According to theoretical calculations, the strength design of each gear in the planetary reduction mechanism meets the requirements. According to the fault phenomenon of the faulty component, both the planetary gear and the floating gear ring are locally broken teeth, so it is considered that the cause of the fault is the gear being biased in the direction of the teeth.

The planetary reduction mechanism uses a planetary carrier as the support component for the planetary gear. If the torsional stiffness of the planetary carrier is insufficient, it will cause the planetary gear to experience tooth misalignment, and in severe cases, it may cause local tooth breakage.

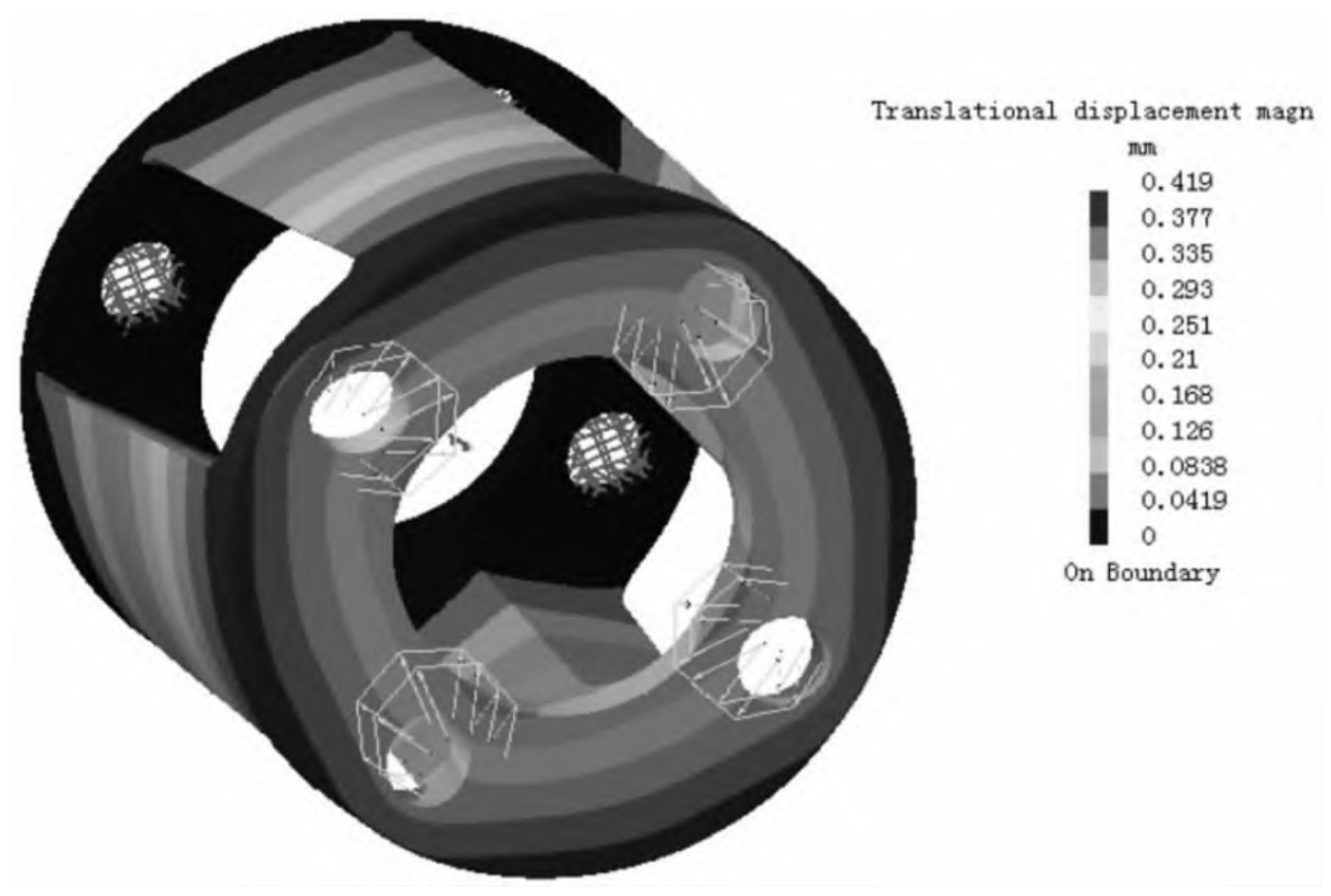

Here, modeling and simulation analysis are conducted on the stiffness of the planetary carrier. After simulation, the torsional deformation of the planetary carrier is severe under the maximum working load, with a maximum deformation of 0.42 mm, as shown in Figure 3.

From the above analysis, it can be concluded that due to insufficient stiffness of the planet carrier, there is significant torsional deformation of the planet carrier under maximum working load. This deformation causes severe eccentric load on the planetary gear along the tooth width direction, resulting in local tooth breakage faults on both the planetary gear and its meshing floating gear ring.