optimal solution. The gear hobbing process for the external teeth of planetary gears is typically performed on high-precision hobbing machines, often equipped with advanced CNC systems like FANUC, which include features such as automatic tooth searching. However, the inherent complexity of a planetary gear—having both internal and external teeth with a specific angular relationship—introduces unique challenges in the gear hobbing stage. The core of this research is to address these challenges, specifically the large fluctuation in the angular phase and the excessive radial runout (eccentricity) between the internal and external tooth sets, which were major bottlenecks affecting yield rates during initial trials.

1. Excessive Fluctuation in Angular Phase Between Internal and External Teeth

One of the most critical quality characteristics of an RV planetary gear is the angular phase, denoted as α. This angle is defined by the center of the gear (o), the midpoint of a specific internal tooth space (a), and the midpoint of a corresponding external tooth (b). The allowable tolerance for this angle is typically very tight. During initial gear hobbing trials, the measured angular phase exhibited unacceptably large variations, often beyond ±0.1°, leading to a low qualification rate. This section analyzes the causes and details the implemented solutions.

1.1 Root Cause Analysis

The primary method to correct angular phase error after gear hobbing is to compensate the machine’s C-axis (workpiece rotation axis). This compensation effectively rotates the external tooth profile relative to the internal teeth by adjusting the cutting amount on the left and right flanks of the external teeth. The compensation value is often converted into a chordal length value for machine input. However, a frequent issue observed was that after applying C-axis compensation based on a previous gear, the subsequent gear would show non-uniform cutting or even a complete lack of material removal on one flank of the external teeth during the gear hobbing operation. This pointed directly to insufficient hobbling allowance on the pre-machined (semi-finished) external teeth of the gear blank. If the allowance is too small, the hob may not engage properly with one flank after angular compensation, leading to an incorrect final tooth position and consequently, a deviated angular phase. The relationship between the angular compensation and the required material removal is governed by the operating pitch circle radius during gear hobbing. The operating pitch circle radius (\( r’ \)) of the external gear during hobbing can be calculated based on the theoretical and actual center distances:

$$ r’ = r \cdot \frac{a’}{a} $$

where \( r \) is the standard pitch circle radius of the external gear, \( a’ \) is the actual center distance during hobbing (obtained from machine coordinates), and \( a \) is the theoretical center distance. The standard pitch circle radius is given by:

$$ r = \frac{m \cdot z}{2} $$

Here, \( m \) is the module and \( z \) is the number of teeth on the external gear. The theoretical center distance \( a \) is the sum of the hob’s pitch radius and the gear’s pitch radius. The chordal compensation value (\( \Delta_s \)) required to rotate the gear by a small angle \( \Delta\theta \) (in radians) is approximately:

$$ \Delta_s \approx r’ \cdot \Delta\theta $$

If the single-sided hobbing allowance on the semi-finished part is less than this \( \Delta_s \), compensation will lead to a non-cutting condition.

Another contributing factor was the automatic tooth search function of the gear hobbing machine. Before each hobbing cycle, the machine runs a program to find the precise position of an external tooth space relative to the hob tooth. This establishes a reference for the C-axis compensation. However, variations in the quality of the semi-finished gear blanks (e.g., minor errors in the pre-machined external teeth) cause this search reference point to fluctuate from one part to another. When a fixed C-axis compensation value, derived from measuring a previous part’s angular error, is applied to the next part, the inherent search error compounds the result. This leads to unpredictable and often excessive angular phase variation in the batch. The inconsistency introduced by the search function was a significant source of the observed fluctuation.

| Observed Problem | Root Cause | Key Solution | Implementation Detail |

|---|---|---|---|

| Large batch-wide variation in angular phase (α) | 1. Insufficient hobbing allowance on semi-finished external teeth. 2. Inconsistency introduced by the machine’s automatic tooth search function. |

1. Increase the single-sided gear hobbing allowance. 2. Disable the continuous tooth search function after the first part. |

– Ensure allowance is ~0.3mm per side, up from ~0.05mm. – Perform search and compensation on the first part only; run subsequent parts without search. |

| Non-cutting (non-spark) on one tooth flank after compensation | Hobbing allowance less than the required chordal compensation value (\( \Delta_s \)). | Recalculate and guarantee minimum allowance based on maximum expected angular correction. | Use formula \( \text{Min Allowance} = r’ \cdot \Delta\theta_{\text{max}} \) to define pre-hobbing tooth thickness. |

1.2 Implemented Solutions and Results

To address the allowance issue, we first meticulously measured the tooth thickness of the semi-finished planetary gear blanks. It was found that the single-sided gear hobbing allowance was only about 0.05 mm. Based on the angular phase tolerance and using the chordal compensation formula, it was determined that a single-sided allowance of approximately 0.3 mm was necessary to accommodate the maximum expected angular correction without risking a non-cutting condition. After modifying the preceding machining step to ensure this larger allowance, the phenomenon of non-cutting flanks completely disappeared during gear hobbing with C-axis compensation.

To eliminate the variability from the tooth search function, we revised the gear hobbing procedure. For a production batch, the automatic search function is now used only for the very first gear. The angular phase of this first gear after hobbing is measured precisely. The required C-axis chordal compensation value is calculated and applied. This first gear may then undergo a second light hobbing pass to fine-tune its angular phase into the acceptable range. Crucially, for all subsequent gears in the batch, the automatic tooth search function is disabled. The machine uses the same setup and C-axis position (with the applied compensation) for the entire batch. This approach assumes consistent blank positioning, which is ensured by high-quality fixtures. By implementing these two changes—increasing the gear hobbing allowance and batching without continuous search—the fluctuation in the angular phase of finished planetary gears was dramatically reduced. The process capability index (Cpk) for the angular phase characteristic showed significant improvement, and the qualification rate increased substantially.

2. Severe Eccentricity Between Internal and External Teeth

Another critical defect encountered was excessive radial runout (Fr) between the internal and external teeth centers. This eccentricity directly harms the meshing quality within the RV reducer. Measurements using high-precision gear testers revealed Fr values between 0.05 mm and 0.08 mm, far exceeding the specified limits for the gear’s accuracy grade.

2.1 Root Cause Investigation

The initial suspicion naturally fell on the gear hobbing machine’s accuracy. Comprehensive checks of the machine’s foundational components, including the runout and face wobble of the workholding fixture’s base and pressure foot, were conducted. All values were within 0.005 mm, confirming that the machine tool condition was not the primary contributor to the large Fr values. Attention then turned to the workholding fixture itself. The fixture used a cylindrical spline that mates with the planetary gear’s internal teeth. The principle is that the gear is located and driven by this spline during the gear hobbing of the external teeth. If the fit between the internal teeth and the cylindrical spline is too loose, the gear can shift or tilt during machining, causing the hobbed external teeth to be eccentric to the internal teeth. To assess the fit, we measured the span measurement (over pins or via base tangent length) of both the fixture’s cylindrical spline and the gear’s internal teeth. The evaluation of tooth thickness for internal gears and splines often uses the concept of ball or pin measurement, but a fundamental related metric is the base tangent length (Wk) for external gears. For the internal spline interface, the effective fit is determined by the difference in their virtual tooth thicknesses. The formula for the base tangent length (Wk) of a standard spur gear is:

$$ W_k = \cos\alpha \, [ \pi (k – 0.5) + z \, \text{inv} \alpha ] \, m $$

where \( \alpha \) is the pressure angle, \( z \) is the number of teeth, \( m \) is the module, \( \text{inv} \alpha = \tan\alpha – \alpha \) (in radians), and \( k \) is the number of teeth spanned, calculated as:

$$ k = \frac{\alpha}{180^\circ}z + 0.5 \quad \text{(rounded to the nearest integer)} $$

While this formula is for external teeth, the comparative measurement of the internal gear/spline equivalent revealed a significant variance. The measurements indicated that the internal teeth of the planetary gear blanks had a larger effective space width compared to the tooth thickness of the cylindrical spline on the fixture, resulting in excessive clearance. This large clearance allowed the gear blank to move radially during the gear hobbing clamping and cutting process, directly translating into radial runout in the finished part. Furthermore, the geometric tolerances of the gear blank, such as the parallelism of its two end faces and the perpendicularity of the internal teeth axis to these end faces, were also found to be potential contributors if not tightly controlled. Any tilt of the blank on the fixture would cause a taper in the hobbed external teeth and contribute to apparent runout.

| Observed Problem | Root Cause | Key Solution | Implementation Detail |

|---|---|---|---|

| High radial runout (Fr) between internal & external teeth (0.05-0.08mm) | 1. Excessive clearance between gear internal teeth and cylindrical spline fixture. 2. Inadequate control of gear blank geometric tolerances (parallelism, perpendicularity). |

1. Replace cylindrical spline fixture with a tapered (conical) spline fixture. 2. Tighten tolerances on gear blank end faces and internal tooth orientation. |

– Tapered spline provides a line/area contact that self-compensates for tooth thickness variation. – Specify and control end face parallelism < 0.01mm and internal tooth perpendicularity < 0.01mm. |

| Inconsistent positioning during gear hobbing | Blank movement due to clearance in fixture. | Use a fixture that eliminates clearance regardless of minor blank variations. | The tapered spline fixture ensures a tight, repeatable lock without need for matching specific blanks to specific fixtures. |

2.2 Implemented Solutions and Results

To solve the clearance issue permanently and efficiently, we redesigned the workholding fixture. The cylindrical spline was replaced with a tapered (conical) spline design. The theoretical advantage is clear: as the planetary gear is pressed onto the tapered spline, it finds a specific diameter along the taper where the fit with its internal teeth becomes tight and virtually clearance-free. This self-compensating feature accommodates normal variations in the internal tooth thickness of the gear blanks without requiring a library of matched fixtures. It ensures a consistent and rigid location for every gear during the gear hobbing process, eliminating radial shift as a source of eccentricity.

Concurrently, we imposed stricter controls on the preceding machining steps for the gear blank. The end faces are now precision ground to ensure high parallelism (less than 0.01 mm). More importantly, the perpendicularity of the internal tooth axis relative to the end faces is controlled to within 0.01 mm. This prevents the gear from tilting when mounted on the fixture, ensuring that the axis of the external teeth being hobbed is coaxial with the internal teeth axis. After implementing the tapered spline fixture and enforcing the tighter blank tolerances, the measured radial runout (Fr) of the finished planetary gears decreased dramatically, consistently falling within the stringent specification limits. This solution also enhanced process efficiency by eliminating the need to select and change fixtures based on individual blank measurements, making the gear hobbing setup more streamlined for batch production.

3. Process Characteristics and Advantages of the Optimized Gear Hobbing Approach

The systematic troubleshooting and optimization of the gear hobbing process for RV planetary gears have led to a robust and reliable methodology. The core control points of this optimized gear hobbing strategy can be succinctly summarized.

| Control Category | Specific Parameter/Step | Target/Requirement | Rationale |

|---|---|---|---|

| Gear Blank (Semi-Finished) Quality | External Tooth Hobbing Allowance | ~0.3 mm per side (minimum) | Ensures sufficient material for angular phase correction via C-axis compensation during gear hobbing. |

| End Face Parallelism | < 0.01 mm | Prevents tilt and ensures uniform tooth depth in gear hobbing. | |

| Internal Tooth Perpendicularity to End Face | < 0.01 mm | Ensures coaxiality between internal and external tooth axes post gear hobbing. | |

| Workholding & Setup | Fixture Type | Tapered (Conical) Spline Fixture | Eliminates locating clearance, reduces radial runout, and simplifies setup for gear hobbing. |

| Machine Setup & Calibration | Fixture Base/Pressure Foot Runout | < 0.005 mm (radial & axial) | Minimizes machine-introduced errors into the gear hobbing process. |

| Tooth Search Function Usage | Enabled for first part in batch only | Eliminates batch-wide variation caused by search inconsistency in gear hobbing. | |

| Process Execution | C-axis Compensation Strategy | Apply compensation based on first-part measurement, maintain for batch. | Stabilizes the angular phase output of the gear hobbing process. |

The advantages of this refined gear hobbing process are significant when compared to other potential manufacturing routes for planetary gears. Generative gear grinding, while precise, requires frequent and time-consuming dressing of the grinding wheel, impacting overall efficiency. Form grinding, another alternative, has even lower efficiency due to larger contact areas and requires customized wheels for different tooth profiles, increasing cost and flexibility. Wire cutting, though capable of high accuracy, often results in poorer surface roughness on tooth flanks, which adversely affects the transmission efficiency and noise characteristics of the final RV reducer. Its serial nature also makes it slow for volume production. In contrast, modern gear hobbing, as applied here, offers remarkable versatility (capable of spur, helical, and even special profiles with custom hobs), high productivity due to continuous cutting, and—as demonstrated—the ability to achieve the stringent positional accuracies required for high-performance planetary gears. The process avoids the auxiliary time for tool conditioning inherent in grinding and is highly scalable. This makes gear hobbing the preferred choice for both development phases and batch trial production, providing a solid foundation for mass manufacturing.

4. Conclusion and Future Perspectives

Through detailed investigation and methodical process optimization, the key challenges of angular phase fluctuation and eccentricity in the gear hobbing of RV reducer planetary gears have been successfully mitigated. The solutions centered on fundamental aspects: ensuring adequate machining allowance, stabilizing the workpiece reference by modifying the fixturing strategy and machine sequence, and tightening the control of incoming blank geometry. The implementation of a tapered spline fixture and the disciplined use of the tooth search function were particularly impactful. The optimized gear hobbing process has demonstrated stable and reliable performance in batch trial production, leading to a substantial increase in qualification rates. The journey underscores that achieving supreme accuracy in gear hobbing complex components like planetary gears requires a holistic view, encompassing pre-machined part quality, fixture design, machine tool capabilities, and precise process control logic. As the demand for high-performance RV reducers continues to grow, driven by advancements in robotics and precision automation, the role of efficient and precise gear hobbing technology will only become more critical. Continuous efforts in machine tool development, cutter technology, process simulation, and intelligent adaptive control will further push the boundaries of what is achievable with gear hobbing, solidifying its position as a cornerstone of modern gear manufacturing.