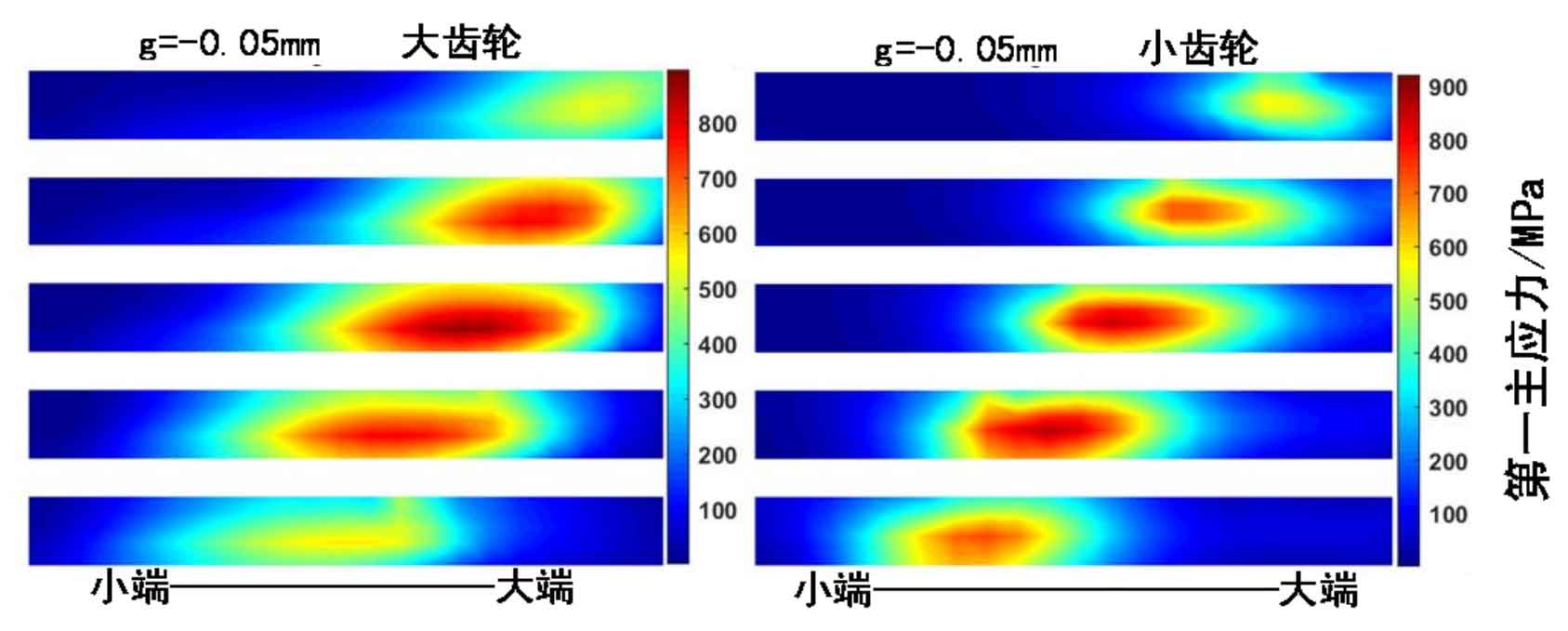

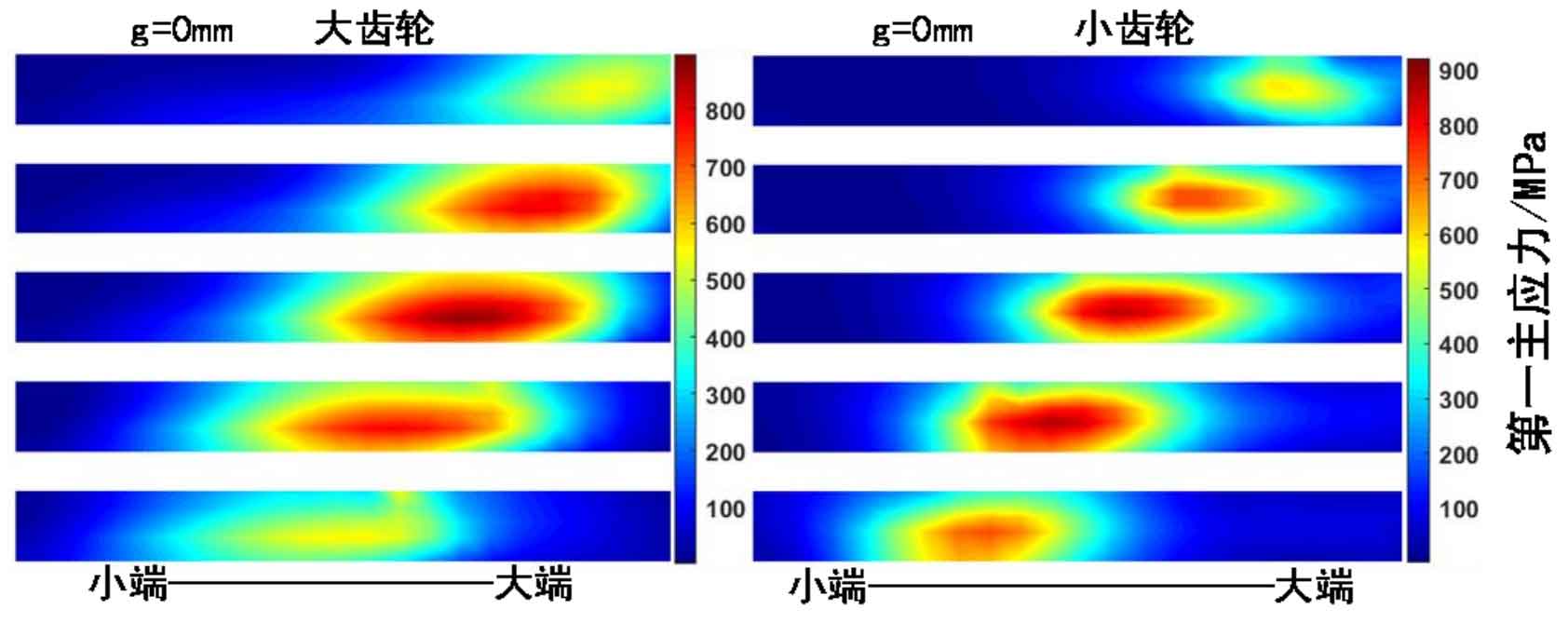

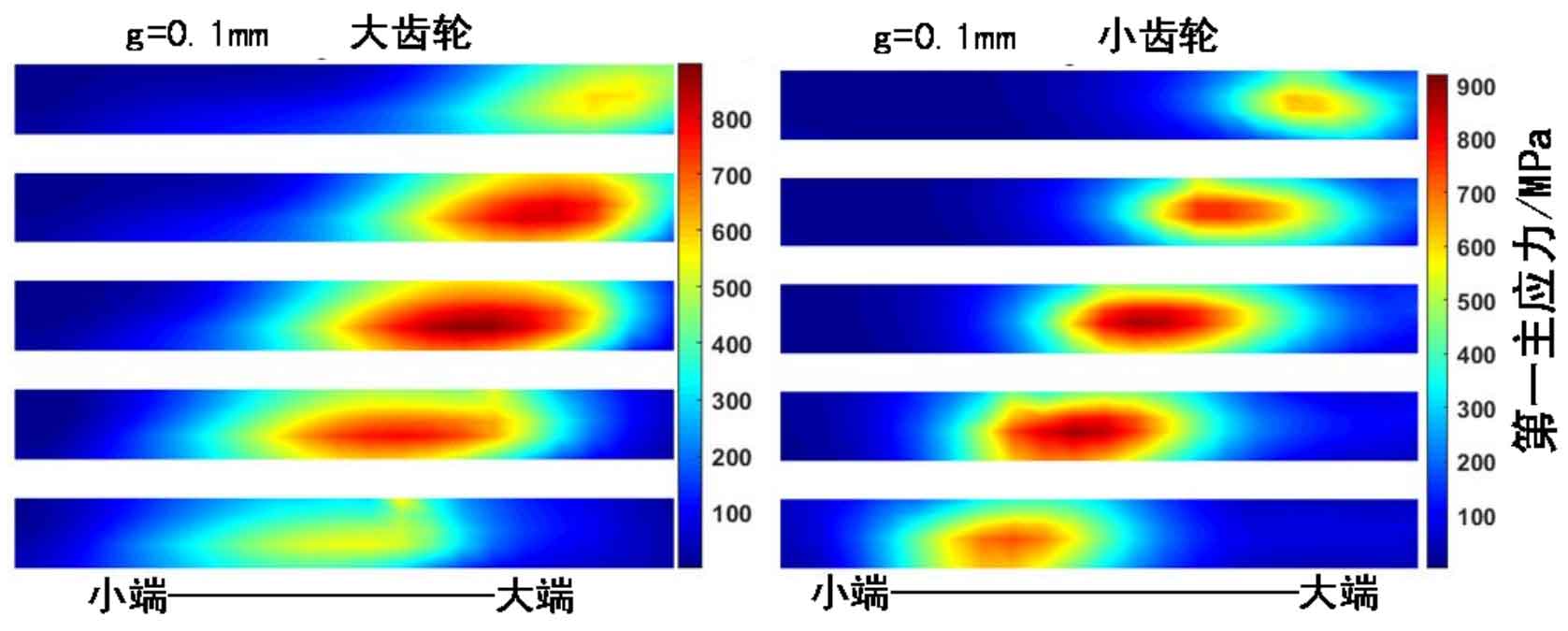

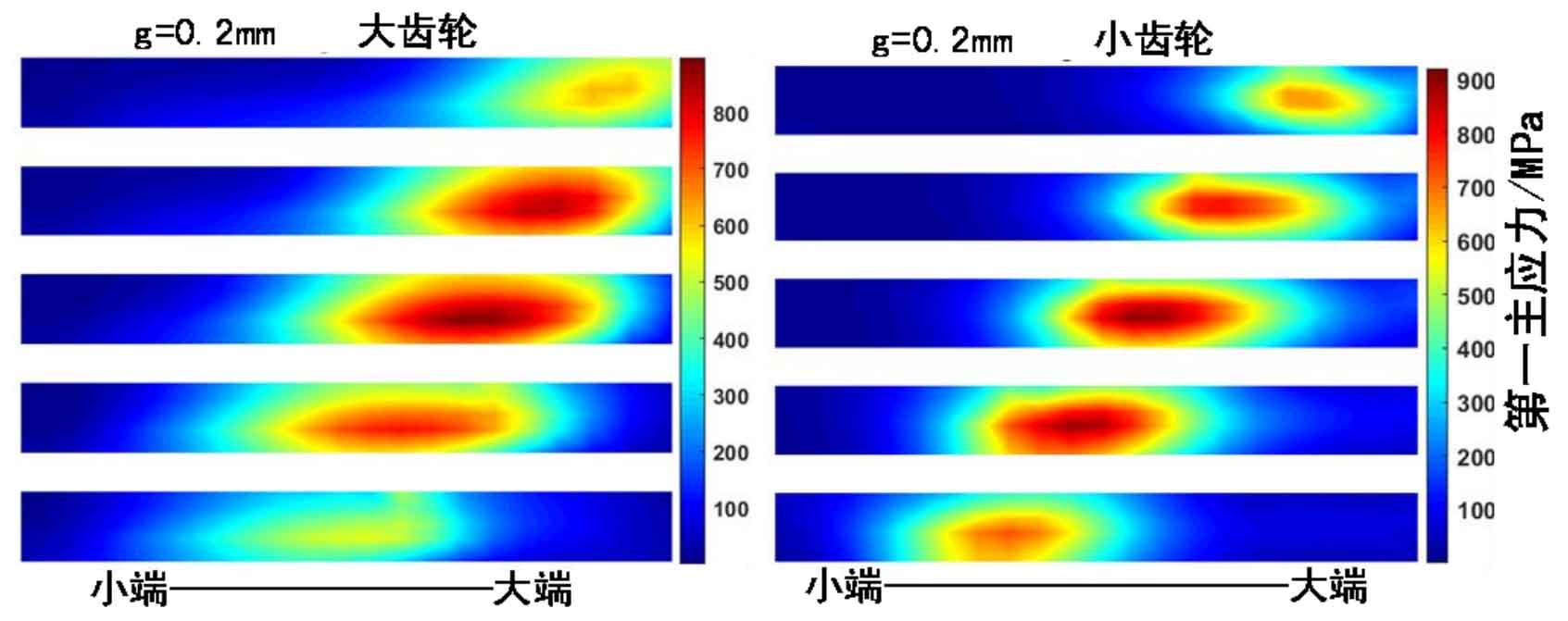

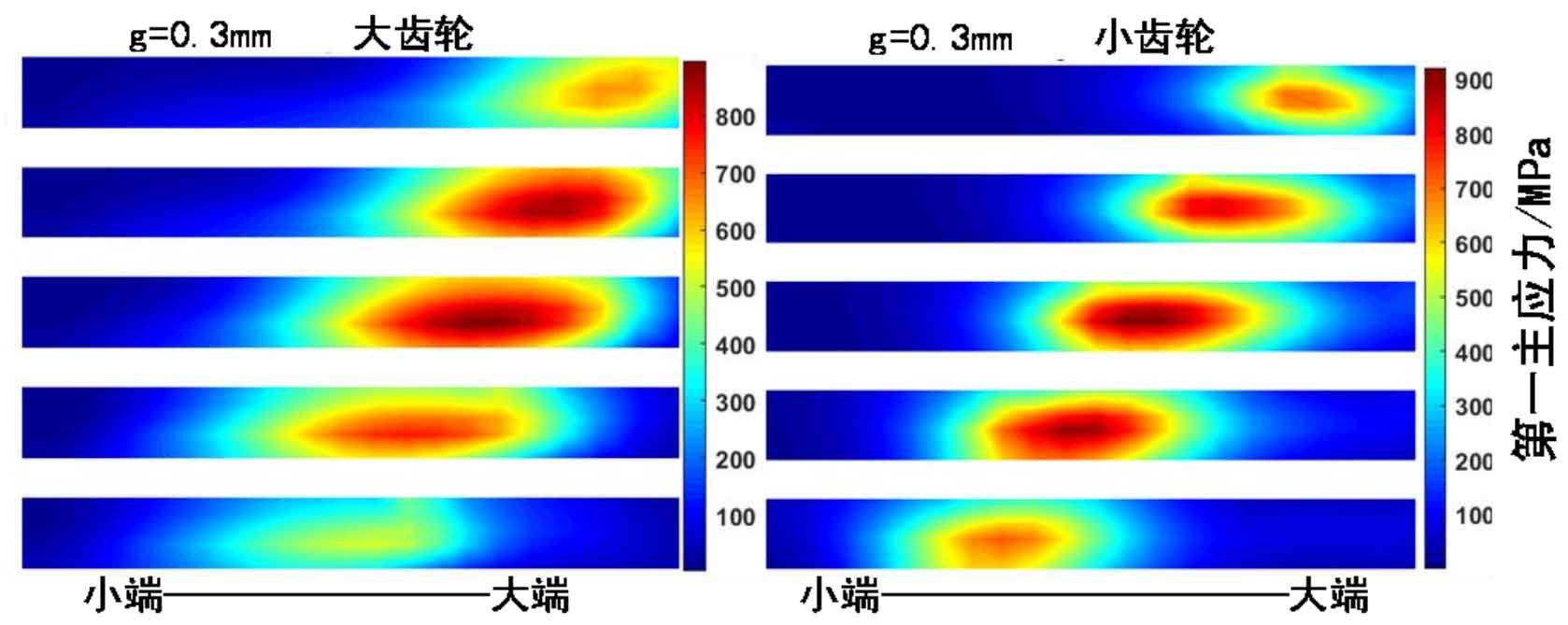

As shown in Figure 1, when the deviation g of the big axle of the hypoid gear changes towards the installation position, the change trend of the tooth root bending stress is shown. In the figure, from top to bottom, are the corresponding changes of the tooth root stress of the hypoid gear when g=-0.05mm, 0mm, 0.1mm, 0.2mm, 0.3mm. The left side of the figure is the change of the tooth root bending stress of the big wheel of the hypoid gear, and the right side is the change of the tooth root bending stress of the small wheel of the hypoid gear. It can be seen that the positive change of G does not cause much change in the stress distribution of the tooth root of the hypoid gear, but the maximum value of the tooth root stress increases. This is mainly because this change causes the meshing point to move from the root to the top of the tooth, which increases the maximum stress of the hypoid tooth root.

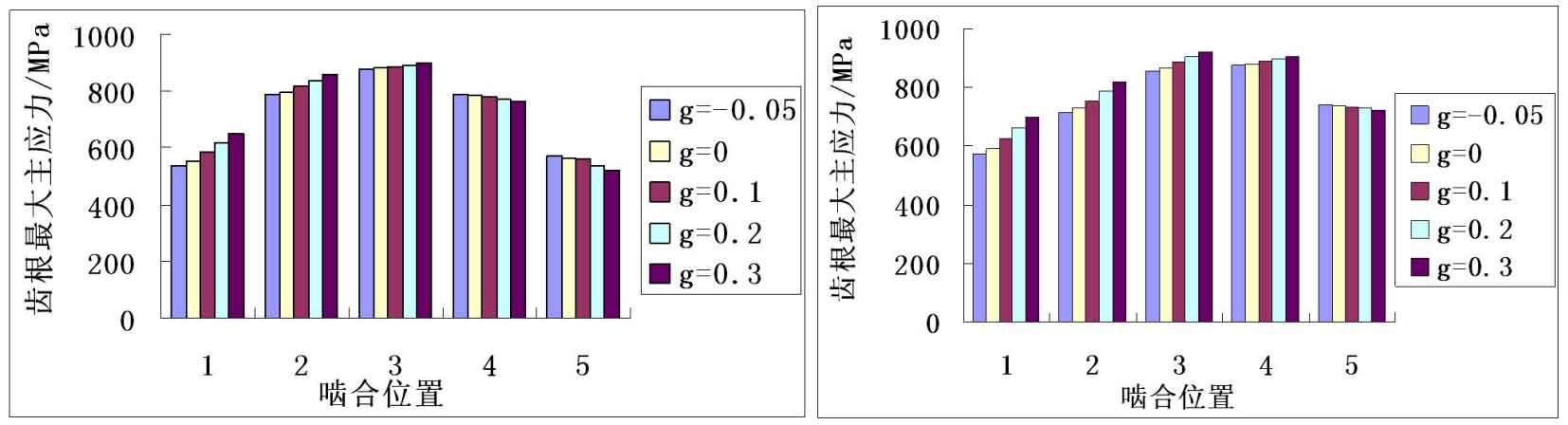

As shown in Figure 2, the maximum value of the first principal stress at the root corresponding to the above meshing position can be seen. It can be seen that the change law of the hypoid gear small wheel is consistent with that of the hypoid gear big wheel. The change of G mainly causes the change of the root stress when the hypoid gear is meshed in and out. When the value of G increases in a negative direction, it will cause the maximum value of the first principal stress at the root when the large and small gears are meshed out to decrease, the middle meshing is basically unchanged, and the meshing is slightly increased, vice versa. It can be seen from the comparison that when the g value changes, it is mainly caused by the change of the maximum principal stress of the tooth root when the big and small gears mesh out, and the change of the small wheel of the hypoid gear is more obvious than that of the big wheel of the hypoid gear.