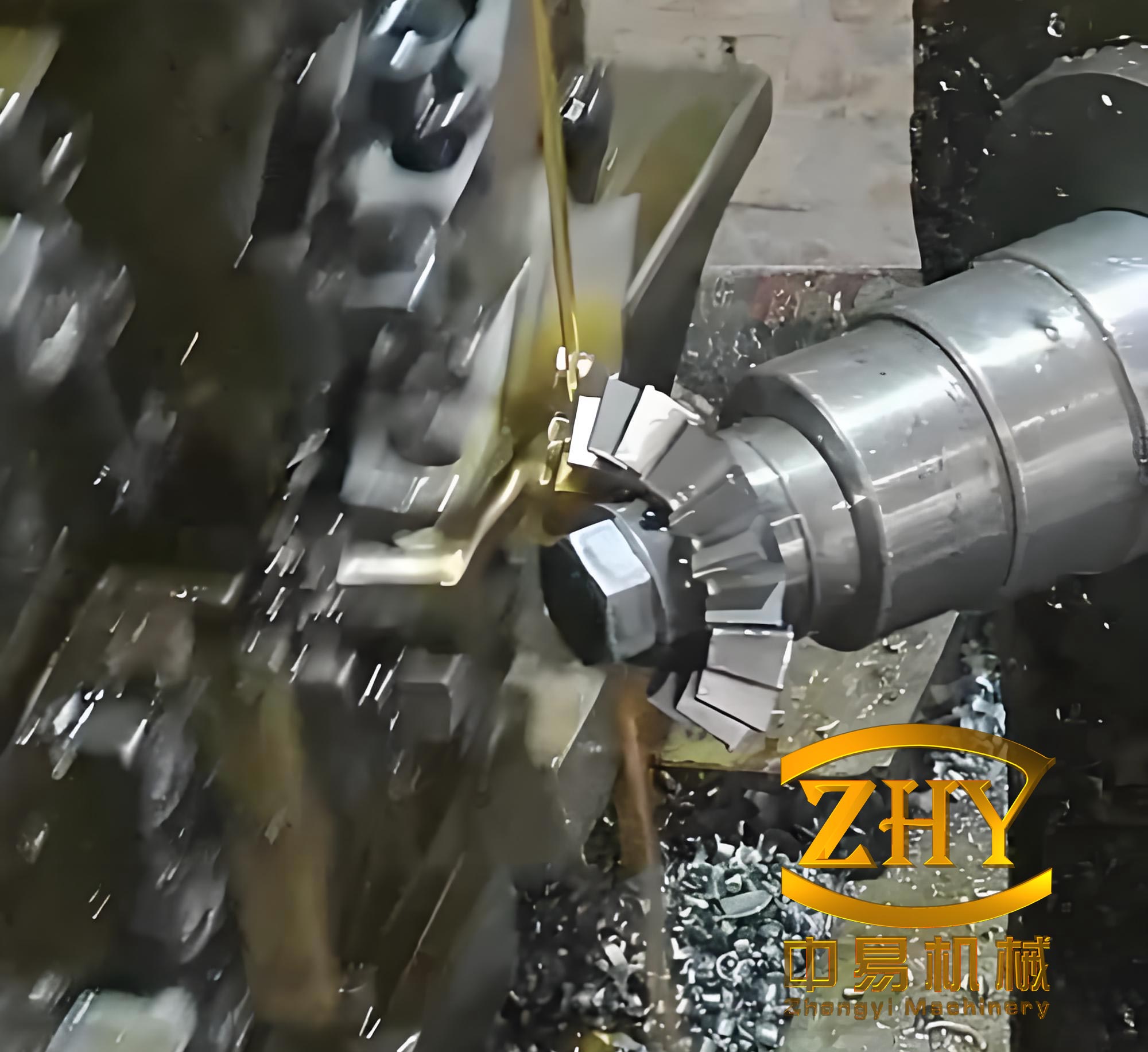

In the realm of gear manufacturing, gear hobbing stands as a fundamental process where a gear hobbing machine utilizes the generating method to produce gear tooth profiles. This involves transforming one element into a cutting tool, typically the hob, and the other into the workpiece. Through the coordinated motion of the gear hobbing machine, the tool and workpiece are forced to perform a strict meshing movement. During this process, the trajectory of the tool’s cutting edges gradually envelops the tooth profile of the workpiece. A critical challenge in gear hobbing operations arises when a gear requires interim precision inspection, necessitating a machine halt, or when the workpiece undergoes secondary processes such as heat treatment after rough or semi-finishing cuts. This often demands re-clamping the gear, leading to the necessity of realigning the hob with the workpiece gear tooth space—a procedure known as secondary gear alignment.

Traditional methods for secondary gear alignment in gear hobbing machines relied heavily on operator experience and visual estimation for centering the workpiece and tool. This approach was highly susceptible to human error and depended extensively on the operator’s skill and familiarity, falling short of the demands for high-precision and high-efficiency manufacturing prevalent today. Subsequently, methods evolved to incorporate contact-type probes for secondary gear alignment. These probes would touch the left and right flanks of a gear tooth, collect signals, and calculate angles to interact with the control system, prompting the rotary table to rotate by half the calculated angle to position the tooth slot center. However, this method introduced significant errors due to inherent inaccuracies in individual gear tooth profiles or slots. Measuring only a single tooth slot could propagate substantial errors, adversely affecting subsequent machining accuracy in the gear hobbing process.

This article elucidates a novel secondary gear alignment apparatus designed for gear hobbing machines, characterized by its structural simplicity, operational robustness, high precision, and capability for automated secondary alignment. This innovation substantially enhances both the efficiency and accuracy of gear hobbing operations. The methodology leverages non-contact sensing technology to overcome the limitations of previous approaches, ensuring reliable performance in modern manufacturing environments where gear hobbing machines are integral to production lines.

The core principle of the secondary gear alignment device involves the use of a non-contact sensor oriented directly towards the gear tooth direction. The workpiece rotary table, or C-axis, rotates at a constant speed, while the sensor emits pulse signals to record the positions of the gear tooth edges. The collected data is then processed to compute the precise gear position, facilitating a positional offset adjustment for the C-axis. To accommodate workpieces of varying sizes, the sensor’s proximity to the workpiece can be adjusted along the X-direction. Similarly, for different workpiece heights requiring fixture changes, the Z-direction travel allows for height adjustment of the sensor. During actual gear hobbing, the sensor must retract from the machining area, achieved through Y-direction movement and the inherent stroke of an integrated pneumatic cylinder.

The structural composition of the secondary gear alignment apparatus primarily consists of a pneumatic cylinder and an inductive sensor. The cylinder can be equipped with components such as two limit switches, a pressure sensor, and a one-way flow control valve to enhance motion precision and repeatability. The selection of cylinder stroke, repeatability, sensor sensing distance, and response curve is tailored based on the specific dimensions of the workpiece being processed on the gear hobbing machine. This customization ensures optimal performance across diverse gear hobbing applications.

The implementation of secondary gear alignment unfolds through a systematic procedure. Initially, the sensor is positioned within its effective detection range, typically 1 to 5 mm, depending on the sensor type, to ensure reliable signal acquisition during gear hobbing setup. The C-axis is then incrementally rotated, and the sensor records the angular positions corresponding to the rising and falling edges of the gear teeth. Specifically, positions for rising edges (denoted as A, C, E) and falling edges (B, D, F) are logged. To mitigate errors stemming from individual tooth inaccuracies, data from incomplete teeth at the start and end of rotation are discarded, and multiple position values are averaged—preferably an odd number to handle absolute data recordings. The average rising edge position \( C_1 \) and average falling edge position \( C_2 \) are calculated as follows:

$$ C_1 = \frac{A + C + E}{3} $$

$$ C_2 = \frac{B + D + F}{3} $$

Given the number of gear teeth \( Z_0 \), the effective rotational value for a specific tooth slot center \( C_0 \) and the tooth top center \( C_0′ \) can be derived:

$$ C_0 = -\left( \frac{C_1 + C_2}{2} + \frac{\pi}{Z_0} \right) $$

$$ C_0′ = -\frac{C_1 + C_2}{2} $$

Subsequently, the workpiece axis is rotationally offset by \( -C_0 \), aligning the tooth slot center with the reference position. For gear hobbing machines equipped with a hob shifting axis (e.g., axial adjustment), the hob position is fine-tuned manually or automatically to ensure proper meshing with the workpiece. In machines lacking this feature, minor adjustments to the workpiece axis can achieve meshing, with the rotational compensation integrated into the \( C_0 \) value. Finally, automatic phase synchronization is initiated to commence gear hobbing. If the control system lacks built-in synchronization, servo delay-induced follow-up errors may occur, necessitating trial cuts and compensatory adjustments to the \( C_0 \) position based on empirical data.

For batch production in gear hobbing, once the initial secondary gear alignment is performed, subsequent parts require only the data collection, calculation, and offset steps, streamlining the process and enhancing throughput. It is crucial to note that the tooth top position data, acquired via non-contact sensor detection of rising and falling edges, may contain inherent deviations. These are effectively eliminated during the hob shifting adjustment phase, ensuring precision in the gear hobbing operation.

The practical application of this secondary gear alignment system has been extensively validated on various models of CNC gear hobbing machines, demonstrating stable and reliable performance. It adeptly meets the diverse requirements of components processed by clients, receiving positive feedback for its contribution to accuracy and efficiency in gear hobbing tasks. The integration of this technology not only elevates the performance of individual gear hobbing machines but also lays a foundational step towards intelligent manufacturing lines, where automated alignment reduces downtime and improves consistency.

To further illustrate the process parameters and calculations involved in secondary gear alignment for gear hobbing machines, the following table summarizes key variables and their descriptions:

| Variable | Description | Role in Gear Hobbing Alignment |

|---|---|---|

| \( A, C, E \) | Rising edge positions of gear teeth | Used to compute average rising edge position \( C_1 \) |

| \( B, D, F \) | Falling edge positions of gear teeth | Used to compute average falling edge position \( C_2 \) |

| \( Z_0 \) | Number of teeth on the workpiece gear | Essential for calculating angular displacement per tooth |

| \( C_1 \) | Average rising edge position | Input for determining tooth slot or top center |

| \( C_2 \) | Average falling edge position | Input for determining tooth slot or top center |

| \( C_0 \) | Effective rotational value for tooth slot center | Target offset for C-axis alignment in gear hobbing |

| \( C_0′ \) | Effective rotational value for tooth top center | Alternative target for specific gear hobbing requirements |

Another table detailing the comparative analysis between traditional and the proposed secondary gear alignment methods highlights the advancements:

| Aspect | Traditional Manual Method | Proposed Automated Method |

|---|---|---|

| Precision | Low, dependent on operator skill | High, based on sensor data and calculations |

| Efficiency | Time-consuming due to manual adjustments | Rapid, automated process reduces setup time |

| Consistency | Variable across operators and sessions | Consistent results through standardized procedure |

| Error Handling | Prone to individual tooth inaccuracies | Averages multiple points to minimize errors |

| Integration | Limited compatibility with automation | Seamlessly integrates with CNC gear hobbing machine systems |

The mathematical foundation of the alignment process can be expanded to include error compensation models. For instance, the total alignment error \( E_{\text{align}} \) in a gear hobbing machine may incorporate factors such as sensor resolution \( \delta_s \), mechanical backlash \( \beta \), and thermal drift \( \Delta T \). A simplified error model can be expressed as:

$$ E_{\text{align}} = \sqrt{ \left( \frac{\partial C_0}{\partial C_1} \delta_{C_1} \right)^2 + \left( \frac{\partial C_0}{\partial C_2} \delta_{C_2} \right)^2 + \left( \frac{\partial C_0}{\partial Z_0} \delta_{Z_0} \right)^2 } + \beta \cdot \Delta T $$

where \( \delta_{C_1} \), \( \delta_{C_2} \), and \( \delta_{Z_0} \) represent uncertainties in the averaged positions and tooth count, respectively. By minimizing these components through robust sensor selection and calibration, the overall accuracy of the gear hobbing process is enhanced.

In conclusion, the development and implementation of this secondary gear alignment methodology mark a significant advancement in gear hobbing technology. By addressing the limitations of conventional approaches through automated, non-contact sensing and precise computational algorithms, this system ensures high-precision alignment essential for modern gear manufacturing. The widespread adoption of such innovations in gear hobbing machines not only boosts productivity and quality but also paves the way for smarter, more connected manufacturing ecosystems. Future work may focus on integrating real-time adaptive control and machine learning to further refine the alignment process, catering to the evolving demands of the industry.