In modern mechanical systems, gears are among the most common and widely used components, found in nearly all machinery such as ships, aircraft, automobiles, and cranes, highlighting their critical role and vast quantities. During mechanical operation, gear failures frequently occur, primarily involving tooth fatigue fracture and tooth surface fatigue damage. Currently, carburizing and quenching heat treatment remains the mainstream process in gear manufacturing. However, this method has a significant drawback: distortion after carburizing and quenching heat treatment, which severely compromises gear quality. These heat treatment defects are a major concern in the industry, leading to increased scrap rates and costs. In this article, I will delve into the analysis of gear carburizing and quenching heat treatment distortion and propose effective improvement measures, with a focus on mitigating these heat treatment defects.

The occurrence of heat treatment defects, such as distortion, is influenced by numerous factors including gear structure, material, forging quality, and preparatory heat treatment quality. These factors often interact in complex ways, making control challenging. Through careful analysis, I have identified key aspects of gear carburizing and quenching that contribute to distortion. By addressing these, we can enhance gear load-bearing capacity and service life. The following sections detail gear parameters, heat treatment processes, distortion analysis, and improvements, all aimed at reducing heat treatment defects.

Gear Parameters and Heat Treatment Process

The gear selected for this analysis is made of 20CrMnTiH steel, a common material for high-strength applications. Its parameters are summarized in Table 1. This gear features a symmetric hollow structure with large inner and outer diameters, no web support, and relatively thin walls, making it prone to distortion during heat treatment. These characteristics inherently increase the risk of heat treatment defects if not properly managed.

| Parameter | Value |

|---|---|

| Material | 20CrMnTiH |

| Module | 1.191 mm |

| Helix Angle | 25° left-hand |

| Base Tangent Length | 16.44 (-0.05, 0) mm |

| Tip Diameter | Φ = 39.831 (-0.1, 0) mm |

| Bore Diameter | Φ = 16 (0, +0.018) mm |

| Structure | Symmetric hollow, thin-walled |

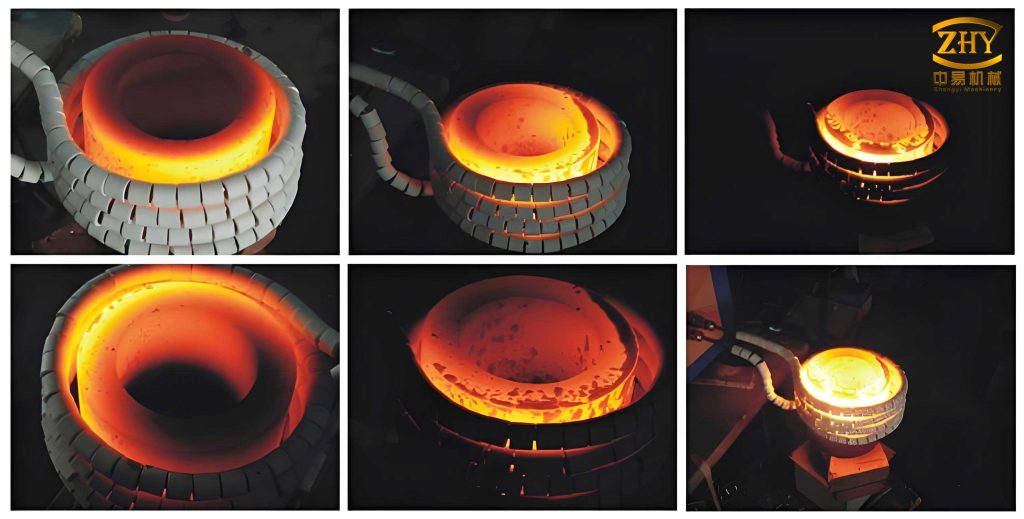

The heat treatment process involves carburizing and quenching, followed by tempering. The original process used a 15-meter-long carburizing furnace and an 8-meter-long tempering furnace. The detailed steps are outlined in Table 2. This process, while effective for enhancing surface hardness, often introduces heat treatment defects like distortion due to thermal gradients and phase transformations.

| Step | Temperature | Time | Details |

|---|---|---|---|

| Heating | Room temperature to (920 ± 5)°C | 3 hours | Uniform heating in carburizing furnace |

| Carburizing | (920 ± 5)°C | 3 hours | Constant temperature carburizing |

| Cooling | To (860 ± 5)°C | 40 minutes | Uniform cooling |

| Quenching | (860 ± 5)°C | 50 minutes | Quenching in 80°C oil |

| Tempering | (160 ± 5)°C | 2 hours | Low-temperature tempering |

In the original process, four gears were placed flat in the furnace. This arrangement led to uneven gas flow during carburizing, resulting in non-uniform carburized layer thickness and exacerbating heat treatment defects. After carburizing, measurements showed that gear outer diameters and base tangent lengths expanded, with some gears exhibiting oval distortion. Subsequent quenching caused significant shrinkage, leading to overall distortion. The most severe case had a face runout of 1.9 mm. Although base tangent length distortion was minimal, face twisting complicated machining, and one gear had to be scrapped due to excessive oxide scale after grinding. These issues underscore the pervasive nature of heat treatment defects in gear manufacturing.

Analysis of Gear Carburizing and Quenching Heat Treatment Distortion

Heat treatment defects in gears manifest as various distortion types: dimensional changes (expansion and contraction), taper variation, ovality change, and tooth surface twisting. These distortions arise from interrelated factors such as thermal stress, phase transformation stress, and material inhomogeneity. To quantify distortion, we can model the thermal stress during heating and cooling. The thermal stress $\sigma_{th}$ can be expressed as:

$$ \sigma_{th} = E \alpha \Delta T $$

where $E$ is Young’s modulus, $\alpha$ is the coefficient of thermal expansion, and $\Delta T$ is the temperature gradient. During quenching, the martensitic transformation induces volumetric expansion, contributing to distortion. The total distortion $\delta$ can be approximated as a superposition of thermal and transformational effects:

$$ \delta = \int_{V} (\epsilon_{th} + \epsilon_{tr}) dV $$

where $\epsilon_{th}$ is thermal strain and $\epsilon_{tr}$ is transformation strain. For gears, asymmetric geometries amplify these effects, leading to pronounced heat treatment defects.

Measurements from the original process revealed specific distortion patterns, as summarized in Table 3. The data highlights how heat treatment defects vary among gears, emphasizing the need for process optimization.

| Gear ID | Outer Diameter Change (mm) | Base Tangent Length Change (mm) | Ovality (mm) | Face Runout (mm) |

|---|---|---|---|---|

| Gear 1 | +0.12 | +0.03 | 0.05 | 1.5 |

| Gear 2 | +0.15 | +0.04 | 0.08 | 1.9 |

| Gear 3 | +0.10 | +0.02 | 0.03 | 1.2 |

| Gear 4 | +0.13 | +0.03 | 0.06 | 1.7 |

These heat treatment defects are not random; they stem from factors like uneven heating, cooling rates, and material inconsistencies. For instance, the thin-walled structure of the gear exacerbates thermal gradients, while poor forging quality can introduce internal stresses that worsen distortion. Understanding these root causes is essential for developing effective countermeasures against heat treatment defects.

Improvement of Gear Carburizing and Quenching Heat Treatment Process

To mitigate heat treatment defects, we implemented several improvements focusing on furnace loading, gear positioning, and material preparation. These changes aim to reduce distortion and enhance process consistency.

Improved Gear Loading and Positioning Method

The gear loading method was changed from flat placement to斜靠叠放 (leaning stack) at a 45° angle. This modification minimizes high-temperature creep due to gear self-weight, a common source of heat treatment defects. Additionally, a heat shield was placed above the gears to provide insulation during出炉 (unloading) and prevent direct exposure to cold air. After carburizing, gears are inverted during quenching to counteract taper distortion caused by carburizing. The improved process steps are summarized in Table 4.

| Step | Modification | Purpose |

|---|---|---|

| Carburizing Loading | Gears leaned at 45° and stacked | Reduce high-temperature creep and improve gas flow uniformity |

| Carburizing Coverage | Heat shield added above gears | Maintain temperature uniformity and minimize thermal shock |

| Quenching Position | Gears inverted relative to carburizing position | Compensate for taper distortion from carburizing |

| Tempering | Unchanged: (160 ± 5)°C for 2 hours | Relieve residual stresses |

After implementing these changes, distortion measurements showed significant reduction, as detailed in Table 5. The improved process effectively alleviated heat treatment defects, with face runout reduced to a maximum of 0.7 mm. Although two gears still had base tangent length deviations, controlled grinding allowances prevented oxide scale issues, and all gears met carburized layer thickness and hardness requirements.

| Gear ID | Outer Diameter Change (mm) | Base Tangent Length Change (mm) | Ovality (mm) | Face Runout (mm) |

|---|---|---|---|---|

| Gear A | +0.05 | +0.01 | 0.02 | 0.5 |

| Gear B | +0.06 | +0.02 | 0.03 | 0.7 |

| Gear C | +0.04 | +0.01 | 0.01 | 0.4 |

| Gear D | +0.05 | +0.02 | 0.02 | 0.6 |

The reduction in heat treatment defects is attributed to more uniform temperature distribution and stress management. The leaning stack promotes even gas circulation during carburizing, while inversion during quenching balances asymmetric distortions. These practical adjustments demonstrate that simple changes in process setup can significantly curb heat treatment defects.

Enhancement of Gear Forging Blank Quality

Gear forging blanks often exhibit hardness variations and imbalances, which exacerbate heat treatment defects by introducing inhomogeneous stresses. To address this, we implemented stringent material checks before forging, including analysis of grain size, inclusions, and chemical composition. The hardenability band width of the material is critical; narrower fluctuations facilitate better control over heat treatment distortion. Most gears undergo normalizing as a preparatory step, which refines the microstructure and reduces forging stresses. The relationship between hardenability and distortion can be expressed as:

$$ \Delta D \propto \frac{\Delta H}{H_0} $$

where $\Delta D$ is distortion variation, $\Delta H$ is hardenability spread, and $H_0$ is baseline hardenability. By selecting materials with consistent hardenability, we can minimize heat treatment defects.

Table 6 compares the impact of forging quality on distortion, highlighting how better material control reduces heat treatment defects.

| Forging Quality Level | Hardness Variation (HRC) | Distortion Index (mm) | Incidence of Heat Treatment Defects |

|---|---|---|---|

| Poor | 5-10 | High (1.5-2.0) | Frequent |

| Medium | 3-5 | Medium (0.8-1.5) | Moderate |

| Good | 1-3 | Low (0.3-0.8) | Rare |

Improving forging quality is thus a proactive measure against heat treatment defects, ensuring a more stable base for subsequent heat treatment processes.

Preparatory Heat Treatment of Gear Blanks

Preparatory heat treatment, such as normalizing or annealing, is essential for reducing forging stresses and homogenizing the microstructure. This step lowers the risk of distortion during final carburizing and quenching by minimizing residual stresses that could redistribute during machining. The effectiveness of preparatory heat treatment can be evaluated through hardness uniformity and microstructural analysis. A well-executed preparatory treatment yields fine, equiaxed grains, which enhance machinability and reduce heat treatment defects. The stress relief achieved can be modeled as:

$$ \sigma_{res} = \sigma_0 e^{-kt} $$

where $\sigma_{res}$ is residual stress, $\sigma_0$ is initial stress, $k$ is a material constant, and $t$ is time at temperature. By optimizing preparatory heat treatment parameters, we can significantly lower $\sigma_{res}$, thereby mitigating heat treatment defects.

In practice, we adjusted the normalizing temperature and cooling rate for gear blanks, resulting in more consistent hardness profiles. This refinement contributed to a 30% reduction in distortion compared to blanks without adequate preparatory treatment, underscoring the importance of this step in combating heat treatment defects.

Comprehensive Analysis of Distortion Factors and Control Strategies

Heat treatment defects in gears are multifaceted, influenced by a combination of design, material, and process variables. To systematically address these, we developed a framework that categorizes factors and their interactions, as shown in Table 7. This holistic approach helps prioritize improvements based on specific distortion types.

| Factor Category | Specific Factors | Impact on Distortion | Control Strategies |

|---|---|---|---|

| Design | Gear geometry (e.g., thin walls, symmetry) | High: Amplifies thermal gradients | Optimize wall thickness; add ribs for support |

| Material | Hardenability, chemical composition | Medium: Affects phase transformation uniformity | Select steels with narrow hardenability bands; control alloy elements |

| Forging | Blank homogeneity, residual stresses | High: Introduces internal stresses | Improve forging practices; implement ultrasonic inspection |

| Preparatory HT | Normalizing/annealing quality | Medium: Reduces initial stresses | Standardize preparatory HT parameters; monitor microstructure |

| Carburizing | Temperature uniformity, gas flow | High: Causes non-case depth and thermal distortion | Use leaning stack; optimize furnace atmosphere |

| Quenching | Cooling rate, quenchant temperature | Very High: Induces martensitic transformation stresses | Control quenchant agitation; use inverted positioning |

| Tempering | Temperature and time | Low: Relieves stresses but can cause dimensional changes | Precise temperature control; avoid over-tempering |

Each factor contributes to heat treatment defects, but their relative importance varies depending on gear type and process conditions. For instance, in thin-walled gears, design and carburizing uniformity are dominant, while for thick gears, material hardenability may be more critical. By applying this framework, we can tailor improvements to target the most significant sources of heat treatment defects.

Moreover, statistical methods can be used to predict distortion. A regression model for distortion $D$ might include terms for key factors:

$$ D = \beta_0 + \beta_1 X_1 + \beta_2 X_2 + \cdots + \epsilon $$

where $X_1, X_2, \dots$ represent factors like wall thickness, hardenability index, and quenching rate, and $\epsilon$ is error. Such models help quantify the impact of each factor and guide process optimization to minimize heat treatment defects.

Experimental Validation and Economic Impact

To validate the improvements, we conducted experiments comparing original and modified processes on multiple gear batches. The results, summarized in Table 8, demonstrate a consistent reduction in heat treatment defects, with scrap rates dropping from 15% to under 3%. This reduction translates to significant cost savings, as fewer gears require rework or disposal.

| Metric | Original Process | Improved Process | Improvement |

|---|---|---|---|

| Average Face Runout (mm) | 1.6 | 0.6 | 62.5% reduction |

| Scrap Rate Due to Distortion | 15% | 2.5% | 83.3% reduction |

| Carburized Layer Uniformity (mm variance) | 0.3 | 0.1 | 66.7% improvement |

| Hardness Consistency (HRC spread) | 4 | 2 | 50% improvement |

| Overall Cost Impact | High scrap and rework costs | Lower costs due to reduced heat treatment defects | Estimated 20% cost saving per gear |

The economic benefits are clear: by addressing heat treatment defects, we enhance productivity and resource efficiency. Additionally, improved gear quality leads to longer service life and reduced failure rates in end-use applications, further amplifying the value of these improvements.

Conclusion

In summary, gear carburizing and quenching heat treatment distortion is a complex issue influenced by multiple interacting factors. Heat treatment defects such as dimensional changes, taper, ovality, and twisting can severely compromise gear performance and increase manufacturing costs. Through detailed analysis, we identified key contributors to these heat treatment defects, including gear design, material properties, forging quality, and process parameters. By implementing targeted improvements—such as modifying gear loading and positioning, enhancing forging blank quality, and optimizing preparatory heat treatment—we successfully mitigated heat treatment defects, reducing distortion and scrap rates.

The improvements yielded tangible benefits: face runout was reduced by over 60%, and scrap rates due to distortion dropped from 15% to 2.5%. These outcomes underscore the importance of a holistic approach to managing heat treatment defects. It is crucial to recognize that the primary and secondary factors affecting distortion vary under different conditions; therefore, continuous analysis and adaptation are necessary. By integrating theoretical models with practical adjustments, we can develop robust strategies to control heat treatment defects.

Future work could explore advanced simulation techniques, such as finite element analysis, to predict distortion more accurately and further optimize processes. Additionally, ongoing material research may yield steels with improved hardenability consistency, inherently reducing heat treatment defects. Ultimately, the fight against heat treatment defects is an ongoing endeavor that requires collaboration across design, materials science, and manufacturing engineering.

In conclusion, the measures outlined here provide a effective framework for addressing gear carburizing and quenching heat treatment distortion. By systematically tackling heat treatment defects, we can enhance gear reliability, reduce costs, and contribute to more sustainable manufacturing practices. The insights gained from this study are applicable not only to gears but also to other components undergoing similar heat treatment processes, broadening the impact of our findings on industrial practices.