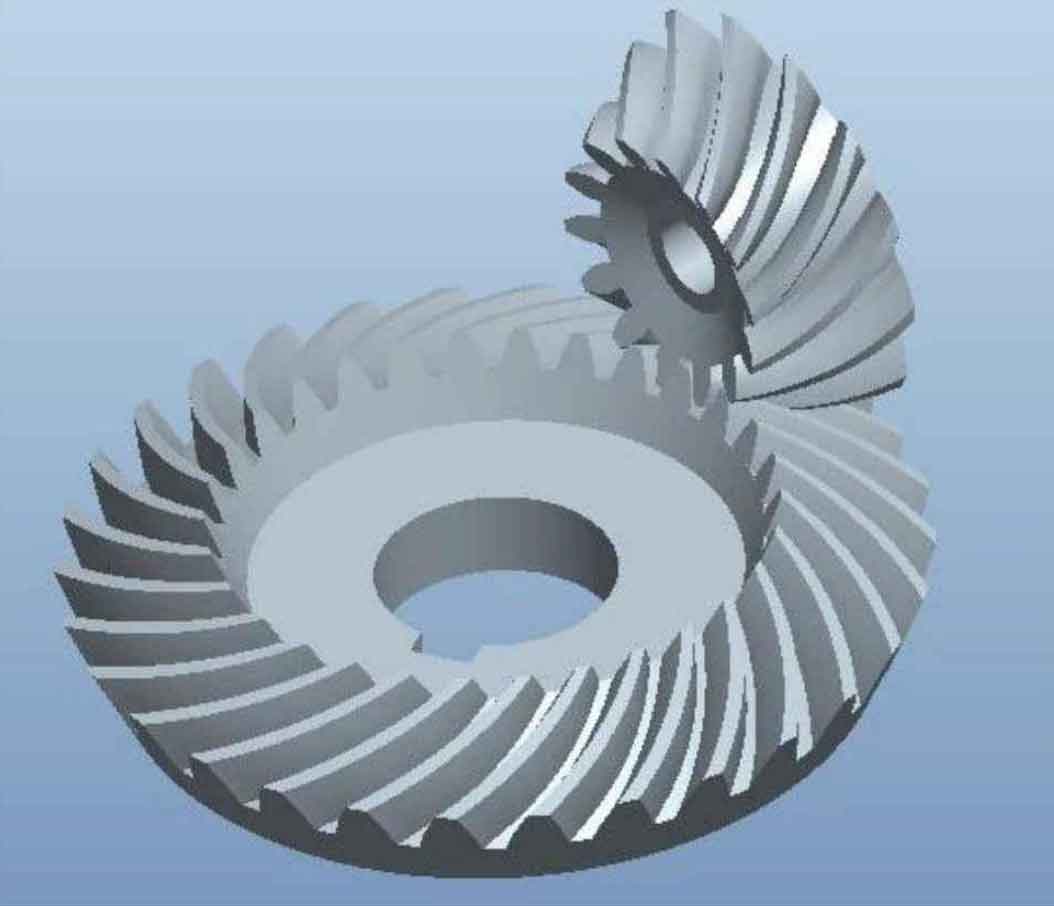

The meshing performance analysis and tooth surface design of cycloid hypoid gear first need to calculate the geometric parameters and machining parameters of hypoid gear pair, and then the tooth surface modeling and subsequent analysis and design can be carried out. Firstly, the calculation method of geometric parameters of cycloid hypoid gear blank and the milling adjustment calculation method of tool inclination semi generative machining method mainly used in this paper are briefly introduced, and then the principles of common tooth meshing performance analysis methods TCA and LTCA are introduced, which lays a theoretical and methodological foundation for the research work of the full text.

Cycloid hypoid gear transmission is also based on the meshing theory based on the reference point. According to the relative position and motion relationship of the paired two gears, a reference point m is given to form a pair of split conical surfaces, which is the basis of the geometric design of hypoid gears. According to the conjugate condition of the two tooth surfaces at the reference point m, the geometric parameters of the split cone can be determined, and the basic formula of hypoid gear transmission can be obtained. Then, the geometric design of the two paired gears and the milling adjustment calculation can be carried out, which lays a foundation for the subsequent tooth surface modeling, meshing performance analysis and tooth surface design. The analysis of tooth meshing performance plays an important role in improving the process and meshing quality of hypoid gears. According to the magnitude of the loaded load, it can be divided into TCA under no-load and LTCA after loading. TCA is mainly used to analyze the meshing and cutting contact of two paired tooth surfaces under no-load condition; LTCA analyzes the meshing performance of hypoid gears under pseudo real loading conditions based on the accurate modeling of tooth surfaces and TCA.

This paper mainly introduces the design method of geometric parameters of cycloid hypoid gear blank and the calculation method of spirac milling adjustment, with emphasis on the calculation of cutter head parameters, cutter parameters and the setting parameters of large and small wheel machine tools. The principles and methods of TCA and LTCA are briefly introduced. The solution of LTCA needs the help of the results of TCA, and the results of LTCA prepare the basic data for the subsequent analysis of stress process and the calculation of time-varying meshing stiffness of hypoid gear pair. The geometric parameter design of wheel blank and the adjustment calculation of milling gear are the premise of subsequent tooth surface modeling, meshing performance analysis and tooth surface design.