The planetary roller screw assembly stands as a superior mechanical transmission device, transmitting power through multi-point contact between thread teeth. Its performance advantages over traditional ball screws are well-documented, offering significantly higher static stiffness, more compact installation space under equivalent axial loads, and greatly extended operational life. A key feature of the planetary roller screw assembly is its ability to achieve ultra-precise, smooth transmission under both light and heavy loads by employing fine leads and engaging multiple thread teeth simultaneously in power transmission. Consequently, it has been widely adopted in various fully-electrified systems.

While extensive research and application have focused on single-stage planetary roller screw assemblies, their use in mechanisms requiring multi-stage linear actuators, such as medium to large-scale erection equipment, presents challenges. The limited stroke and relatively slow linear velocity of a single-stage assembly can hinder performance. The development and implementation of a two-stage planetary roller screw assembly can address these limitations, offering increased erection speed, greater stroke, and reduced operation time. This article focuses on the structural parameter matching and kinematic analysis of a two-stage planetary roller screw assembly, which is crucial for its engineering application.

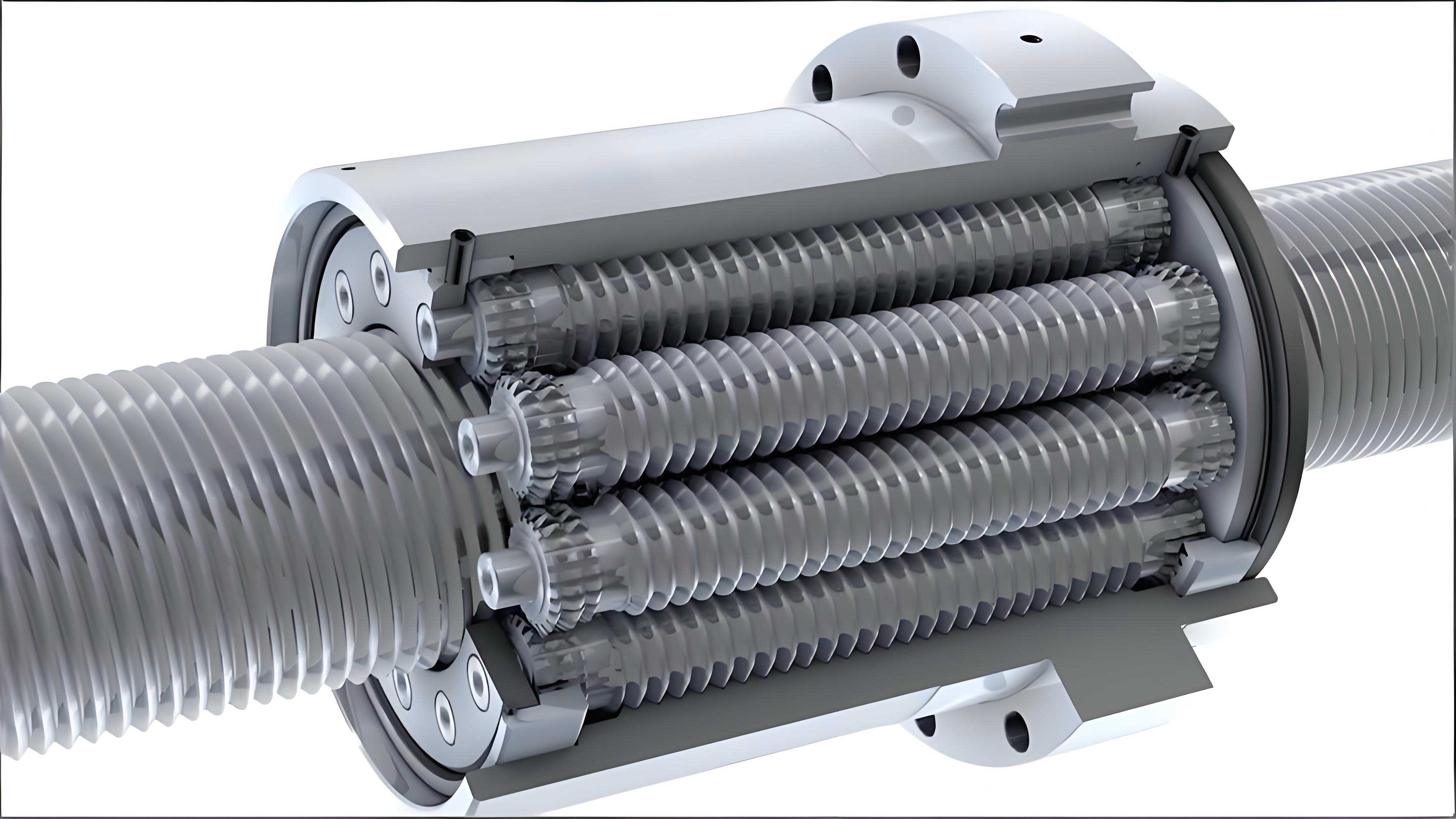

Structural Configuration and Operational Principle

The two-stage planetary roller screw assembly exhibits a more complex structure and transmission mechanism compared to its single-stage counterpart. Its core components include the primary screw, the primary nut, the secondary hollow screw, the secondary nut, sleeves, a push rod, thrust bearings, internal ring gears, and retainers. The connection and force transmission between stages are critical design aspects.

A significant feature of the proposed design is the use of a profile connection between the primary screw and the secondary hollow screw for motion transfer. The right end of the primary screw is designed with a hexagonal profile. This profile connection offers ease of assembly/disassembly, good alignment, and the absence of keyways and sharp corners on the connecting surfaces, thereby reducing stress concentration while being capable of transmitting substantial torque. The secondary hollow screw is driven rotationally via this hexagonal profile. Furthermore, an appropriate clearance is maintained between the mating profiles, allowing the hexagonal end of the primary screw to also guide the axial motion of the secondary hollow screw.

The operational principle is as follows: The rotation of the primary screw drives the primary rollers and causes the axial movement of the primary nut. Simultaneously, the primary nut transmits its axial motion to the secondary stage via a sleeve and a thrust bearing. The secondary nut, which is fixed to the push rod, moves axially. The thrust bearing between the primary nut and the secondary hollow screw is essential as it transmits thrust while accommodating the relative rotation between these two components. The rotational motion is transmitted from the primary screw to the secondary hollow screw via the hexagonal profile, causing them to rotate coaxially. Thus, the push rod’s final linear motion is the superposition of the axial movement from the primary stage and the axial movement generated by the rotation of the secondary hollow screw.

Parameter Matching and Design Criteria

The structural parameter matching for a two-stage planetary roller screw assembly must adhere to all established design conditions for a single-stage assembly. Beyond these, two additional critical criteria must be satisfied for the two-stage configuration: strength conditions and compressive member (column) stability.

1. Strength Conditions

The primary screw and the secondary hollow screw must be evaluated for strength. Based on the material’s yield strength limit $\sigma_{max}$ and a chosen safety factor $K$, the allowable stress $[\sigma]$ is:

$$[\sigma] = \sigma_{max} / K$$

The primary screw and secondary hollow screw must respectively satisfy:

$$\sigma_1 = \frac{4F_a}{\pi d_{01}^2} < [\sigma] \quad \text{and} \quad \sigma_2 = \frac{4F_a}{\pi (d_{02}^2 – d_{01}^2)} < [\sigma]$$

where $\sigma_1, \sigma_2$ are the stress in the primary and secondary screws, $F_a$ is the axial load, and $d_{01}, d_{02}$ are their pitch diameters.

2. Compressive Member Stability

When employed in erection systems, the two-stage planetary roller screw assembly often works under compression. Under high axial loads, the assembly may buckle. Therefore, stability analysis is essential. The slenderness ratio $\lambda$ is given by:

$$\lambda = \mu l / r_{min}$$

where $r_{min}$ is the minimum radius of gyration of the cross-section, $l$ is the length, and $\mu$ is the effective length factor. The critical stress $\sigma_c$ is calculated based on $\lambda$:

$$\sigma_c =

\begin{cases}

\sigma_l, & \lambda < \lambda_l \\

a – b\lambda, & \lambda_l \leq \lambda \leq \lambda_p \\

\pi^2 E / \lambda^2, & \lambda > \lambda_p

\end{cases}$$

Here, $\sigma_l$ is the material’s yield limit, $a, b$ are material constants, $\lambda_l, \lambda_p$ are the slenderness ratios corresponding to the yield limit and proportional limit, respectively, and $E$ is the elastic modulus. The critical load $F_c = \sigma_c S_c$, where $S_c$ is the cross-sectional area. For a long column ($\lambda > \lambda_p$), Euler’s formula applies: $F_c = \pi^2 E I / (\mu l)^2$, where $I$ is the area moment of inertia.

For a multi-stage assembly with variable cross-section, the total critical load considering bending energy can be derived. For an assembly with $N$ stages, the critical load $F_c$ is expressed as:

$$F_c = \pi^2 E I_1 / (\mu_1 \mu_2 L)^2$$

where $I_1$ is the moment of inertia of the first stage, $L$ is the total length, $\mu_1$ is the end-condition coefficient, and $\mu_2$ is a coefficient accounting for the variable cross-section.

Kinematic Analysis of the Planetary Roller Screw Assembly

The kinematic relationships within a single stage of a standard planetary roller screw assembly form the basis for analyzing the two-stage system. In a standard assembly, the nut’s rotation is constrained. The rollers rotate about their own axes (spin) while also revolving around the screw axis (orbit).

1. Roller Angular Velocities

The relationship between the screw angular velocity $\omega_s$ and the roller’s orbital (revolution) angular velocity $\omega_c$ is derived from the condition of no slip at the screw-roller contact point (pitch circles):

$$\omega_c = \frac{\omega_s d_{0s}}{2(d_{0s} + d_{0R})}$$

where $d_{0s}$ is the screw pitch diameter and $d_{0R}$ is the roller pitch diameter.

Under pure rolling conditions between the roller and the nut, the roller’s spin angular velocity $\omega_R$ relative to its carrier is:

$$\omega_R = \frac{d_{0s} + 2d_{0R}}{d_{0R}} \omega_c$$

For a two-stage planetary roller screw assembly where the secondary hollow screw rotates at the same speed as the primary screw ($\omega_{s1} = \omega_{s2} = \omega_s$), the orbital and spin velocities for rollers in both stages can be calculated using the above formulas with their respective pitch diameters.

2. Nut Axial Velocity and Displacement

The axial displacement $L_{Ni}$ of the nut in stage $i$ is related to the screw rotation:

$$L_{Ni} = \frac{\omega_s t}{2\pi} n_s p, \quad i = 1, 2$$

where $n_s$ is the number of screw thread starts and $p$ is the pitch. Differentiating with respect to time gives the axial velocity $v_{Ni}$:

$$v_{Ni} = \frac{\omega_s}{2\pi} n_s p$$

For the two-stage assembly, the total axial velocity of the secondary nut $v_{N2}$ is the superposition of two components: the velocity imparted by the axial movement of the primary nut/primary stage ($v_{N12}$), and the velocity generated by the rotation of the secondary hollow screw acting on the secondary nut ($v_{N22}$). Since $v_{N12} = v_{N1}$ and $v_{N22} = v_{N2}$ (from the same screw speed $\omega_s$), the total velocity is:

$$v_{N2} = v_{N12} + v_{N22} = 2 \times \frac{\omega_s}{2\pi} n_s p = \frac{\omega_s}{\pi} n_s p$$

This indicates a theoretical doubling of the output velocity for the two-stage planetary roller screw assembly compared to a single stage with the same screw input speed.

| Component | Major Diameter $d_1$ (mm) | Pitch Diameter $d_0$ (mm) | Minor Diameter $d_2$ (mm) | Pitch $p$ (mm) | Starts $n_s$ | Length $l$ (mm) | Thread Angle $\alpha$ (°) |

|---|---|---|---|---|---|---|---|

| Stage 1 Screw | 100.35 | 99.00 | 97.11 | 4 | 5 | 1680 | 90 |

| Stage 1 Nut | 166.60 | 165.00 | 163.45 | 4 | 5 | 200 | 90 |

| Stage 1 Roller | 34.30 | 33.00 | 31.15 | 4 | 1 | 160 | 90 |

| Stage 2 Screw | 150.39 | 150.00 | 148.15 | 4 | 5 | 1557 | 90 |

| Stage 2 Nut | 252.35 | 250.00 | 249.20 | 4 | 5 | 357 | 90 |

| Stage 2 Roller | 51.80 | 50.00 | 48.65 | 4 | 1 | 317 | 90 |

Dynamic Simulation Modeling and Verification

A multi-body dynamics model of the two-stage planetary roller screw assembly was developed using ADAMS software to validate the theoretical kinematic analysis and parameter matching. A 3D assembly was first created based on parameters like those in Table 1, then simplified for computational efficiency (e.g., reducing the number of rollers per stage from the design number to two symmetric ones).

1. Model Constraints and Contact Forces

Appropriate joints were applied to reflect the actual kinematics:

- Fixed Joints: Between nuts and their internal ring gears, and between the primary nut and its thrust bearing.

- Revolute Joints: For the primary screw rotation relative to ground, and for each roller relative to its carrier (planet frame).

- Translational Joints: Between the primary screw and secondary hollow screw (hexagonal profile connection, allowing relative axial slide), and for each nut relative to the fixed frame (allowing only axial translation).

- Planar Joint: Between the thrust bearing and the secondary hollow screw to allow both rotation and translation.

- Driving Motion: A rotational motion was applied to the revolute joint of the primary screw.

Contact forces were defined between the screw-roller and roller-nut interfaces using the IMPACT function, which includes a nonlinear spring-damper model for normal force and Coulomb friction for tangential force. The contact parameters (stiffness, damping, exponent, friction coefficients) were set to simulate realistic interaction with lubrication.

2. Simulation Results and Theoretical Comparison

The simulation was run with an input screw speed $\omega_s = 800^\circ/s$ (or $\frac{40}{9}\pi$ rad/s). The theoretical and simulated values for key kinematic outputs were compared.

Axial Velocities: The theoretical axial velocity for a single-stage nut is $v_{Ni} = \frac{\omega_s}{2\pi} n_s p = \frac{800}{360} \times 5 \times 4 = 44.44 \text{ mm/s}$. The simulation gave an average velocity of 44.35 mm/s for the primary nut and the secondary hollow screw’s axial movement, yielding a 0.20% error. The theoretical total velocity for the secondary nut is $v_{N2} = 2 \times 44.44 = 88.88 \text{ mm/s}$. The simulation average was 87.56 mm/s, a 1.49% error.

Axial Displacements: Over 1 second, the theoretical displacement for a single stage is 44.44 mm. The simulated primary nut displacement was 42.07 mm (5.33% error). The theoretical secondary nut displacement is 88.88 mm, compared to the simulated 86.67 mm (2.49% error).

Roller Angular Velocities: For Stage 1 rollers ($d_{0s}=99$ mm, $d_{0R}=33$ mm):

$$ \omega_{c1}^{theo} = \frac{800 \times 99}{2(99+33)} = 300.0^\circ/s, \quad \omega_{R1}^{theo} = \frac{99+2\times33}{33} \times 300 = 1500.0^\circ/s $$

The simulation gave $\omega_{c1}^{sim} \approx 293.40^\circ/s$ and an absolute spin $\omega_{abs1}^{sim} \approx 1179.55^\circ/s$. The true spin relative to the carrier is $\omega_{R1}^{sim} = \omega_{c1}^{sim} + \omega_{abs1}^{sim} \approx 1472.95^\circ/s$. Errors are 2.20% (orbit) and 1.80% (spin).

For Stage 2 rollers ($d_{0s}=150$ mm, $d_{0R}=50$ mm):

$$ \omega_{c2}^{theo} = \frac{800 \times 150}{2(150+50)} = 300.0^\circ/s, \quad \omega_{R2}^{theo} = 1500.0^\circ/s $$

The simulation gave $\omega_{c2}^{sim} \approx 296.92^\circ/s$, $\omega_{abs2}^{sim} \approx 1183.58^\circ/s$, thus $\omega_{R2}^{sim} \approx 1480.50^\circ/s$. Errors are 1.03% (orbit) and 1.30% (spin).

| Parameter | Theoretical Value | Simulation Value | Relative Error |

|---|---|---|---|

| $v_{N1}$ (mm/s) | 44.44 | 44.35 | 0.20% |

| $v_{N2}$ (mm/s) | 88.88 | 87.56 | 1.49% |

| $L_{N1}$ (mm in 1s) | 44.44 | 42.07 | 5.33% |

| $L_{N2}$ (mm in 1s) | 88.88 | 86.67 | 2.49% |

| $\omega_{c1}$ (°/s) | 300.00 | 293.40 | 2.20% |

| $\omega_{R1}$ (°/s) | 1500.00 | 1472.95 | 1.80% |

| $\omega_{c2}$ (°/s) | 300.00 | 296.92 | 1.03% |

| $\omega_{R2}$ (°/s) | 1500.00 | 1480.50 | 1.30% |

The minor discrepancies between theory and simulation are acceptable and can be attributed to several factors inherent in a real or simulated planetary roller screw assembly. The theoretical calculations assume ideal pure rolling. In practice, motion transmission relies on rolling friction, and the 45° contact angle between the screw and roller threads induces a sliding tendency. Furthermore, small clearances were intentionally modeled between thread teeth to prevent interference during assembly. These clearances introduce initial engagement impacts and slight sliding, leading to the observed velocity fluctuations at startup and minor deviations from ideal kinematic values. As the axial load seats the components, the contact points stabilize, and the motion becomes smoother, as seen in the simulation results.

Conclusion

This work focused on the analysis of a two-stage planetary roller screw assembly. The primary contributions are the extension of single-stage design criteria to include strength and buckling stability checks specific to the two-stage configuration, and the derivation of its compound kinematic relations. A detailed multi-body dynamics model was successfully developed and simulated. The close agreement between the theoretical predictions and simulation results, with all relative errors within an acceptable range (mostly below 3%, and within 6% for displacement which is sensitive to initial engagement conditions), validates the rationality of the parameter matching methodology and the accuracy of the kinematic analysis for the two-stage planetary roller screw assembly. This analysis provides a foundational framework for the design and performance evaluation of such multi-stage linear actuators, which are critical for advancing high-performance, fully-electrified motion systems in demanding applications.