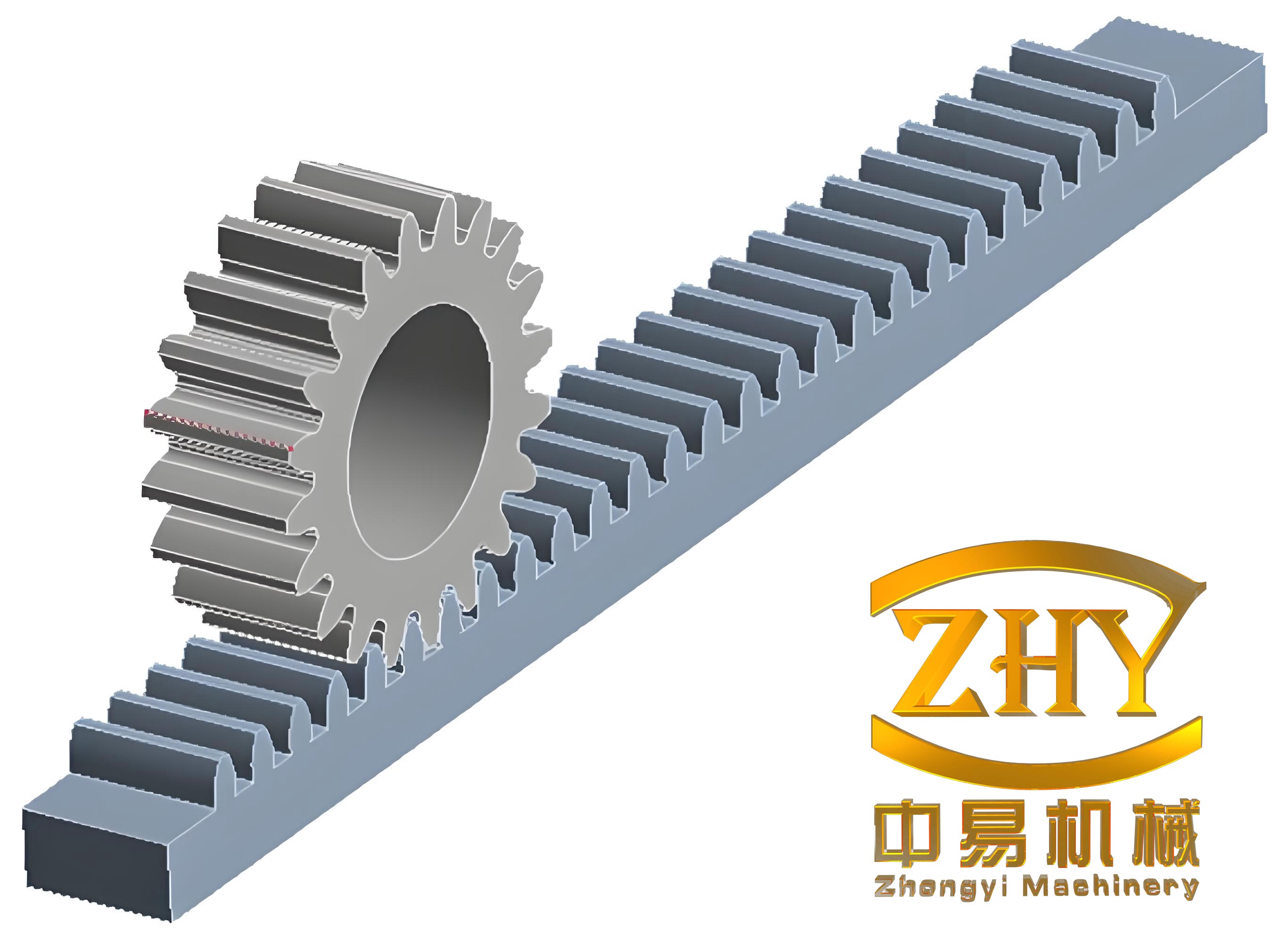

In the field of heavy-duty machine tool design, the rack and pinion gear system is widely adopted for long-travel feed mechanisms due to its advantages of high transmission ratio, excellent mechanical efficiency, good rigidity, and cost-effective manufacturing. However, a critical challenge associated with this system is the presence of backlash, which can significantly degrade positioning accuracy and machining precision. This article presents a comprehensive analysis and redesign of a dual-pinion rack and pinion gear backlash elimination structure, specifically for the feed system of a heavy-duty horizontal CNC lathe. The original system, designed for a 14-ton workpiece capacity, proved inadequate when applied to a more demanding 20-ton machine. I will detail the entire redesign process, from theoretical calculations and kinematic analysis to advanced finite element simulation, demonstrating the effectiveness of the new configuration in mitigating backlash and enhancing structural integrity.

The core of the feed drive in question utilizes a rack and pinion gear mechanism. Backlash, the unwanted clearance between mating gear teeth, becomes a pronounced issue under heavy loads and can lead to non-linear motion, vibration, and reduced contouring accuracy. The primary goal of this work was to develop a robust dual-pinion system that actively eliminates this clearance. The specific requirements for the 20-ton machine included a maximum cutting force of 40 kN and a tool holder assembly weighing approximately 3.5 tons. The existing design’s backlash adjustment range was insufficient, and the slender gear shaft was prone to excessive deflection under the higher operational loads.

The redesign focused on several key modifications to the gearbox (designated as the new model 201120240). First, the center distance between the gears and the housing was increased to allow for a greater range of backlash adjustment. Second, the sizes of specific gears were altered, and the overall transmission ratio was recalculated and modified. Third, and most crucially, the final output gear shaft—previously the most slender and vulnerable component—was strengthened by increasing its number of teeth, which consequently allowed for a larger shaft diameter and a shorter length, thereby drastically improving its bending stiffness.

The kinematic design began with the determination of the new transmission ratio. The gear train consisted of multiple stages. The overall transmission ratio \( i \) is the product of the ratios of each engaged pair. For the new arrangement, the ratio was calculated as follows:

$$ i = \left( \frac{Z_1}{Z_2} \right) \times \left( \frac{Z_3}{Z_4} \right) \times \left( \frac{Z_5}{Z_6} \right) \times \left( \frac{Z_7}{Z_8} \right) \times \left( \frac{Z_9}{Z_{10}} \right) = \left( \frac{24}{53} \right) \times \left( \frac{17}{46} \right) \times \left( \frac{18}{46} \right) \times \left( \frac{22}{47} \right) \times \left( \frac{18}{51} \right) $$

Performing the calculation:

$$ i \approx \frac{24}{53} \times \frac{17}{46} \times \frac{18}{46} \times \frac{22}{47} \times \frac{18}{51} = \frac{1}{92.43} $$

This transmission ratio is critical for matching the motor speed to the desired linear feed rate. The relationship between the linear velocity \( v \) (in mm/min), the motor speed \( n_m \) (in rpm), the transmission ratio \( i \), and the pitch diameter \( D \) of the final pinion (in mm) is given by:

$$ v = n_m \times i \times \pi D $$

Given a target rapid traverse rate \( v = 6000 \, \text{mm/min} \) and a final pinion pitch diameter \( D \approx 101.859 \, \text{mm} \), the required motor speed is:

$$ n_m = \frac{v}{i \times \pi D} = \frac{6000}{\left(\frac{1}{92.43}\right) \times \pi \times 101.859} \approx 1733.9 \, \text{rpm} $$

This motor speed is well within the operational range of standard servo motors, confirming the feasibility of the kinematic design. The key parameters of the main gears in the redesigned dual-pinion rack and pinion gear system are summarized in the table below.

| Gear Location | Module (mm) | Number of Teeth (Z) | Helix Angle (β) | Hand | Primary Function |

|---|---|---|---|---|---|

| Input Stage | 3 | 50 | 12°15’30” | Left | Initial speed reduction |

| Intermediate Stage 1 | 4 | 44 / 17 | 12°15’30” | — | Ratio step |

| Intermediate Stage 2 | 4 | 20 / 44 | 12°15’30” | Left / — | Ratio step |

| Dual-Pinion Output Stage | 4 | 18 (x2) | 21°10′ | One Left, One Right | Backlash elimination via preload |

| Final Drive to Rack | 6 | 16 | 19°31’42” | Left | Engagement with the rack |

The heart of the backlash elimination in this rack and pinion gear system lies in the dual-pinion output stage. Two identical pinions (module 4, 18 teeth) are mounted on parallel shafts but are preloaded against each other through a precision adjustment mechanism. One pinion is directly driven, while the other is spring-loaded or mechanically adjusted to rotate slightly out of phase. This action forces the teeth of both pinions to maintain contact with opposite flanks of the rack teeth, effectively eliminating any free play or backlash. The theoretical backlash \( j_t \) that needs to be compensated can be expressed as a function of manufacturing tolerances and assembly errors:

$$ j_t = j_{nmin} + J_a + J_b + \cdots $$

Where \( j_{nmin} \) is the minimum normal backlash from gear design, and \( J_a, J_b, \) etc., are error components from various sources. Our design ensures the adjustment mechanism can overcome the cumulative effect of these tolerances.

Following the kinematic design, a critical mechanical analysis was performed on the most critical component: the slender gear shaft in the dual-pinion rack and pinion gear assembly. The shaft is subjected to torsional shear stress from transmitted torque and bending stress from the gear mesh force. The bending stress at the critical section can be estimated using the standard formula:

$$ \sigma_b = \frac{M_b y}{I} = \frac{32 M_b}{\pi d^3} $$

Where \( M_b \) is the bending moment, \( d \) is the shaft diameter at the section, and \( y = d/2 \). The torsional shear stress is given by:

$$ \tau = \frac{T r}{J} = \frac{16 T}{\pi d^3} $$

Where \( T \) is the transmitted torque and \( J \) is the polar moment of inertia. Using the von Mises criterion for ductile materials, the equivalent stress \( \sigma_{eq} \) is:

$$ \sigma_{eq} = \sqrt{\sigma_b^2 + 3\tau^2} $$

The transmitted torque \( T \) can be derived from the cutting force. With a maximum cutting force \( F_c = 40 \, \text{kN} \) and assuming the force acts at the tool tip, the torque on the final pinion engaging the rack is related by \( T = F_c \times r_{effective} \), where \( r_{effective} \) considers the mechanical advantage. For a preliminary check, a significant safety factor was applied. The material selected for the gear shaft was a medium-carbon alloy steel such as 42CrMo4, with a yield strength \( \sigma_y \) typically exceeding 600 MPa. The calculated equivalent stress from these simplified formulas was well below the yield strength, indicating a safe design from a static strength perspective. However, deflection often governs the design of long, slender shafts in precision rack and pinion gear drives. The maximum deflection \( \delta_{max} \) for a simply supported shaft with a concentrated load (representing the gear mesh force) at the center is:

$$ \delta_{max} = \frac{F L^3}{48 E I} $$

Where \( F \) is the mesh force, \( L \) is the distance between bearings, \( E \) is the modulus of elasticity (~210 GPa for steel), and \( I \) is the area moment of inertia \( (\pi d^4 / 64) \). The original design had a smaller diameter \( d_{old} \) and a longer unsupported length \( L_{old} \). The redesign increased the diameter significantly and reduced the length. Since deflection is proportional to \( L^3 \) and inversely proportional to \( d^4 \), the improvement is dramatic. A comparative calculation is shown below:

| Shaft Design | Diameter (d) [mm] | Bearing Span (L) [mm] | Relative Stiffness (I ∝ d⁴) | Relative Deflection (δ ∝ L³/d⁴) |

|---|---|---|---|---|

| Original (201080140) | ~40 | ~600 | 1 (Baseline) | 1 (Baseline) |

| Redesigned (201120240) | ~55 | ~450 | (55/40)⁴ ≈ 3.56 | (450/600)³ / 3.56 ≈ 0.21 |

This simplified analysis predicted a reduction in shaft deflection to approximately one-fifth of the original value, a crucial gain for maintaining precise mesh alignment in the rack and pinion gear system and minimizing induced backlash.

To validate the design and obtain a more accurate picture of stress distribution and deformation under complex loading conditions, a detailed Finite Element Analysis (FEA) was conducted. The process began with creating a high-fidelity three-dimensional solid model of the critical gear shaft assembly using Siemens NX (UG) software. The model included accurate geometry of the shaft, gears, keyways, and bearing seats. This model was then imported into the MSC Nastran solver for structural analysis.

The meshing strategy was critical for accuracy. A hex-dominant mesh was employed, as hexahedral (brick) elements generally provide higher accuracy for stress analysis, especially for problems involving contact and non-linear behavior. The mesh was refined in areas of high-stress concentration, such as the gear tooth fillets, keyway corners, and shoulder regions. The final mesh consisted of several hundred thousand elements. Boundary conditions were applied to simulate real-world operation: the shaft was constrained at the bearing locations (cylindrical supports allowing rotation but restraining radial and axial movement as per the bearing type), and the gear tooth surfaces were loaded with the calculated mesh forces derived from the 40 kN cutting force. The force was distributed among the contacting teeth following the load-sharing ratio of the helical gears.

The material properties assigned were for high-quality alloy steel: Young’s Modulus \( E = 210,000 \, \text{MPa} \), Poisson’s ratio \( \nu = 0.3 \), and a yield strength \( \sigma_y = 650 \, \text{MPa} \). The analysis solved for static structural stresses and displacements. The FEA results for the new gear shaft (201120240) were then compared directly with the results from a similar analysis of the old gear shaft (201080140). The key findings are summarized in the table below.

| Parameter | Original Shaft (201080140) | Redesigned Shaft (201120240) | Improvement Factor |

|---|---|---|---|

| Maximum Von Mises Stress (MPa) | 133.0 | 74.5 | ≈ 1.78 (Stress reduced by ~44%) |

| Maximum Total Deformation (mm) | 2.13 × 10⁻¹ (0.213) | 1.03 × 10⁻¹ (0.103) | ≈ 2.07 (Deformation reduced by ~52%) |

| Critical Stress Location | Gear root fillet & mid-span | Gear root fillet (less severe) | — |

| Critical Deformation Location | Mid-span and smallest diameter section | Mid-span (significantly reduced) | — |

The contour plots from the FEA vividly illustrated these outcomes. For the new design, the stress distribution was more uniform, with the peak stress concentrated at the gear mesh contact region and well below the material’s yield strength. The deformation plot showed a smooth, symmetrical deflection curve, with the maximum value at the center of the shaft’s length. Crucially, this maximum deformation of approximately 0.103 mm is acceptable for the intended application, as it is within the range that can be compensated by the dual-pinion preload adjustment mechanism without losing contact with the rack. The rack and pinion gear interface remains positively engaged.

The improvement factors of nearly 1.8 for stress and 2 for deformation align remarkably well with the predictions from the simplified theoretical calculations. This confirms that the redesign strategy—increasing shaft diameter, reducing unsupported length, and optimizing the gear geometry—was fundamentally correct and highly effective. The reduced deformation directly translates to a more stable and predictable mesh condition between the pinions and the rack, which is essential for maintaining the backlash elimination function under heavy load. Furthermore, the lower stress level increases the fatigue life of the component, enhancing the overall reliability of the rack and pinion gear feed drive system.

The successful integration of this redesigned dual-pinion rack and pinion gear subsystem into the complete feed box assembly requires careful consideration of the adjustment mechanism for preload. The design includes precision tapered roller bearings to support the shafts and take up axial loads from the helical gears. The preload between the two counter-acting pinions is set using a combination of shims and threaded adjusters, allowing fine control over the elimination of backlash. The housing itself was also reinforced in critical areas to ensure that deflections under load do not misalign the gear shafts, which could reintroduce backlash.

In conclusion, this detailed analysis and redesign project for a heavy-duty machine tool feed system demonstrates a systematic engineering approach to solving the perennial problem of backlash in rack and pinion gear drives. By moving from an initial problem statement through kinematic redesign, theoretical strength and stiffness calculations, and finally rigorous finite element simulation, a robust and effective solution was developed. The new dual-pinion rack and pinion gear backlash elimination system, embodied in the gearbox model 201120240, shows a dramatic improvement over its predecessor. The maximum stress was reduced by about 44%, and the critical shaft deflection was halved, both of which contribute directly to improved positional accuracy, dynamic stiffness, and long-term reliability of the machine tool. The methodologies employed—particularly the synergistic use of theoretical modeling and advanced FEA—provide a reliable template for the design and optimization of similar precision mechanical systems where the elimination of clearance in rack and pinion gear engagements is paramount.