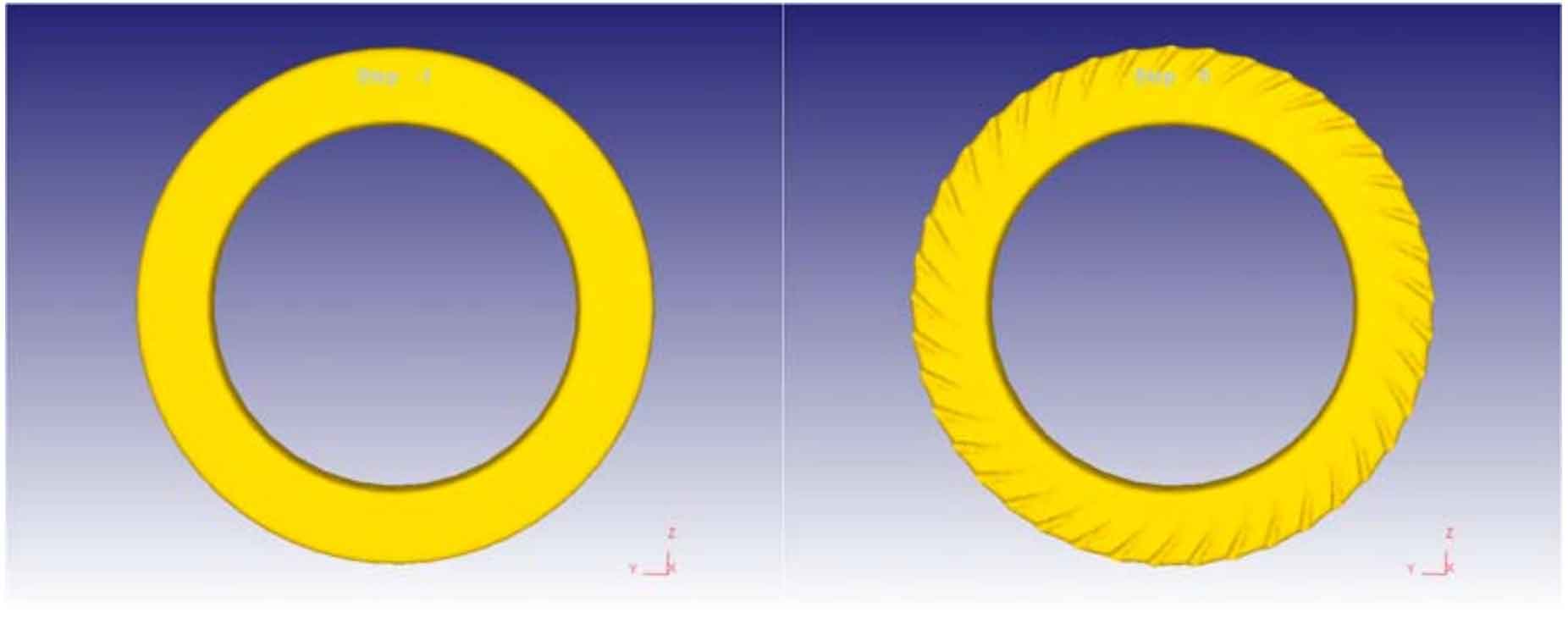

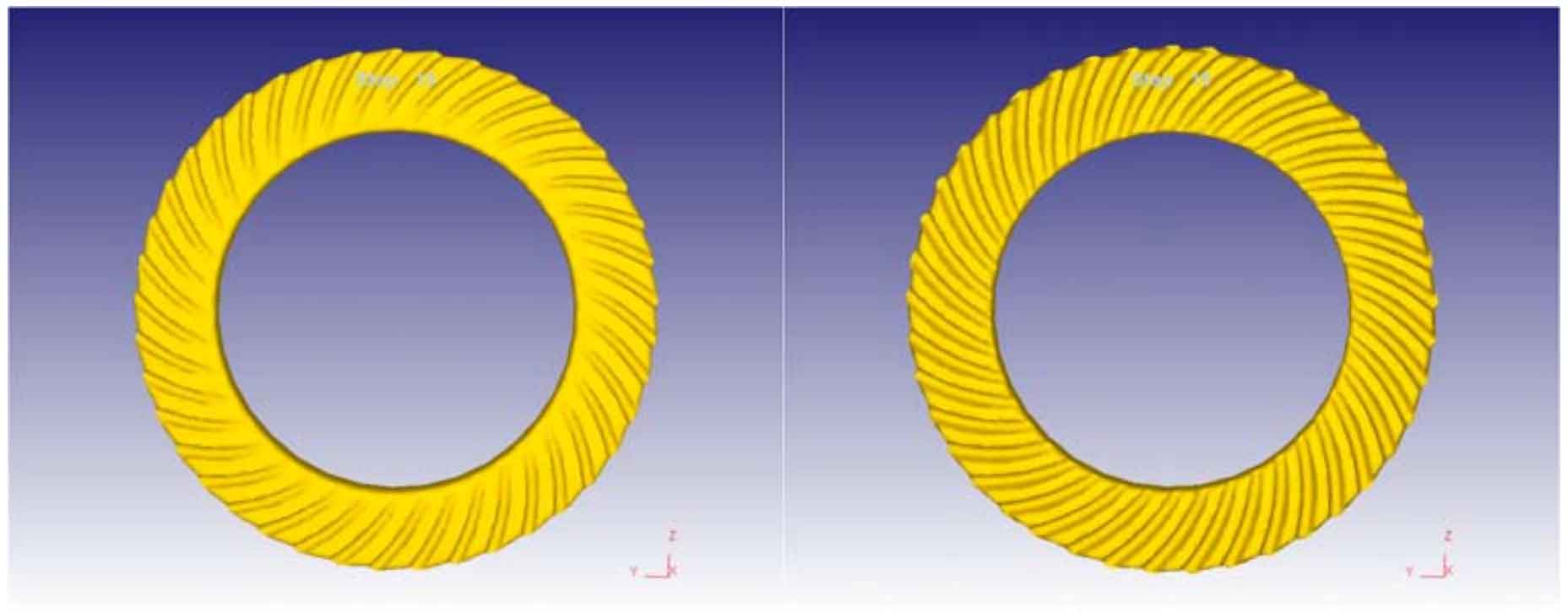

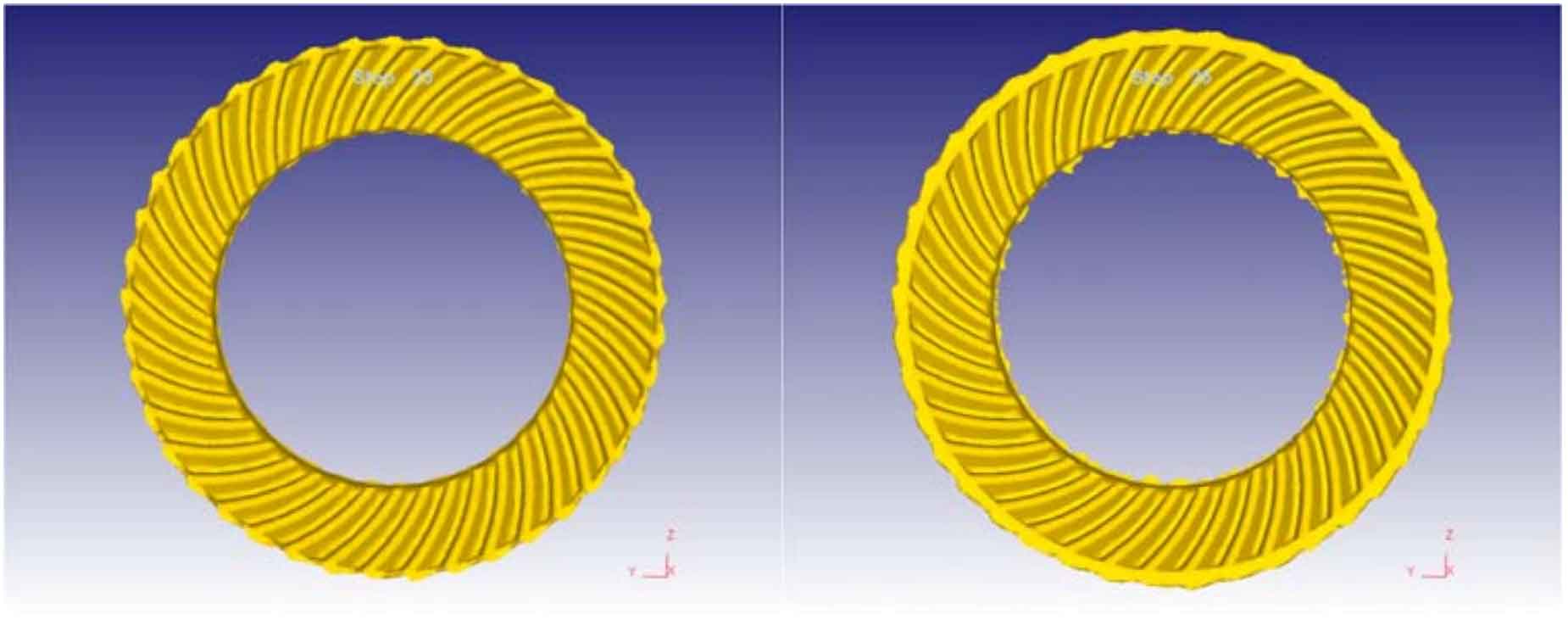

After the simulation, open the post-processing option in the DEFORM-3D main window to view the simulation results. The post-processing window of the software includes graphic display window, step selection and animation playback, graphic display selection control window, etc. the forming process of the big wheel can be displayed through animation, as shown in the figure is the forging process diagram of the big wheel.

In the figure, on the whole, during the forming process, the blank is gradually extruded by the die to produce the tooth shape impression, and then slowly presents the outline of the gear teeth. Finally, the gear forging is simulated and forged; Specifically, in step 1, the die does not contact the blank, in step 5, the blank begins to contact, and then the blank gradually deforms. By step 25, the blank has become a forging. This process describes the forming of the blank in the forging process; In step 5, when the blank comes to the pressure from the die, the conical part of the tooth surface deforms, and the large end deforms first. The reason is analyzed: the tooth model comes from the tooth design during machining, which belongs to the tapered tooth shape. Therefore, the full tooth height of the large end is greater than that of the small end, so the large end is first forged out of the tooth shape, which conforms to the design principle; Steps 5 to 25 are the process that the blank is gradually forged into a gear forging, the material flows continuously, and the tooth shape is finally filled; It can be seen from the figure in step 25 that the forming accuracy of the large wheel is very high, the tooth shape is accurate, there are no parts and defect areas that are difficult to form, and the surplus parts can be processed through subsequent processing. It is a successful forging simulation, which provides a model basis for the forging processing of spiral bevel gear.