The analysis of metal flow law can make us more clearly understand the flow law of metal in the forming process, intuitively observe the filling state and ability of metal in the forming process of spiral bevel gear, so as to find the location and causes of defects, and put forward improvements.

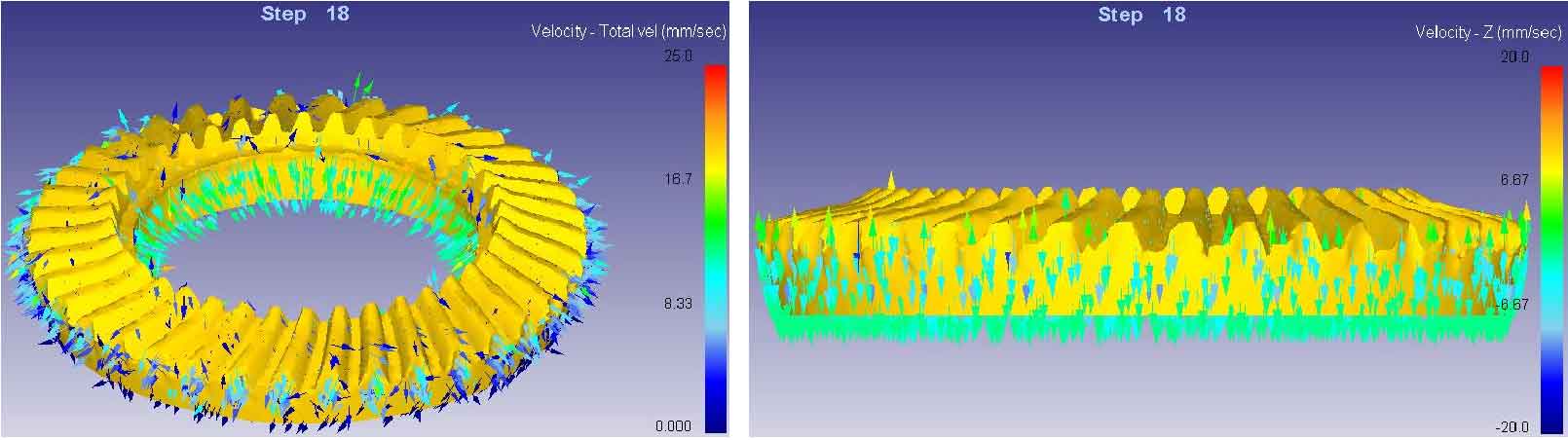

The figure shows the metal flow velocity distribution of different strokes in the warm precision forging process of spiral bevel gear. Figure (a) shows the metal flow velocity distribution when the stroke is 2.7 mm. It can be seen from the figure that at this time, the blank metal mainly flows along the radial direction, the metal at the large end flows outward in the radial direction, and the metal at the small end flows inward in the radial direction. In the z-axis direction, most of the metal flows downward along the z-axis, Only the metal at the top of the spiral bevel gear flows upward along the z-axis, indicating that the metal at the root of the tooth flows to the top of the tooth under the pressure of the upper die at this time; Figure (b) shows the distribution of metal flow velocity when the stroke is 11 mm. At this time, the metal flows only along the radial direction and there is almost no flow in other directions. Compared with figure (a), the radial flow velocity increases significantly. At this time, the metal flows almost only along the Z-axis in the z-axis direction. The main deformation from figure (a) to figure (b) is upsetting deformation, so it can be seen that in the process of upsetting, Under the pressure of the upper die, the main flow mode of metal is along the radial flow, and its flow speed increases gradually with the increase of stroke; Figure (c) shows the metal flow velocity distribution of the final step. At this time, the part with large metal flow velocity is mainly concentrated on the tooth profile, and the metal at the tooth root flows from the tooth root of the spiral bevel gear to the tooth top. In this process, the metal will also flow along the radial direction, but the flow velocity is relatively small. It can be seen from the metal flow in the z-axis direction that the metal flow velocity at the tooth top of the spiral bevel gear is along the z-axis, Moreover, the flow speed is large, and the metal at the tooth root and the bottom of the spiral bevel gear flows downward along the z-axis, and the flow rate is relatively small. The process from figure (b) to figure (c) is the forming process of the tooth profile. The metal flow law of this process is that the metal at the tooth root of the spiral bevel gear flows to the tooth top and fills the cavity of the tooth profile.