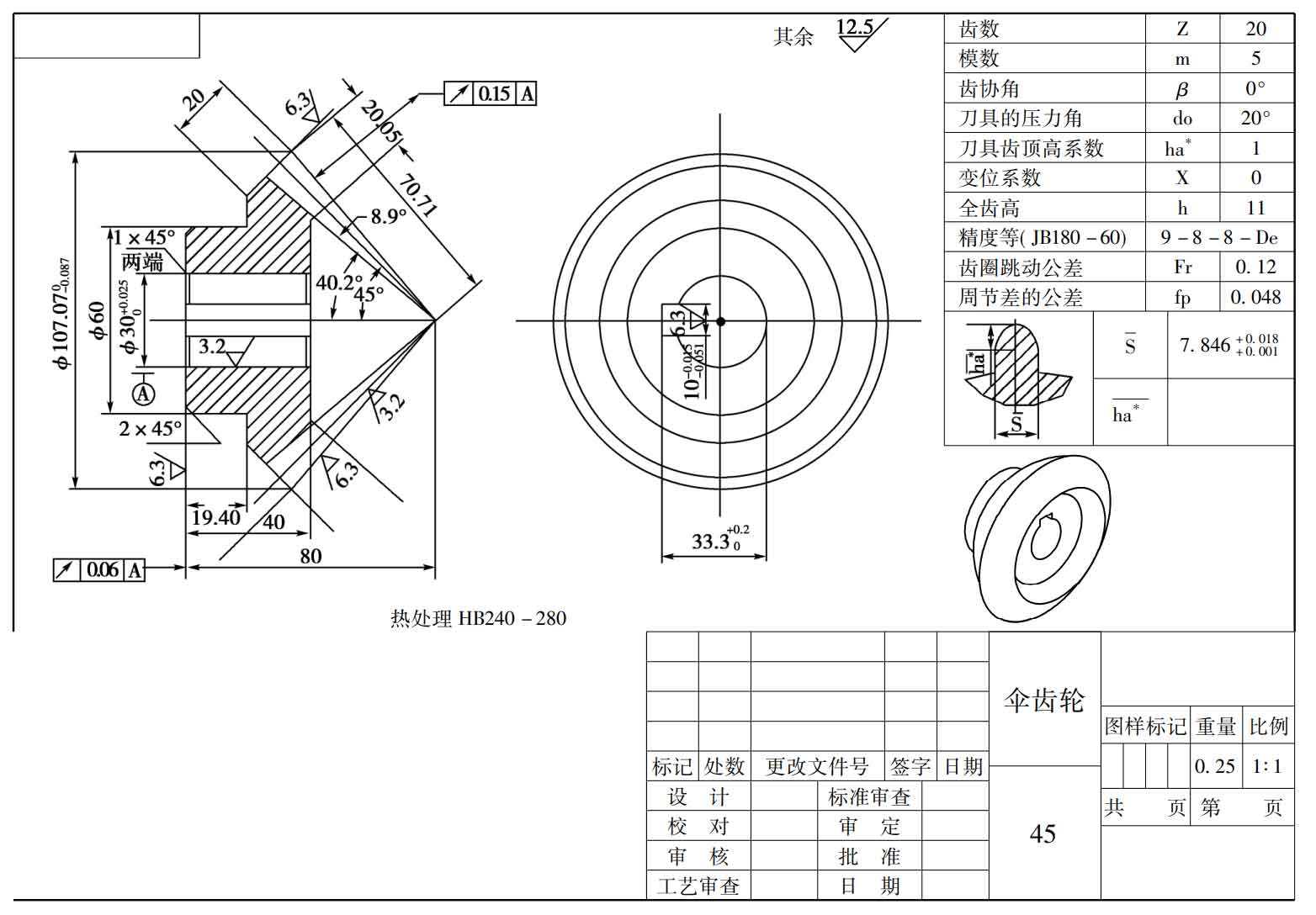

Conical gear is the key part of the three piece special machine. The material of the part is 45# medium carbon steel, and the blank form is forging. Quenching and tempering treatment is carried out after rough machining to ensure that the part has high strength, good machinability, toughness, plasticity and wear resistance. The part drawing of conical gear is shown in the figure.

1. Conical gear reference selection

As for the parts to be machined, the surface not machined shall be selected as the rough datum as far as possible. For conical gears with several unmachined surfaces, the unmachined surface with high position accuracy relative to the machining requirements should be used as the rough datum. The selection of precise datum should mainly consider the problem of datum coincidence. When the design datum does not coincide with the process datum, the dimension conversion should be carried out. When milling or hobbing, the machined roughness RA6 3 end face Φ 30 holes and keyways are fine datum, and the roughness is RA6 3. The end face is limited to 3 degrees of freedom, Φ The 30 holes are limited to 2 degrees of freedom and the keyway is limited to 1 degree of freedom.

2. Determine the production type of conical gear

The production program of known parts is 1200 pieces / year. Check the mechanical manufacturing process and equipment design manual to determine that such parts are medium batch production.

3. Process design basis of conical gear

As the annual output of conical gear is 1200 pieces, which belongs to medium batch production, and the structure of the part is complex, the requirements for dimensional accuracy and geometric tolerance are high. Using ordinary processing methods, the dimensional accuracy and position accuracy of the part are difficult to be guaranteed, the processing efficiency is low, the processing quality is poor, and the scrap rate is high. Therefore, it is necessary to design the process specification of the part, prepare the part process card, draw the part blank drawing, prepare the part machining process card, and design the conical gear milling tooling and conical gear hobbing tooling for part processing, so as to improve the work efficiency.