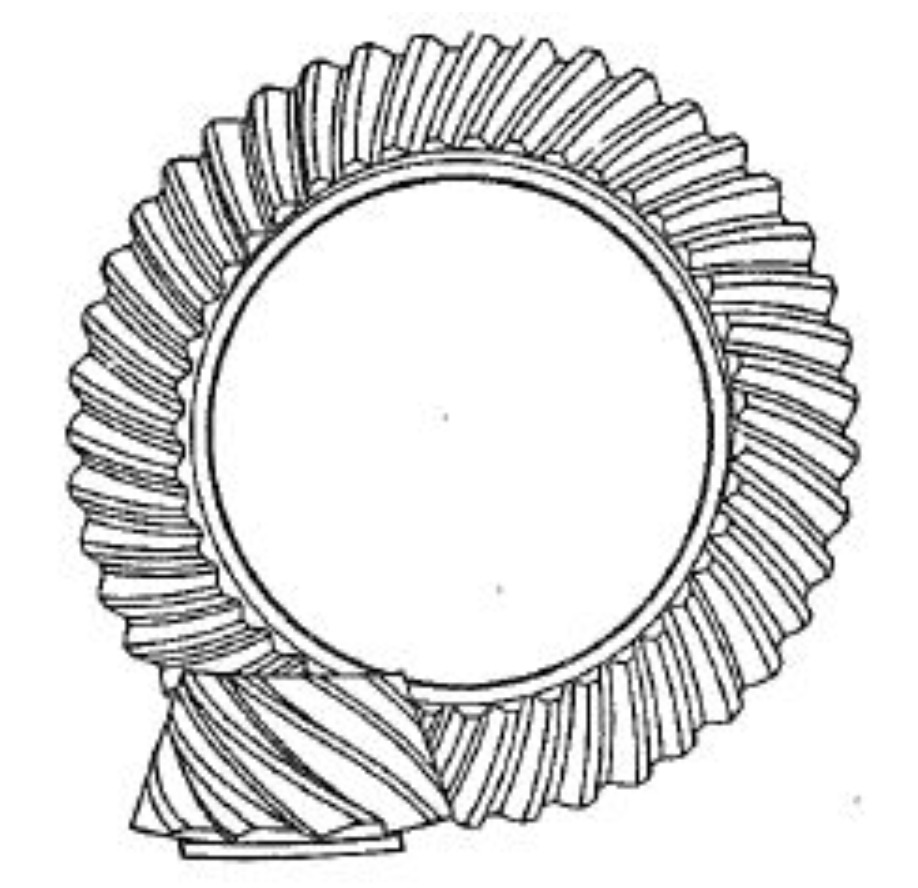

Advancements in hypoid gear manufacturing have ushered in a new era of precision, significantly enhancing their performance and applications. These advancements are driven by innovations in several key areas:

- Computer-Aided Design (CAD) and Simulation: The use of sophisticated CAD software allows for precise design of hypoid gears, taking into account complex factors like load distribution, tooth contact patterns, and stress analysis. Simulation tools enable engineers to predict performance and identify potential issues before manufacturing, thus reducing the risk of costly errors.

- CNC Machining: Computer Numerical Control (CNC) machining has revolutionized the manufacturing of hypoid gears. CNC machines offer unparalleled precision in cutting gears, allowing for complex shapes and patterns that were difficult or impossible to achieve with traditional methods. This precision results in gears with better contact patterns and smoother operation.

- Advanced Metrology: The use of advanced metrological tools and techniques, such as laser scanning and coordinate measuring machines, ensures extremely high accuracy in the measurement of gear dimensions and surface topology. This is critical in achieving the tight tolerances required for optimal gear performance.

- Improved Materials and Heat Treatment Processes: The development of new materials and sophisticated heat treatment processes has significantly improved the strength and durability of hypoid gears. High-performance alloys and treatments like carburizing, nitriding, or induction hardening enhance the wear resistance and longevity of the gears.

- Gear Grinding Technology: Advances in gear grinding technology, particularly in the area of precision grinding machines, have greatly enhanced the finish and accuracy of hypoid gears. This results in quieter operation, higher load capacity, and longer life.

- Lubrication Technologies: The development of advanced lubricants and lubrication systems has also played a significant role. These lubricants reduce friction and wear, thereby extending the life of hypoid gears and allowing them to operate more efficiently.

- Customization and Flexibility in Production: Modern manufacturing techniques enable the production of hypoid gears tailored to specific applications, providing flexibility in design and the ability to meet unique performance requirements.

- Sustainability and Energy Efficiency: There is an increasing focus on making the manufacturing process more sustainable and energy-efficient, which includes using eco-friendly materials and reducing waste.

- Collaborative Robotics and Automation: The integration of robotics and automation in gear manufacturing not only improves efficiency but also ensures consistent quality, especially in repetitive and high-precision tasks.

- Quality Control and Testing: Enhanced quality control measures and rigorous testing protocols ensure that the gears meet stringent performance standards, reducing the likelihood of failures in the field.

These advancements in hypoid gear manufacturing not only lead to superior product quality but also open up new possibilities in their application across various industries, from automotive to aerospace. The combination of precision engineering, advanced materials, and innovative manufacturing techniques positions hypoid gears at the forefront of high-performance gear technology.