The pursuit of high-performance, durable power transmission components in demanding sectors like aerospace and advanced machinery places immense importance on the final geometric and physical state of critical parts such as spiral bevel gears. Among the various manufacturing stages, heat treatment, particularly carburizing and quenching, is a pivotal process designed to enhance surface hardness and fatigue resistance. However, this very process is a primary source of significant and complex heat treatment defects, predominantly in the form of uncontrolled distortion and residual stresses. These heat treatment defects can severely compromise the designed gear geometry, leading to poor contact patterns, increased noise, vibration, and ultimately, premature failure—issues that are unacceptable in high-reliability applications.

Traditionally, the analysis of these heat treatment defects has heavily relied on commercial finite element analysis (FEA) software. While these tools offer high accuracy in simulating coupled thermo-metallurgical-mechanical phenomena, they come with substantial computational costs. Simulating the full process—from carburizing kinetics to phase transformations and stress development—for a complex gear geometry can be prohibitively time-consuming, especially during iterative design or process optimization phases. This creates a critical gap between the need for precision and the requirement for efficiency in modern manufacturing. There is a clear demand for a methodology that can predict heat treatment defects with reasonable fidelity while dramatically reducing computational overhead, enabling faster design cycles and more robust process windows.

This article addresses this challenge by introducing and detailing a novel semi-analytical prediction method. The core innovation lies in explicitly modeling the carburizing-meshing coupling effect—the interaction between the heat treatment-induced material changes and the subsequent loaded contact conditions during gear operation—and establishing a direct functional relationship between fundamental machine tool settings (used in gear cutting/grinding) and the final tooth flank distortion. By moving away from a purely numerical simulation paradigm and leveraging analytical relationships for key aspects of the problem, this method aims to provide a powerful tool for efficiently predicting and ultimately controlling heat treatment defects in complex gear systems.

Fundamental Theories: Gear Modeling and Carburizing

Tooth Flank Generation and Modeling

Spiral bevel gears lack a standard, simple mathematical definition for their tooth flanks. Their geometry is intrinsically linked to the manufacturing process. Therefore, accurate modeling is achieved through a simulation of the machining kinematics, typically using methods like the duplex helical or Formate processes. The tooth surface is generated as the envelope of a family of tool surfaces (e.g., a cutting or grinding wheel) as it moves relative to the gear blank according to a specific machine setup.

The position vector of a point on the cutter surface in the cutter coordinate system $S_1$ is defined as $\mathbf{r}_1(\mu, \theta)$, where $\mu$ and $\theta$ are the Gaussian parameters. This point is transformed into the gear blank coordinate system $S_P$ through a series of coordinate transformations that embody the machine kinematics:

$$

\mathbf{p}(\phi, \mu, \theta) = \mathbf{M}_{b1}(\phi_P, X_D, \gamma_m, X_B, E_M, S_r, \sigma, \zeta, R_a) \cdot \mathbf{r}_1(\mu, \theta) = \begin{bmatrix} x_P \\ y_P \\ z_P \\ 1 \end{bmatrix}

$$

Here, $\phi$ is the machine cradle angle, and the transformation matrix $\mathbf{M}_{b1}$ is a concatenation of matrices representing each machine axis motion (e.g., sliding base $X_D$, swivel angle $\gamma_m$, blank offset $X_B$, etc.). The machine settings ($X_D$, $\gamma_m$, $X_B$, $E_M$, $S_r$, $\sigma$, $\zeta$) and the ratio of roll $R_a$ are the key parameters that define the unique gear geometry. The basic kinematic chain of a modern multi-axis hypoid generator can be represented as:

$$

\mathbf{M}_{b1}(\phi) = \mathbf{M}_{bg}(\phi_P, X_D) \cdot \mathbf{M}_{gx}(\gamma_m) \cdot \mathbf{M}_{xe}(X_B) \cdot \mathbf{M}_{em}(E_M) \cdot \mathbf{M}_{mc}(\phi, S_r) \cdot \mathbf{M}_{c1}(\sigma, \zeta)

$$

The generated tooth surface must satisfy the equation of meshing between the tool and the blank:

$$

f(\phi, \mu, \theta) = \mathbf{n}_P \cdot \mathbf{v}^{(b1)} = \left( \frac{\partial \mathbf{p}}{\partial \mu} \times \frac{\partial \mathbf{p}}{\partial \theta} \right) \cdot \frac{\partial \mathbf{p}}{\partial \phi} = 0

$$

where $\mathbf{n}_P$ is the unit normal to the surface and $\mathbf{v}^{(b1)}$ is the relative velocity. By simultaneously solving the coordinate transformation and the equation of meshing for a grid of $(\mu, \theta)$ parameters, a discrete point cloud $\mathbf{p}_{i,j}$ representing the theoretical tooth flank is obtained. This geometry serves as the foundational “as-manufactured” state before heat treatment, and any deviation from it constitutes a heat treatment defect.

Numerical Loaded Tooth Contact Analysis (NLTCA)

To understand the operational performance and the contact stresses that interact with the heat-treated layer, a loaded tooth contact analysis is essential. The NLTCA determines the contact pattern, transmission error, and load distribution under a specified torque. For spiral bevel gears with complex surface curvatures and varying stiffness, this is a nonlinear contact problem.

A common and efficient approach for solving this is the Discrete Convolution and Fast Fourier Transform (DC-FFT) method combined with a influence coefficient method. The tooth flanks of both the pinion and gear are discretized into a regular grid in a common contact plane. The instantaneous contact condition is governed by the compatibility and equilibrium equations:

Compatibility Equation:

$$

\mathbf{C} \cdot \mathbf{F} + \mathbf{D} – \Theta \cdot \mathbf{e} \ge \mathbf{0}

$$

where $\mathbf{C}$ is the matrix of flexibility (influence) coefficients, $\mathbf{F}$ is the vector of contact forces at grid points, $\mathbf{D}$ is the vector of initial separations (unloaded gap), $\Theta$ is the rigid body approach (load-dependent), and $\mathbf{e}$ is a unit vector.

Equilibrium Equation:

$$

\mathbf{e}^T \cdot \mathbf{F} = P

$$

where $P$ is the total normal load. Solving this system identifies the contact ellipse(s), the pressure distribution within them, and the associated tooth deformations under load. This loaded contact state is a crucial component of the carburizing-meshing coupling effect, as the stress field from contact modifies the driving forces for heat treatment defects like distortion.

Carburizing Process Fundamentals

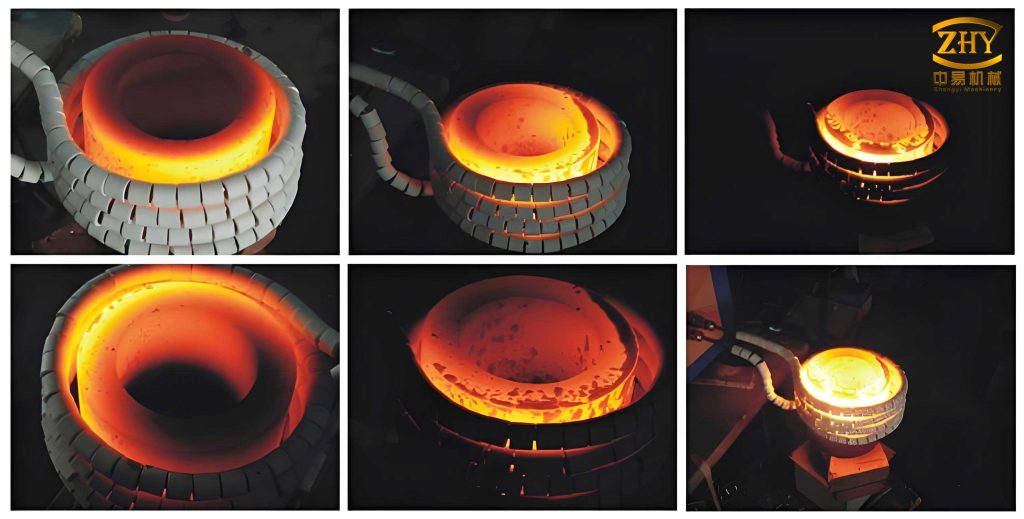

Carburizing is a thermochemical diffusion process where carbon is introduced into the surface layer of a low-carbon steel (e.g., common aerospace gear steel 9310) to create a hard, wear-resistant case while maintaining a tough core. The process involves exposing the gear to a carbon-rich atmosphere (e.g., containing CO, H₂, CH₄) at elevated temperatures (typically 850-950°C).

The key reactions at the steel surface involve the generation of active carbon atoms [C], which then diffuse inward. The rate of carbon transfer and its subsequent diffusion govern the final carbon profile, which is the precursor to hardness after quenching. This profile is a primary factor influencing the development of transformation-induced stresses and heat treatment defects.

The diffusion of carbon into the steel is governed by Fick’s second law. Considering the concentration-dependent diffusion coefficient $D(T, C)$, the governing equation is:

$$

\frac{\partial C}{\partial t} = \nabla \cdot \left[ D(T, C) \nabla C \right]

$$

where $C$ is the carbon concentration (mass %), $t$ is time, and $T$ is temperature. The diffusion coefficient is often expressed empirically as:

$$

D(T,C) = D_{0.4} \exp\left(-\frac{Q}{RT}\right) \exp[-B(0.4 – C)]

$$

where $D_{0.4}$ is the diffusion coefficient at 0.4% C, $Q$ is the activation energy, $R$ is the gas constant, and $B$ is a constant. The boundary condition at the surface is typically a flux condition related to the atmosphere’s carbon potential $C_e$ and the surface carbon content $C_s$:

$$

-D \frac{\partial C}{\partial n}\bigg|_{\text{surface}} = \beta (C_e – C_s)

$$

where $\beta$ is the carbon transfer coefficient, also temperature-dependent: $\beta = \beta_0 \exp(-E / RT)$. The resulting carbon gradient, after the diffusion cycle, sets the stage for the final quench. During quenching, the high-carbon case transforms to hard martensite, while the lower-carbon core transforms to softer phases (ferrite/pearlite or lower-carbon martensite/bainite). The differential volumetric expansion between the case and core, constrained by the part geometry, is the fundamental source of quenching distortion and residual stresses—the most critical heat treatment defects.

Table 1 summarizes typical chemical composition and key carburizing parameters for a common gear steel.

| Parameter Category | Symbol / Element | Value / Composition (wt.%) | Note |

|---|---|---|---|

| Chemical Composition | Fe | Balance | Base |

| Ni | 3.00 – 3.50 | Enhances core toughness | |

| Cr | 1.00 – 1.40 | Enhances hardenability | |

| Mo | 0.08 – 0.15 | Refines grain, increases strength | |

| C | 0.08 – 0.13 | Low carbon for carburizing | |

| Diffusion Parameters | $D_{0.4}$ | ~ $2.55 \times 10^{-5}$ m²/s | Pre-exponential factor |

| $Q$ | ~ 140 kJ/mol | Activation energy for diffusion | |

| $B$ | ~ 0.8 | Concentration dependency constant | |

| $\beta_0$ | ~ $3.47 \times 10^{-3}$ m/s | Pre-exponential for transfer coefficient |

The Semi-Analytical Prediction Method for Coupled Distortion

The proposed methodology seeks to establish a direct, computationally efficient link between the initial manufacturing parameters (machine settings), the operational contact condition, and the final heat treatment distortion. It avoids a full-scale, transient thermo-metallurgical-stress simulation by focusing on the final deformed state and its functional drivers.

Concept of Carburizing-Meshing Coupling Effect

The central hypothesis is that the final heat treatment defects on the tooth flank, specifically its distortion $\mathbf{u}$, are not merely a function of the heat treatment process parameters applied to a static geometry. Instead, they are the result of a coupled interaction: the heat treatment induces a transformation strain field $\boldsymbol{\varepsilon}^{th}$; when the gear is subsequently put into service, the operational contact loads $\mathbf{F}$ create an additional elastic-plastic strain field $\boldsymbol{\varepsilon}^{el}$. These fields are not independent because the heat treatment alters the material properties (yield strength, Young’s modulus) locally through the carbon gradient and phase distribution, thereby changing the contact response. Conversely, the contact pressure influences the local stress state that drives distortion during quenching and tempering. This two-way interaction is the carburizing-meshing coupling effect.

We propose that this final coupled distortion state $\mathbf{u}_{\Omega}$ can be expressed as a function of the machine settings $\mathbf{m}$ (which define the initial geometry), the position on the tooth flank $(\phi_i, \theta)$, and the process time/temperature history $t$:

$$

\mathbf{u}_{\Omega} := \mathbf{u}_{\Omega}(\mathbf{m}, \phi_i, \theta, t) = \mathbf{u}_{th}(\mathbf{m}, \phi_i, \theta, t) + \mathbf{u}_{el}(\mathbf{m}, \phi_i, \theta, \mathbf{F}(\mathbf{u}_{th}))

$$

This shows the implicit coupling: the elastic contact deformation $\mathbf{u}_{el}$ depends on the force $\mathbf{F}$, which itself acts on a geometry already altered by thermal distortion $\mathbf{u}_{th}$.

Semi-Analytical Formulation

The goal is to find a semi-analytical expression for $\mathbf{u}_{\Omega}$. We start from the principle of virtual work for the coupled system under equilibrium conditions after heat treatment and under load. For the tooth flank domain $\Phi$, the weak form of the equilibrium is:

$$

\int_{\Phi} \boldsymbol{\sigma}_{\Omega} : \delta \boldsymbol{\varepsilon} \, d\Phi – \int_{\Omega_{LCP}} \mathbf{t} \cdot \delta \mathbf{u} \, d\Omega – \int_{\Phi} \mathbf{P} \cdot \delta \mathbf{u} \, d\Phi = 0

$$

where $\boldsymbol{\sigma}_{\Omega}$ is the coupled stress field (incorporating thermal and mechanical components), $\mathbf{t}$ is the surface traction from contact in the loaded contact path zone $\Omega_{LCP}$, and $\mathbf{P}$ represents body forces.

Discretizing the tooth flank using finite elements, the displacement field within an element is $\mathbf{u}^e = \mathbf{N} \mathbf{U}^e$, where $\mathbf{N}$ is the shape function matrix and $\mathbf{U}^e$ is the nodal displacement vector. The strain is $\boldsymbol{\varepsilon}^e = \mathbf{B} \mathbf{U}^e$, with $\mathbf{B}$ being the strain-displacement matrix.

The key step is to relate the stress increment to the strain increment through a constitutive matrix $\mathbf{C}_{\Omega}^e$ that embodies the coupled material behavior. Using an incremental Newton-Raphson approach to solve the nonlinear problem, the stiffness equation for an iteration $i+1$ is:

$$

\left( \mathbf{K}_{\Omega} \right)_{i}^{t+\Delta t} \Delta \mathbf{U}^{e} = \left( \mathbf{P}_{\Omega} \right)^{t+\Delta t} – \left( \mathbf{R}_{\Omega} \right)_{i}^{t+\Delta t}

$$

Here, $\left( \mathbf{K}_{\Omega} \right)_{i} = \int_{\Phi} \mathbf{B}^T \mathbf{C}_{\Omega, i}^e \mathbf{B} \, d\Phi$ is the global tangent stiffness matrix, $\left( \mathbf{P}_{\Omega} \right)$ is the global external force vector (from contact tractions $\mathbf{t}$), and $\left( \mathbf{R}_{\Omega} \right)_{i}$ is the internal force vector corresponding to the current stress state.

The semi-analytical “leap” is in the treatment of $\mathbf{C}_{\Omega}^e$ and the contact forces. Rather than computing $\mathbf{C}_{\Omega}^e$ from a full thermomechanical history, we relate it to the machine settings $\mathbf{m}$ and the local carbon profile $C(\mathbf{m}, z)$ (where $z$ is depth), which can be estimated from diffusion models. Similarly, the contact traction $\mathbf{t}$ is determined not by a full NLTCA on the deformed geometry in each iteration, but by using influence coefficients derived from the *initial* geometry and corrected via a linear relationship to the distortion.

For the instantaneous contact ellipse at a given meshing position, the compatibility and equilibrium conditions (from NLTCA theory) are solved simultaneously with a constraint representing the thermally-induced displacement. This can be formulated as a linear complementarity problem (LCP) or solved via linear programming. The solution yields the contact force distribution $\mathbf{F}_{\Omega}$ that satisfies both the geometric gap (modified by thermal distortion $\mathbf{u}_{th}$) and force equilibrium.

The final incremental displacement solution can be approximated in a functional form:

$$

\Delta \mathbf{U}^{e} \approx \left[ \int_{\Phi} \mathbf{B}^T \widetilde{\mathbf{C}}_{\Omega}^e(\mathbf{m}, C) \mathbf{B} \, d\Phi \right]^{-1} \cdot \left\{ \int_{\Omega_{LCP}} \mathbf{N}^T \widetilde{\mathbf{t}}(\mathbf{m}, \mathbf{F}_{\Omega}(\mathbf{u}_{th})) \, d\Omega + \int_{\Phi} \mathbf{N}^T \mathbf{b} \, d\Phi \right\}

$$

where $\widetilde{\mathbf{C}}_{\Omega}^e$ and $\widetilde{\mathbf{t}}$ are semi-analytic functions of the machine settings $\mathbf{m}$ and the local state. This formulation demonstrates the direct functional mapping $\mathbf{m} \rightarrow \mathbf{u}_{\Omega}$ that the method aims to establish. The coefficients for these functions are determined through a limited set of detailed FEA simulations (the “data-driven” aspect) for a baseline geometry, and then the functions are used to extrapolate/predict for variations in $\mathbf{m}$.

Solution Procedure

The step-by-step procedure for predicting the heat treatment deformation of a tooth flank is as follows:

- Geometry Generation: Input the machine settings $\mathbf{m}$ to generate the discrete nominal tooth flank points $\mathbf{p}_{i,j}$ using the kinematic model and equation of meshing.

- Finite Element Discretization: Create a shell or solid finite element model of the gear based on the nominal geometry from step 1.

- Estimate Carbon Profile: Calculate or look up the effective case carbon profile $C(z)$ for the material and carburizing cycle. This defines the transformation strain potential.

- Compute Uncoupleed Baseline Fields: Perform a decoupled analysis:

- A simplified thermal-stress analysis to estimate the “free” heat treatment distortion $\mathbf{u}_{th}^{(0)}$ without contact constraint.

- A NLTCA on the nominal geometry to compute the influence coefficient matrix $\mathbf{C}$ and baseline contact forces $\mathbf{F}^{(0)}$ for the desired load.

- Formulate and Solve Coupled System at Contact Points: At each key meshing position (e.g., points along the path of contact), set up the coupled compatibility equation:

$$

\mathbf{C} \cdot \mathbf{F}_{\Omega} + \mathbf{D} + \mathbf{u}_{th}(\mathbf{m}) – \Theta \cdot \mathbf{e} = \mathbf{Y} \quad \text{(with } \mathbf{Y} \ge 0, \mathbf{F}_{\Omega} \ge 0, \mathbf{Y}^T \mathbf{F}_{\Omega}=0 \text{)}

$$Here, $\mathbf{u}_{th}(\mathbf{m})$ is added to the initial separation $\mathbf{D}$, explicitly coupling the thermal displacement. Solve this LCP using a simplex or iterative method to find the coupled contact forces $\mathbf{F}_{\Omega}$.

- Semi-Analytical Distortion Calculation: Use the functional approximation (like the one in Eq. 10) to compute the full-field distortion $\mathbf{u}_{\Omega}$. The inputs are $\mathbf{m}$, the carbon profile, and the coupled forces $\mathbf{F}_{\Omega}$ from step 5. This step uses pre-derived functional relationships and avoids a full FE solve for the coupled physics.

- Iteration for Consistency (Optional): Check if the calculated distortion $\mathbf{u}_{\Omega}$ significantly alters the contact pattern from that assumed in step 5. If needed, update the contact condition and repeat steps 5-6 until convergence.

This process efficiently yields a prediction for the deformed tooth flank geometry after heat treatment, accounting for the carburizing-meshing coupling effect.

Results, Analysis, and Validation

To demonstrate the method, we consider a non-orthogonal spiral bevel gear pair typical of aerospace applications. The basic geometric and manufacturing parameters are summarized in Table 2.

| Parameter | Pinion | Gear | Unit |

|---|---|---|---|

| Number of Teeth | 31 | 38 | – |

| Module (Normal) | 5.3 | 5.3 | mm |

| Shaft Angle | 52 | deg | |

| Hand of Spiral | Right | Left | – |

| Face Width | 32 | mm | |

| Cutter Radius (Sr) | 152.07 | 163.36 | mm |

| Machine Center to Back (Em) | 1.95 | 0.00 | mm |

| Sliding Base (Xb) | -37.14 | -3.95 | mm |

| Ratio of Roll (Ra) | 2.352 | 2.073 | – |

Applying the semi-analytical method, the heat treatment deformation is predicted for both the pinion and gear. The distortion is analyzed in a cylindrical coordinate system attached to the gear: Radial (R), Axial (Z), and direction normal to the nominal tooth flank (U). The total distortion magnitude is also computed. Key results for the pinion are summarized in Table 3, showing the deformation at the center of the contact ellipse for several meshing positions from entry (1) to exit (9).

| Meshing Position | Radial (R) Deformation (mm) | Axial (Z) Deformation (mm) | Normal (U) Deformation (mm) | Total Deformation Magnitude (mm) |

|---|---|---|---|---|

| 1 (Entry) | -0.2964 | -0.2110 | -0.0213 | 0.3645 |

| 2 | -0.3151 | -0.2055 | -0.0158 | 0.3772 |

| 3 | -0.3322 | -0.2001 | -0.0101 | 0.3893 |

| 4 | -0.3478 | -0.1950 | -0.0044 | 0.4007 |

| 5 (Mid) | -0.3621 | -0.1902 | -0.0009 | 0.4116 |

| 6 | -0.3752 | -0.1887 | 0.0078 | 0.4222 |

| 7 | -0.3874 | -0.1869 | 0.0145 | 0.4326 |

| 8 | -0.4011 | -0.1858 | 0.0198 | 0.4437 |

| 9 (Exit) | -0.4133 | -0.1849 | 0.0233 | 0.4532 |

Analysis of Results:

- Trends: The results reveal clear, physically interpretable trends. The radial deformation becomes more negative (inward contraction) from entry to exit. This is often linked to the cumulative effect of case hardening on the tooth flank curvature and the constraint of the gear web. Axial deformation is also negative but shows less variation. The most interesting trend is in the normal (U) direction: it transitions from negative to positive from entry to exit. This indicates a “warping” or change of slope of the tooth flank, which would directly alter the loaded contact pattern and is a critical heat treatment defect.

- Magnitude: The total distortion magnitude increases steadily along the path of contact, with the exit region being the most distorted (0.4532 mm). This has significant implications for tip relief design and end-of-action contact.

- Coupling Effect: Comparing these results with a decoupled analysis (where thermal distortion and contact analysis are performed independently and superimposed) shows notable differences, especially in the U-direction distribution and the total magnitude. The semi-analytical coupled solution predicts a more severe and differently shaped distortion field, confirming that the carburizing-meshing coupling effect is non-negligible and must be considered for accurate prediction of heat treatment defects.

Validation

Validating such a predictive model is crucial. The proposed semi-analytical method was validated by comparing its predictions for a subset of results against those from a high-fidelity, fully coupled thermo-metallurgical-mechanical FEA simulation performed in a commercial software (like DEFORM™ or SYSWELD™) for the same gear and process parameters. The comparison focused on the normal (U) direction deformation as it most directly affects transmission error.

The relative error between the semi-analytical method (SAM) and the full FEA (FEA) was calculated for the contact ellipse centers:

$$

\text{Relative Error} = \frac{|\text{U}_{\text{SAM}} – \text{U}_{\text{FEA}}|}{|\text{U}_{\text{FEA}}|} \times 100\%

$$

The validation showed a strong agreement. The maximum relative error for the pinion U-direction deformation was found to be below 0.9%, and for the gear, below 0.8% across all meshing positions. This high level of accuracy, achieved at a fraction of the computational time (the semi-analytical method can be 10-50 times faster depending on the gear complexity), strongly supports the reliability and practical utility of the proposed approach for predicting heat treatment defects.

Discussion and Practical Implications

The successful development and validation of this semi-analytical prediction method opens several important avenues for improving gear manufacturing and performance.

1. Proactive Compensation of Heat Treatment Defects: The most direct application is in the realm of compensation machining. By predicting the distortion $\mathbf{u}_{\Omega}(\mathbf{m})$ before heat treatment, the original machine settings $\mathbf{m}$ used for finish grinding (or hard finishing) can be proactively modified to produce a “pre-distorted” gear. After heat treatment, this pre-distorted gear is designed to spring back or deform into the desired nominal geometry. The semi-analytical model provides the functional map $\mathbf{m} \rightarrow \mathbf{u}_{\Omega}$ needed to invert this problem: find the modified settings $\mathbf{m}’$ such that $\mathbf{u}_{\Omega}(\mathbf{m}’)$ cancels out the nominal distortion, i.e., $\mathbf{p}_{nominal} + \mathbf{u}_{\Omega}(\mathbf{m}’) \approx \mathbf{p}_{nominal}$. This is a powerful strategy for achieving net-shape or near-net-shape hardening, drastically reducing or eliminating post-heat-treatment grinding, which is costly and can introduce other heat treatment defects like grinding burns.

2. Optimization of Heat Treatment Process: The model can be used to perform virtual design of experiments (DoE) for the heat treatment process itself. By linking the carbon profile parameters (case depth, surface carbon) to the distortion output through the constitutive functions, one can optimize the carburizing and quenching parameters (temperature, time, atmosphere, quenchant agitation) to minimize distortion for a given gear geometry. This helps in developing robust heat treatment recipes that reduce the scatter and magnitude of heat treatment defects.

3. Integrated Design for Manufacturing (DFM): Gear designers often work with a “soft” (pre-heat treat) geometry. This method allows for the performance (contact, stress) of the “hard” (post-heat treat) geometry to be evaluated early in the design cycle. Engineers can assess whether the anticipated heat treatment defects will push the loaded contact pattern into detrimental areas (e.g., towards the edge of the tooth) and adjust the initial macro-geometry (profile, bias) accordingly. This facilitates a true concurrent engineering approach where design, manufacturing process planning, and performance verification are integrated.

4. Root Cause Analysis and Troubleshooting: When excessive heat treatment defects are observed in production, the model can be used diagnostically. By inputting the actual measured machine settings and heat treatment parameters, the predicted distortion can be compared to the measured distortion. Discrepancies can point to unmodeled factors (e.g., fixturing effects, material batch variations, quenching non-uniformity), guiding engineers to the true root cause more efficiently.

Conclusion

This article has presented a comprehensive overview of a novel semi-analytical method for predicting heat treatment deformation in spiral bevel gears, with a specific focus on the critical carburizing-meshing coupling effect. By establishing a direct functional relationship between the fundamental gear manufacturing parameters (machine tool settings) and the final distorted tooth flank geometry, this method bridges a significant gap between the high accuracy of detailed numerical simulation and the practical need for computational efficiency in industrial settings.

The method synthesizes gear generation kinematics, loaded contact mechanics, and carburizing diffusion principles into a unified framework. It solves for the coupled state using a combination of influence coefficients, linear programming for contact resolution, and semi-analytic constitutive relations, validated against full-scale FEA with high accuracy (<1% error in key outputs).

The implications are profound for the manufacture of high-performance gears. This approach enables the proactive compensation of heat treatment defects, leading to potential savings in finishing costs and improvements in gear quality and consistency. It supports the optimization of both gear design and heat treatment processes, fostering an integrated design-for-manufacturing philosophy. Ultimately, by providing a fast and reliable tool to predict and control distortion, this semi-analytical method contributes directly to the production of more reliable, efficient, and quieter gear transmissions for the most demanding applications in aerospace, energy, and transportation industries. Future work will focus on extending the model to include other hardening processes (e.g., induction hardening) and further automating the calibration of the semi-analytic functions for a broader range of materials and geometries.