The pursuit of higher performance in robotic joints and precision servo mechanisms has consistently driven innovation in compact, high-ratio speed reducers. Among these, the strain wave gear (also widely known as a harmonic drive) stands out due to its exceptional combination of high reduction ratio, compactness, minimal backlash, and high torque capacity. The core of its performance lies in the controlled elastic deformation of its flexible spline (Flexspline) and the subsequent meshing action with a rigid circular spline. Consequently, the geometry of the tooth profiles engaged during this dynamic deformation process is a paramount factor influencing critical performance metrics such as transmission accuracy, load distribution, stress concentration, and fatigue life. Traditional profile designs, including the involute, the double circular arc, and the S-shape, each present distinct advantages and limitations in terms of conjugate meshing characteristics, backlash uniformity, and stress state. This work introduces a novel, synthesized tooth profile design methodology for strain wave gears that leverages an enhanced kinematic model for precise conjugate generation and employs transient dynamics for comprehensive performance validation. The primary objective is to synergize the beneficial attributes of existing profiles to achieve superior meshing performance characterized by minimized and uniform functional backlash and reduced peak stresses within the Flexspline.

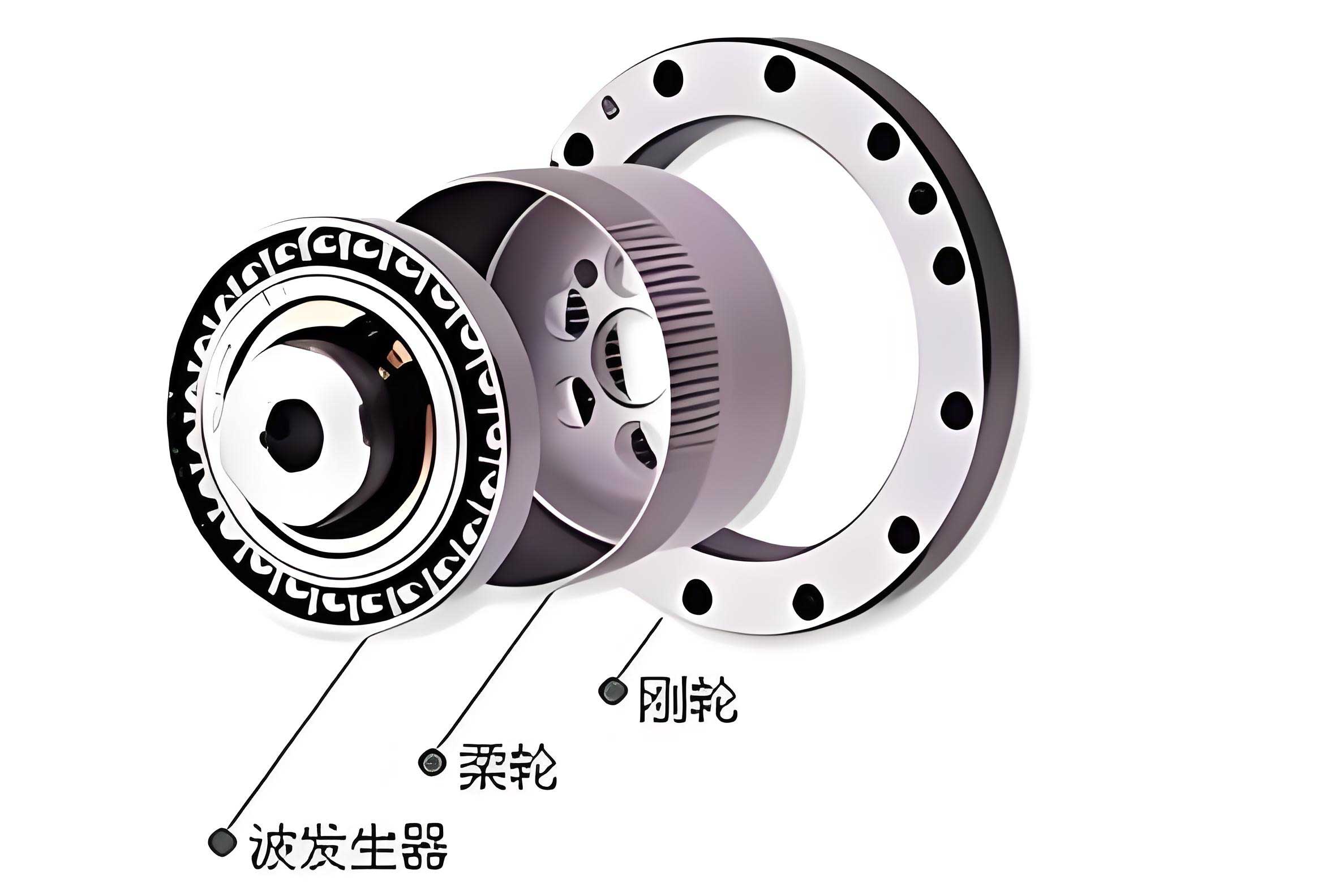

The operational principle of the strain wave gear revolves around the wave generator (often an elliptical cam with a specially fitted bearing) inducing a controlled wave-like deformation in the thin-walled Flexspline. This deformation causes the teeth of the Flexspline to engage with the teeth of the rigid Circular Spline at two diametrically opposite regions along the major axis of the ellipse. As the wave generator rotates, the engagement zones travel, resulting in an incremental relative motion between the Flexspline and the Circular Spline. The kinematic relationship governing this motion is non-linear and highly dependent on the deformed state of the Flexspline’s neutral curve. Therefore, an accurate mathematical model for determining the conjugate tooth profile of the Circular Spline corresponding to a given Flexspline profile is essential. The classical methods often simplify the deformation, considering only radial displacement. The enhanced kinematic method employed here provides a more comprehensive model, accounting for radial and tangential displacements as well as the angular deflection of the tooth normal, leading to a more accurate prediction of the true meshing conditions.

Synthesis of a Novel Flexspline Tooth Profile

Existing tooth profiles for strain wave gears exhibit specific meshing behaviors. The double circular arc profile and its variant, the common tangent double circular arc profile, are known for providing a relatively small magnitude of functional backlash. However, the backlash distribution over the meshing cycle is often non-uniform, typically showing a peak at a specific wave generator angle. Conversely, the S-shaped profile, designed based on a conjugate mapping principle, offers a significantly more uniform distribution of backlash throughout the engagement, albeit sometimes with a slightly higher average magnitude. This characteristic promotes smoother transmission and more consistent contact across multiple tooth pairs.

A comparative analysis of the functional backlash for these profiles reveals a distinct crossover pattern. There exist specific angular intervals where the common tangent double arc profile exhibits smaller backlash, and other intervals where the S-profile excels. The novel design philosophy is to synthesize an optimal profile by selectively combining the superior segments from each. Specifically, the segments from each profile that yield the minimal backlash at any given meshing phase are extracted and joined to form a new, composite Flexspline tooth profile. This hybrid profile aims to inherit the low-backlash trait of the double arc design and the uniformity trait of the S-profile.

The proposed novel Flexspline profile is constructed in three distinct segments: a convex circular arc segment (AB) near the tooth tip, a middle segment (BC) derived from the optimal portion of the S-profile, and a concave circular arc segment (CD) near the tooth root. The transition points B and C are carefully chosen to ensure first-order continuity (a common tangent) between adjacent segments, guaranteeing geometric smoothness and avoiding stress concentrations at the junctions.

The parametric equations for the novel profile in the Flexspline coordinate system are thus defined as follows:

Segment AB (Convex Arc):

$$ x_1(s) = \rho_a \cos(\beta_a – s/\rho_a) + x_{Oa} $$

$$ y_1(s) = \rho_a \sin(\beta_a – s/\rho_a) + y_{Oa} $$

where $s \in (0, l_1)$ is the arc length parameter, $\rho_a$ is the radius of the convex arc, $\beta_a$ is the pressure angle at the tooth tip, $(x_{Oa}, y_{Oa})$ are the coordinates of the arc center, and $l_1$ is the total arc length of segment AB.

Segment BC (Optimized S-Profile Segment):

$$ x_2(\varepsilon) = 0.25m(\pi + \varepsilon – k \sin \varepsilon) + \xi + \tau + \Delta D $$

$$ y_2(\varepsilon) = -0.5m(1 – k \cos \varepsilon) $$

Here, $m$ is the module, $k$ is the radial deformation coefficient, $\varepsilon$ is the kinematic pressure angle (a parameter along the curve), $\xi$ is a side clearance adjustment, $\tau$ controls the tooth thickness, and $\Delta D$ is a fine-tuning transition variable ensuring smooth connection to the adjacent arcs.

Segment CD (Concave Arc):

$$ x_3(s) = x_{Of} – \rho_f \cos[\delta + (s – l_2)/\rho_f] $$

$$ y_3(s) = y_{Of} – \rho_f \sin[\delta + (s – l_2)/\rho_f] $$

where $s \in (l_2, l_3)$, $\rho_f$ is the radius of the concave arc, $\delta$ is its inclination angle, $(x_{Of}, y_{Of})$ are the coordinates of its center, and $l_2$, $l_3$ are cumulative arc lengths.

| Profile Feature | Double Circular Arc | S-Shaped Profile | Common Tangent Double Arc | Novel Hybrid Profile |

|---|---|---|---|---|

| Backlash Magnitude | Moderate, with peak | Larger average, very uniform | Small, with distinct peak | Minimized, optimized |

| Backlash Uniformity | Low | Very High | Low | High |

| Design Philosophy | Simple conjugate arcs | Continuous contact mapping | Tangentially connected arcs | Optimal segment synthesis |

| Primary Advantage | Simple geometry | Smooth multi-tooth contact | Good load capacity potential | Combined low & uniform backlash |

Enhanced Kinematic Method for Conjugate Circular Spline Profile Generation

Determining the exact tooth profile of the Circular Spline that will correctly conjugate with the deformed novel Flexspline profile requires a precise kinematic model. The foundation is the fundamental law of gear meshing, which states that at the point of contact between two conjugate surfaces, their relative velocity vector must be orthogonal to the common normal vector. Mathematically, for surfaces 1 (Flexspline) and 2 (Circular Spline):

$$ \mathbf{n} \cdot \mathbf{v}^{(12)} = 0 $$

To apply this law effectively to the complex deformation of the strain wave gear, an enhanced kinematic model is established using coordinate transformation matrices. Let $S_1(O_1, X_1, Y_1)$ be the coordinate system attached to the undeformed Flexspline, and $S_2(O_2, X_2, Y_2)$ be the system attached to the Circular Spline. The position vector of a point on the Flexspline tooth profile, $\mathbf{r}_1$, is known from the profile equations. When the Flexspline deforms under the action of the wave generator, its position and orientation relative to the Circular Spline change. This relationship is described by a transformation matrix $\mathbf{M}_{21}(\phi_d)$ which is a function of the wave generator’s rotation angle $\phi_d$. This matrix incorporates not just a simple rotation, but also the radial deflection $w(\phi_d)$, the tangential displacement, and the angular twist $\gamma(\phi_d)$ of the Flexspline’s neutral line, derived from the specific cam profile and Flexspline mechanics.

The profile point in the Circular Spline system is:

$$ \mathbf{r}_2 = \mathbf{M}_{21} \, \mathbf{r}_1 $$

The relative velocity $\mathbf{v}^{(12)}_2$ in system $S_2$ is the time derivative of $\mathbf{r}_2$:

$$ \mathbf{v}^{(12)}_2 = \frac{d\mathbf{r}_2}{dt} = \frac{d\mathbf{M}_{21}}{dt} \mathbf{r}_1 $$

The normal vector in $S_2$ is related to the normal in $S_1$ by the rotation part of the transformation, denoted by matrix $\mathbf{W}_{21}$: $\mathbf{n}_2 = \mathbf{W}_{21} \mathbf{n}_1$. Substituting into the meshing equation yields:

$$ (\mathbf{W}_{21} \mathbf{n}_1)^T \left( \frac{d\mathbf{M}_{21}}{dt} \mathbf{r}_1 \right) = 0 \quad \Rightarrow \quad \mathbf{n}_1^T \left( \mathbf{W}_{21}^T \frac{d\mathbf{M}_{21}}{dt} \right) \mathbf{r}_1 = 0 $$

Defining a key matrix $\mathbf{B} = \mathbf{W}_{21}^T \frac{d\mathbf{M}_{21}}{dt}$, the final form of the enhanced kinematic meshing condition for the strain wave gear is obtained:

$$ \mathbf{n}_1^T \, \mathbf{B} \, \mathbf{r}_1 = 0 $$

For a given strain wave gear configuration, the matrix $\mathbf{B}$ is a function only of the kinematic derivatives of the deformation ($\phi’$, $w’$, $\gamma’$) and is independent of the specific tooth profile geometry. This is the crucial enhancement: once $\mathbf{B}$ is computed for the chosen wave generator and Flexspline cup geometry, it can be used universally with any Flexspline tooth profile defined by $\mathbf{r}_1(s)$ and its normal $\mathbf{n}_1(s)$ to solve for the corresponding engagement condition. Solving this equation for the wave generator angle $\phi_d$ as a function of the profile parameter $s$ (or $\varepsilon$) provides the family of contact points. The envelope of these points, transformed back to the Circular Spline coordinate system, defines its required conjugate tooth profile. This profile is typically generated as a dense set of numerical points and then fitted with a smooth curve, such as a high-order spline or a circular approximation, for manufacturing.

Transient Dynamics Analysis for Performance Validation

The theoretical conjugate profile from the kinematic model must be validated under dynamic operating conditions, considering the complex interactions between deformation, contact, and inertia. A three-dimensional transient dynamics simulation using the Finite Element Method (FEM) is employed for this purpose. A simplified yet representative model of the strain wave gear assembly is created, consisting of:

- A cup-type Flexspline with external teeth.

- A rigid Circular Spline with internal teeth.

- A wave generator assembly modeled as an elliptical cam core.

The model is constructed using a parametric workflow. The novel Flexspline tooth profile is generated programmatically based on the equations and parameters, and this curve data is imported into CAD software to create the solid model. The Circular Spline profile is generated from the kinematic conjugate results. The assembled model is then imported into a dedicated transient dynamics solver (e.g., ANSYS Mechanical).

| Component | Material | Density (kg/m³) | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|---|

| Flexspline | Alloy Steel (e.g., 40CrMoNiA) | 7830 | 209 | 0.269 |

| Circular Spline | Carbon Steel (e.g., 45#) | 7850 | 210 | 0.30 |

| Wave Generator Core | Carbon Steel (e.g., 45#) | 7850 | 210 | 0.30 |

The finite element model employs high-order hexahedral elements for accuracy. A fine mesh is applied to the tooth contact regions of both the Flexspline and Circular Spline, as well as the contact zone between the Flexspline inner wall and the wave generator. The following boundary conditions and loads are applied in a multi-step transient analysis:

- Contacts: Frictional contact is defined between the Flexspline inner surface and the wave generator, and between the Flexspline teeth and Circular Spline teeth. “Large Deflection” analysis is activated to account for the significant geometric nonlinearity of the Flexspline deformation.

- Joints: Revolute joints are applied to the appropriate cylindrical surfaces of the Circular Spline, Flexspline cup bottom, and wave generator bore to allow rotation about the central axis.

- Load Steps:

- Step 1 (Assembly): A small rotational velocity is applied to the Circular Spline to achieve a stress-free, interference-free initial meshed position. The Flexspline load is zero.

- Step 2 & 3 (Operation): The Circular Spline is fixed. A constant output torque (e.g., 10 N·m) is applied to the Flexspline. A constant input speed (e.g., 180 rad/min) is applied to the wave generator.

The transient analysis solves the dynamic equations of motion over several wave generator rotations until a periodic steady-state response is observed. From this solution, two critical performance indicators are extracted:

- Functional Meshing Backlash: The minimum distance between non-contacting, conjugate flanks of the Flexspline and Circular Spline teeth during the meshing cycle. This is a direct measure of transmission error and positional precision.

- Von-Mises Equivalent Stress in the Flexspline: The stress distribution, particularly the maximum value, indicates the load severity and is crucial for predicting fatigue life and potential failure locations (often at the tooth root or the cup fillet).

Case Study and Comparative Results

A specific case study is conducted to compare the novel profile against the standard double circular arc, S-shaped, and common tangent double arc profiles. The core parameters for the strain wave gear are: Module $m = 0.396$ mm, Radial Deformation Coefficient $k = 1$, Flexspline Tooth Count $z_1 = 160$, Circular Spline Tooth Count $z_2 = 162$.

| Parameter Symbol | Description | Value |

|---|---|---|

| $\rho_a$ | Convex arc radius (Segment AB) | 0.600 mm |

| $\rho_f$ | Concave arc radius (Segment CD) | 0.657 mm |

| $x_a$, $y_a$ | Convex arc center offset | 0.3621 mm, 0.0657 mm |

| $x_f$, $y_f$ | Concave arc center offset | 0.2633 mm, 0.0682 mm |

| $\xi$ | Side clearance adjustment | 0.00085 mm |

| $\Delta D$ | Transition fine-tuning variable | 0.0008 mm |

Conjugate Profile and Backlash Analysis: Using the enhanced kinematic method, the conjugate Circular Spline profiles for all four Flexspline designs are calculated. The functional backlash over a 90-degree wave generator rotation interval (covering the major axis region) is computed and compared. The results conclusively demonstrate the advantage of the novel hybrid design. While the other profiles show a characteristic peak in backlash (e.g., around 50° for the arc-based designs), the novel profile maintains a consistently minimal and uniform backlash level. The maximum calculated backlash for the novel profile is only 0.0036 mm, which is significantly lower and more stable than the peaks observed in the other designs.

Transient Dynamics Stress Results: The finite element-based transient dynamics analysis provides a realistic comparison of the stress states under load. The key metric is the peak Von-Mises equivalent stress in the Flexspline body.

| Tooth Profile Type | Peak Stress (No Load) | Peak Stress (Under 10 N·m Load) |

|---|---|---|

| Double Circular Arc | 1212.0 MPa | 1392.5 MPa |

| S-Shaped | 1284.4 MPa | 1385.5 MPa |

| Common Tangent Double Arc | 1211.8 MPa | 1365.8 MPa |

| Novel Hybrid Profile | 1038.0 MPa | 1211.6 MPa |

The results are striking. Under both no-load (primarily assembly stress) and loaded conditions, the novel strain wave gear tooth profile exhibits the lowest maximum equivalent stress. The 10 N·m load case is particularly relevant for performance. Here, the novel profile’s peak stress of 1211.6 MPa is approximately 13% lower than that of the common tangent double arc profile (1365.8 MPa) and about 12.5% lower than the standard double arc profile (1392.5 MPa). This reduction in peak stress is directly attributable to the optimized meshing conditions—more uniform load sharing and reduced edge contact—achieved by the synthesized profile geometry. Lower stress translates directly into higher torque capacity, improved fatigue resistance, and enhanced reliability for the strain wave gear transmission.

Conclusion

This work has presented a comprehensive and effective methodology for designing high-performance tooth profiles for strain wave gears. By synthesizing the most favorable segments of established profile types—specifically the low-backlash characteristic of the double arc family and the uniform meshing characteristic of the S-profile—a novel hybrid Flexspline tooth profile was developed. The theoretical foundation for generating the precise conjugate Circular Spline profile was provided by an enhanced kinematic model, which efficiently accounts for the full deformation state of the Flexspline. Finally, rigorous validation through three-dimensional transient dynamics analysis confirmed the superior performance of the new design.

The comparative study demonstrated that the novel strain wave gear profile achieves two primary objectives simultaneously: it minimizes the functional meshing backlash to a very low level (0.0036 mm) and ensures its uniformity throughout the engagement cycle. Furthermore, it significantly reduces the peak equivalent stress in the Flexspline under operational loads. This combined improvement in transmission accuracy and mechanical durability addresses key challenges in advanced strain wave gear applications, such as those found in precision robotics and aerospace mechanisms. The proposed design methodology, integrating profile synthesis, enhanced conjugate theory, and dynamic validation, establishes a robust theoretical framework for the continued development of next-generation, high-performance strain wave gear reducers.