In modern industrial applications, the demand for precision screw gear transmissions has escalated, requiring compact designs that deliver high torque, zero backlash, large reduction ratios, high accuracy, stiffness, reliability, and longevity. Particularly in specialized fields like helicopter and robotics, there is an additional need for power-splitting or multi-load capabilities. To address these challenges, I have focused on a novel planar enveloping internal-meshing screw gear transmission. This design leverages the advantages of traditional screw gear systems, such as large transmission ratios, compact structure, high torque capacity, and precision, while enabling multi-output configurations and power distribution. By employing an internal-meshing arrangement with multiple output gears, it is possible to achieve zero-backlash operation through differential engagement of the left and right tooth flanks. My previous work laid the theoretical groundwork for this transmission, including its kinematic principles and manufacturing considerations. However, a comprehensive analysis of how key design parameters affect the contact performance and load-bearing capacity was lacking. Therefore, in this study, I delve into the influence of critical parameters on the contact zone distribution, aiming to identify optimal design ranges and enhance the overall performance of planar enveloping internal-meshing screw gear transmissions.

To analyze the contact characteristics, I base my approach on gear meshing theory. The planar enveloping internal-meshing screw gear transmission consists of a screw (worm) and an internal gear (worm wheel). The tooth surface of the screw is generated by enveloping a plane (the generating plane) that is rigidly connected to the gear. Establishing coordinate systems is essential for describing the relative motion and meshing conditions. I define a static coordinate system \( S_1(O_1; i_1, j_1, k_1) \) fixed to the screw, and a moving coordinate system \( S_1′(O_1′; i_1′, j_1′, k_1′) \) that rotates with the screw at angular velocity \( \omega_1 \). Similarly, for the gear, I set up a static system \( S_2(O_2; i_2, j_2, k_2) \) and a moving system \( S_2′(O_2′; i_2′, j_2′, k_2′) \) rotating at \( \omega_2 \). On the generating plane \( \Sigma \), I attach a moving coordinate system \( S_0(O_0; i_0, j_0, k_0) \), where the \( j_0 \) and \( k_0 \) axes lie on the plane, and the origin \( O_0 \) is positioned on the main base circle with coordinates \( \mathbf{r}_0 = (0, r, 0) \) in \( S_2′ \). At the contact point \( p \), I define another moving system \( S_p(O_p; e_1, e_2, \mathbf{n}) \), with \( e_1 \) parallel to \( k_0 \), \( e_2 \) parallel to \( j_0 \), and \( \mathbf{n} \) as the normal vector. The contact point coordinates in \( S_0 \) are \( \mathbf{r}_p = (0, u, v) \). The angular displacements of the screw and gear are denoted as \( \phi_1 \) and \( \phi_2 \), respectively, with transmission ratio \( i_{12} = 1 / i_{21} = z_1 / z_2 \), where \( z_1 \) and \( z_2 \) are the number of teeth on the screw and gear. Key parameters include the center distance \( A \), the inclination angle of the generating plane \( \beta \), and the installation angle of the gear axis \( \delta_F \).

The coordinate transformation from the gear’s moving system \( S_2′ \) to the screw’s moving system \( S_1′ \) is derived as:

$$

\mathbf{M}_{2’1′} = \mathbf{M}_{1’1}^{-1} \cdot \mathbf{M}_{12} \cdot \mathbf{M}_{22′} = \begin{bmatrix}

f_{11} & f_{12} & f_{13} & f_{14} \\

f_{21} & f_{22} & f_{23} & f_{24} \\

f_{31} & f_{32} & f_{33} & f_{34} \\

f_{41} & f_{42} & f_{43} & f_{44}

\end{bmatrix}

$$

where the elements are given by:

$$

\begin{aligned}

f_{11} &= \cos \phi_1 \cos \phi_2 + \sin \phi_1 \sin \phi_2 \sin \delta_F, \\

f_{12} &= \sin \delta_F \cos \phi_2 \sin \phi_1 – \cos \phi_1 \sin \phi_2, \\

f_{13} &= -\cos \delta_F \sin \phi_1, \\

f_{14} &= A \cos \phi_1, \\

f_{21} &= -\sin \delta_F \cos \phi_1 \sin \phi_2 – \sin \phi_1 \cos \phi_2, \\

f_{22} &= \sin \phi_1 \sin \phi_2 + \sin \delta_F \cos \phi_1 \cos \phi_2, \\

f_{23} &= -\cos \delta_F \cos \phi_1, \\

f_{24} &= -A \sin \phi_1, \\

f_{31} &= \cos \delta_F \sin \phi_2, \\

f_{32} &= \cos \delta_F \cos \phi_2, \\

f_{33} &= \sin \delta_F, \\

f_{34} &= 0, \\

f_{41} &= 0, \quad f_{42} = 0, \quad f_{43} = 0, \quad f_{44} = 1.

\end{aligned}

$$

The meshing condition for the screw gear transmission is expressed as:

$$

\Phi = \mathbf{v}_{1’2′} \cdot \mathbf{n} = 0

$$

where \( \mathbf{v}_{1’2′} \) is the relative velocity vector at the contact point in \( S_0 \). Its components are derived as:

$$

\begin{aligned}

v_{x0} &= \sin \beta \left[ \cos \delta_F \cos \phi_2 (u + A \cos \phi_2) + \cos \delta_F \sin \phi_2 (A \sin \phi_2 – r \sin \beta) \right] + \cos \beta \left[ (u + A \cos \phi_2)(-i_{12} \sin \delta_F) + \cos \delta_F \cos \phi_2 (A i_{12} \cos \beta \sin \phi_2 – v) \right], \\

v_{y0} &= \sin \phi_2 \left[ -A i_{12} \sin \delta_F + \sin \beta (A \sin \phi_2 – r \sin \beta) \right] + \cos \phi_2 \left[ \cos \delta_F \cos \beta (A i_{12} \cos \beta \sin \phi_2 – v) \right], \\

v_{z0} &= \cos \beta \left[ (u + A \cos \phi_2)(-i_{12} \sin \delta_F) + \cos \delta_F \cos \phi_2 (A i_{12} \cos \beta \sin \phi_2 – v) \right] + \sin \beta \left[ \cos \delta_F \cos \phi_2 (u + A \cos \phi_2) + \cos \delta_F \sin \phi_2 (A \sin \phi_2 – r \sin \beta) \right].

\end{aligned}

$$

The tooth surface equation of the screw is formed by the locus of contact points during meshing. In the screw’s moving coordinate system \( S_1′ \), it can be written as:

$$

\mathbf{r}_1′(\zeta) = \mathbf{M}_{2’1′} \cdot \mathbf{r}_2′(\zeta), \quad \text{with} \quad \phi_2 = i_{21} \phi_1, \quad 0 < \phi_1 < 2\pi.

$$

For the gear, the tooth surface equation in \( S_2′ \) is:

$$

\mathbf{r}_2′ = x_{2′} \mathbf{i}_{2′} + y_{2′} \mathbf{j}_{2′} + z_{2′} \mathbf{k}_{2′}, \quad \text{where} \quad x_{2′} = u, \quad y_{2′} = r – v \sin \beta, \quad z_{2′} = v \cos \beta, \quad \text{and} \quad \Phi = 0.

$$

To analyze the contact zone, I map the spatial contact lines onto the gear tooth surface using the following transformation:

$$

R = \sqrt{x_{2′}^2 + y_{2′}^2}, \quad Z = v \cos \beta.

$$

The tooth width of the gear, based on mechanical design handbooks, is given by:

$$

b = d_{f1} – h_f – c = k_1 A – h_f – c

$$

where \( h_f = 0.8m \) is the dedendum, \( m = (2A – d_{f1}) / 2 \) is the module, \( c = 0.2m \) is the clearance, \( d_{f1} = k_1 A \) is the root circle diameter of the screw, and \( k_1 \) is the screw pitch circle coefficient. The effective tooth width on the mapped surface is:

$$

B = b \cos \beta.

$$

Using these equations, I perform numerical calculations in MATLAB to investigate the effects of key parameters on the contact zone distribution. The parameters include center distance \( A \), transmission ratio \( i_{12} \), generating plane inclination angle \( \beta \), gear rotation angle \( \phi_2 \), installation angle \( \delta_F \), screw pitch circle coefficient \( k_1 \), and main base circle coefficient \( k_b \). The contact lines are projected onto the gear tooth surface, and the distribution is analyzed to determine optimal design ranges.

The influence of the center distance \( A \) on the contact zone is examined first. I vary \( A \) from 100 mm to 400 mm while keeping other parameters constant, as shown in Table 1. The contact lines on the gear tooth surface shift from the root toward the tip as meshing progresses from entry to exit, with the longest contact occurring in the middle region of the tooth. The distribution remains consistent across different center distances, indicating that \( A \) primarily scales the geometry without drastically altering the contact pattern. However, larger center distances may affect the overall size and load capacity of the screw gear transmission.

| Parameter | Value 1 | Value 2 | Value 3 | Value 4 |

|---|---|---|---|---|

| Center distance \( A \) (mm) | 100 | 200 | 300 | 400 |

| Transmission ratio \( i_{12} \) | 1/40 | 1/40 | 1/40 | 1/40 |

| Generating plane angle \( \beta \) (°) | 24 | 24 | 24 | 24 |

| Gear rotation angle \( \phi_2 \) (°) | 90 | 90 | 90 | 90 |

| Installation angle \( \delta_F \) (°) | 35 | 35 | 35 | 35 |

| Screw pitch circle coefficient \( k_1 \) | 0.38 | 0.38 | 0.38 | 0.38 |

| Main base circle coefficient \( k_b \) | 0.56 | 0.56 | 0.56 | 0.56 |

Next, I analyze the impact of the transmission ratio \( i_{12} \). As summarized in Table 2, I consider values from 1/10 to 1/40. The results show that larger transmission ratios (e.g., 1/10) yield longer and more uniformly distributed contact lines across the gear tooth surface. This suggests that higher reduction ratios enhance the load-bearing capacity and meshing performance of the screw gear transmission. The contact zone covers a broader area, reducing stress concentration and improving durability.

| Parameter | Value 1 | Value 2 | Value 3 | Value 4 |

|---|---|---|---|---|

| Center distance \( A \) (mm) | 100 | 100 | 100 | 100 |

| Transmission ratio \( i_{12} \) | 1/10 | 1/20 | 1/30 | 1/40 |

| Generating plane angle \( \beta \) (°) | 24 | 24 | 24 | 24 |

| Gear rotation angle \( \phi_2 \) (°) | 90 | 90 | 90 | 90 |

| Installation angle \( \delta_F \) (°) | 35 | 35 | 35 | 35 |

| Screw pitch circle coefficient \( k_1 \) | 0.38 | 0.38 | 0.38 | 0.38 |

| Main base circle coefficient \( k_b \) | 0.56 | 0.56 | 0.56 | 0.56 |

The generating plane inclination angle \( \beta \) plays a crucial role. As per Table 3, when \( \beta \) exceeds 40°, the contact zone deteriorates, with contact lines concentrated only on the upper-left corner of the gear tooth. This uneven distribution increases contact stress and reduces the load capacity of the screw gear. Based on my analysis, I recommend that \( \beta \) be maintained between 18° and 36° for optimal meshing performance. This range ensures a well-distributed contact zone across the tooth surface, enhancing the reliability of the screw gear transmission.

| Parameter | Value 1 | Value 2 | Value 3 | Value 4 |

|---|---|---|---|---|

| Center distance \( A \) (mm) | 100 | 100 | 100 | 100 |

| Transmission ratio \( i_{12} \) | 1/40 | 1/40 | 1/40 | 1/40 |

| Generating plane angle \( \beta \) (°) | 10 | 20 | 30 | 40 |

| Gear rotation angle \( \phi_2 \) (°) | 90 | 90 | 90 | 90 |

| Installation angle \( \delta_F \) (°) | 35 | 35 | 35 | 35 |

| Screw pitch circle coefficient \( k_1 \) | 0.38 | 0.38 | 0.38 | 0.38 |

| Main base circle coefficient \( k_b \) | 0.56 | 0.56 | 0.56 | 0.56 |

The gear rotation angle \( \phi_2 \) defines the starting point of meshing in the internal-meshing screw gear. As shown in Table 4, when \( \phi_2 \) is less than 90°, the initial contact lines do not fully project onto the gear tooth, indicating incomplete engagement. For the internal-meshing configuration, where the screw envelops the gear internally, I find that \( \phi_2 \) should be between 90° and 138° to achieve proper contact. Angles beyond 138° cause the transmission to degenerate into an end-face meshing screw gear, losing the internal-meshing advantages. Thus, selecting \( \phi_2 \) within this range is critical for effective screw gear operation.

| Parameter | Value 1 | Value 2 | Value 3 | Value 4 |

|---|---|---|---|---|

| Center distance \( A \) (mm) | 100 | 100 | 100 | 100 |

| Transmission ratio \( i_{12} \) | 1/40 | 1/40 | 1/40 | 1/40 |

| Generating plane angle \( \beta \) (°) | 24 | 24 | 24 | 24 |

| Gear rotation angle \( \phi_2 \) (°) | 70 | 80 | 90 | 100 |

| Installation angle \( \delta_F \) (°) | 35 | 35 | 35 | 35 |

| Screw pitch circle coefficient \( k_1 \) | 0.38 | 0.38 | 0.38 | 0.38 |

| Main base circle coefficient \( k_b \) | 0.56 | 0.56 | 0.56 | 0.56 |

The installation angle \( \delta_F \), which is the angle between the screw and gear axes, significantly affects the contact zone. According to Table 5, when \( \delta_F \) is below 30°, contact lines are confined to the upper-left portion of the tooth, leading to poor load distribution. For the internal-meshing screw gear, if \( \delta_F \) exceeds 54°, interference may occur between the gear axis and the screw tooth profile, unless the axis is housed within the screw body. Practically, setting \( \delta_F \) between 30° and 54° facilitates easier assembly and ensures a favorable contact pattern. This range optimizes the meshing performance and avoids geometric conflicts in the screw gear design.

| Parameter | Value 1 | Value 2 | Value 3 | Value 4 |

|---|---|---|---|---|

| Center distance \( A \) (mm) | 100 | 100 | 100 | 100 |

| Transmission ratio \( i_{12} \) | 1/40 | 1/40 | 1/40 | 1/40 |

| Generating plane angle \( \beta \) (°) | 24 | 24 | 24 | 24 |

| Gear rotation angle \( \phi_2 \) (°) | 90 | 90 | 90 | 90 |

| Installation angle \( \delta_F \) (°) | 10 | 20 | 30 | 40 |

| Screw pitch circle coefficient \( k_1 \) | 0.38 | 0.38 | 0.38 | 0.38 |

| Main base circle coefficient \( k_b \) | 0.56 | 0.56 | 0.56 | 0.56 |

I also investigate the screw pitch circle coefficient \( k_1 \) and the main base circle coefficient \( k_b \). As shown in Tables 6 and 7, varying \( k_1 \) from 0.33 to 0.38 and \( k_b \) from 0.5 to 0.67 has minimal impact on the contact zone distribution. These parameters influence the geometric dimensions but do not substantially alter the meshing characteristics. Therefore, when designing a screw gear for optimal contact performance, \( k_1 \) and \( k_b \) can be selected based on standard design practices or space constraints without compromising the contact quality.

| Parameter | Value 1 | Value 2 | Value 3 | Value 4 |

|---|---|---|---|---|

| Center distance \( A \) (mm) | 100 | 100 | 100 | 100 |

| Transmission ratio \( i_{12} \) | 1/40 | 1/40 | 1/40 | 1/40 |

| Generating plane angle \( \beta \) (°) | 24 | 24 | 24 | 24 |

| Gear rotation angle \( \phi_2 \) (°) | 90 | 90 | 90 | 90 |

| Installation angle \( \delta_F \) (°) | 35 | 35 | 35 | 35 |

| Screw pitch circle coefficient \( k_1 \) | 0.33 | 0.3467 | 0.3634 | 0.38 |

| Main base circle coefficient \( k_b \) | 0.56 | 0.56 | 0.56 | 0.56 |

| Parameter | Value 1 | Value 2 | Value 3 | Value 4 |

|---|---|---|---|---|

| Center distance \( A \) (mm) | 100 | 100 | 100 | 100 |

| Transmission ratio \( i_{12} \) | 1/40 | 1/40 | 1/40 | 1/40 |

| Generating plane angle \( \beta \) (°) | 24 | 24 | 24 | 24 |

| Gear rotation angle \( \phi_2 \) (°) | 90 | 90 | 90 | 90 |

| Installation angle \( \delta_F \) (°) | 35 | 35 | 35 | 35 |

| Screw pitch circle coefficient \( k_1 \) | 0.38 | 0.38 | 0.38 | 0.38 |

| Main base circle coefficient \( k_b \) | 0.5 | 0.56 | 0.62 | 0.67 |

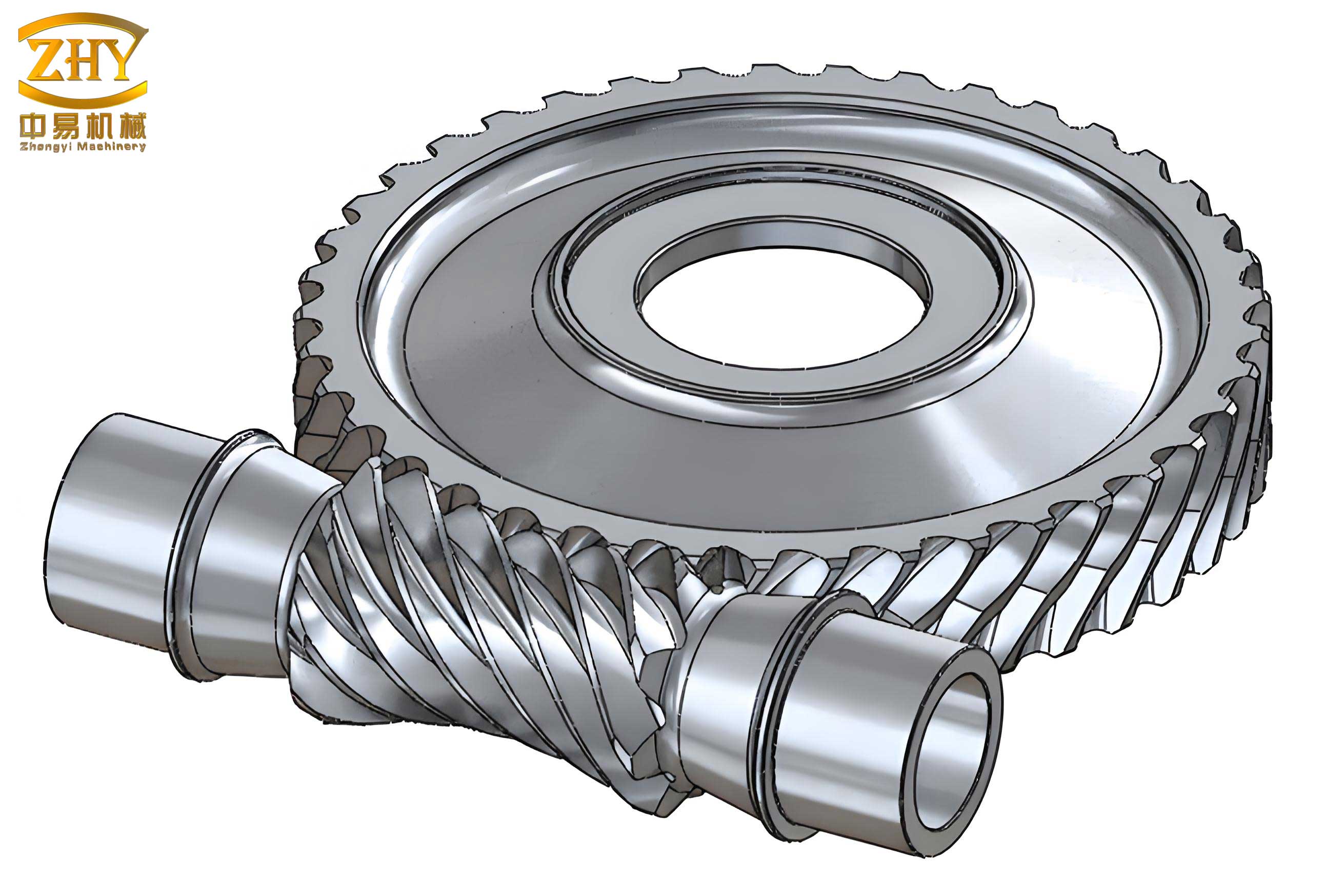

Based on these analyses, I select a set of optimal parameters to generate a three-dimensional model of the planar enveloping internal-meshing screw gear transmission. Using the contact line equations, I construct the screw tooth surface and assemble it with the internal gear. To achieve zero-backlash operation, I propose a multi-gear output configuration, where two or more gears engage with the screw simultaneously. This arrangement distributes the load evenly and eliminates tooth flank clearance by adjusting the meshing phases. The 3D model validates the theoretical findings and demonstrates the feasibility of the screw gear design for high-performance applications.

In conclusion, my investigation reveals that the transmission ratio, gear rotation angle, and installation angle have profound effects on the contact zone in planar enveloping internal-meshing screw gear transmissions. For optimal performance, I recommend the following parameter ranges: generating plane inclination angle \( \beta \) between 18° and 36°, installation angle \( \delta_F \) between 30° and 54°, and gear rotation angle \( \phi_2 \) between 90° and 138°. These ranges ensure a well-distributed contact area, enhancing load capacity and meshing efficiency. The screw pitch circle coefficient and main base circle coefficient have negligible impact and can be chosen flexibly. This study provides a solid theoretical foundation for designing advanced screw gear transmissions, paving the way for future research and practical implementations in precision machinery.