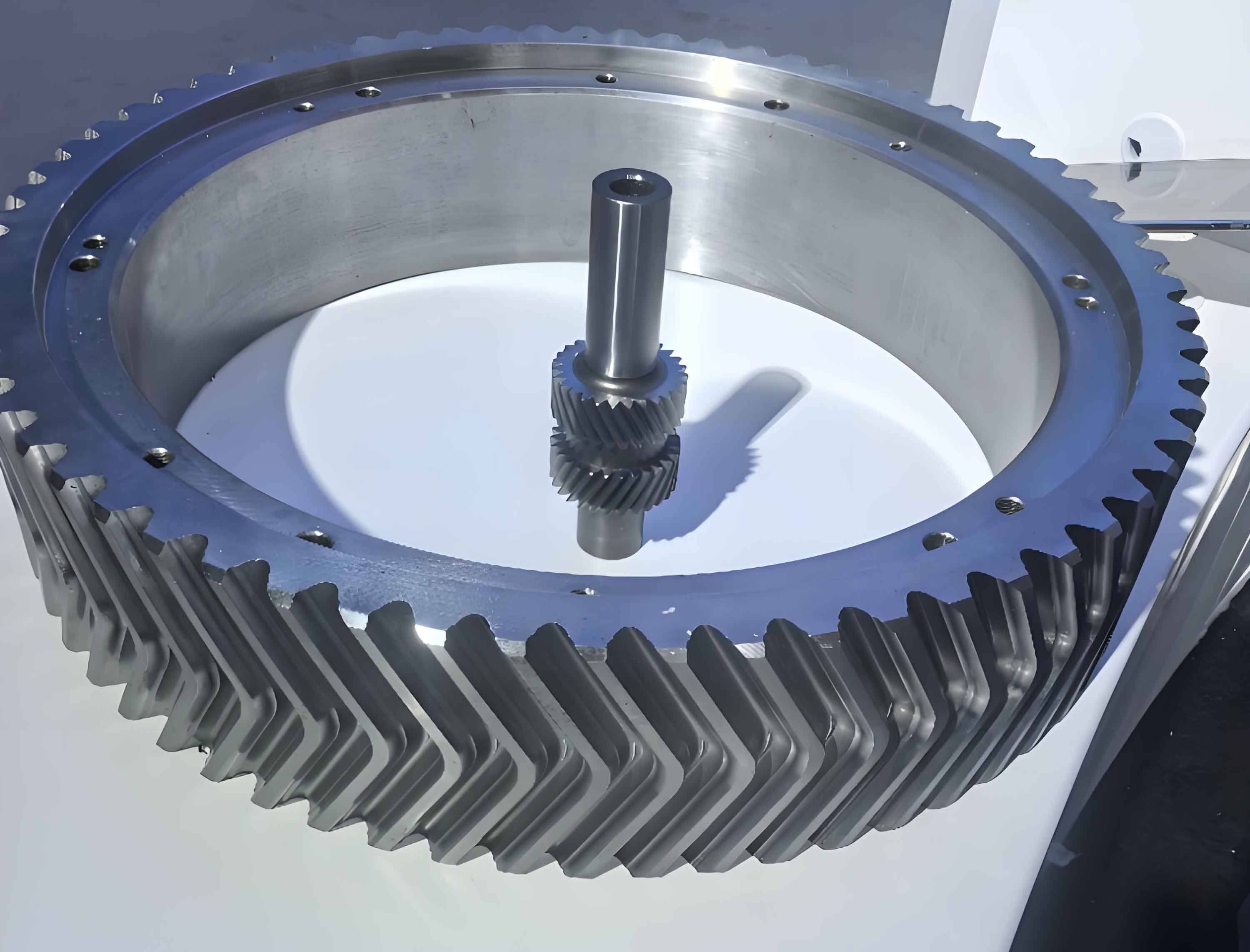

In modern marine propulsion systems, herringbone gears are critical components within reducer assemblies, transmitting power efficiently under high-speed and heavy-load conditions. The analysis of the temperature field in herringbone gears has become increasingly vital, as non-uniform temperature distributions can severely impact gear performance, leading to reduced load-carrying capacity, operational instability, and even catastrophic failures such as scuffing or thermal deformation. This study focuses on the steady-state temperature field analysis of a herringbone gear used in a large ship reducer, employing finite element methods to evaluate thermal behavior and provide insights for design optimization. We emphasize the importance of understanding thermal dynamics in herringbone gears to enhance reliability and longevity in demanding applications.

The thermal analysis of herringbone gears involves complex interactions between frictional heat generation, heat conduction within the gear material, and convective heat transfer to the surrounding environment. As herringbone gears operate, the sliding friction between meshing teeth generates significant heat, which, if not properly managed, can lead to localized hot spots and thermal stresses. This paper presents a comprehensive approach to modeling the temperature field, starting with mathematical formulations based on heat transfer principles, followed by finite element simulations. Our goal is to elucidate the temperature distribution patterns in herringbone gears and assess their implications for gear design and operation. Throughout this analysis, we will repeatedly reference herringbone gears to underscore their unique geometric and functional characteristics in thermal contexts.

To establish a robust foundation, we first develop a mathematical model for the steady-state temperature field in herringbone gears. This model relies on several assumptions to simplify the complex real-world scenario while retaining physical accuracy. Based on Block’s theory, we assume that heat generated by friction is entirely transferred to the contacting bodies, with negligible dissipation to the surrounding medium. This is valid when the heat source moves rapidly across the surface, exceeding the rate of heat conduction. Additionally, the heat intensity distribution in the contact zone follows a parabolic pattern, mirroring the pressure distribution. We further assume that each tooth of the herringbone gear experiences identical thermal conditions over one revolution, allowing us to analyze a single tooth representative of the entire gear. Finally, we consider that the gear’s core temperature remains constant at the ambient or oil temperature during operation, and each tooth receives an equal amount of frictional heat per cycle.

The governing equation for steady-state heat conduction in three-dimensional Cartesian coordinates is given by Laplace’s equation:

$$ \nabla^2 T = \frac{\partial^2 T}{\partial x^2} + \frac{\partial^2 T}{\partial y^2} + \frac{\partial^2 T}{\partial z^2} = 0 $$

where \( T \) represents the temperature field. For herringbone gears, the boundary conditions are periodic due to the cyclic nature of gear engagement. Over a time interval \( \Delta t \), frictional heat is applied to the tooth surface, leading to rapid temperature rise. During this phase, three types of boundary conditions exist: Condition A for the meshing surface, Condition B for non-meshing surfaces, and Condition C for symmetric planes. In the subsequent interval \( t – \Delta t \), no frictional heat is applied, and only conduction and convection occur, causing a gradual temperature decrease, with Conditions B and C prevailing.

Boundary Condition A, applicable to the meshing surface, combines convective heat transfer and heat flux input:

$$ -k \frac{\partial T}{\partial n} = \alpha (T – T_0) – q $$

where \( k \) is the thermal conductivity of the gear material, \( n \) is the outward normal direction, \( \alpha \) is the convective heat transfer coefficient, \( T_0 \) is the ambient temperature, and \( q \) is the heat flux due to friction. For herringbone gears, this condition captures the intense thermal loading at tooth contacts.

Boundary Condition B, for non-meshing surfaces, accounts for convection only:

$$ -k \frac{\partial T}{\partial n} = \alpha (T – T_0) $$

Boundary Condition C, applied to symmetric cross-sectional planes of the herringbone gear, enforces temperature and heat flux continuity:

$$ T|_{s_1} = T|_{s_2} $$

$$ \frac{\partial T}{\partial n}\bigg|_{s_1} = \frac{\partial T}{\partial n}\bigg|_{s_2} $$

These equations form the basis for our finite element analysis, ensuring that the thermal behavior of herringbone gears is accurately represented.

The finite element model for the herringbone gear is constructed to leverage geometric symmetry and reduce computational cost. A herringbone gear consists of two helical gear halves with equal but opposite helix angles. Therefore, we analyze only one helical half, representing a single tooth of the herringbone gear, and apply axial constraints on one cross-section to simulate the full herringbone gear’s behavior. This approach is valid due to the symmetric loading and geometry of herringbone gears. The model focuses on the steady-state condition, as the gear reaches thermal equilibrium after continuous operation. We import the CAD geometry into ANSYS software, mesh it with appropriate element sizes for accuracy, and define material properties. The table below summarizes key parameters used in the analysis:

| Parameter | Value | Unit |

|---|---|---|

| Pressure Angle (\(\alpha\)) | 20 | ° |

| Helix Angle (\(\beta\)) | 28.75 | ° |

| Face Width (\(b\)) | 240 | mm |

| Thermal Conductivity | 46.4 | W/(m·°C) |

| Transmitted Torque | 10967.5 | N·m |

| Module (\(m_n\)) | 7.0 | mm |

| Addendum Coefficient (\(h_a^*\)) | 1.0 | – |

| Gear Ratio (\(u\)) | 8.295 | – |

| Ambient Temperature (\(T_0\)) | 20 | °C |

| Large Gear Speed (\(n\)) | 200 | r/min |

Load calculation is crucial for determining the heat flux input. The average normal load \( F_n \) on the herringbone gear tooth is computed from the transmitted torque:

$$ F_n = \frac{T}{r \cdot \cos \alpha \cdot \cos \beta} $$

where \( r \) is the pitch radius. The average relative sliding velocity \( V_s \) between meshing teeth is derived from the velocities at the limits of engagement:

$$ V_s = \frac{V_1 + V_2}{2} $$

Assuming sliding friction dominates, the heat flux \( q \) per unit time and area is:

$$ q = \frac{f \cdot F_n \cdot V_s}{J \cdot B} $$

Here, \( f \) is the sliding friction coefficient (taken as 0.06 for this analysis), \( J \) is the mechanical equivalent of heat, and \( B \) is the Hertzian contact width, approximated as the length of the line of action. For the given herringbone gear parameters, we calculate \( q = 1.67 \times 10^2 \, \text{W/m}^2\text{s} \). This heat flux is applied to the meshing surface in the finite element model.

In the finite element loading phase, we apply boundary conditions to the herringbone gear tooth model. The heat flux \( q \) is imposed on the contact tooth surface where meshing occurs. For non-contact surfaces, including the tooth flank, root fillets, and front/back faces, convective boundary conditions are applied with a heat transfer coefficient estimated based on oil bath cooling. The symmetric cross-section is constrained to reflect the herringbone gear’s continuity. We neglect bearing heat effects in this localized analysis. The loading schematic ensures that thermal interactions are accurately captured for the herringbone gear tooth.

Results from the finite element analysis reveal the temperature distribution in the herringbone gear. At an oil temperature of 70°C, the steady-state temperature field shows non-uniform patterns, with contour values ranging from 70°C to 97°C. The highest temperature occurs near the mid-section of the meshing side, gradually decreasing toward the non-meshing side along the tooth width. This gradient indicates significant thermal asymmetry in herringbone gears, which can lead to thermal deformation and affect load distribution. The temperature distribution is visualized through contour plots and path analyses. We define five radial paths on the mid-cross-section to examine temperature variations quantitatively. The table below presents temperature values at key points along these paths:

| Path Number | Distance from Tooth Root (mm) | Temperature (°C) | Observations |

|---|---|---|---|

| 1 | 0 | 72.5 | Near root, lower temperature |

| 1 | 10 | 85.3 | Rapid increase near contact |

| 1 | 20 | 96.8 | Peak at meshing region |

| 2 | 0 | 71.8 | Similar root temperature |

| 2 | 15 | 92.4 | High gradient observed |

| 3 | 5 | 78.9 | Moderate rise |

| 4 | 10 | 88.7 | Consistent with path 1 |

| 5 | 20 | 95.1 | Slightly lower peak |

The path analysis demonstrates that temperatures near the tooth tip drop sharply, while regions below the mid-height stabilize at lower values. This behavior highlights the influence of frictional heat flux on thermal gradients in herringbone gears. The non-uniform temperature field can cause helical angle errors and misalignment, emphasizing the need for thermal considerations in herringbone gear design.

Further discussion centers on the factors affecting the temperature field in herringbone gears. Key parameters include the input heat flux, convective heat transfer coefficient, ambient temperature, and friction coefficient. Precise determination of these parameters is challenging but essential for accurate modeling. Under normal lubricated conditions, herringbone gears maintain relatively stable temperatures, but under starved lubrication or overload scenarios, temperatures can escalate rapidly, accelerating thermal failure. The transient flash temperature during meshing, though not directly analyzed here, also plays a critical role; it peaks near the engagement points and can be mitigated through profile modifications. For herringbone gears, optimizing tooth geometry and cooling systems is vital to manage thermal effects.

To generalize, the steady-state temperature field in herringbone gears is governed by the heat conduction equation with mixed boundary conditions. The finite element method provides a powerful tool for simulating this field, as shown in our analysis. We can derive the following insights for herringbone gears: First, the temperature distribution is inherently non-uniform, with hotspots at the meshing side mid-section. Second, thermal gradients along the tooth width can induce deformations that alter contact patterns and increase vibration. Third, proper lubrication and cooling are crucial to suppress excessive temperatures in herringbone gears. These findings align with industry observations that herringbone gears require careful thermal management in high-performance applications.

In conclusion, this study has presented a detailed analysis of the temperature field in herringbone gears using mathematical modeling and finite element simulations. We have shown that herringbone gears exhibit significant thermal gradients under operational loads, primarily driven by frictional heat generation. The results underscore the importance of incorporating thermal analysis into the design process for herringbone gears to prevent failures and enhance efficiency. Future work could explore dynamic thermal effects, advanced cooling techniques, and experimental validation for herringbone gears. By continuously refining our understanding of thermal behavior, we can improve the reliability and performance of herringbone gears in marine and industrial systems.