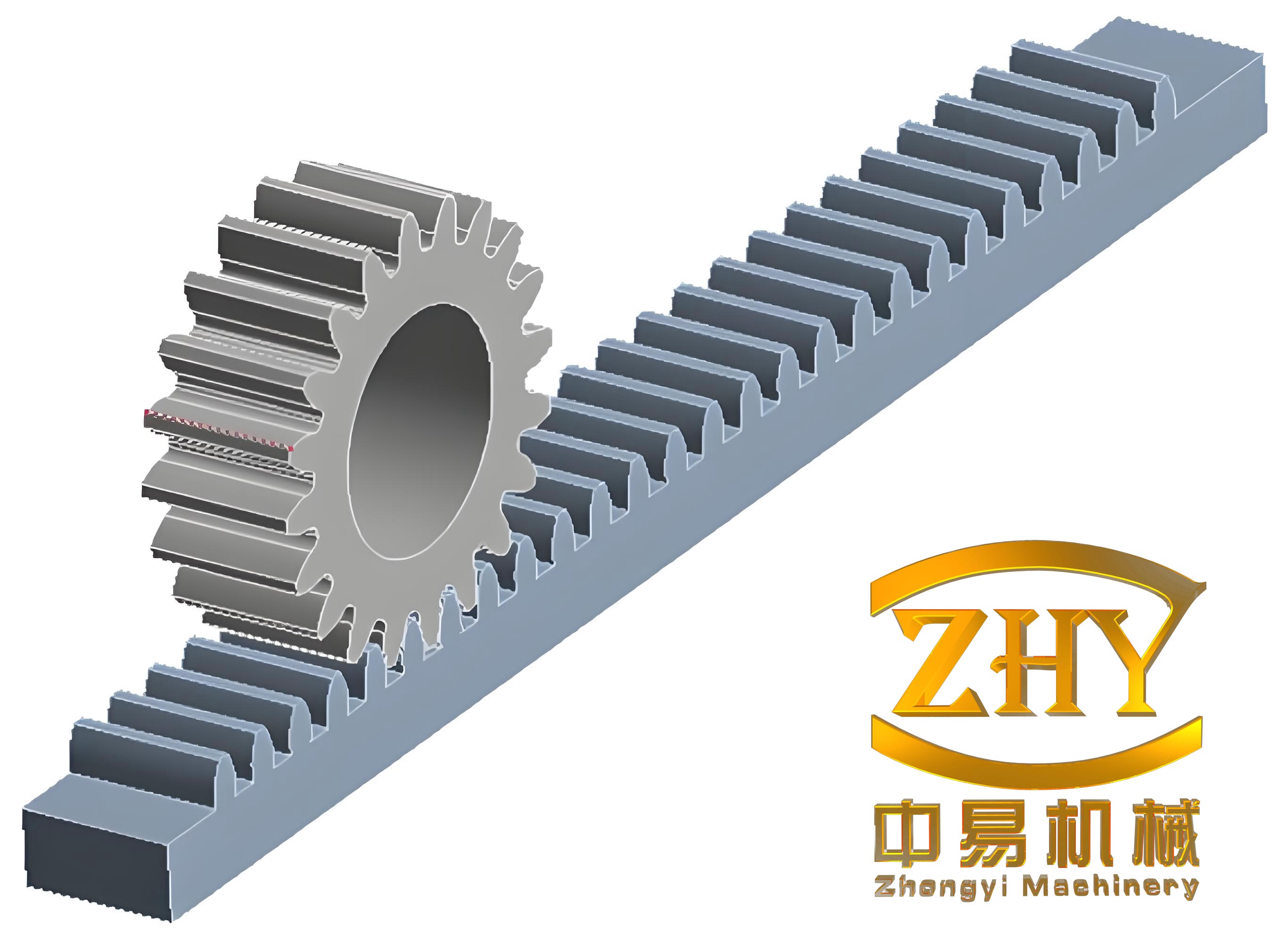

In my extensive experience with large-scale hydroelectric projects, the installation of balance weight system wire ropes in a rack and pinion gear hoist ship lift represents one of the most critical and technically demanding phases. This technology is pivotal for ensuring the safe and efficient operation of vertical ship lifts, which rely on the precise interaction of the rack and pinion gear mechanism to hoist vessels across significant elevation changes. The rack and pinion gear system, characterized by its robustness and accuracy, demands meticulous alignment and load distribution, with the balance weight system playing a key role in counterbalancing the ship chamber. In this article, I will delve into the key installation techniques, drawing from firsthand involvement in a major hydropower station project, focusing on the challenges posed by wire rope behavior under free suspension and the strategic sequencing of tensioning operations. The rack and pinion gear hoist’s reliability hinges on these details, and the methodologies described here have proven to be mature, safe, and economically sound, applicable to similar engineering endeavors worldwide.

The project in question features a full-balance, rack and pinion gear climbing type vertical ship lift, with a maximum lifting height of 114.20 meters. This rack and pinion gear system is integral to the lift’s operation, providing the driving force for vertical movement. The balance weight system comprises 128 wire ropes, each with a diameter of 76 mm, organized into 16 groups symmetrically on both sides of the ship chamber. Each group consists of 8 ropes, with a single rope length of approximately 142.017 meters. One end of each rope connects to the ship chamber via an adjustment assembly (including components like turnbuckles, clevis nuts, and self-lubricating spherical bearings), while the other end passes over pulley sets in the tower top machinery room and links to balance weight blocks through connection assemblies (such as balance beams and pins). The entire configuration is designed to work in harmony with the rack and pinion gear mechanism, ensuring smooth and balanced hoisting. The rack and pinion gear drive, combined with this balance system, minimizes power requirements and enhances operational stability, making it a preferred choice for high-lift ship navigation structures.

The installation of wire ropes for the rack and pinion gear hoist balance weight system follows a meticulously planned sequence, initiated after the placement of corresponding balance weight blocks and pulley sets. Key processes include the arrangement of hoisting winches, installation of balance beams on weight blocks, positioning and lifting of wire ropes, removal of winches, connection of ropes to the ship chamber via turnbuckles, and systematic tensioning. Each step is crucial to avoid damage such as crushing, breakage, or wear on the rope surfaces, which could compromise the integrity of the rack and pinion gear system. Below is a summarized table of the primary installation workflow:

| Step | Description | Equipment Used | Key Considerations |

|---|---|---|---|

| 1. Hoisting Winch Arrangement | Deploy two 15-ton winches on the platform, fixed via embedded parts or drilled-in rebars. Install support beams with 20-ton guide pulleys at balance weight shaft openings. | 15-ton winches, support beams, 20-ton guide pulleys, M20 expansion bolts | Ensure winch placement avoids interference with functional rooms and other structures; secure all fixings robustly. |

| 2. Wire Rope Lifting and Positioning | Transport ropes and accessories below rope holes. Use bridge cranes to thread winch lines over pulley sets. Connect and lift two ropes simultaneously from reels, guiding them through holes and into pulley grooves. | Bridge crane, winches, lifting slings, levers | Monitor rope passage to prevent friction with holes; assist rope entry into grooves with tools; avoid surface damage. |

| 3. Connection to Balance Weight Blocks | Attach rope heads to balance beam eyes via pins using chain hoists and winch adjustments. Repeat for all ropes in groups. | Chain hoists, winches, pins, lifting straps | Maintain parallel alignment of ropes; ensure secure pin connections without bending stresses. |

| 4. Connection to Ship Chamber | Adjust turnbuckles to initial tension values. Use chain hoists to pull ropes downward for connection to chamber lugs. Employ tensioning rigs to achieve design tension, suspending weight blocks 100-150 mm. | Chain hoists, tensioning rigs, turnbuckles, locking nuts | Synchronize tensioning across groups; control chamber weight to exceed balance weight during process. |

| 5. Systematic Tensioning and Water Loading | Tension ropes in symmetric batches while gradually filling chamber with water. Follow a sequence from middle to sides within groups. | Tensioning equipment, water pumps, measurement tools | Maintain chamber weight ≥ balance weight; monitor chamber levelness and structural deformation. |

The rack and pinion gear system’s efficiency depends heavily on the uniformity of wire rope lengths and tensions. During installation, a significant challenge arises from the untwisting phenomenon (松捻现象) of wire ropes under free suspension. Due to self-weight, ropes tend to untwist unpredictably, leading to irregular elongations that can affect tension distribution and, consequently, the balance of the rack and pinion gear hoist. Based on field measurements and statistical analysis of all 128 ropes, the untwisting ranged from 4 to 7 revolutions in free hang. Each revolution corresponds to a length increase, which can be modeled empirically. For a wire rope of diameter $d$ and length $L_0$ in its manufactured state, the additional length $\Delta L$ due to untwisting by $n$ revolutions can be approximated by:

$$ \Delta L = k \cdot n \cdot d $$

where $k$ is a material and construction-dependent coefficient. From experimental data, for the 76 mm ropes, each revolution added approximately 30–45 mm in length, aligning with tension tests. To address this, we implemented corrective measures by reversely twisting some ropes by 1–2 revolutions and adjusting turnbuckle lengths, ensuring that during chamber ascent to the upper limit, the balance weight blocks would not bottom out. This adjustment is vital for the synchrony of the rack and pinion gear drive, as uneven rope lengths could induce skewed loads on the gear teeth. The relationship between untwisting and elongation can be further expressed in terms of rope lay angle $\alpha$ and strand geometry. If the original lay length (pitch) is $P$, the change in length per revolution is roughly:

$$ \Delta L \approx P \cdot \sin(\alpha) $$

For typical wire ropes used in rack and pinion gear hoists, $\alpha$ ranges from 10° to 20°, yielding $\Delta L$ values consistent with observations. The table below summarizes the untwisting analysis:

| Parameter | Value Range | Impact on Installation | Corrective Action |

|---|---|---|---|

| Untwisting Revolutions (n) | 4 to 7 revolutions | Causes variable rope lengths, leading to load imbalance in rack and pinion gear system. | Reverse twisting by 1–2 revolutions; adjust turnbuckle length accordingly. |

| Length Increase per Revolution (ΔL) | 30–45 mm | Accumulates to significant differences, affecting tension uniformity. | Incorporate into initial tension calculations; use empirical coefficient k ≈ 0.4–0.6 mm/mm·rev. |

| Empirical Coefficient (k) | 0.4–0.6 mm/mm·rev | Helps predict elongation for planning adjustments. | Apply in pre-installation simulations for rack and pinion gear balance. |

Another critical aspect is the tensioning sequence of the wire ropes, which directly influences the levelness of the ship chamber corners, structural deformation, and the safe suspension of balance weight groups. The rack and pinion gear mechanism requires that the chamber remain precisely horizontal to avoid undue stress on the gears. Through theoretical analysis and tensioning trials, we adopted a batch-wise symmetric approach, where ropes are tensioned in groups while gradually adding water to the chamber. This ensures that the chamber-side weight always exceeds the balance weight side, preventing sudden shifts. The tensioning process involves 16 groups, with each group’s 8 ropes tensioned from the middle outward. The mechanical principle can be described using force equilibrium equations. For a given group, let $T_i$ be the tension in rope $i$, $W_c$ the chamber weight (including water), and $W_b$ the balance weight. During tensioning, the condition $W_c \geq W_b$ must hold to maintain control. The total vertical force balance is:

$$ \sum_{i=1}^{128} T_i \cdot \cos(\theta_i) = W_c – W_b $$

where $\theta_i$ is the angle of rope deviation from vertical, typically small in rack and pinion gear hoists. For symmetric groups, tensions should be equalized to minimize torque on the chamber. The tensioning sequence aims to reduce variance in $T_i$. If we define an objective function $F$ representing tension uniformity:

$$ F = \sum_{j=1}^{16} \left( \max(T_{j}) – \min(T_{j}) \right)^2 $$

the optimal sequence minimizes $F$ stepwise. In practice, we tensioned two symmetric groups at a time, starting with two ropes per group (linked to balance weight blocks III), then progressively adding water and tensioning remaining ropes. This method ensured that balance weight blocks were suspended uniformly, with clearance gaps meeting design specifications. The rack and pinion gear system’s performance benefits from such precise tensioning, as it reduces dynamic fluctuations during operation. Below is a formulaic representation of the tensioning stages:

Let $N$ be the total number of tensioning steps, $Q_w$ the water inflow rate, and $t$ time. At step $k$, the chamber weight is:

$$ W_c(k) = W_{c0} + Q_w \cdot t_k $$

where $W_{c0}$ is the initial chamber weight. The tension increment $\Delta T$ for ropes tensioned at step $k$ is calculated to satisfy:

$$ \Delta T = \frac{W_c(k) – W_b}{n_k} $$

with $n_k$ being the number of ropes tensioned in that step. This incremental approach, coupled with symmetric grouping, kept structural deformations within 5 mm and corner levelness under 2 mm, as required for the rack and pinion gear engagement. The table outlines the tensioning sequence:

| Stage | Action | Chamber Water Level | Ropes Tensioned | Objective |

|---|---|---|---|---|

| 1 | Initial tensioning of 2 groups symmetrically | Dry or minimal water | 2 ropes per group (total 4 ropes), from balance weight III | Partially suspend balance weights; establish baseline tensions. |

| 2 | Gradual water addition and symmetric tensioning | Increasing gradually | Remaining ropes in batches, middle to sides within groups | Maintain chamber weight ≥ balance weight; ensure uniform lift. |

| 3 | Final adjustments and locking | Full operational level | All 128 ropes, fine-tuned via turnbuckles | Achieve design tensions; verify clearances and levelness for rack and pinion gear operation. |

The installation of balance weight system wire ropes is a cornerstone in the commissioning of rack and pinion gear hoist ship lifts. From the project referenced, the entire process from rope hanging to tensioning completion spanned approximately one year, successfully overcoming issues like unpatterned elongation due to untwisting. All 128 ropes were installed and tensioned, resulting in the safe suspension of balance weight groups, controlled structural deformation, and chamber corner levelness within design limits. The rack and pinion gear system’s reliability was thereby ensured, demonstrating that this technology is mature, safe, and economical. Key takeaways include the importance of pre-installation analysis of rope behavior, systematic tensioning sequences, and continuous monitoring. These principles are transferable to other vertical ship lifts employing rack and pinion gear mechanisms, contributing to advancements in navigational infrastructure. Future improvements could involve automated tensioning systems integrated with rack and pinion gear controls, further enhancing precision and efficiency.

In reflection, the interplay between wire rope installation and the rack and pinion gear system’s performance cannot be overstated. Every detail, from winch placement to tensioning logic, impacts the holistic operation of the hoist. The rack and pinion gear, as a driving element, demands absolute balance and symmetry, which the described techniques adeptly provide. As hydropower and ship lift projects evolve globally, the methodologies detailed here will serve as a robust reference, underscoring the critical role of meticulous engineering in harnessing the power of rack and pinion gear technology for vertical transportation.