Gear hobbing technology has undergone significant advancements over the years, revolutionizing the gear manufacturing industry. These advancements have led to improvements in precision, productivity, and overall efficiency. This article explores the latest innovations in gear hobbing technology and their impact on enhancing gear manufacturing processes.

- High-Precision Gear Hobbing:

- Improved Machine Rigidity: Advanced gear hobbing machines now feature enhanced rigidity, minimizing vibration and deflection during the cutting process. This results in improved gear accuracy and surface finish.

- CNC Control Systems: Computer Numerical Control (CNC) systems have become more sophisticated, allowing for precise control of hob positioning, cutting parameters, and tool path movements. CNC control systems enable tighter tolerances and greater repeatability.

- Optical Metrology Systems: Gear hobbing machines now incorporate optical metrology systems for in-process measurement and feedback. These systems provide real-time data on gear quality, enabling immediate adjustments and corrections, resulting in higher precision.

- High-Speed Gear Hobbing:

- Improved Spindle Speeds: Gear hobbing machines are now equipped with high-speed spindles capable of achieving higher rotational speeds. This allows for faster cutting rates, reducing cycle times and increasing productivity.

- Advanced Cutting Tool Materials: The development of cutting tool materials, such as carbide and ceramic, with superior wear resistance and heat dissipation properties, enables higher cutting speeds without compromising tool life or gear quality.

- Efficient Cooling and Lubrication Systems: Enhanced cooling and lubrication systems ensure optimal heat dissipation and lubrication during high-speed gear hobbing, reducing tool wear and improving cutting efficiency.

- Automation and Robotics:

- Automated Loading and Unloading: Gear hobbing machines can be integrated with automated loading and unloading systems, minimizing manual intervention and increasing overall productivity.

- Robotic Workpiece Handling: Robots can be employed for precise workpiece positioning and transferring between machining operations, reducing setup times and improving process reliability.

- Data Integration and Monitoring: Gear hobbing machines can be connected to advanced data monitoring and analysis systems, allowing for real-time performance monitoring, predictive maintenance, and process optimization.

- Simulation and Virtual Prototyping:

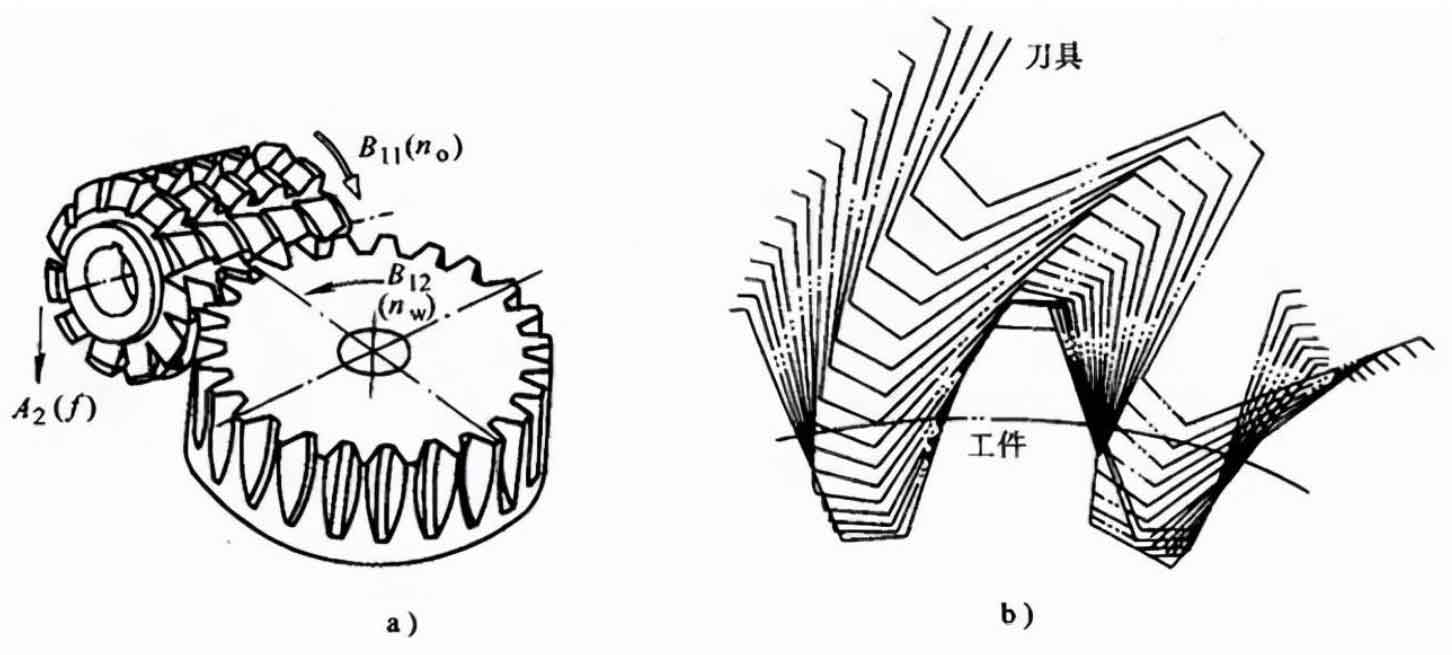

- Virtual Gear Hobbing Simulation: Computer-aided design (CAD) and computer-aided manufacturing (CAM) software enable virtual simulations of the gear hobbing process. This allows for optimization of tool path, cutting parameters, and gear designs, minimizing errors and reducing the need for physical prototypes.

- Digital Twin Technology: Digital twin models can be created to simulate the behavior of gear hobbing machines and predict their performance. This enables manufacturers to identify potential issues, optimize machine parameters, and enhance productivity.

Advancements in gear hobbing technology have significantly improved precision and productivity in gear manufacturing processes. With high-precision machines, high-speed capabilities, automation, and simulation tools, gear manufacturers can achieve tighter tolerances, faster production rates, and higher-quality gears. These advancements pave the way for more efficient and cost-effective gear production, meeting the evolving demands of industries that rely on precise and reliable gears. As technology continues to evolve, further innovations in gear hobbing are expected, driving the industry towards even greater levels of precision and productivity.