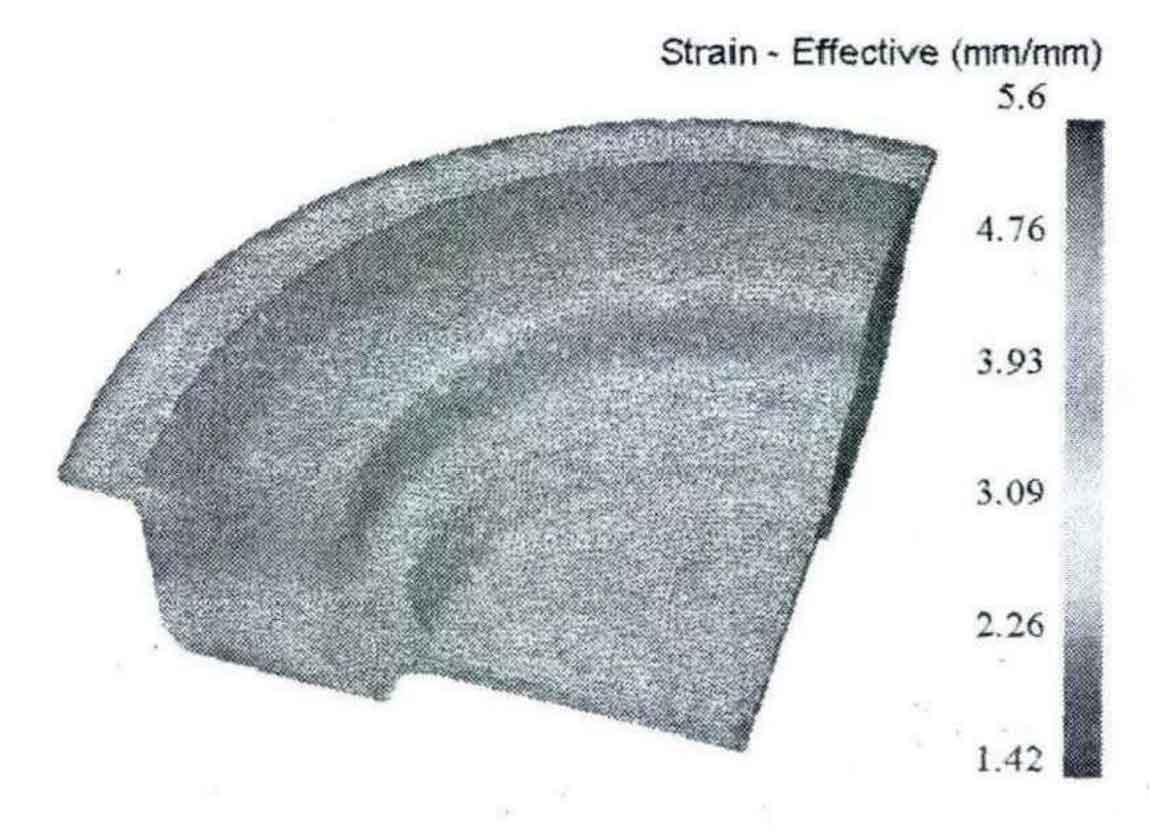

The strain distribution of helical gear blank during final forging is shown in the figure.

The maximum strain during final forging is 5.60, and the maximum strain also occurs at the steps of the outer side and flash of the helical gear blank. At the same time, the strain at the steps of the inner side and the concave thin layer is also large. The strain at the step between the outer side of the helical gear blank and the flash is 3.58-5.60, the strain at the step between the inner side and the concave thin layer is 3.46-4.69, the strain at the flash and the concave thin layer is 2.32-3.36, and the strain of the main body of the spiral gear blank is 1.42-3.32.

Therefore, when the helical gear blank is finally forged, the large strain also occurs at the steps of the outer side and flash of the helical gear blank and the steps of the inner side and concave thin layer. This is also because the metal flow at the steps is difficult, resulting in the increase of strain.