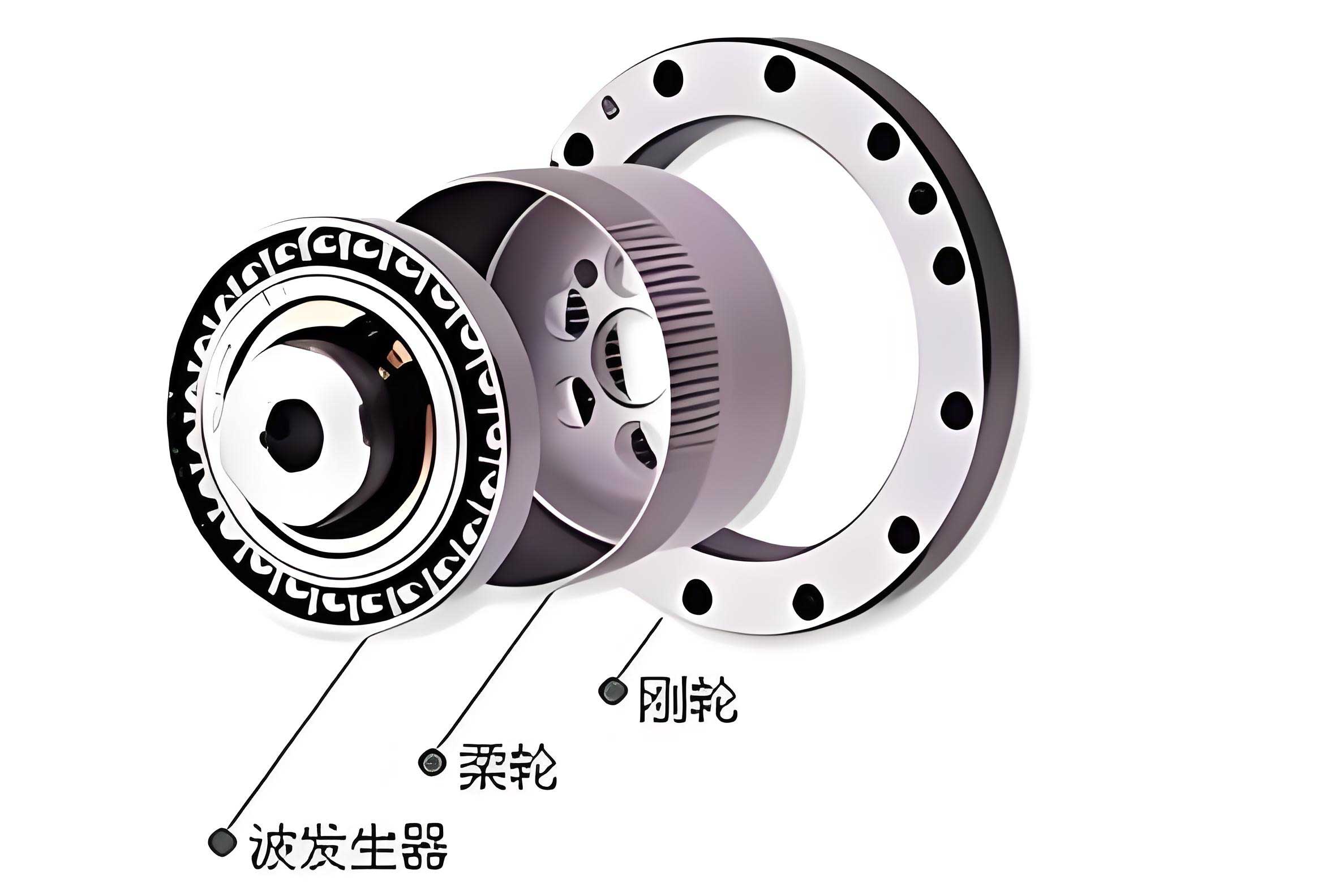

As a critical component determining the operational lifespan of a strain wave gear, the fatigue strength of the flexspline is paramount. The alternating stress amplitude the flexspline endures is typically twice its maximum assembly stress. Therefore, accurately determining this maximum assembly stress and understanding the factors influencing it are essential for improving the durability of strain wave gear systems. This analysis investigates the influence of the tooth profile on the assembly stress within the flexspline’s tooth ring, with a focus on the combined effects of increased bending stiffness and stress concentration introduced by the teeth.

Traditional structural analysis of the strain wave gear flexspline often simplifies the toothed ring into a smooth ring or shell of equivalent thickness. While this approach offers a theoretical foundation, it primarily reflects the average increase in stress due to the added stiffness from the teeth. It fails to capture the localized peak stress occurring at the critical section—the tooth slot root. To address this, a more precise computational model is required. This study develops a parametric three-dimensional finite element model (FEM) incorporating the actual involute tooth profile of the flexspline. A fine mesh is applied to the high-stress regions, such as the tooth slots, to ensure accuracy. The model is used to analyze the circumferential stress under the deformation imposed by a four-roller wave generator.

The validity of the finite element model is first established by comparing its results for a smooth ring (with teeth removed) against classical thin-ring theory. The model calculates the circumferential stress, $\sigma(\phi)$, and the roller force, $F$, required to achieve a specified maximum radial deformation, $u_0$, at the major axis. For a smooth ring with thickness $h$, width $b$, and neutral radius $r_m$, subjected to radial forces at positions $\beta$, the bending moment $M(\phi)$ at any polar angle $\phi$ is given by:

$$ M(\phi) = \begin{cases}

F r_m \left( \frac{2}{\pi} \sin\beta \cos\phi – \cos\beta \sin\phi \right), & 0 \leq \phi \leq \beta \\

F r_m \left( \frac{2}{\pi} \cos\beta \sin\phi – \sin\beta \cos\phi \right), & \beta < \phi \leq \pi/2

\end{cases} $$

The roller force $F$ required to achieve $u_0$ is derived from displacement conditions:

$$ F = \frac{E I_z u_0}{r_m^3} \cdot \frac{2}{\left[ \frac{\pi}{2} – \beta \cos\beta – \sin\beta \cos\beta – \frac{4}{\pi} \sin^2\beta \right] } $$

where $I_z = b h^3 / 12$ is the area moment of inertia, and $E$ is the Young’s modulus. The circumferential bending stress on the outer surface is then:

$$ \sigma(\phi) = \frac{M(\phi) h}{2 I_z} = \frac{6 M(\phi)}{b h^2} $$

Substituting $F$ yields the theoretical stress distribution. Comparison with FEM results for small deformations ($u_0=0.1m$, where $m$ is the module) shows excellent agreement, validating the modeling approach. For the analysis, the following base parameters are used: number of teeth $z_1=200$, module $m=0.5$ mm, addendum $h_a=m$, dedendum clearance $c=0.35m$, profile shift coefficient $x_1=3$, pressure angle $\alpha_0=20^\circ$, elastic modulus $E=210$ GPa, nominal tooth ring thickness $h=0.7$ mm ($h^*=h/m=1.4$), and roller position $\beta=25^\circ$.

To systematically study the influence of tooth geometry on peak stress, several key coefficients are defined. The tooth stress influence coefficient, $K_T$, quantifies the total magnification of peak stress due to the presence of teeth. It is the ratio of the maximum circumferential stress from the toothed FEM model to the theoretical maximum stress from the smooth ring model under identical deformation $u_0$:

$$ K_T = \frac{\sigma_{\phi,\ max}^{(toothed)}}{\sigma_{\phi,\ max}^{(smooth,\ theory)}} $$

The bending stiffness magnification factor, $K_{tr}$, represents the increase in structural rigidity. It is calculated as the ratio of the roller force from the toothed FEM model to the theoretical roller force for the smooth ring:

$$ K_{tr} = \frac{F^{(toothed)}}{F^{(smooth,\ theory)}} $$

Finally, the stress concentration factor, $K_C$, isolates the geometric stress-raising effect at the tooth slot, independent of the global stiffness increase. It is derived as:

$$ K_C = \frac{K_T}{K_{tr}} $$

These coefficients are analyzed as functions of dimensionless parameters: the normalized wall thickness $h^* = h/m$, the normalized dedendum fillet radius $r_4^* = r_4/m$, and the tooth slot width ratio $v = e_k / s_k$, defined at the specific radius $r_k$ where tooth thickness equals slot width for the profile-shifted gear.

Parametric Analysis of Key Geometric Parameters

The impact of the dedendum fillet radius on the maximum circumferential stress is investigated first. As shown in the analysis, increasing $r_4^*$ initially reduces the peak stress significantly by alleviating the geometric discontinuity at the tooth root. However, beyond an optimal point, further increase leads to a slight rise in stress. This is because a larger fillet adds more material near the neutral axis, increasing the local bending stiffness and thus the bending moment and stress in the slot section. The optimum fillet radius that minimizes the peak assembly stress for the studied configuration is found to be approximately $r_4^* \approx 0.36$. All subsequent analyses of maximum stress use this optimal fillet radius.

The primary focus is on the effects of tooth ring thickness $h^*$ and tooth slot width ratio $v$. A wider tooth slot (higher $v$) is known to reduce stress. In this model, $v$ is increased by reducing the tooth thickness while keeping the tooth height, number of teeth, and pitch constant. The table below summarizes the calculated coefficients for different combinations of $h^*$ and $v$.

| $h^*$ | $v$ | $K_{tr}$ (FEM) | $K_T$ (FEM) | $K_C = K_T / K_{tr}$ |

|---|---|---|---|---|

| 1.0 | 1.0 | 1.81 | 2.78 | 1.54 |

| 1.2 | 1.73 | 2.60 | 1.50 | |

| 1.4 | 1.66 | 2.45 | 1.48 | |

| 1.6 | 1.60 | 2.32 | 1.45 | |

| 1.4 | 1.0 | 1.73 | 2.64 | 1.53 |

| 1.2 | 1.65 | 2.48 | 1.50 | |

| 1.4 | 1.58 | 2.35 | 1.49 | |

| 1.6 | 1.52 | 2.23 | 1.47 | |

| 2.2 | 1.0 | 1.65 | 2.50 | 1.52 |

| 1.2 | 1.57 | 2.36 | 1.50 | |

| 1.4 | 1.50 | 2.24 | 1.49 | |

| 1.6 | 1.44 | 2.13 | 1.48 | |

| 3.0 | 1.0 | 1.59 | 2.42 | 1.52 |

| 1.2 | 1.52 | 2.29 | 1.51 | |

| 1.4 | 1.45 | 2.18 | 1.50 | |

| 1.6 | 1.39 | 2.08 | 1.50 |

The results clearly demonstrate several trends. The bending stiffness magnification factor $K_{tr}$ decreases with increasing $h^*$ and increasing $v$. A thicker ring relies less on the teeth for its overall bending stiffness, reducing $K_{tr}$. A wider tooth slot naturally removes material, also reducing the stiffness contribution of the teeth. The total stress influence coefficient $K_T$ also decreases with both increasing $h^*$ and $v$. Remarkably, the stress concentration factor $K_C$ remains relatively stable, showing only a mild decrease with increasing slot width $v$ and being largely independent of $h^*$ for a given $v$. This indicates that the geometric stress concentration effect at the tooth slot root is primarily a function of the local notch geometry (influenced by $v$ and $r_4^*$) rather than the global wall thickness.

It is insightful to compare the FEM-derived $K_{tr}$ with values from established design guidelines. A common approximation for the stiffness increase in strain wave gear design is $K_{rt} = (1 + h^*)/h^*$. This formula is based on an equivalent thickness model. The comparison reveals that the guideline consistently overestimates the bending stiffness magnification factor compared to the detailed FEM results. The discrepancy grows slightly with increasing $h^*$, from about 0.6% at $h^*=1.0$ to about 4.2% at $h^*=3.0$ for $v=1.0$.

Regarding stress concentration, design guidelines often propose an effective stress concentration factor of the form $K_{\sigma} = (1.6h^* + 0.8) / (1 + h^*)$. The FEM-calculated $K_C$ values are consistently higher than this guideline $K_{\sigma}$. The underestimation by the guideline ranges from approximately 11.2% at $h^*=1.0$ to 16.9% at $h^*=3.0$ for a standard slot width ($v=1.0$). This signifies that conventional design rules may non-conservatively underestimate the peak stress in the flexspline tooth ring, potentially affecting fatigue life predictions.

The combined effect on the maximum circumferential stress can be summarized. Increasing the tooth slot width ratio $v$ from 1.0 to 1.6 leads to a reduction in the peak assembly stress by 13% to 18%, depending on the wall thickness. This confirms the significant stress-relieving benefit of using a wider tooth slot design in strain wave gear flexsplines.

Conclusions

This analysis provides a detailed investigation into the maximum assembly stress within the tooth ring of a strain wave gear flexspline. By employing a parametric three-dimensional finite element model with a true involute tooth profile, the study successfully decouples and quantifies the dual influences of the teeth: the global increase in bending stiffness and the local stress concentration at the tooth slot.

The key findings are: First, an optimal dedendum fillet radius of approximately $r_4^* \approx 0.36$ exists, which minimizes the peak stress by balancing stress concentration relief against added local stiffness. Second, the bending stiffness magnification factor decreases with both increasing wall thickness and tooth slot width, and common design guidelines tend to slightly overestimate this factor. Third, and most importantly, the stress concentration factor derived from detailed FEM analysis is significantly higher than values suggested by simplified design formulas. This underestimation by guidelines increases with wall thickness, indicating they may not accurately capture the stress growth rate as the flexspline becomes thicker.

Furthermore, the analysis quantitatively demonstrates the substantial benefit of increasing the tooth slot width, with stress reductions of 13-18% achievable by moving from a standard to a wide slot design. The methodology and results presented offer a more accurate basis for calculating the highest assembly stress in strain wave gear flexsplines, contributing to more reliable fatigue life prediction and optimized design for this critical component in precision motion systems.