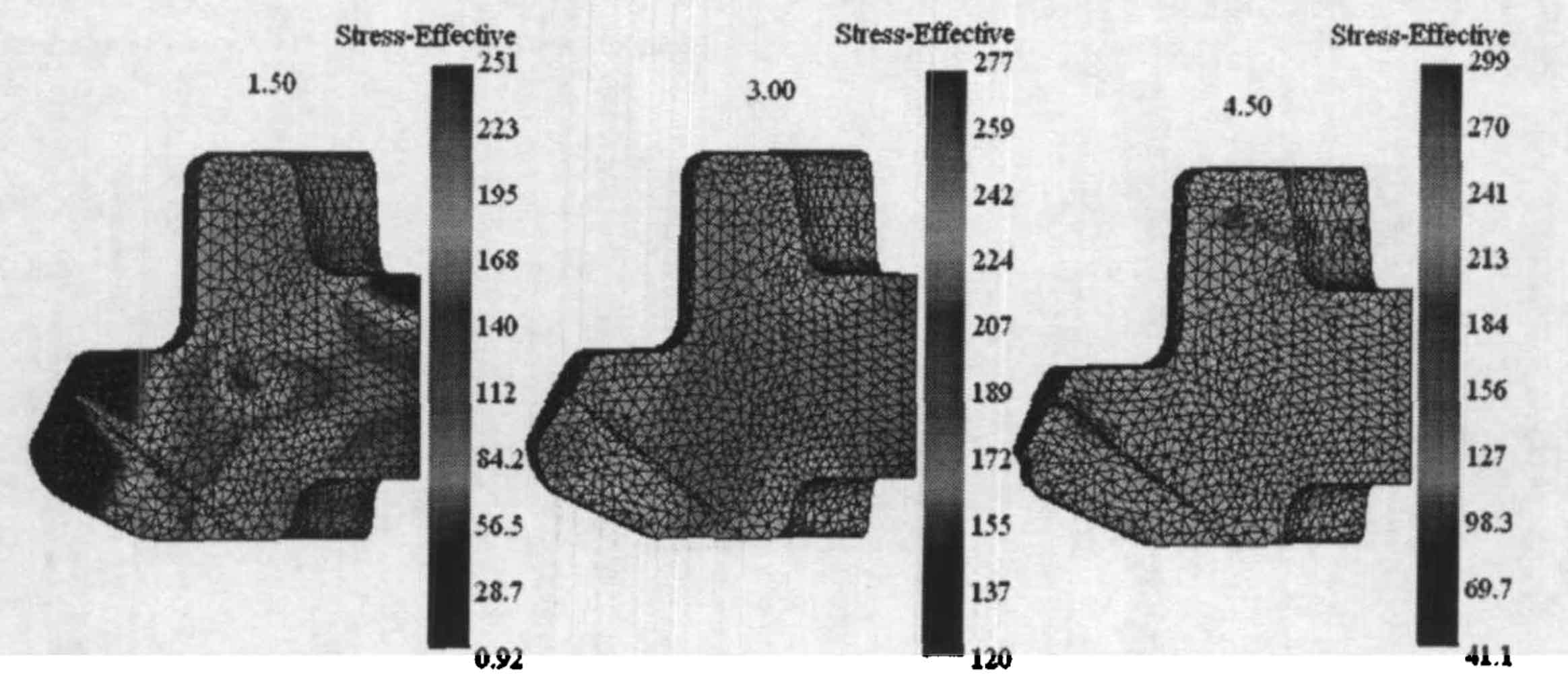

As shown in the figure, the stress distribution is given when the reduction is 1.5mm, 3.0mm and 4.5mm respectively. At the initial stage of deformation, the maximum stress is mainly concentrated in the half shaft area and small end face, and the stress of the gear tooth is very small because it is not in contact with the die.

With the contact between the side shaft gear and the tooth die, the top attachment of the side shaft gear produces greater stress. In the later stage of deformation, the stress distribution in the whole half shaft gear is more uniform, and the maximum stress is distributed on the tooth surface with large deformation, the end face and the transition fillet of the boss.