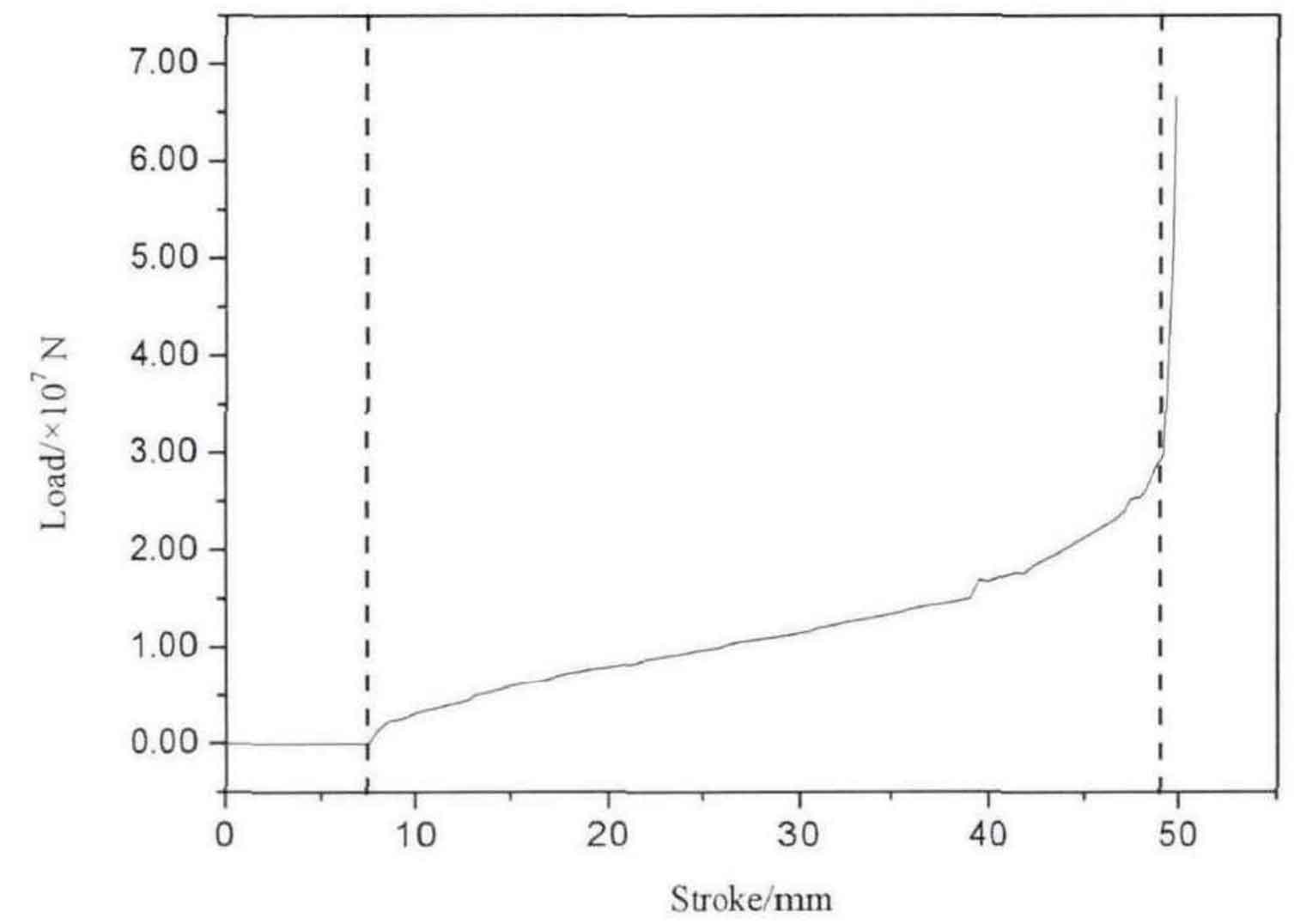

The service life of die and the selection of screw press are closely related to the forming load. Therefore, it is necessary to focus on the analysis of the change of load in the forging process. Firstly, taking the blank of No. 2 equal height spiral bevel gear as an example, the variation law of load in the forging process is analyzed. Figure 1 shows the load stroke curve of the lower die in the forging process of equal height spiral bevel gear. Obviously, the change of forming load is mainly divided into three stages. In the profiling stage, the upper die moves down and does not contact the blank of equal height spiral bevel gear. At this time, the load is zero; In the filling forming stage, with the downward movement of the upper die, the upper die begins to contact with the blank of equal height spiral bevel gear, and the load begins to increase slowly; At the stage of die drawing, the blank of equal height spiral bevel gear begins to flow into the inner flash, and the upper and lower dies are closed. The load increases sharply, and the maximum load is 66612667n.

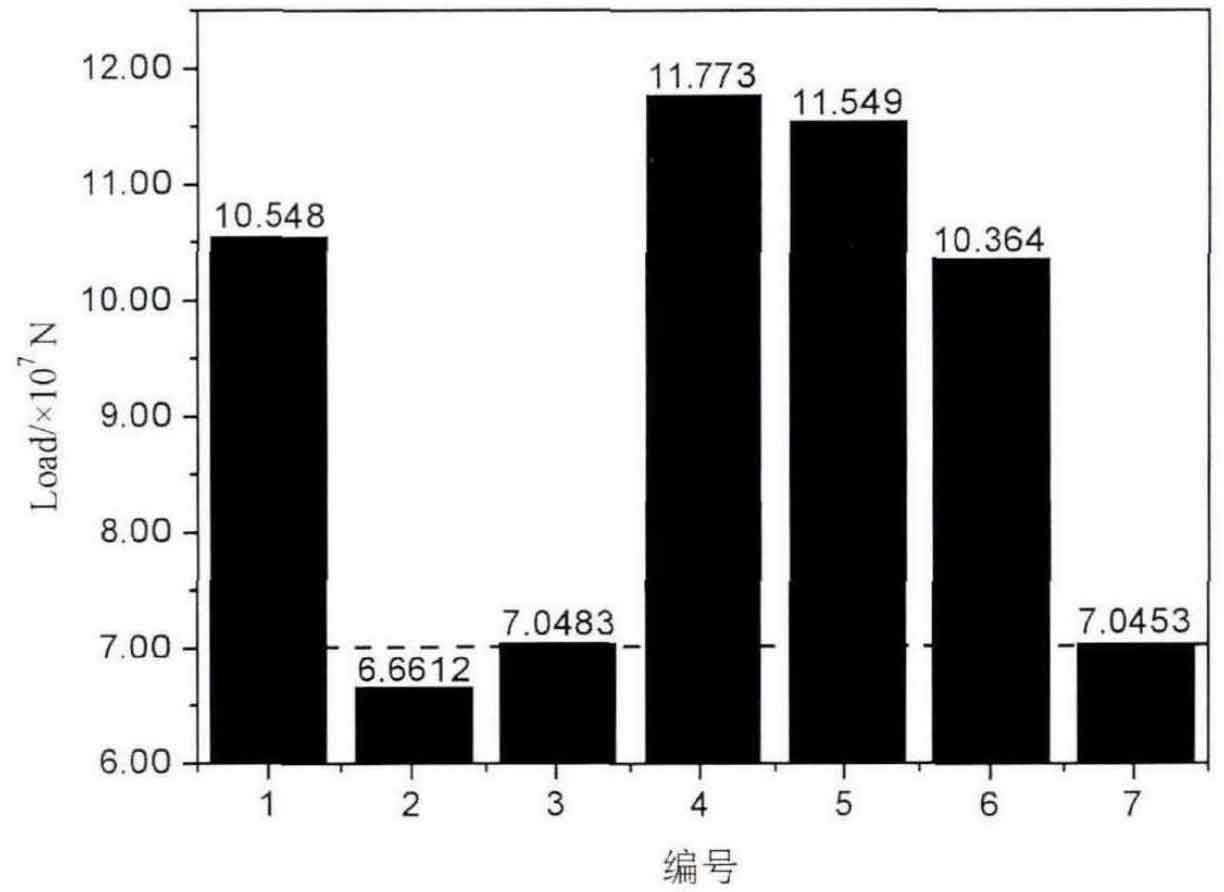

In order to better compare the forming load of special-shaped section blank and rectangular section blank, the maximum forming load of 7 groups of equal height spiral bevel gear blank at the end of forging is extracted respectively, as shown in Figure 2. The maximum load of the spiral forming blank No. 1 and the rectangular blank No. 2 is slightly higher than the maximum load of the rectangular blank No. 1 and the rectangular blank No. 2 in the profile of the spiral forming blank No. 3.

Therefore, from the point of view of the maximum equivalent stress and maximum forming load of forgings in the forging process of equal height spiral bevel gear, the blanks of No. 2 and No. 3 equal height spiral bevel gear can obtain good results. At the same time, the blank of equal height spiral bevel gear needs to be obtained by rolling. The blank of No. 2 equal height spiral bevel gear has a large enough fillet radius, which can significantly reduce the difficulty and cost of rolling forming, and its rolling effect is better than that of No. 3 equal height spiral bevel gear. Therefore, the blank of No. 2 equal height spiral bevel gear is finally selected as the preform.