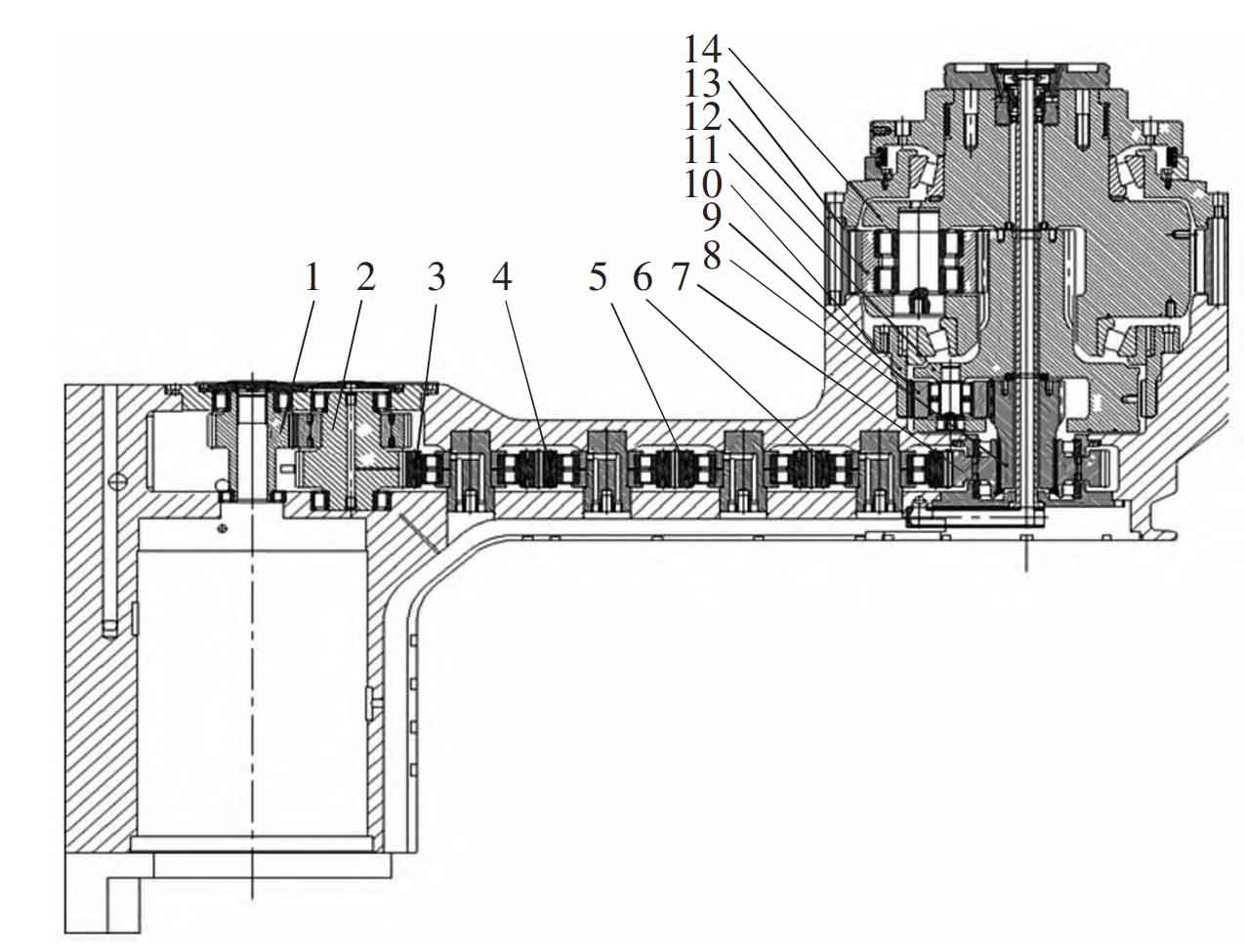

The transmission system of the cutting section (hereinafter referred to as the rocker arm) of the imported 6C shearer of M company is shown in the figure. The transmission idlers are all spur gears, with an overall transmission ratio of 47.225, a motor power of 750 kW and a rotation speed of 1475 R / min. after the first and second reduction with different reduction ratios, they are transmitted to the second-stage planetary reduction mechanism by the idler gear group. The rotation speed of the idler gear group is 777.36 R / min, which is relatively high. At the same time, the transmission power of the rocker arm is increasing, and it bears a large impact load when working, so the reliability of the idler gear is required to be higher.

Company M adopts full fillet design for rocker gear, increases the pressure angle and gear center distance, and ultra deep tooth profile to maximize the bending strength of gear teeth; High quality steel is used, and most gears are made of “super steel” in AGMA standard; Adopt induction hardening and carbonization treatment process; The strength balance of the gears in the whole gearbox is realized, the overall design is optimized, and the influence of load change is evaluated by the computer design program.