1. Small module gear processing method and its advantages and disadvantages

At present, the common processing methods of small module gears can be roughly divided into two categories according to the gear tooth processing mode:

(1) cutting;

(2) near net shape processing.

The above process method basically follows the process and method of ordinary gear processing.

The manufacturing of dies and cutting tools is the main reason that restricts the machining accuracy and manufacturing speed of small module gears.

2. SLA light curing molding

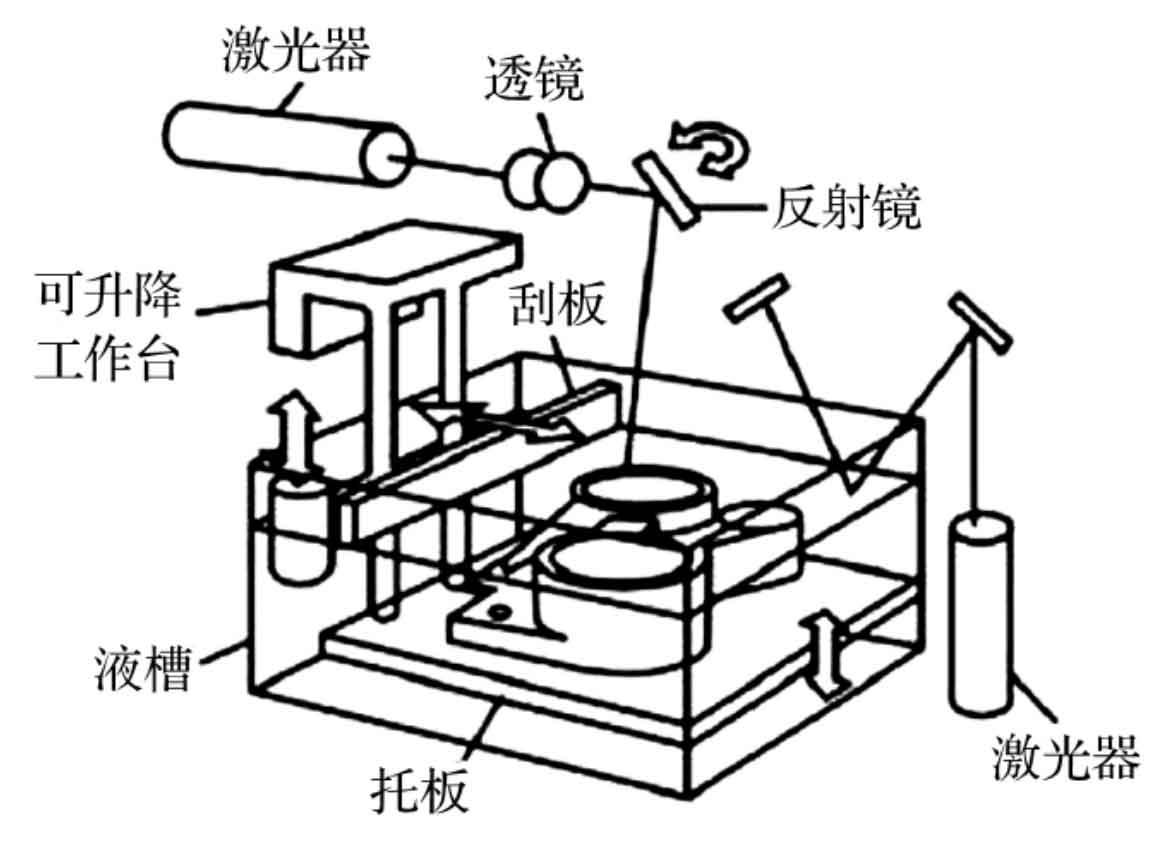

Photo curing molding is also called stereo lithography molding (SLA), and its principle is shown in Figure 1.

Using liquid photosensitive resin as raw material, the movement of ultraviolet laser beam is controlled by computer to solidify the photosensitive resin layer by layer to form a three-dimensional entity. The main features of this process are:

(1) high manufacturing accuracy (up to 0.05 mm);

(2) high utilization rate and cost performance of materials;

(3) the strength and hardness of parts are good, and special parts with extremely complex structure can be manufactured.

Therefore, the process is widely used in mold processing, precision casting, biomedicine and other fields.

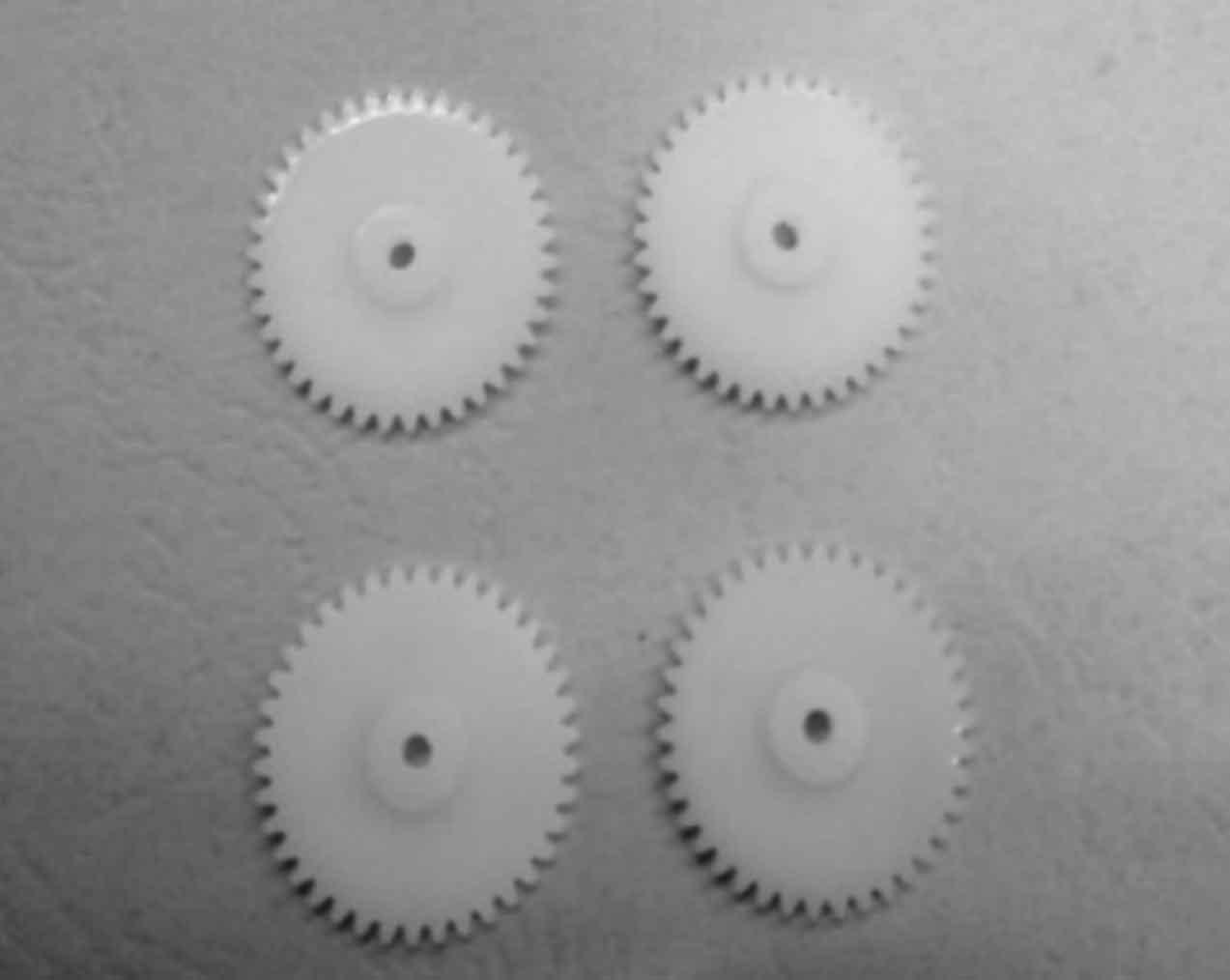

Firstly, the CAD model of small module gear drawn by Pro / E software is shown in Figure 2.

Then export the model to triangular format (STL format), import the STL format file of the part into the pre-processing software materialise for processing, and import the processed file into liantai 460 HD rapid prototyping machine for rapid manufacturing.

Clean the printed products with absolute alcohol, and then peel off the auxiliary support; Move the cleaned parts into the secondary curing box and irradiate them for about 20 minutes. The finished parts after curing are shown in Figure 3.