The rack and pinion gear system is a cornerstone of modern jack-up platform technology, providing the robust and continuous lifting action required for these critical offshore assets. This system’s performance under varying operational and extreme conditions is paramount for the safety and reliability of the entire platform. A deep understanding of the dynamic interactions within the rack and pinion gear assembly during normal and emergency scenarios is therefore essential. This analysis delves into the kinematics and dynamics of a single-leg rack and pinion lifting unit, employing simulation to unravel the complex load-sharing mechanisms and motion synchronization between multiple pinions and the rack, particularly when faced with a partial drive failure.

1. Introduction to the Rack and Pinion Lifting Mechanism

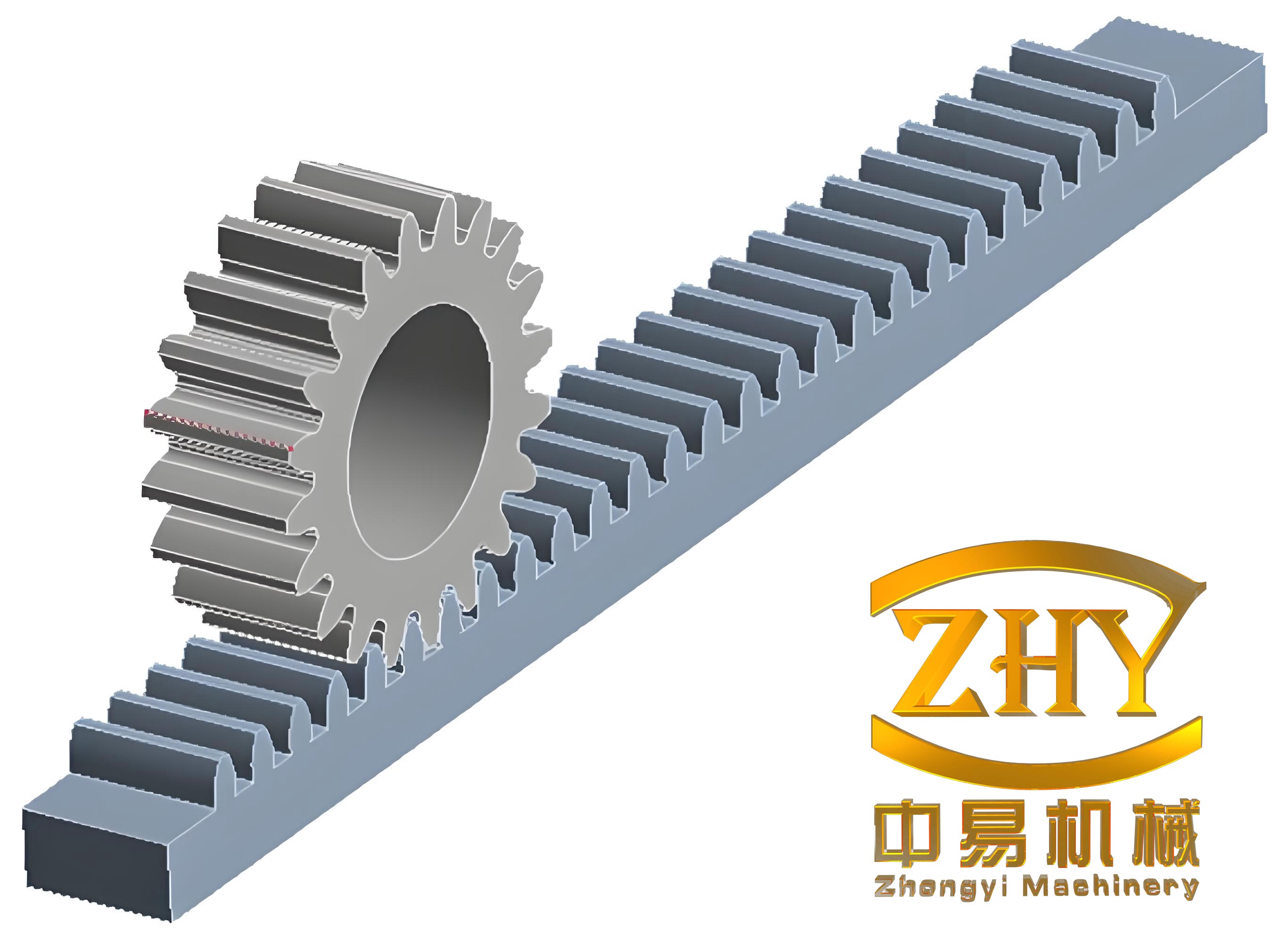

The rack and pinion gear system stands out for its high load capacity, operational continuity, and relatively straightforward control logic. In a typical jack-up platform configuration, each leg is equipped with one or more racks on opposing sides. These racks engage with multiple pinions driven by electric or hydraulic motors, facilitating the controlled ascent or descent of the platform hull relative to the seabed. The rack and pinion gear assembly must be designed to handle immense loads, which can vary drastically between operational states such as normal jacking, storm survival, and preloading. Consequently, the dynamic behavior—encompassing load distribution among pinions, synchronization of motion, and response to transient events like a motor failure—becomes a critical area of study. While traditional gear pair dynamics are well-researched, the specific case of multiple pinions engaging a common rack, especially under fault conditions, presents unique challenges that warrant detailed investigation to inform safer operational procedures and design improvements.

2. Simulation Model and Methodology

The focus of this study is a representative single-leg rack and pinion gear lifting unit. The system features a rack on each side of the leg, with each rack engaged by three pinions. Symmetrically opposite pinions across the leg are typically driven by a common motor through a planetary reduction gearbox, forming a “one-input, two-output” drive unit. Key geometric and material parameters for the rack and pinion gear set are summarized below.

| Component | Parameter | Value / Specification |

|---|---|---|

| Pinion | Number of Teeth | 7 |

| Module | 100 mm | |

| Face Width | 200 mm | |

| Rack | Pressure Angle | 28° |

| Face Width | 127 mm | |

| Pinion Material | SAE 4340 | |

| Rack Material | ASTM A514 Gr. Q | |

A high-fidelity three-dimensional model of the assembly was constructed. This model was then imported into a multi-body dynamics simulation environment to conduct a transient dynamic analysis. The interactions between all pinions and the rack were modeled using a robust contact algorithm (solid-to-solid contact), which accurately captures the time-varying forces and impacts during meshing. All necessary kinematic joints (revolute joints for pinion rotation) and prescribed motions were applied. Three primary design load cases were simulated for the normal lifting operation, corresponding to different platform operational states:

| Operational State | Design Lifting Load (Flift) | Lifting Speed |

|---|---|---|

| Normal Operation | 12,000 kN | 0.25 m/min |

| Storm Survival | 24,000 kN | |

| Preloading | 36,000 kN |

The force \( F_{lift} \) was applied as an external load on the leg, opposing the lifting direction. Each pinion drive was assigned a corresponding rotational speed to achieve the target lifting velocity. The dynamic equations solved at each time step are governed by the fundamental principles of mechanics, expressed for the system as:

$$ \mathbf{M}(\mathbf{q})\ddot{\mathbf{q}} + \mathbf{C}(\mathbf{q}, \dot{\mathbf{q}}) + \mathbf{K}\mathbf{q} = \mathbf{Q}_{ext} + \mathbf{Q}_{contact} $$

Where \( \mathbf{M} \) is the mass matrix, \( \mathbf{q} \) is the vector of generalized coordinates, \( \mathbf{C} \) represents Coriolis and centrifugal forces, \( \mathbf{K} \) is the stiffness matrix, \( \mathbf{Q}_{ext} \) includes external loads like \( F_{lift} \), and \( \mathbf{Q}_{contact} \) encapsulates all forces generated at the rack and pinion gear contact interfaces.

3. Normal Lifting Operation: Kinematic and Dynamic Response

Under normal operating conditions with all six pinions actively driven, the primary objectives are to evaluate motion synchronism and load distribution within the rack and pinion gear system.

3.1 Kinematic Performance and Synchronization

The angular velocity of each pinion was extracted from the simulation. The results demonstrate excellent synchronization characteristics. Pinions driven by the same motor (symmetrically opposite) exhibited nearly identical angular velocity histories. Furthermore, the angular velocity curves for all six pinions were virtually superimposed, indicating near-perfect motion synchronicity under all three load cases. However, a periodic fluctuation was observed, centered around the nominal value required for the 0.25 m/min lift speed. The magnitude of this velocity fluctuation \( \Delta \omega \) was found to be directly correlated with the applied lifting load \( F_{lift} \), as quantified below:

| Lifting Load, Flift (kN) | Pinion Angular Velocity Range, \( \omega \) (°/s) | Fluctuation Magnitude, \( \Delta \omega \) (°/s) |

|---|---|---|

| 12,000 | 36 – 50 | 14 |

| 24,000 | 32 – 54 | 22 |

| 36,000 | 31 – 60 | 29 |

The relationship suggests increasing meshing impact and system excitation with higher load. The nominal angular velocity \( \omega_{nom} \) can be derived from the lifting speed \( v \) and pinion pitch radius \( r_p \):

$$ \omega_{nom} = \frac{v}{r_p} $$

Where \( r_p = \frac{m \cdot z}{2} \), with \( m \) being the module and \( z \) the number of pinion teeth.

3.2 Dynamic Load Sharing and Forces

The contact forces at each rack and pinion gear interface are critical for assessing structural integrity. These forces are resolved into tangential (\( F_t \)) and radial (\( F_r \)) components relative to the pinion.

Tangential Force (Ft): This component directly counteracts the lifting load. The simulation confirmed an exceptionally even load distribution. For all load cases, the instantaneous tangential force on each pinion oscillated around a mean value of \( F_{lift}/6 \).

$$ \bar{F_t} \approx \frac{F_{lift}}{6} $$

The amplitude of oscillation around this mean increased proportionally with \( F_{lift} \), mirroring the trend observed in velocity fluctuation.

Radial Force (Fr): This component, acting along the line connecting the pinion and rack centers, is crucial for assessing bending loads on the pinion shaft and support structure. The results showed that pinions on the same side of the rack experience radial forces of similar magnitude and phase. Crucially, pinions on opposite sides of the rack experienced radial forces of equal magnitude but in opposite directions. This indicates that the net radial force on the leg structure is balanced, a vital condition for smooth operation and minimal structural deflection. The radial force for a single pinion can be related to the tangential force and the pressure angle \( \alpha \):

$$ F_r = F_t \cdot \tan(\alpha) $$

The simulated values aligned with this fundamental gear relationship, fluctuating in time with \( F_t \).

4. Emergency Lifting Scenario: Analysis of a Pinion Drive Failure

A critical engineering consideration is the system’s behavior during a partial failure. An emergency scenario was simulated where one pair of symmetrically opposed pinions (driven by a common motor) experiences a complete drive failure at t = 1 second during a lift under the 12,000 kN load.

4.1 Post-Failure Kinematic Response

Upon failure, the affected pinions’ angular velocity dropped precipitously. However, they did not lock or decelerate to zero. Because the rack continued to be driven by the remaining healthy pinions, it engaged the teeth of the failed pinions and forcibly drove them. This caused a severe transient disturbance in the rotational speed of the failed pinions, characterized by large, rapid oscillations before settling into a new, forced steady state. The healthy pinions also exhibited increased velocity fluctuations post-failure, though their average rotational speed remained largely unchanged to maintain the target lifting velocity. The synchronization of the system was degraded but not lost; all pinions, both driven and dragged, ultimately moved in a synchronized manner dictated by the rack’s motion.

4.2 Dynamic Load Redistribution

The failure instantaneously alters the load-bearing topology of the rack and pinion gear system. The tangential load \( F_{lift} \) must now be carried by only four pinions instead of six.

Tangential Force Redistribution: As expected, the tangential force on the failed pinions dropped to near zero (only minor frictional components remain). The tangential force on each of the four operational pinions immediately increased to a new average level:

$$ \bar{F_{t, new}} \approx \frac{F_{lift}}{4} = 3000 \text{ kN} $$

The transient spike during the failure event was significant, and the steady-state oscillation amplitude around the new mean was larger than in the pre-failure condition for six pinions, indicating a more strenuous dynamic loading condition for the surviving rack and pinion gear interfaces.

Radial Force Redistribution: Following the relationship \( F_r = F_t \cdot \tan(\alpha) \), the radial forces on the failed pinions also approached zero. The radial forces on the operational pinions increased proportionally to their increased tangential load. Importantly, the symmetry was maintained: the radial forces on opposite sides of the rack remained equal and opposite. Thus, even in this degraded state, the overall rack and pinion gear system maintains global radial force balance on the leg structure, a key finding for emergency operational guidelines. The table below summarizes the force changes before and after the failure event (steady-state averages).

| Condition | Operational Pinions (Each) | Failed Pinions (Each) | ||

|---|---|---|---|---|

| Tangential Force \( \bar{F_t} \) (kN) | Radial Force \( \bar{F_r} \) (kN) | Tangential Force \( \bar{F_t} \) (kN) | Radial Force \( \bar{F_r} \) (kN) | |

| Pre-Failure (All 6 active) | ~2000 | ~1060 (2000·tan28°) | N/A | N/A |

| Post-Failure (4 active) | ~3000 | ~1590 (3000·tan28°) | ~0 | ~0 |

5. Conclusion

This comprehensive dynamic analysis of a jack-up platform rack and pinion gear lifting system yields several critical insights for design and operation. Under normal conditions, the system exhibits robust synchronization and remarkably even load sharing among all pinions, validating the design principle of distributed load carrying through multiple rack and pinion gear contact points. The observed increase in velocity and force fluctuations with applied load highlights the non-linear dynamic interaction within the system, which should be accounted for in fatigue assessments.

The emergency failure analysis reveals the inherent resilience of the rack and pinion gear configuration. The system demonstrates a passive fail-adaptive capability: failed pinions are dragged by the rack, allowing lifting to continue with reduced capacity. The immediate and uniform redistribution of the total load among the remaining healthy pinions confirms the system’s redundancy. Most importantly, the global radial force balance is preserved even after a drive failure, preventing the introduction of severe bending moments on the leg. However, the increased dynamic forces and fluctuations on the operational pinions underscore the need for conservative safety factors in the design of these components and suggest that emergency lifting operations should be conducted with caution and possibly at reduced speeds. This study provides a validated dynamic framework for analyzing and optimizing the performance of these essential rack and pinion gear systems in offshore engineering.