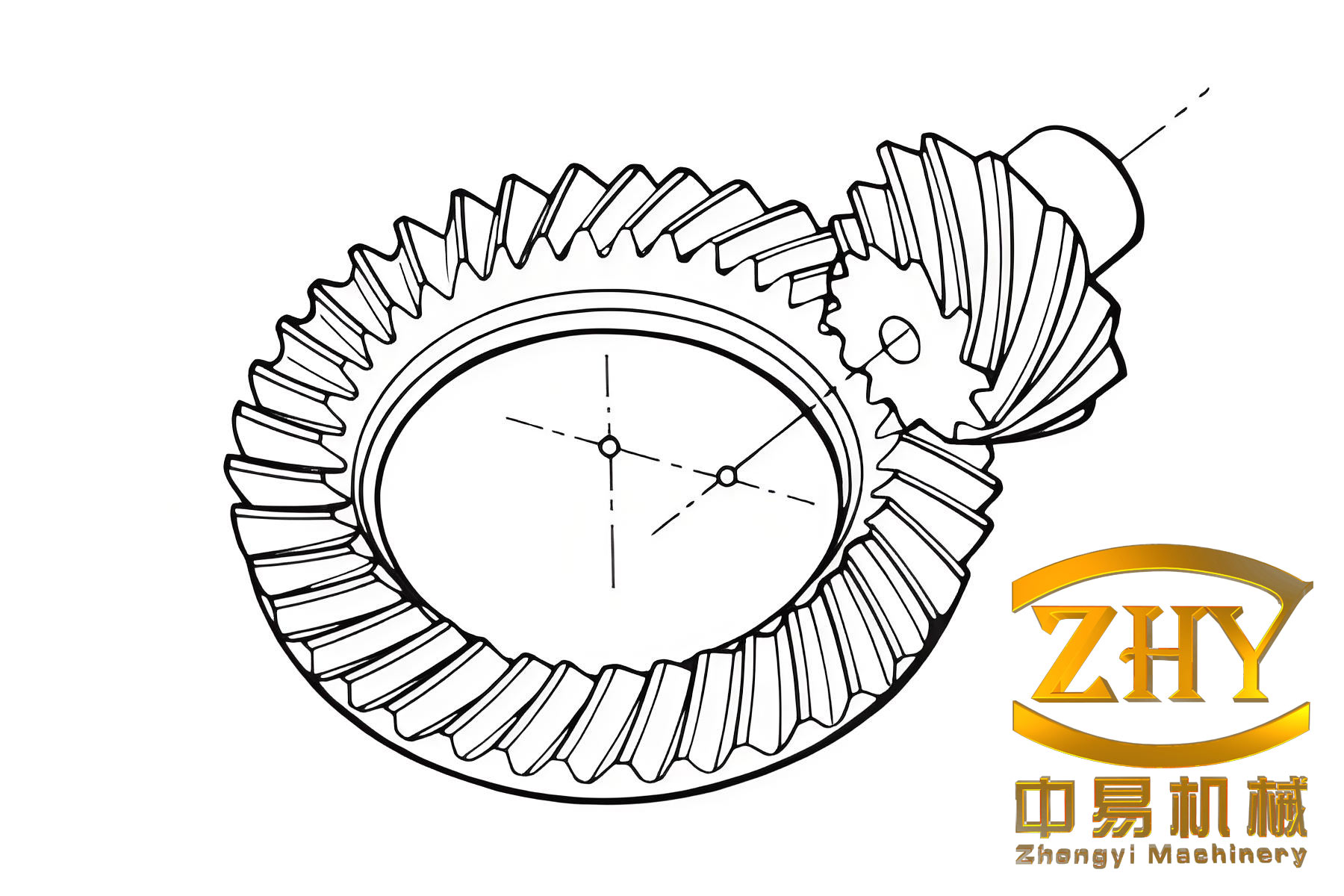

The relentless pursuit of higher power density, superior efficiency, and lower carbon footprint in modern mechanical systems places immense demands on their core transmission components. Among these, gears are paramount, and their meshing quality and transmission efficiency are subjects of intense focus. Hypoid bevel gears, with their ability to transmit motion between non-intersecting, non-parallel shafts, are indispensable in automotive drivetrains, aerospace applications, and heavy machinery due to their smooth operation, high load capacity, and compact design. Particularly, high reduction ratio hypoid (HRH) bevel gears offer an exceptional combination of significant speed reduction and spatial compactness, making them ideal for highly integrated electromechanical drives. However, the very geometric complexity that grants them these advantages—characterized by intricate topological surfaces, substantial sliding, and point contact under load—also makes the accurate prediction of their performance, especially friction losses and efficiency, a formidable challenge. This article delves into a comprehensive methodology, from geometric modeling through loaded contact analysis to elastohydrodynamic lubrication (EHL) assessment, to dissect the friction power loss mechanisms in hypoid bevel gears. All developments and analyses are presented from a first-person, application-oriented engineering perspective.

The foundation of any accurate performance analysis lies in a precise geometric model of the tooth flanks. For hypoid bevel gears, manufactured via a face-milling or face-hobbing process, the tooth surfaces are not simple involutes but complex conjugate surfaces generated by the relative motion between the cutter head and the gear blank. To model these, we employ a Dual Equitangent Conjugate Method. This approach conceptualizes a generating gear (or crown gear) as a zero-thickness cutter head. During the simulation of the manufacturing process, this imaginary generator simultaneously engages with both the gear and pinion blanks according to their respective ratios. If the pinion is cut in a kinematic configuration that is conjugate to the gear-cutting process, the resulting pinion and gear surfaces are guaranteed to be conjugate. The mathematical framework involves defining a series of coordinate systems: a machine coordinate system \(S_m\), a cradle system \(S_g\) holding the cutter system \(S_c\), and a fixed positioning system \(S_f\) where the pinion and gear axes are set in their relative spatial orientation. The pinion coordinate system \(S_1\) rotates within \(S_f\).

The surface of the cutter blade, typically a straight-sided cone, is defined in \(S_c\). Its vector equation is denoted as \(\mathbf{r}_c(u, \theta)\), where \(u\) and \(\theta\) are surface parameters. Through a series of coordinate transformations \(\mathbf{M}_{cg}\) and the cradle rotation \(\phi_g\), we obtain the family of cutter surfaces in the generating gear coordinate system: \(\mathbf{r}_g(u, \theta, \phi_g) = \mathbf{M}_{gc}(\phi_g) \cdot \mathbf{r}_c(u, \theta)\). The conjugation condition is enforced by the equation of meshing, which states that the common normal vector at the contact point must be perpendicular to the relative velocity vector between the generating surface and the workpiece. For the pinion generation, this leads to an equation of the form:

$$(n_{gy} z_t – n_{gz} y_g) \sin \gamma_m + … = (n_{gy} x_g – n_{gz} y_g) m_t + …$$

Solving this equation for the cradle angle \(\phi_g\) for given \((u, \theta)\) provides the specific instance of the generating surface that contacts the pinion. The pinion tooth surface \(\mathbf{r}_1\) is then obtained by transforming \(\mathbf{r}_g\) through the composite matrix \(\mathbf{M}_{1m} = \mathbf{M}_{1f} \mathbf{M}_{ff’} \mathbf{M}_{f’m} \mathbf{M}_{mg}\):

$$\mathbf{r}_1(u, \theta) = \mathbf{M}_{1m} \cdot \mathbf{r}_g(u, \theta, \phi_g(u, \theta))$$

For the gear, a formate or generating process is simulated similarly, yielding its surface \(\mathbf{r}_2\). To achieve a controlled point contact and compensate for deflections under load, the pinion surface is purposefully modified relative to its theoretically conjugate form. This modification is defined by an ease-off surface or topology. Let \(\mathbf{r}_{c1}\) be the theoretically conjugate pinion surface derived from the gear cutter. The ease-off value \(z_d\) at a corresponding point on the pinion is the normal deviation between the theoretical and the actual manufactured surface:

$$z_d(u, \theta) = (\mathbf{r}_{c1} – \mathbf{r}_1) \cdot \mathbf{n}_{c1}$$

This \(z_d\) surface is a three-dimensional map representing the intentional gap between the flanks outside the intended contact path. It is the primary driver for defining the transmission error curve and the contact pattern under light load. The contact pattern emerges as the locus of points where the composite ease-off, considering gear rotation, falls below a minimal threshold. Analyzing this ease-off surface is crucial as it directly defines the unloaded kinematics and initial contact conditions. The transmission error (TE), defined as the difference between the actual and theoretical angular position of the driven gear, is derived from this ease-off topography. A well-designed ease-off yields a parabolic TE function, which is known to be beneficial for dynamic performance.

The kinematic and geometric parameters at the potential contact points are essential inputs for both stress and lubrication analysis. For a given instant of meshing, the line of contact (or its instantaneous approximation) is determined via tooth contact analysis (TCA). Along this line, we need to compute the principal curvatures, the entrainment velocity, and the slide-to-roll ratio.

- Curvature: The gear tooth surface curvature can often be derived directly from the known cutter geometry. For a generated surface, the principal directions and curvatures are computed using the first and second fundamental forms of the surface. The key parameter for lubrication analysis is the effective radius of curvature \(R\) in the direction perpendicular to the instantaneous contact line. This is not simply the curvature of the contact path but the composite or reduced radius of curvature of the two surfaces in that principal direction. It accounts for both the relative (induced) curvature from the gear kinematics and the local ease-off curvature \(K_{op}\): \(K_p = K_{sp} + K_{op}\), and \(R = 1/K_p\).

- Entrainment and Sliding Velocities: The surface velocities of the pinion \(\mathbf{v}_1\) and gear \(\mathbf{v}_2\) at the contact point are:

$$\mathbf{v}_1 = \boldsymbol{\omega}_1 \times \mathbf{r}_1, \quad \mathbf{v}_2 = \boldsymbol{\omega}_2 \times \mathbf{r}_2$$

The relative sliding velocity is \(\mathbf{v}_s = \mathbf{v}_1 – \mathbf{v}_2\). For EHL analysis, the component of these velocities in the direction perpendicular to the contact line (the entraining direction) is critical. Projecting \(\mathbf{v}_1\) and \(\mathbf{v}_2\) onto this direction (denoted by unit vector \(\mathbf{p}\)) gives \(u_1 = \mathbf{v}_1 \cdot \mathbf{p}\) and \(u_2 = \mathbf{v}_2 \cdot \mathbf{p}\). The entrainment velocity \(u_e\) and the slide-to-roll ratio \(SRR\) are then:

$$u_e = \frac{|u_1 + u_2|}{2}, \quad SRR = \frac{|u_1 – u_2|}{u_e}$$

In hypoid bevel gears, particularly high-ratio ones, the sliding velocity is significant along the entire contact path, leading to \(SRR\) values typically greater than 1 across much of the face width. This has profound implications for friction and wear.

The unloaded TCA provides the potential contact line, but under operational torque, the contact extends into an ellipse (or a more complex shape) due to elastic deformation. Predicting the actual pressure distribution requires a Loaded Tooth Contact Analysis (LTCA). Our approach uses a differential element method along the contact line. The process is as follows:

- Discretization: The instantaneous unloaded contact line is discretized into a series of \(m\) small segments or elements.

- Compliance Matrix: The local compliance (inverse of stiffness) \(D_{ij}\) for each element \(j\) on tooth pair \(i\) is calculated. This compliance includes Hertzian contact deflection and the bending and shear deflection of the gear tooth as a cantilever beam. Advanced models may also incorporate gear body and fillet foundation deflections.

- Deformation Compatibility: Under a total applied load \(F\), the gear teeth deflect. Let \(\delta_i\) be the normal approach (rigid body displacement) of the two gears at the specific angular position \(i\). The actual deformation \(\delta_{ij}\) at a discrete element \(j\) on the contact line of tooth pair \(i\) is reduced by the local ease-off gap \(z_{d(ij)}\) (which includes the nominal unloaded gap and any separation from preceding teeth in the mesh cycle):

$$\delta_{ij} = \delta_i – z_{d(ij)}$$

A contact condition is enforced: if \(\delta_{ij} \le 0\), the element is not in contact and carries no load. - Load-Deflection Relationship: The load on an element is proportional to its deformation: \(f_{ij} = D_{ij} \cdot \delta_{ij}\) for \(\delta_{ij} > 0\).

- Equilibrium Solution: The sum of all elemental loads must equal the total transmitted load. Furthermore, for multi-tooth contact (common in high-contact-ratio hypoid bevel gears), the deformation \(\delta_i\) must be consistent for all simultaneously engaged tooth pairs. This leads to a system of equations:

$$\sum_{i=1}^{n} \sum_{j=1}^{m} D_{ij} (\delta_i – z_{d(ij)})^+ = F$$

where \(n\) is the number of tooth pairs in simultaneous contact and \((x)^+\) denotes the positive part. Solving this system yields the load distribution \(f_{ij}\) across all active contact elements.

The resulting pressure at the center of each elemental contact, modeled as a narrow rectangular patch, is approximated using a line contact Hertzian formula. For an element of length \(\Delta l\) carrying load \(f_j\), with an effective radius of curvature \(R_j\), the maximum Hertzian pressure \(\sigma_h\) and semi-half-width \(b_j\) are:

$$\sigma_h = 182.38 \sqrt{\frac{f_j / \Delta l}{R_j}}, \quad b_j = 3.33 \sqrt{\frac{(f_j / \Delta l) R_j}{E’}}$$

where \(E’\) is the combined elastic modulus \(\frac{2}{1/E_1 + 1/E_2}\). The pressure distribution across the width is elliptical: \(\sigma(p) = \sigma_h \sqrt{1 – (p/b_j)^2}\). This differential element approach elegantly handles the transition from an interior elliptical contact to edge contacts where the Hertzian assumption breaks down, as each element’s contact width is small compared to the local tooth geometry.

| Parameter | Symbol | Role in Friction Analysis |

|---|---|---|

| Effective Radius of Curvature | \(R\) | Directly influences contact pressure and oil film thickness in EHL equations. |

| Entrainment Velocity | \(u_e\) | The primary driver for hydrodynamic film generation. Higher \(u_e\) promotes thicker films. |

| Slide-to-Roll Ratio | \(SRR\) | Critically affects friction coefficient. Higher \(SRR\) generally increases friction, especially in mixed/boundary regimes. |

| Maximum Hertzian Pressure | \(\sigma_h\) | Affects lubricant viscosity piezochemically and influences surface deformation. |

| Local Elemental Load | \(f_j\) | Determines the shear force contribution: \(dF_{friction} = \mu_j \cdot f_j\). |

With the loaded contact pressure and kinematics known, we can analyze the lubrication regime. In hypoid bevel gears, the combination of high pressure and rolling/sliding motion leads to elastohydrodynamic lubrication (EHL). The key outputs are the central film thickness \(h_c\) and the friction coefficient \(\mu\). We employ established empirical and semi-empirical formulas, applied differentially to each contact element.

1. Central Film Thickness: For line contact conditions applicable to each differential element, the Dowson-Hamrock formula is widely used:

$$h_{c, j} = 3.06 \frac{(\alpha \eta_0 u_e)^{0.69} R_j^{0.41}}{E’^{0.03} (f_j/\Delta l)^{0.10}}$$

where \(\alpha\) is the pressure-viscosity coefficient and \(\eta_0\) is the atmospheric dynamic viscosity. This gives a local film thickness map across the contact zone.

2. Lubrication Regime & Friction Coefficient: The regime is determined by the lambda ratio \(\lambda = h_c / \sigma\), where \(\sigma = \sqrt{\sigma_1^2 + \sigma_2^2}\) is the composite root-mean-square surface roughness.

- Full Film EHL (\(\lambda > 3\)): Surfaces are fully separated. Friction is primarily due to shearing of the viscous film. Friction coefficients are typically low (0.02-0.08).

- Mixed EHL (\(1 < \lambda \leq 3\)): Partial metal-to-metal contact occurs. Friction arises from both viscous shear and boundary asperity interaction.

- Boundary Lubrication (\(\lambda \leq 1\)): The film is very thin, and load is carried mostly by contacting asperities protected by boundary films. Friction is high and heavily dependent on surface chemistry.

For hypoid bevel gears operating under typical conditions, the mixed EHL regime is most prevalent. Empirical friction models for this regime take the form:

$$\mu = \exp\left( C_0 + C_1 SRR \right) \cdot (U^*)^{a}(G^*)^{b}(W^*)^{c}(\lambda)^{d}…$$

where \(U^* = \eta_0 u_e / (E’ R)\) is the dimensionless speed parameter, \(G^* = \alpha E’\) is the dimensionless material parameter, and \(W^* = f/(E’ R \Delta l)\) is the dimensionless load parameter. The coefficients \(C_0, C_1, a, b, c, d,…\) are determined by regression from experimental or detailed numerical EHL results. Such a model captures the complex interplay between rolling, sliding, pressure, and film thickness.

The instantaneous friction power loss \(P_{loss}\) for a single meshing tooth pair is the integral of the product of friction force and sliding velocity over the entire contact area. Using our differential element discretization, this becomes a summation:

$$P_{loss, i} = \sum_{j=1}^{m} \mu_{ij} \cdot f_{ij} \cdot v_{s, ij}$$

where \(v_{s, ij}\) is the sliding velocity at element \(j\). The total average power loss over a mesh cycle is then the average of \(P_{loss, i}\) across all angular positions \(i\), weighted by the mesh stiffness. The mechanical mesh efficiency \(\eta_{mesh}\) is:

$$\eta_{mesh} = 1 – \frac{\bar{P}_{loss}}{P_{in}} = 1 – \frac{\bar{P}_{loss}}{T_1 \omega_1}$$

where \(T_1\) and \(\omega_1\) are the pinion input torque and angular speed, and \(\bar{P}_{loss}\) is the cycle-averaged power loss. For a high-reduction hypoid bevel gear set, the pinion is typically the driving member. It is important to note that this calculated efficiency is specifically the mesh efficiency. The overall transmission efficiency of a gearbox will be lower due to losses from bearings, seals, and windage/churning of the lubricant.

The validity of the entire modeling chain—from ease-off topography and LTCA to the EHL friction model—must be confirmed experimentally. A standard method is to conduct transmission efficiency tests on a dedicated test rig. The setup typically consists of a prime mover (motor), the test gearbox, a load brake, and highly accurate torque transducers on both the input and output shafts. The test is run at various combinations of input speed (\(n_1\)) and output torque (\(T_2\)), covering the intended operating range. The overall transmission efficiency is calculated from the measured input and output power:

$$\eta_{test} = \frac{T_2 \cdot \omega_2}{T_1 \cdot \omega_1} = \frac{T_2}{T_1 \cdot i}$$

where \(i\) is the gear ratio. The measured \(\eta_{test}\) includes all losses (bearings, seals, mesh). By subtracting estimated or measured non-mesh losses (from a dummy or “spin loss” test), one can approximate the experimental mesh efficiency \(\eta_{mesh, exp}\). This is then compared to the predicted \(\eta_{mesh}\) from the model. A successful correlation, typically within 1-3 percentage points across the operating map, validates the modeling approach. Discrepancies can guide refinements in the ease-off design, the LTCA stiffness model, or the EHL friction coefficients.

In conclusion, the accurate prediction of friction power loss in hypoid bevel gears demands an integrated, multi-physics approach that respects their inherent geometric and kinematic complexity. The methodology outlined here—spanning differential topology definition via ease-off surfaces, kinematic and curvature analysis, differential-element-based loaded tooth contact analysis, and mixed elastohydrodynamic lubrication modeling—provides a robust framework for this task. The use of differential elements along the contact path is particularly effective, as it naturally accommodates the varying contact conditions, handles edge contact scenarios, and seamlessly integrates geometric, kinematic, load, and lubrication parameters at a local level. While the computational effort is non-trivial, it is far more efficient than full 3D finite element analysis for parametric studies and design optimization. The ultimate goal is to leverage this understanding to perform topology optimization of the ease-off surface not just for low transmission error and stress, but explicitly for low friction power loss. This involves iteratively adjusting the ease-off topography to favorably influence the pressure distribution, entrainment velocity alignment, and slide-to-roll ratio along the contact path, thereby pushing the gear mesh into more favorable lubrication regimes. As the demand for efficiency grows ever stronger, such sophisticated, physics-based design tools will become standard in developing the next generation of high-performance hypoid bevel gear drives.